Sound wave soot blower

The technology of a sonic soot blower and a soot blowing tube is applied in the field of soot blowing devices, which can solve problems such as affecting furnace efficiency and hidden dangers of safe operation of a heating furnace, and achieve the effects of wide soot blowing range and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

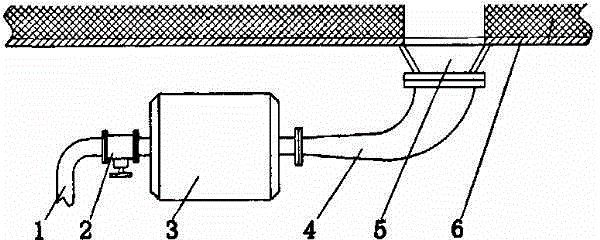

[0011] A sonic soot blower according to the present invention comprises a compressed air pipe 1, a control valve 2, a sound wave generating device 3, a sound conduit 4 and a soot blowing pipe 5 connected in sequence, the control valve 2 is opened, and the compressed air passes through the compressed air pipe 1 enters the sound wave generator 3, and the sound wave is emitted by the sound wave generator 3. The sound wave is amplified by the sound guide 4 and then enters the soot blowing pipe 5, and the soot blowing pipe 5 is deep into the heating furnace wall plate 6 for purging. The sound wave energy can make the area The air molecules in the furnace and the dust particles oscillate, and under the action of repeated vibrations of the sound waves, the cyclic variable load and cyclic stress of the ash accumulation in the furnace also act repeatedly, destroying the combination of the dust particles, the heat exchange surface and the particles. Coupled with the collision between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com