Method for controlling rail pressure

A tube pressure and regulating circuit technology, applied in fuel injection control, engine control, machine/engine, etc., can solve problems such as harsh regulation deviation

Active Publication Date: 2014-04-23

ROLLS ROYCE SOLUTIONS GMBH

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since there is no B-side I component in the regulator, this solution is critical in terms of remaining regulation deviation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

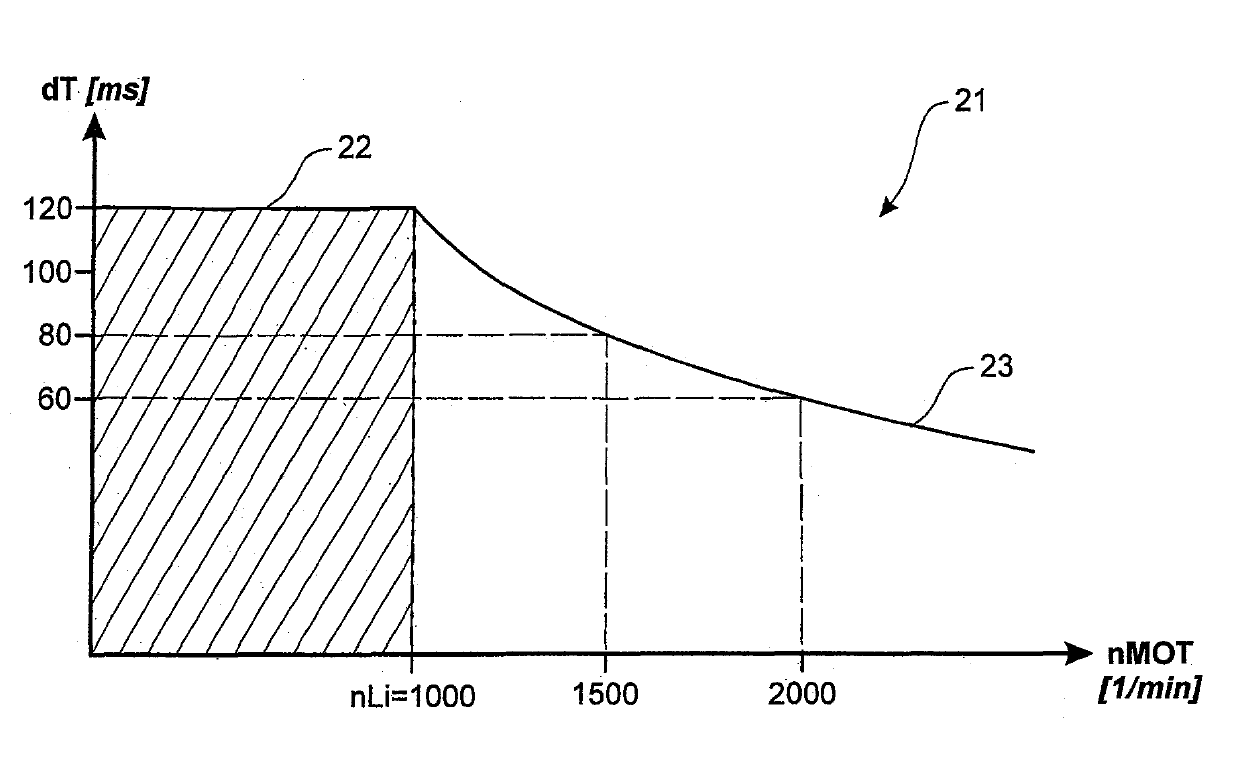

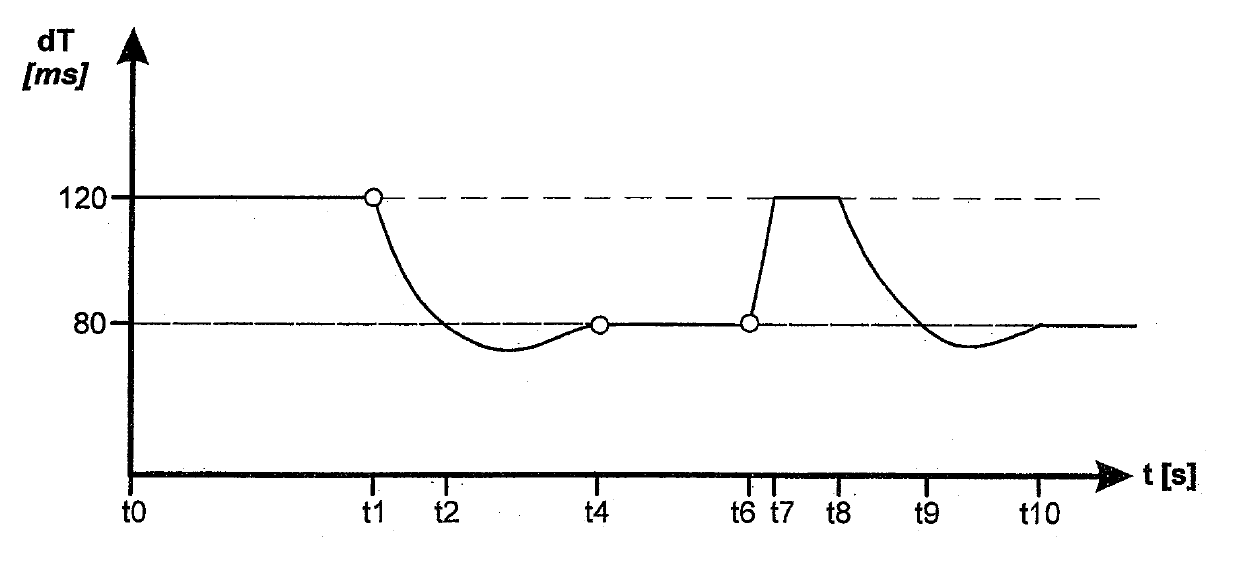

The invention relates to a method for controlling the rail pressure of an internal combustion engine in a V arrangement having an unequal ignition sequence, in which method an actual rail pressure is calculated from the measured rail pressure, a control deviation is determined on the basis of the actual rail pressure and a target rail pressure, and a manipulated variable for controlling a pressure actuator, in particular a suction throttle, is calculated in order to control the rail pressure. The invention is characterized in that the actual rail pressure is calculated from the measured rail pressure by means of a mean value filter, in that below a limit rotational speed (nLi) the rail pressure is averaged over a constant time and above the limit rotational speed (nLi) the rail pressure is averaged over a working cycle of the internal combustion engine.

Description

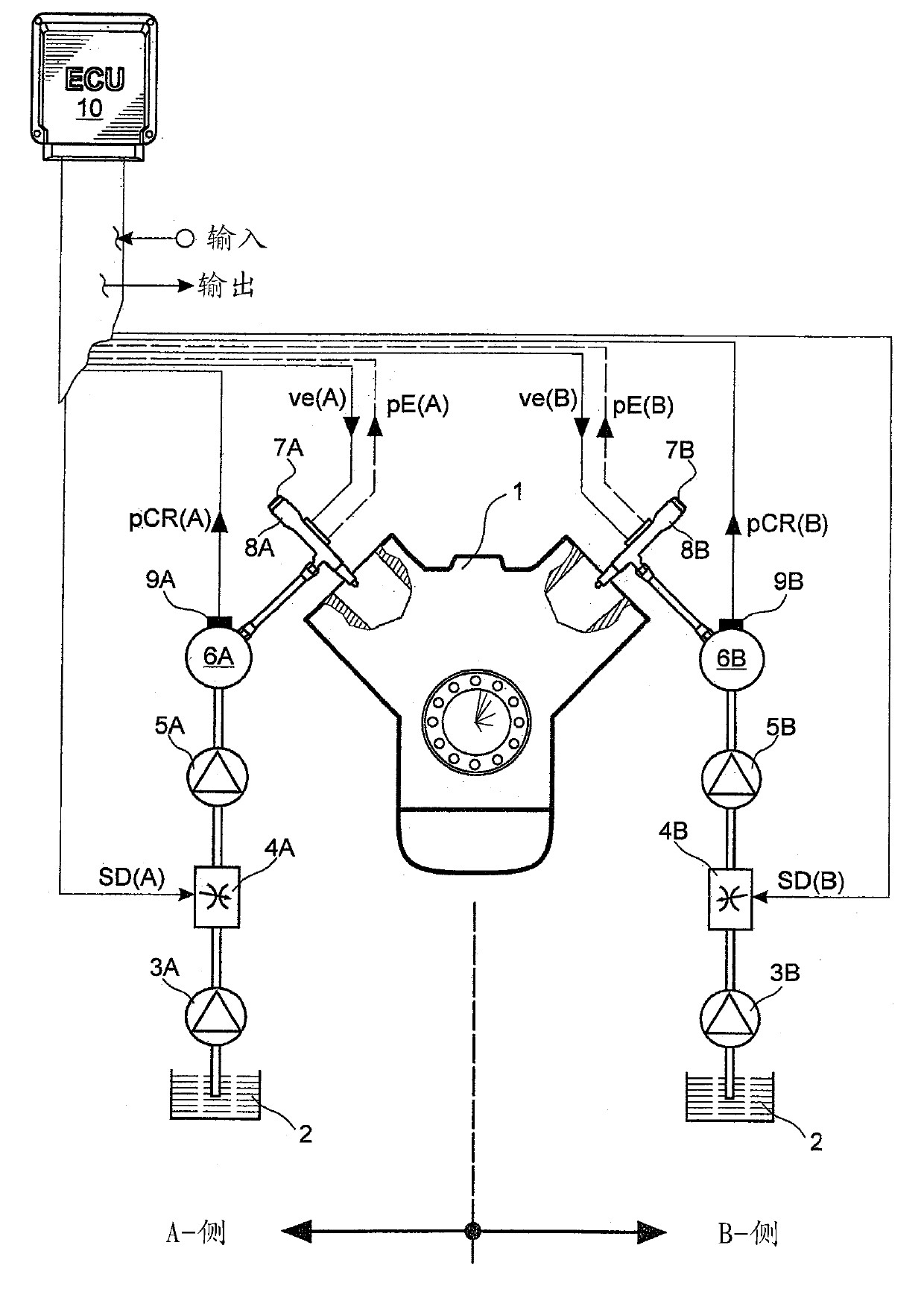

technical field The invention relates to a method according to the preamble of claim 1 for regulating the accumulator pressure of a V-arranged internal combustion engine with different firing sequences. Background technique A V-arranged internal combustion engine has accumulators on the A side and the B side for the intermediate storage of fuel. Injectors are connected to the accumulator, through which fuel is injected into the combustion chamber. In the first embodiment of the rail-co-injection system, the individual high-pressure pumps deliver fuel under increased pressure in parallel into the two rails. The same rail pressure therefore exists in both rails. The second embodiment of the accumulator-common injection system differs in that the first high-pressure pump feeds into the first pressure accumulator and the second high-pressure pump feeds into the second pressure accumulator. Two structural forms are known, for example, from DE 43 35 171 . Since the combustion...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02D41/38

CPCF02D2041/3881F02D2041/1432F02D41/3845F02D2041/286F02D41/14F02D2200/0602

Inventor A.德尔克

Owner ROLLS ROYCE SOLUTIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com