Elastic limiting mechanism

A technology of elastic limit and limit steel ball, which is applied to the parts of the flip switch/rocker switch, etc., can solve the problems of switch misoperation, short handle of the toggle switch, and no design to prevent misoperation of the toggle switch. Achieve the effects of preventing misoperation, convenient and quick operation, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

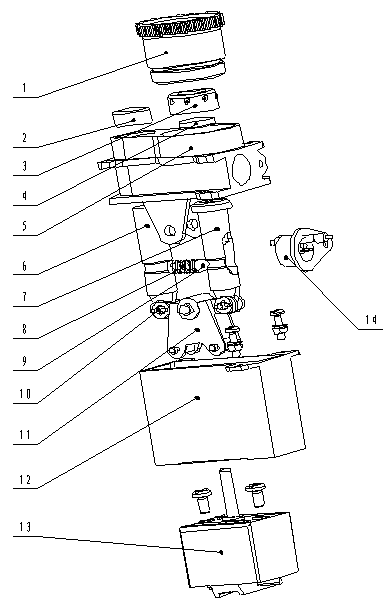

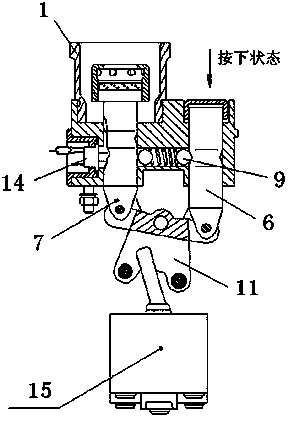

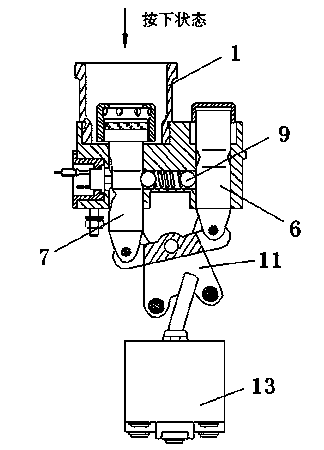

[0011] See figure 1 , shows an elastic limit mechanism, its structure includes: retaining ring, upper shell, lower shell, large end cap, small end cap, switch position swing block, guide rod, spring, steel ball, light-transmitting cover , lights and other parts.

[0012] Such as figure 1 As shown: the upper housing 5 and the lower housing 12 are fixed by M3 screws and M3 nuts. The first guide rod 6 and the second guide rod 7 are vertically installed inside the upper casing, and grooves are provided on the guide rods. Two steel balls 9 are horizontally installed inside the upper casing, and a spring 8 is arranged between the two steel balls. support. When the guide rod moves vertically, the steel ball and the groove of the guide rod move relative to each other. When the steel ball enters the groove, with the help of the spring force, the steel ball and the groove are closely matched to play a position-limiting role. The upper end surface of the first guide rod 6 fixes the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com