Passive polarizing type three-dimensional display device and manufacturing method thereof

A three-dimensional display and polarization technology, which is applied in optics, optical elements, nonlinear optics, etc., can solve the problems that passive polarized three-dimensional display devices are difficult to have a large vertical viewing angle, and the width of the black matrix bar 108 cannot be too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

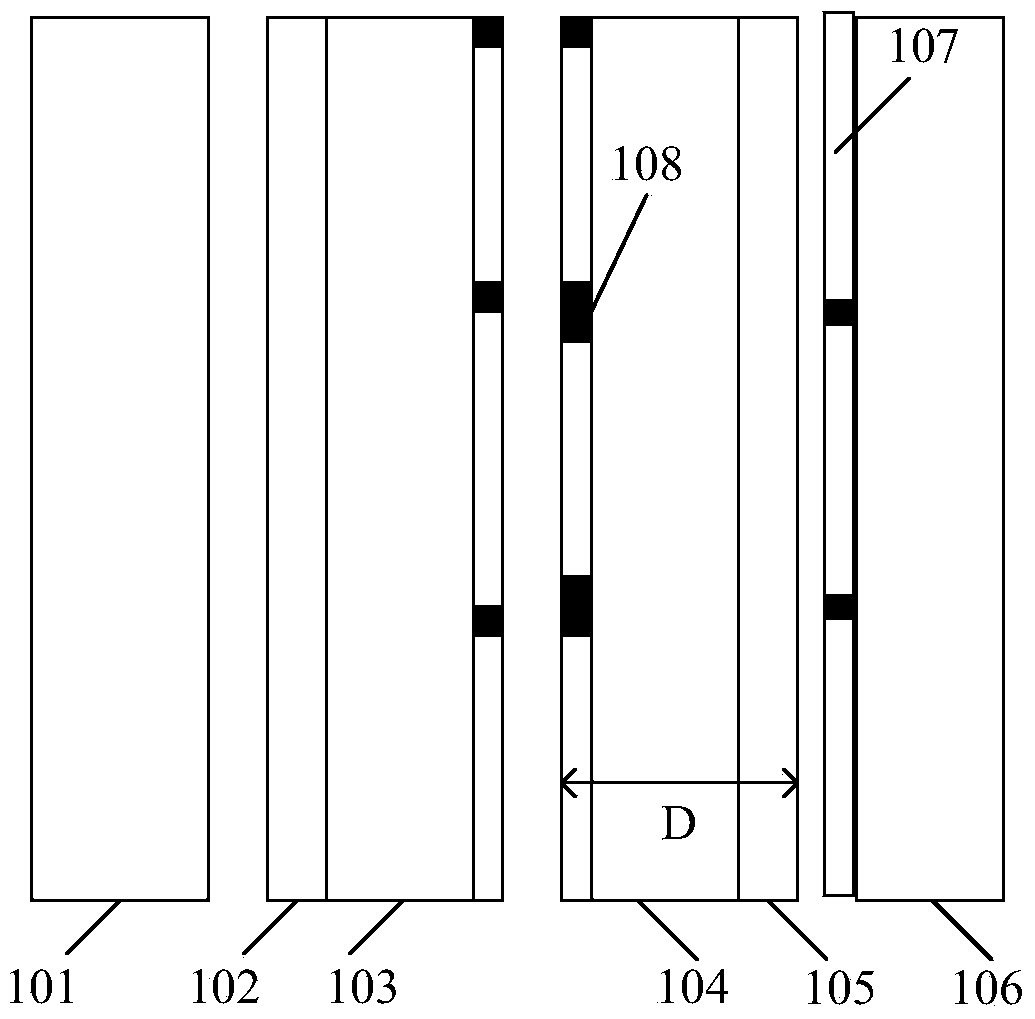

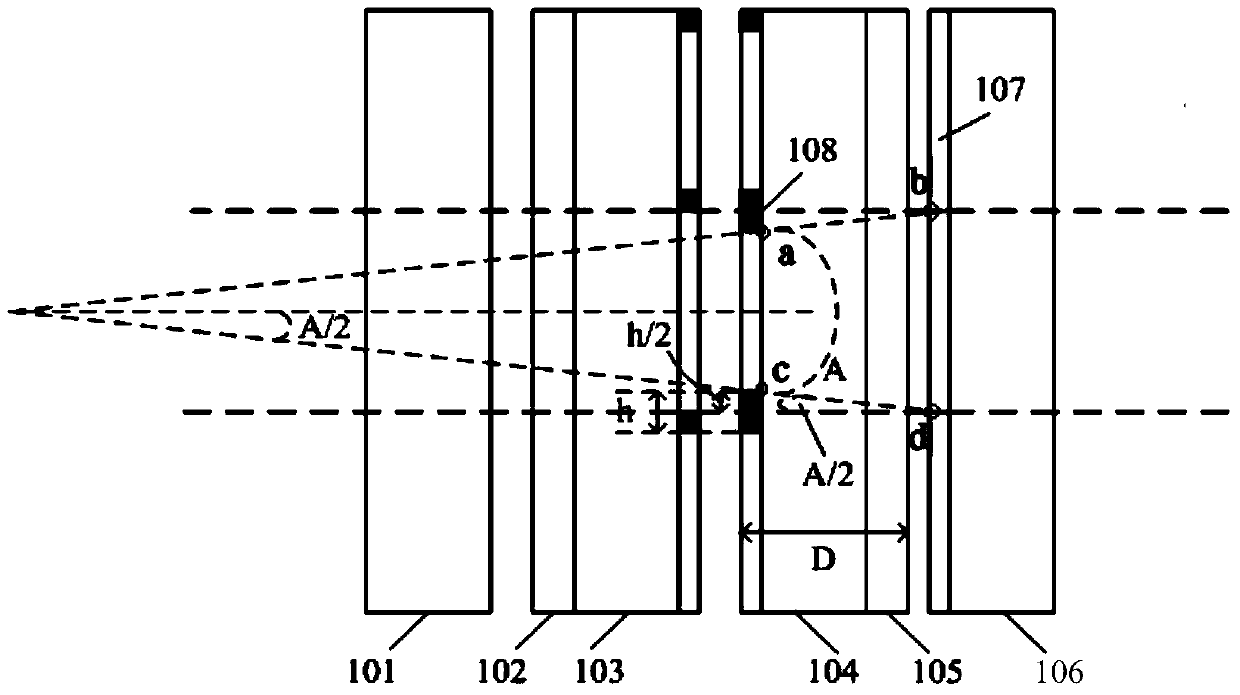

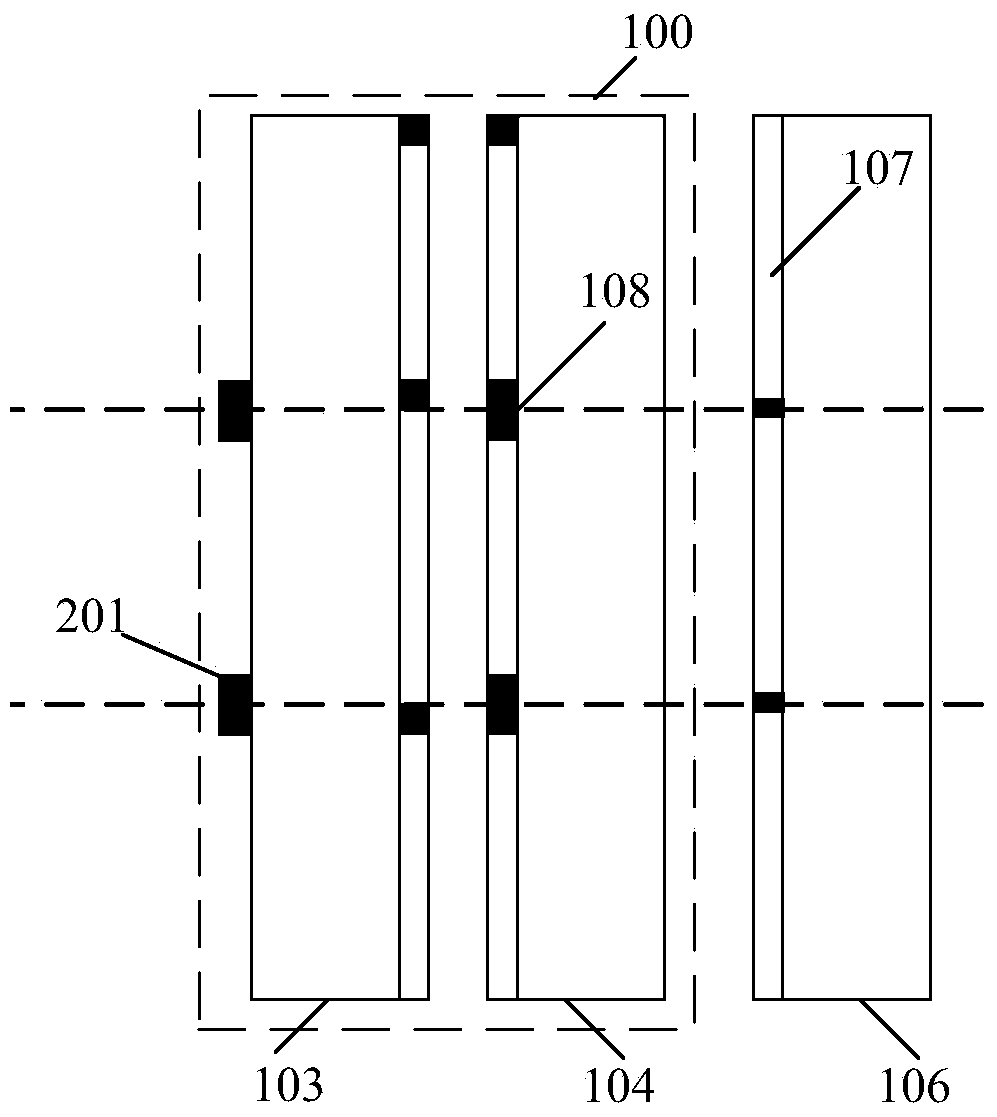

[0030] Embodiments of the present invention provide a passive polarized three-dimensional display device and a manufacturing method thereof. A light-shielding strip is provided on the side where the array substrate is connected to the first polarizer, and a plurality of black matrix strips are provided on the side where the color filter substrate is connected to the array substrate. Orthographic projections of the light-shielding strips and the plurality of black matrix strips on the phase difference structure cover the boundary lines of the phase difference diaphragms of the patterns on the phase difference structure. Under the shading effect of the shading strips and black matrix strips, while ensuring the aperture ratio, the viewing angle without optical interference between adjacent pixels of the passive polarizing three-dimensional display device is increased, thereby increasing the passive polarizing three-dimensional display device. vertical viewing angle.

[0031] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com