Device and method for testing lateral impact friction

A technology of impact friction and testing equipment, which is applied in the direction of measuring equipment, mechanical equipment, instruments, etc., and can solve the problems such as the inconvenience of side impact friction testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments.

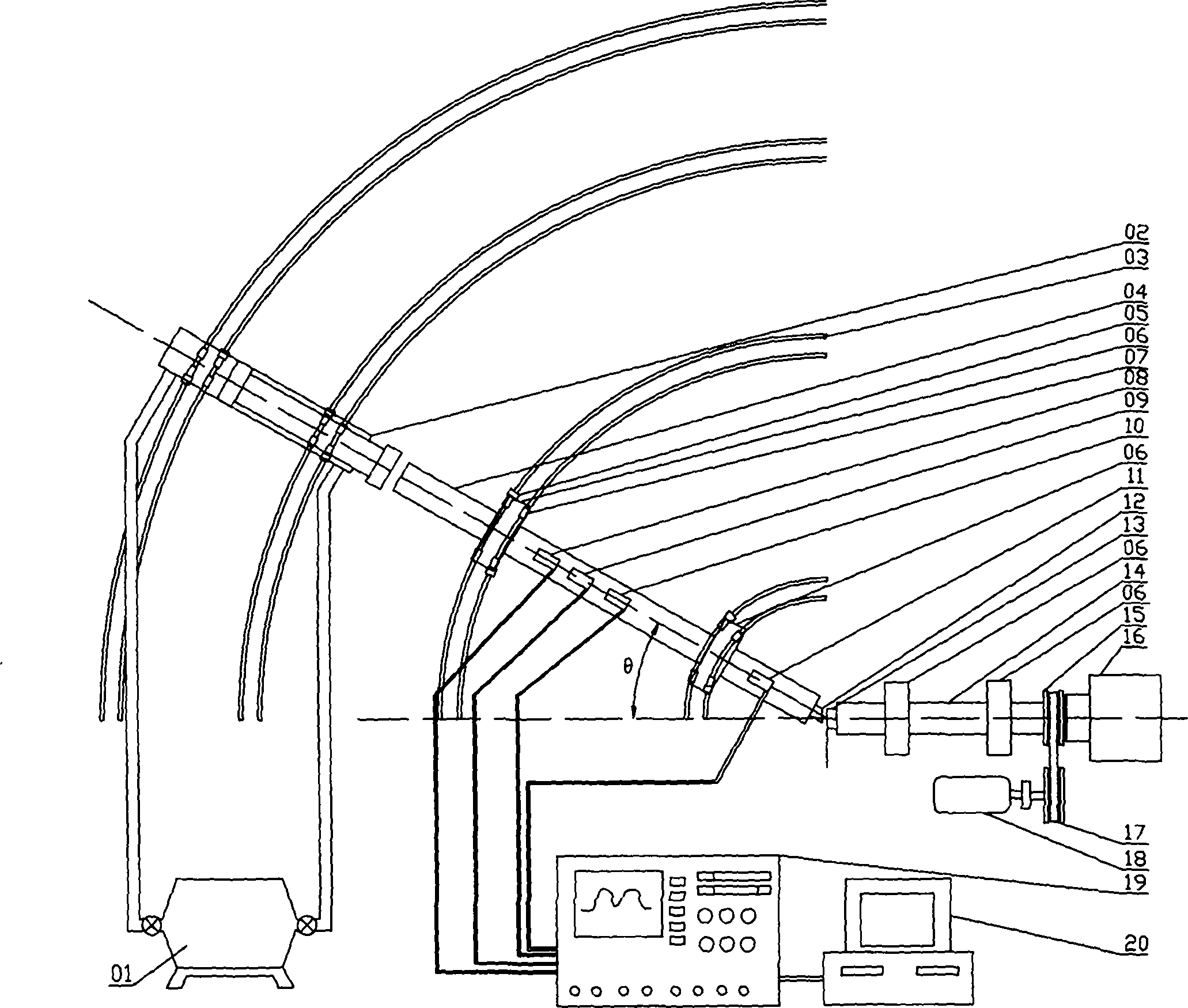

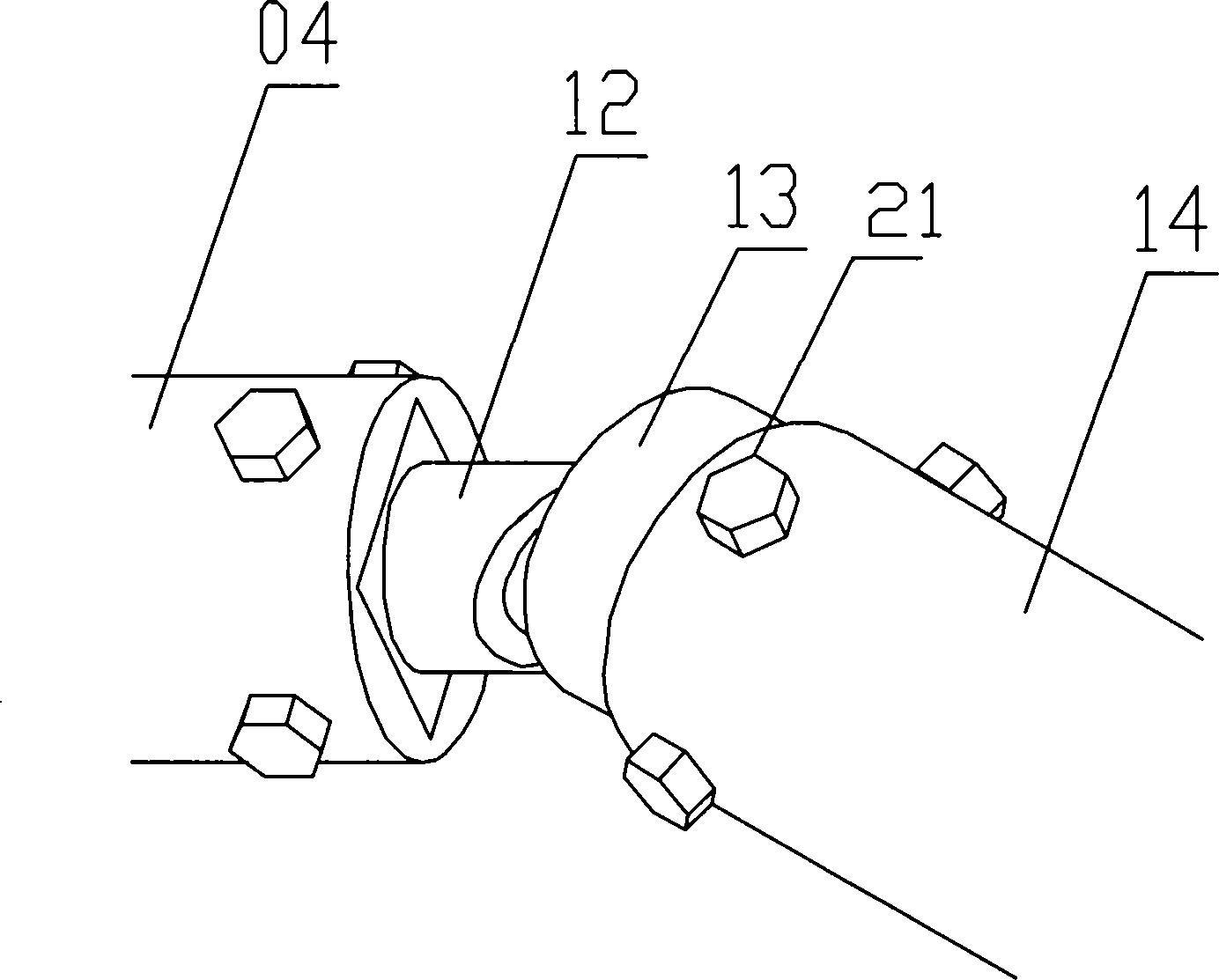

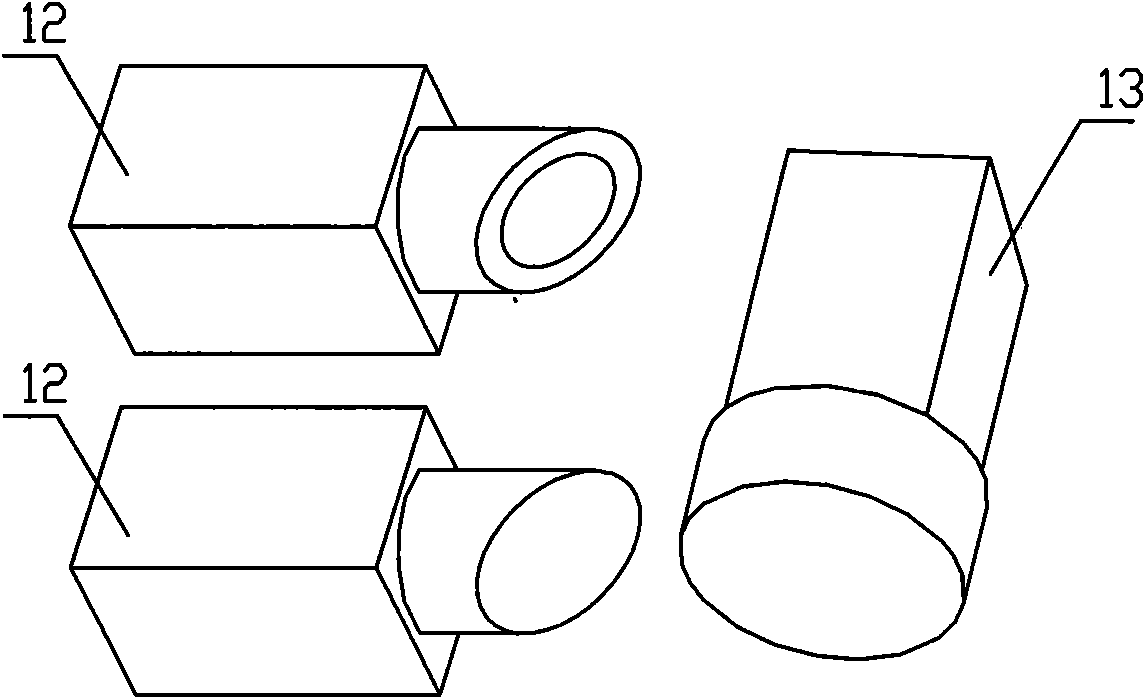

[0030] see figure 1 and figure 2 , a side impact friction test device, including an air pump 01, a pneumatic impact device 02, an arc-shaped track 03, an incident rod 04, a support 06, an acceleration sensor 08, a speed sensor 09, a first strain gauge 10, a second strain gauge Meter 11, first sample 12, second sample 13, transmission rod 14, pulley 15, shock absorber 16, belt 17, frequency conversion motor 18, computer 20 and signal acquisition device 19; incident rod 04 and bearing 06 pass through The sliding bearing connection enables the incident rod 04 to move axially and circumferentially; the transmission rod 14 and the support 06 are connected by rolling bearings, the pneumatic impact device 02 and the incident rod 04 are coaxial, the incident rod 04 and the transmission rod 14 are not coaxial, and the two The axis has an included angle θ; the pneumatic impact d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com