Horizontal compensation mechanism used for dental chair

A compensation mechanism, a technology for dental chairs, applied in dental chairs, dental chairs, surgical chairs, etc., can solve the problems of backrest and seat cushion rubbing, occupying a large space, unsatisfactory, etc., and achieve the effect of stable transmission and low resonance sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

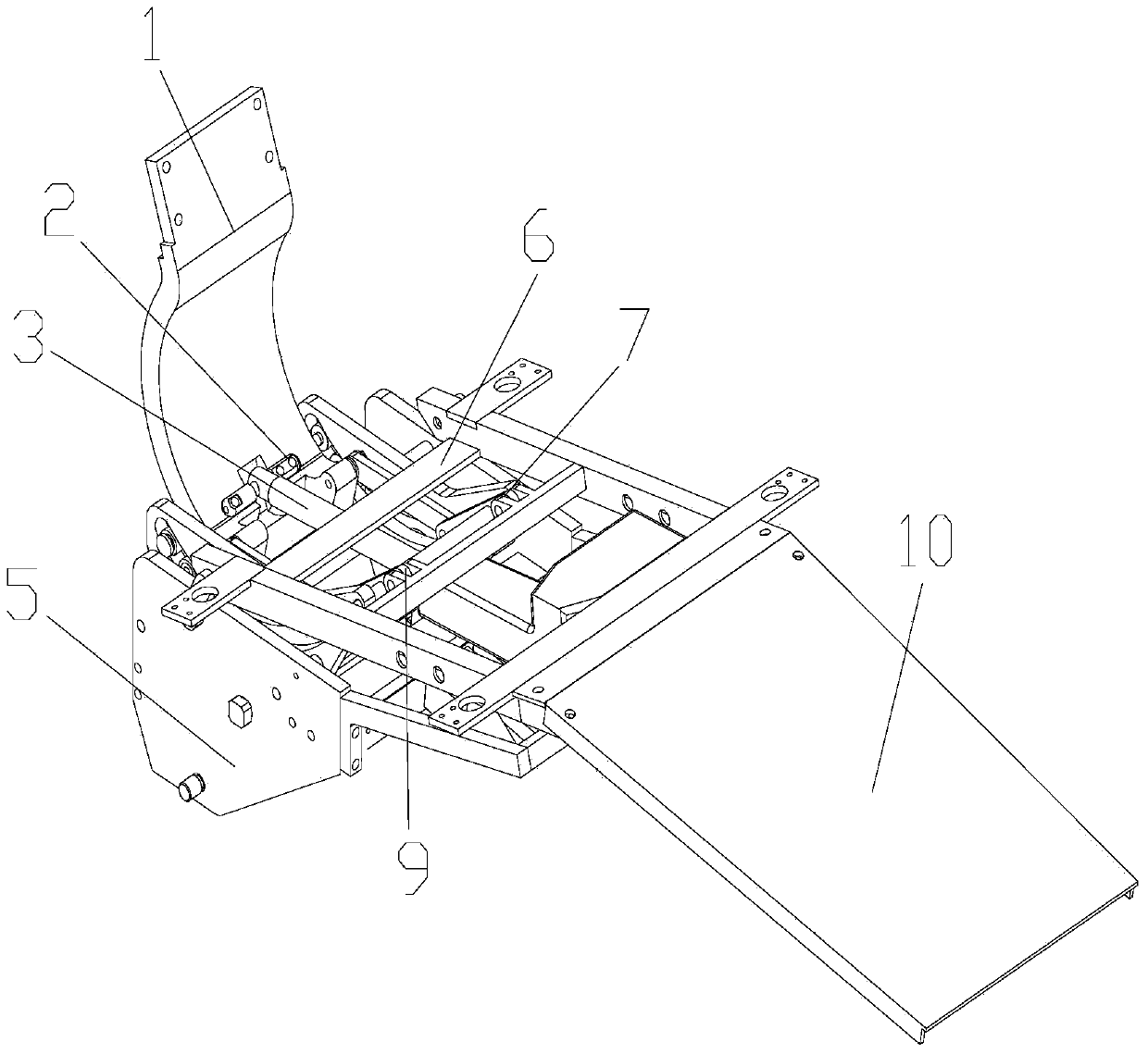

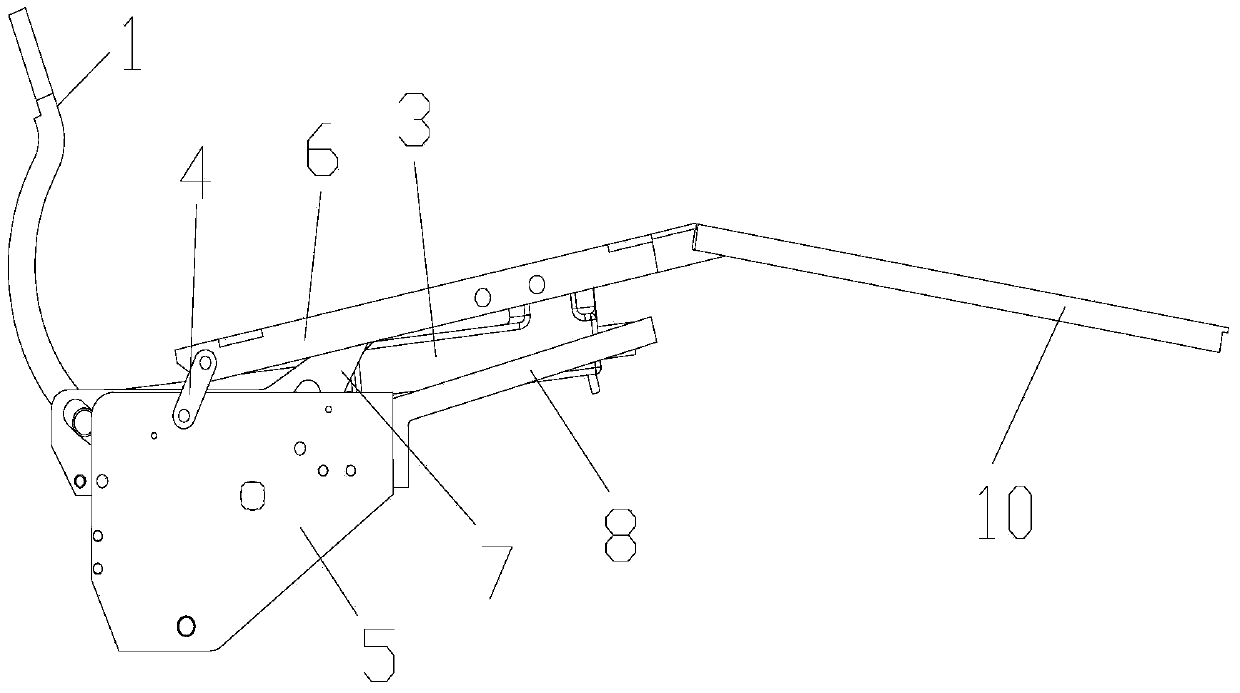

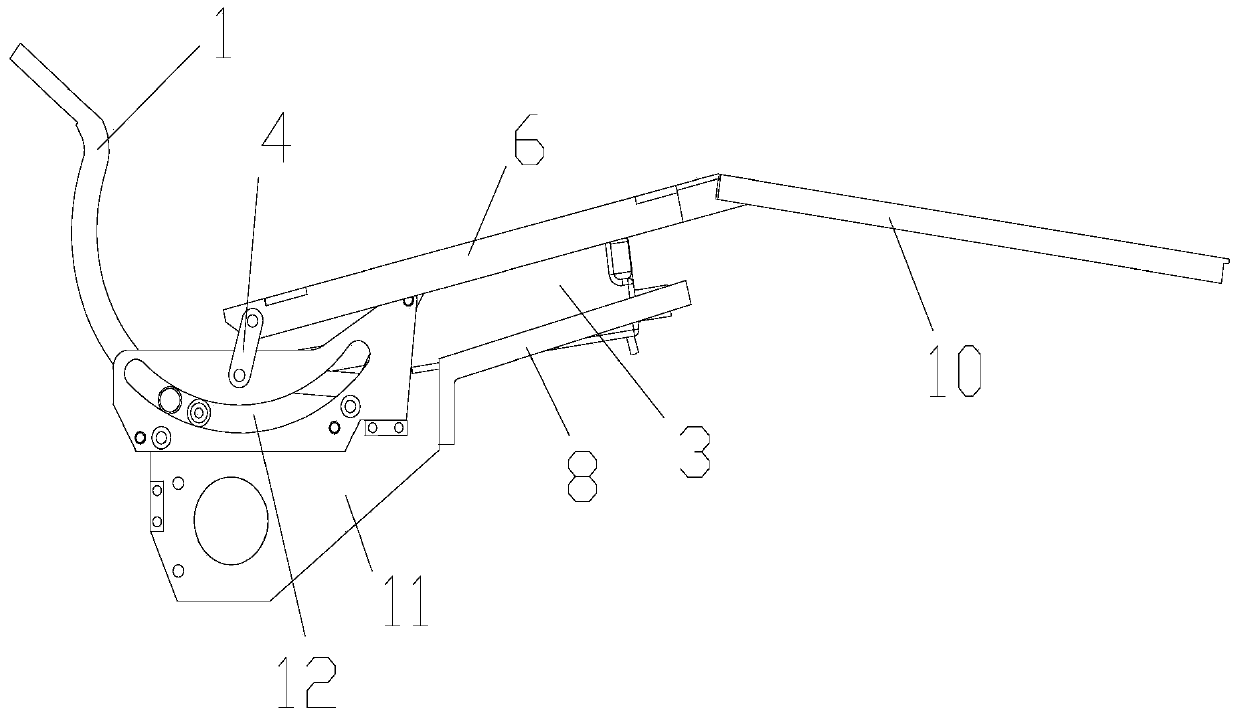

[0012] Attached below Figure 1-5 An embodiment of the present invention is described.

[0013] A horizontal compensation mechanism for a dental chair, which has a curved plate 1, a DC motor 3, a seat cushion support 6, an extension plate 10, a left side plate 5 and a right side plate 11, and the left side plate 5 and the right side plate 11 There are guide rails 7 between them, and the guide rails 7 are formed with arc-shaped grooves 12 matching the shape of the bent plate 1. Specifically, the two ends of the guide rails 7 are fixed between the left side plate 5 and the right side plate 11, and the arc-shaped The arc portion of the groove 12 is provided with a screw that prevents the bent plate 1 from coming out during reciprocating motion, so that the bent plate 1 can slide through the guide rail arc groove 12, but cannot swing left and right. The upper end of the curved plate 1 fixes the back support plate, the lower end of the curved plate 1 passes through the arc groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com