A preparation method of superhydrophobic surface of copolymer grafted hollow silica microspheres

A super-hydrophobic surface, silica technology, applied in the field of surface chemistry, can solve the problems of poor super-hydrophobic surface strength, different operation complexity, different processes, etc., to achieve stable performance, high mechanical strength, and good transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

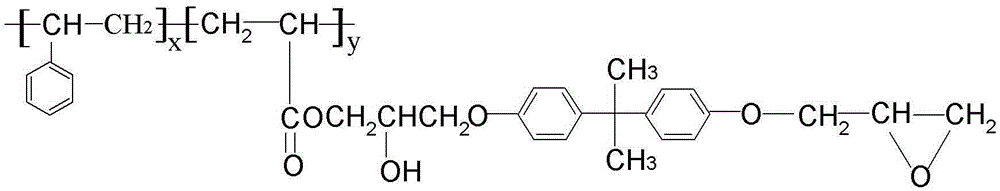

[0027] 1. Synthesis of bisphenol A diglycidyl ether monoacrylate

[0028] Dissolve 0.025g of potassium hydroxide in 0.648g of acrylic acid, add 0.3g of hydroquinone into 40ml of toluene solution of 3.4g of bisphenol A diglycidyl ether, mix the above two solutions, blow nitrogen, at 110°C Stir the reaction for 48 hours, cool to room temperature, add 15ml toluene and 7.5ml deionized water, stir thoroughly, extract, separate liquid, wash with deionized water until neutral, distill off the solvent under reduced pressure, and obtain bisphenol A di Glycidyl ether monoacrylate;

[0029] 2. Synthesis of styrene-bisphenol A diglycidyl ether monoacrylate copolymer

[0030] Add 4.16g of styrene and 1.03g of bisphenol A diglycidyl ether monoacrylate to 12ml of tetrahydrofuran, add 0.035g of azobisisobutyronitrile, blow nitrogen, and stir the reaction at 70°C for 24 hours. Precipitate with water volume ratio of 2:8, filter with suction, dissolve the precipitate with acetone, precipitate ...

Embodiment 2

[0040] 1. Synthesis of bisphenol A diglycidyl ether monoacrylate

[0041] Dissolve 0.05g of potassium hydroxide in 1.296g of acrylic acid, add 0.58g of hydroquinone into 80ml of toluene solution of 6.8g of bisphenol A diglycidyl ether, mix the above two solutions, blow nitrogen, at 108°C Stir the reaction for 550 hours, cool to room temperature, add 30ml of toluene and 15ml of deionized water, stir thoroughly, extract, separate liquid, wash with deionized water until neutral, distill off the solvent under reduced pressure, and obtain bisphenol A bisphenol A dihydrate by column chromatography Glyceryl ether monoacrylate;

[0042] 2. Synthesis of styrene-bisphenol A diglycidyl ether monoacrylate copolymer

[0043]Add 5.15g of styrene and 1.03g of bisphenol A diglycidyl ether monoacrylate to 15ml of tetrahydrofuran, add 0.04g of azobisisobutyronitrile, blow nitrogen, and stir the reaction at 75°C for 26 hours. Precipitate with water volume ratio of 2:8, filter with suction, dis...

Embodiment 3

[0053] 1. Synthesis of bisphenol A diglycidyl ether monoacrylate

[0054] Dissolve 0.03g of potassium hydroxide in 0.648g of acrylic acid, add 0.38g of hydroquinone into 40ml of toluene solution of 3.4g of bisphenol A diglycidyl ether, mix the above two solutions, and blow nitrogen, at 105°C Stir the reaction for 60 hours, cool to room temperature, add 15ml toluene and 7.5ml deionized water, stir thoroughly, extract, separate liquid, wash with deionized water until neutral, distill off the solvent under reduced pressure, and obtain bisphenol A di Glycidyl ether monoacrylate;

[0055] 2. Synthesis of styrene-bisphenol A diglycidyl ether monoacrylate copolymer

[0056] Add 3.03g of styrene and 0.5g of bisphenol A diglycidyl ether monoacrylate to 10ml of tetrahydrofuran, add 0.03g of azobisisobutyronitrile, blow nitrogen, and stir the reaction at 68°C for 30 hours. Precipitate with water volume ratio of 2:8, filter with suction, dissolve the precipitate with acetone, precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com