A kind of composite nano-electrolyte for preparing micro-arc oxidation film on aluminum alloy surface and its application

An aluminum alloy surface, composite electrolyte technology, applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problems of reducing residual stress of oxide film, easy to produce defects and cracks, affecting practical application, etc. Wide sintering temperature range, reduction of cracks and defects, good effect of grain boundary bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

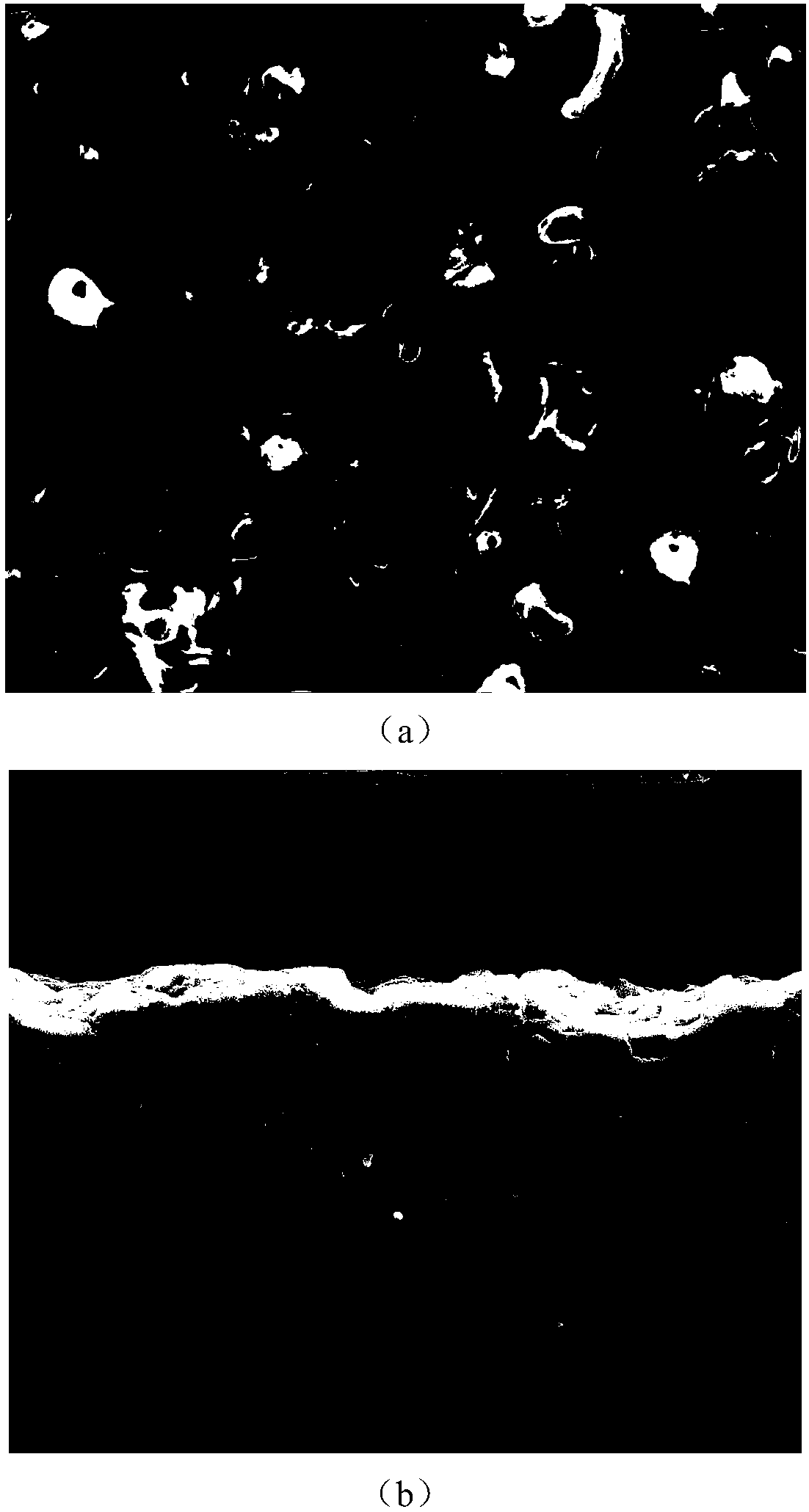

[0028] Specimen material: LY12, size 100×100mm, the surface of the aluminum alloy workpiece is placed in the electrolyte as the anode, and the stainless steel as the cathode. First place the aluminum alloy workpiece in the initial treatment electrolyte containing sodium hydroxide concentration of 4.5g / L, sodium silicate concentration of 3.7g / L and solvent as water, and the current density is controlled at 4.5A / dm 2 Take it out after oxidizing for 10 minutes. After washing with water, put the aluminum alloy workpiece into the secondary treatment nano-composite electrolyte. The electrolyte composition is: the concentration of sodium hydroxide is 4.6g / L, the concentration of sodium silicate is 3.5g / L, and the concentration of sodium molybdate is 0.2 g / L, the concentration of sodium malate is 0.75 / L, the concentration of nano-magnesia is 0.8g / L, the concentration of nano-yttrium oxide is 0.5g / L, and water is the balance. Then apply a high-frequency composite carrier to the electr...

Embodiment 2

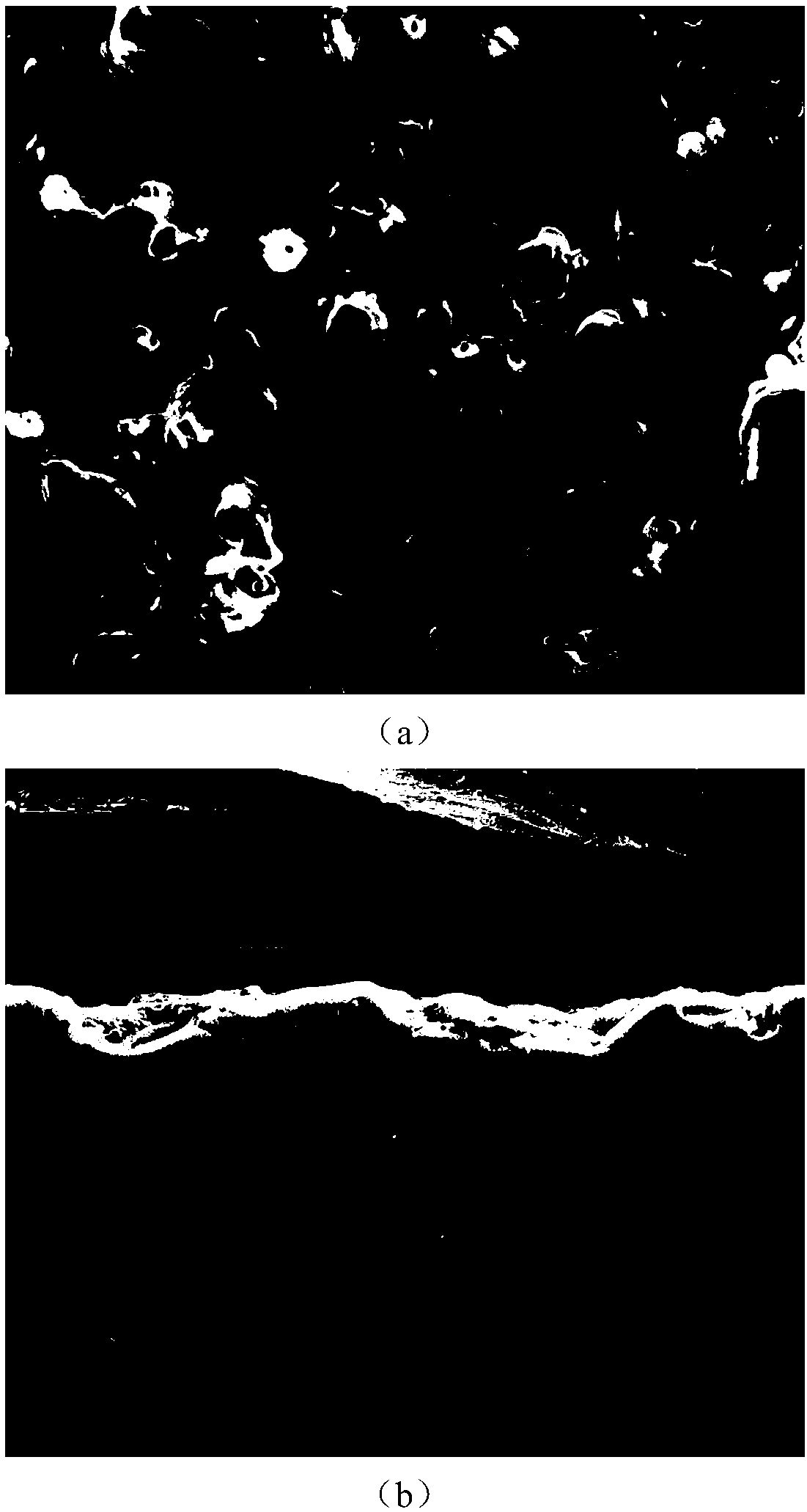

[0030] Specimen material: 5083, size 100×100mm, the surface of the aluminum alloy workpiece is placed in the electrolyte as the anode, and the stainless steel as the cathode. First place the aluminum alloy workpiece in the initial treatment electrolyte containing sodium hydroxide concentration of 4.7g / L, sodium silicate concentration of 3.8g / L and solvent as water, and the current density is controlled at 3.6A / dm 2 Take it out after oxidizing for 10 minutes. After washing with water, put the aluminum alloy workpiece into the nanocomposite electrolyte for secondary treatment. The concentration of triazole is 0.96g / L, the concentration of sodium malate is 0.78g / L, the concentration of nano-magnesia is 1.2g / L, the concentration of nano-yttrium oxide is 0.6g / L, and water is the balance. Then apply a high-frequency composite carrier to the electrolytic circuit to oxidize the surface of the workpiece, and the current density is controlled at 9A / dm 2 Between, pulse wave voltage fre...

Embodiment 3

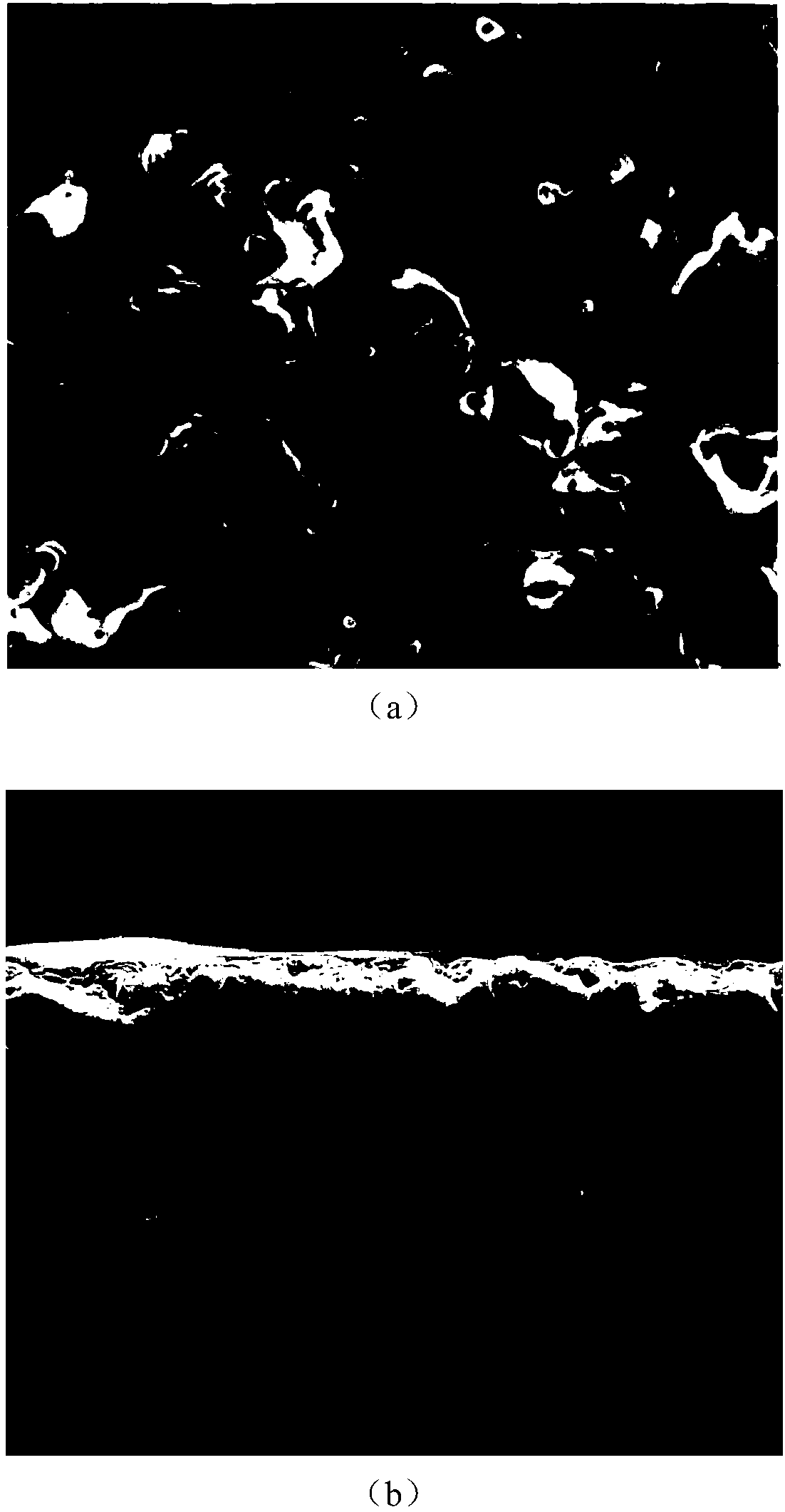

[0032] Specimen material: LC4, size 100×100mm, the surface of the aluminum alloy workpiece is placed in the electrolyte as the anode, and the stainless steel as the cathode. First place the aluminum alloy workpiece in the initial treatment electrolyte containing sodium hydroxide concentration of 5g / L, sodium silicate concentration of 4g / L and solvent as water, and the current density is controlled at 4.2A / dm 2 Take it out after oxidizing for 10 minutes. After washing with water, put the aluminum alloy workpiece into the secondary treatment nano-composite electrolyte, the electrolyte composition is: the concentration of sodium hydroxide is 5g / L, the concentration of sodium silicate is 4g / L, and the concentration of sodium phosphate is 7g / L. The concentration of sodium molybdate is 0.25g / L, the concentration of benzotriazole is 1g / L, the concentration of nano-magnesium oxide is 0.6g / L, the concentration of nano-yttrium oxide is 0.7g / L, and water is the balance. Then apply a hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com