A kind of preparation method of porous ceramic alumina type humidity sensor

A technology of humidity sensor and porous ceramics, which is applied in the direction of ceramic products, instruments, scientific instruments, etc., can solve the problems of sensitivity degradation, capacitive characteristic drift, etc., and achieve the effect of sufficient phase change, stable microstructure, and uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

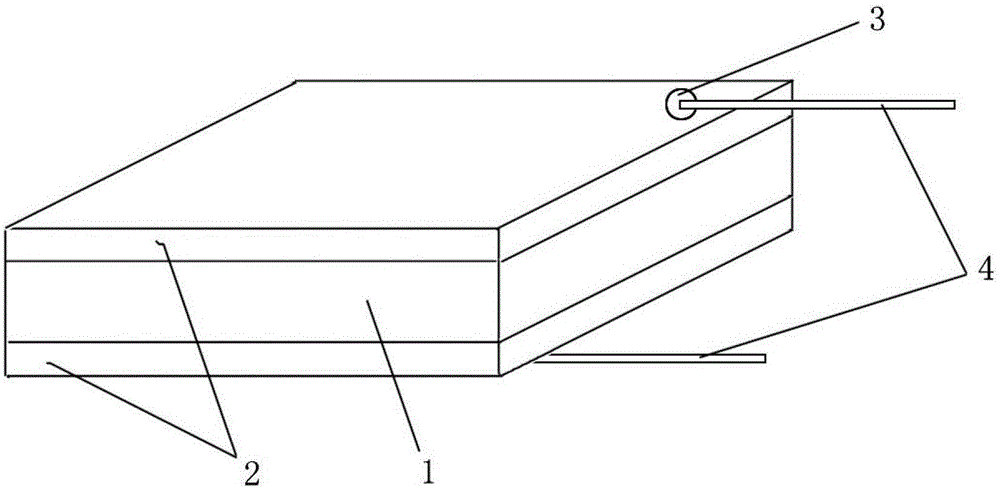

[0029] The present embodiment porous ceramic Al 2 o 3 The preparation process of the type humidity sensor is as follows:

[0030] 1. Pretreatment of high-purity aluminum test pieces

[0031]The size of the high-purity aluminum sample in this embodiment is 50mm×50mm×0.5mm, and the purity is 99.99%. The pretreatment process is to use acetone to remove oil for 15-20 minutes under the action of ultrasonic waves. After degreasing, put it in 1mol / L NaOH solution for about 5 minutes to remove the natural oxide layer, and then use it.

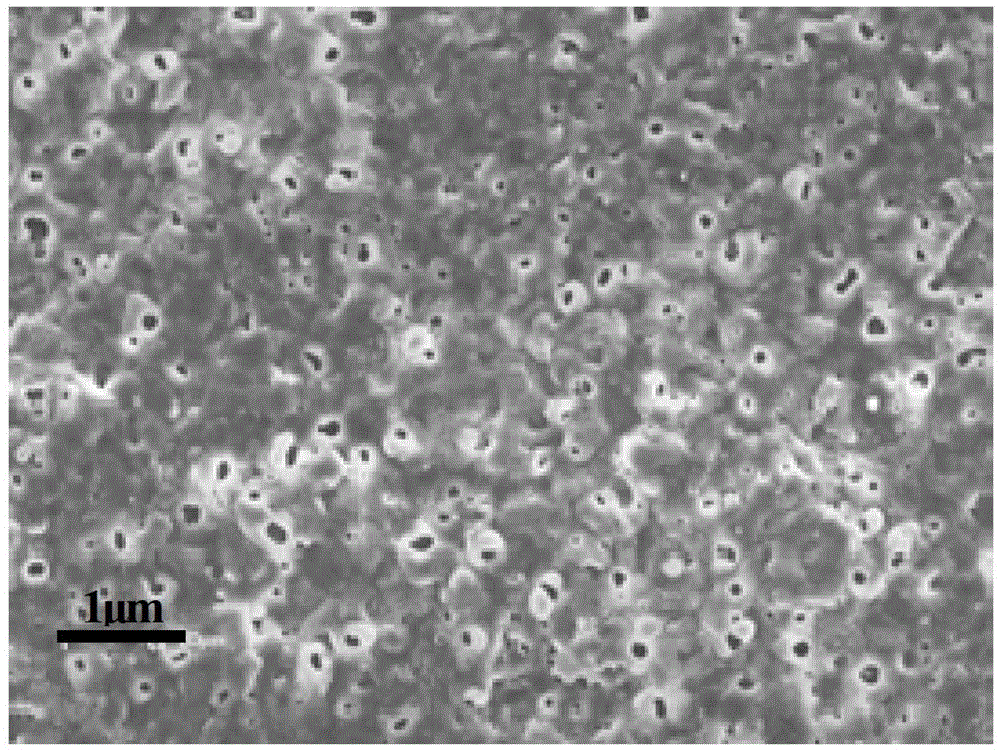

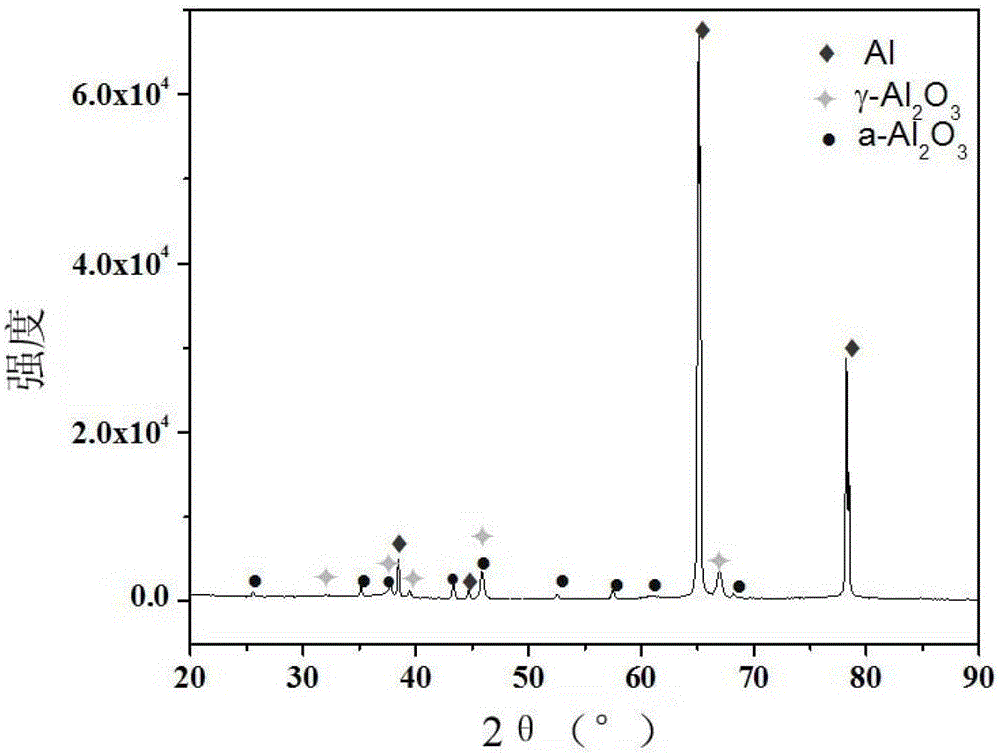

[0032] 2. Preparation of porous ceramic Al by transient self-feedback micro-arc oxidation technology 2 o 3 Moisture Sensitive Film

[0033] The pretreated high-purity aluminum test piece is placed in a stainless steel tank containing electrolyte, the high-purity aluminum is used as the working electrode, and the stainless steel is used as the counter electrode to form a circuit. Utilize Durcourt IV high-power pulse power supply to apply double-p...

Embodiment 2

[0046] The difference from Example 1 is that step 2 adopts transient self-feedback micro-arc oxidation technology to prepare porous ceramic Al 2 o 3 For moisture sensitive films:

[0047] The main composition of the electrolyte is: sodium hydroxide 3~5g / L, sodium silicate 2~5g / L, sodium borate 5~8g / L, sodium molybdate 0.2~0.8g / L, sodium caprate 0.8~1.9g / L, sodium malate 0.7~1.2g / L, cerium nitrate 0.8~2.1g / L, electrolyte pH value 5~8 (use diluted NaOH, or dilute nitric acid solution to adjust). The double-pulse square-wave voltage with high-frequency carrier is applied to the electrolysis circuit by using Durcott Ⅳ high-power pulse power supply. The pulse frequency of the parent square-wave pulse voltage is 320-340Hz, and the forward pulse voltage amplitude is 330-350V. The pulse width is 0.6ms, the negative voltage amplitude is 540-620V, and the pulse width is 0.4ms; the high-frequency carrier frequency is 2500-2800Hz, and the high-frequency carrier voltage amplitude is 70-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com