Sound-proof double air inlet micro air pump

A micro air pump and dual air intake technology, which is applied in variable capacity pump parts, pump components, liquid variable capacity machines, etc., can solve the problem of insufficient air intake in the intake chamber, loud noise in the output air, and problems with the air intake of the pump body. To solve problems such as large resistance, to improve hidden dangers in performance, increase air intake, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

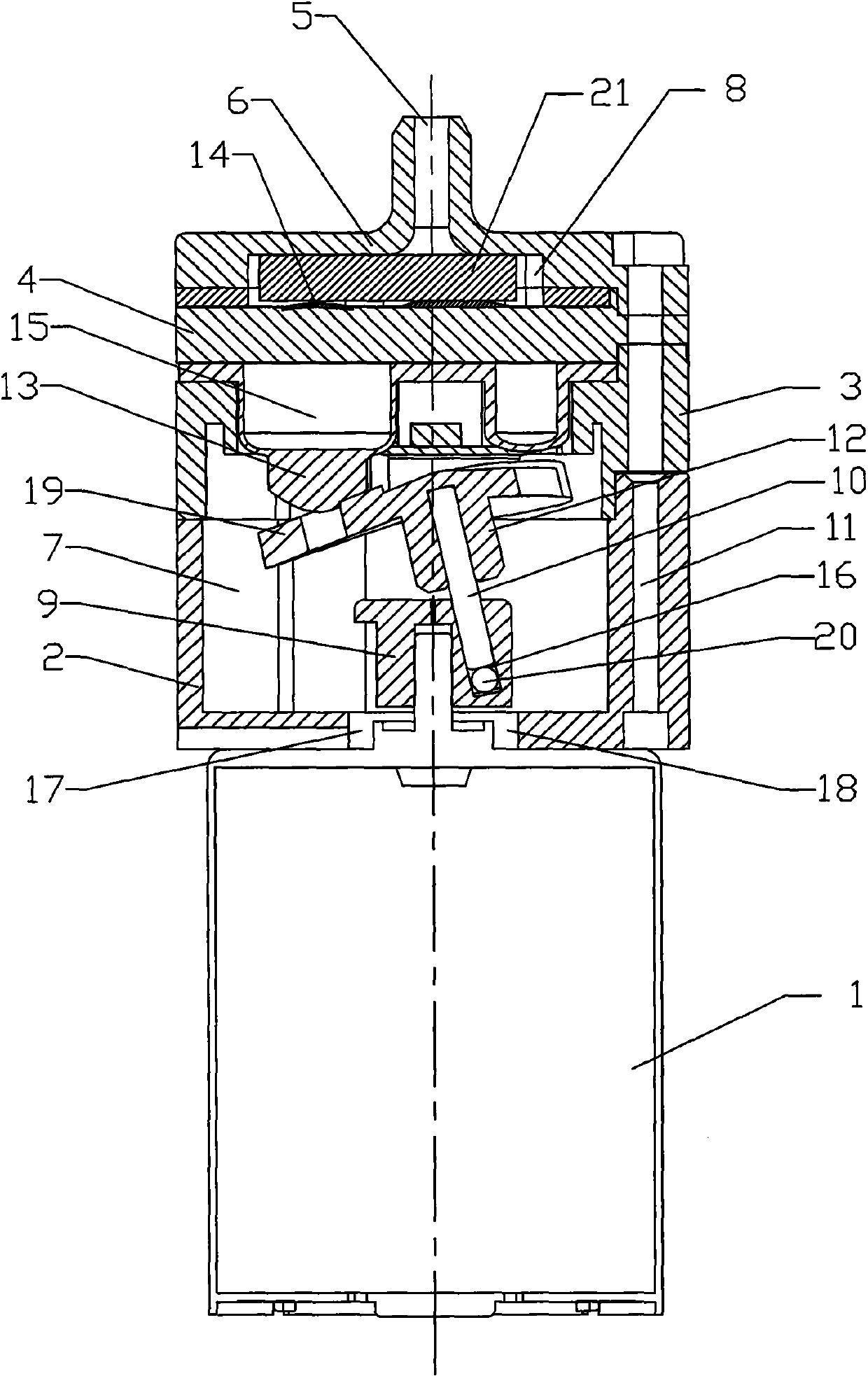

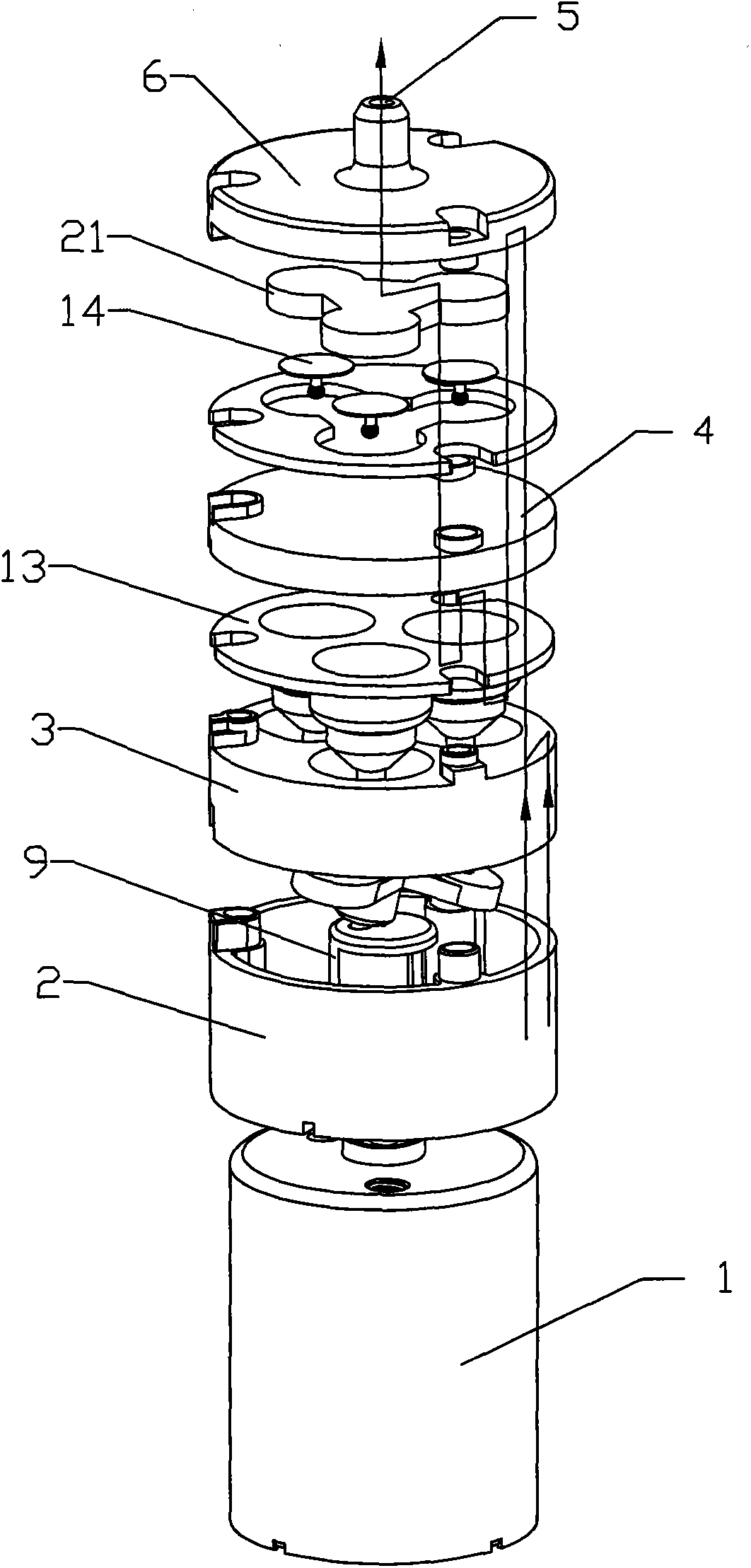

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] according to figure 1 and figure 2 As shown, the soundproof double-intake micro air pump of the present invention includes a motor 1 and a housing assembly, the housing assembly includes a fixed seat 2 with an open end and a cup holder 3 with an open end, the fixed seat 2 and the cup holder 3 The counterparts are installed together, and a valve seat 4 is installed on the cup seat 3 .

[0017] The above-mentioned valve seat 4 is provided with an upper cover 6 with an air outlet 5, the fixed seat 2 and the cup seat 3 encircle an air intake cavity 7, and the valve seat 4 and the upper cover 6 enclose an exhaust cavity 8. The air cavity body 7 is provided with an eccentric cap 9, a linkage shaft 10 and a linkage bracket 12, and a gas compression cup 13 is installed on the cup holder 3, and the gas compression cup 13 is made of a compressible rubber bell-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com