Vortex generator structure for suppressing boundary layer separation under action of shock waves

A vortex generator and boundary layer technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of anti-separation, restriction and mutual weakening of unfavorable boundary layers, and achieve improved anti-separation ability, small mutual weakening effect, and reduced separation. effect of zone size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

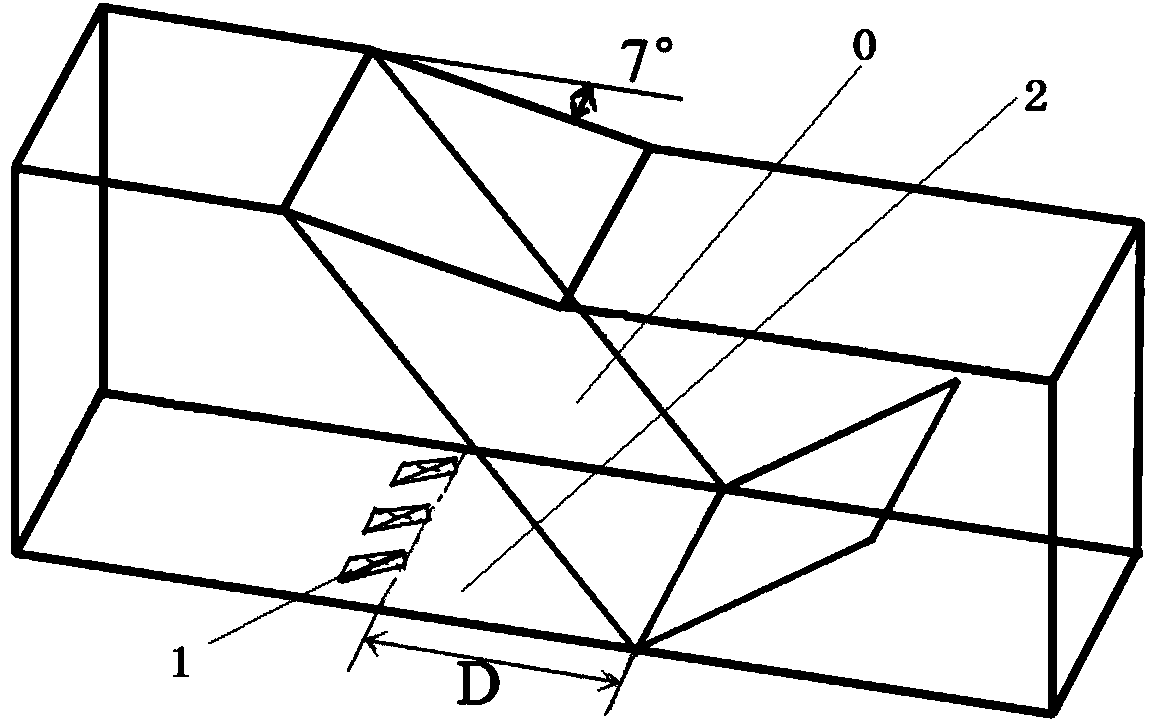

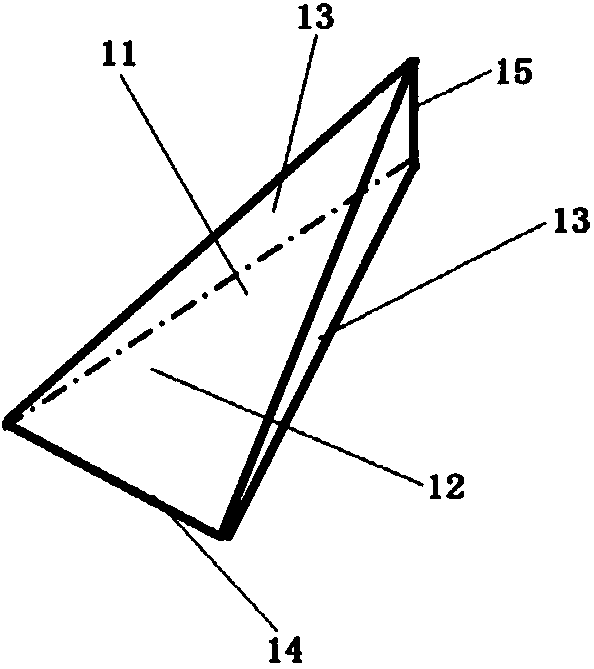

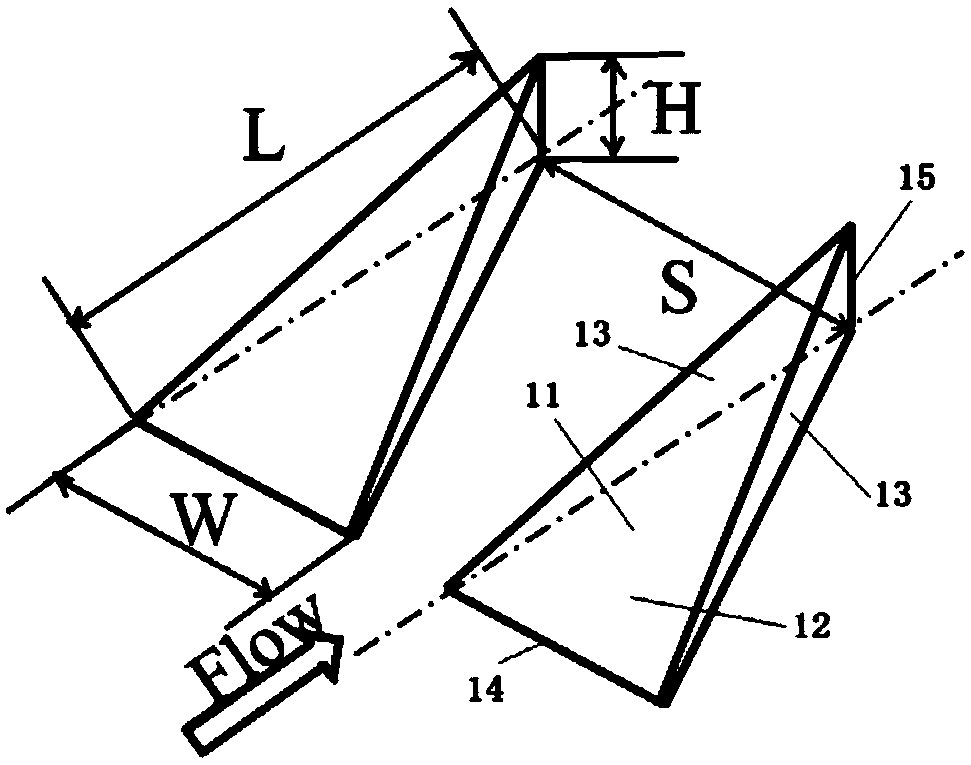

[0028] As an implementation, for example, the height H of the trailing edge of the vortex generator can be 70% of the boundary layer thickness B when there is no vortex generator control at the position; the length L along the flow direction is 7 times the height H of the trailing edge of the vortex generator ; The spanwise width W in the vertical flow direction is 3 times the height H of the trailing edge; the spacing S between adjacent structures in the arrangement of vortex generators is 7.5 times the height H of the trailing edge.

[0029] Numerical calculation results show that the incompressible shape factor of the boundary layer downstream of the shock boundary layer interaction zone decreases from 1.47 without control to 1.39 with vortex generator control. The incompressible shape factor of the boundary layer is the ratio of the displacement thickness to the momentum thickness of the boundary layer. The value of the shape factor is inversely proportional to the ability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com