An adjustable sonic soot blower

A sonic soot blower, adjustable technology, applied in the direction of combustion product treatment, combustion method, solid residue removal, etc., can solve the problems of affecting furnace efficiency, complex structure, and poor sonic cleaning effect of sonic soot cleaner, etc. Achieve cost saving, low cost and wide range of soot blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0017] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

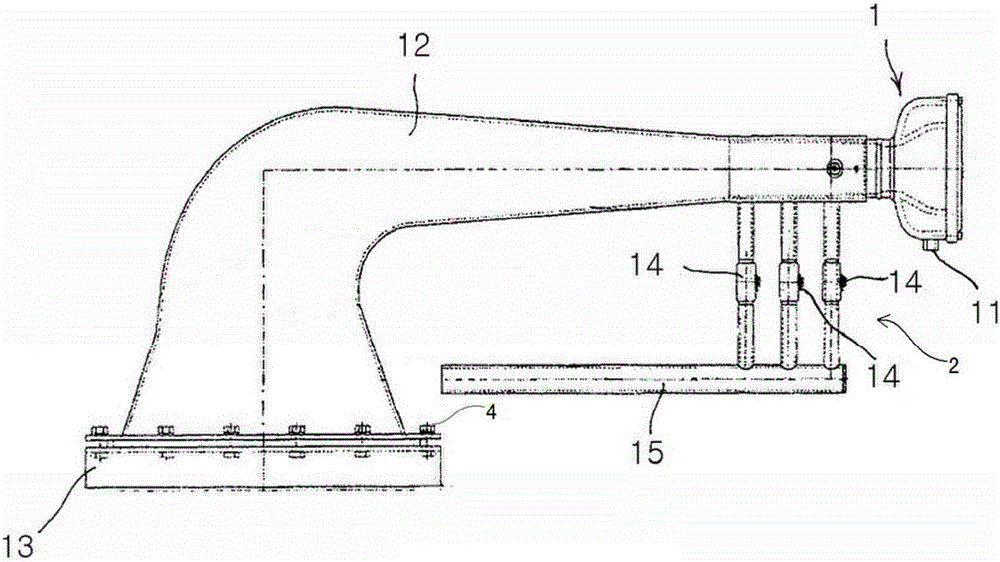

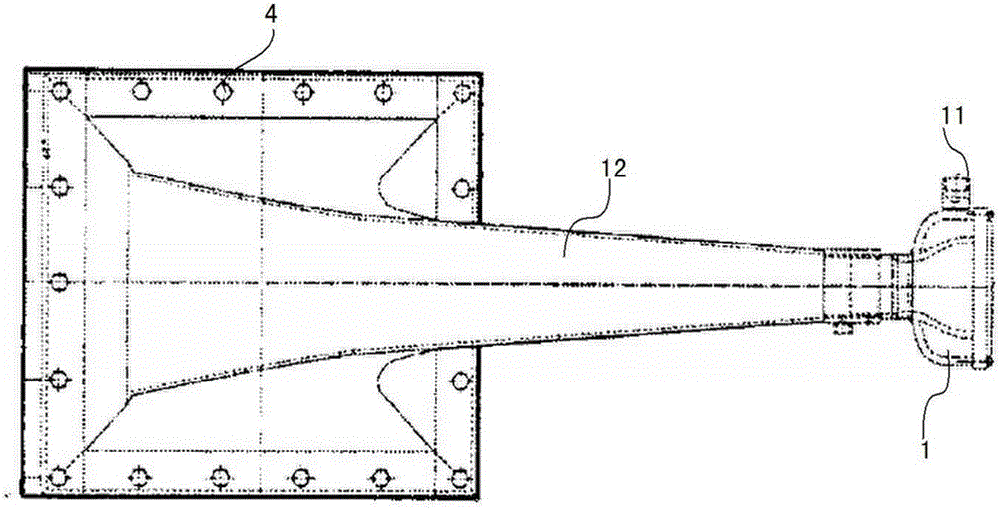

[0018] see figure 1 , which is a schematic diagram of the overall structure of the adjustable sonic soot blower of the present invention, as shown in the figure, the adjustable sonic soot blower of the present invention includes: a sound wave generating device (1), which is arranged at one end of the sonic soot blower; Conduit (12), is connected with aforementioned sound wave generating device (1);

[0019] A soot blowing pipe (13) is connected with the aforementioned sound conduit (12); the acoustic wave regulator (2) has a plurality of tubular acoustic wave regulating valves (14), and the sound wave regulating valve (14) is connected with the afor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com