Patents

Literature

30 results about "Pressure.mean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure(noun) impression; stamp; character impressed. Pressure(noun) the action of a force against some obstacle or opposing force; a force in the nature of a thrust, distributed over a surface, often estimated with reference to the upon a unit's area.

Electronic atomization device and control method thereof

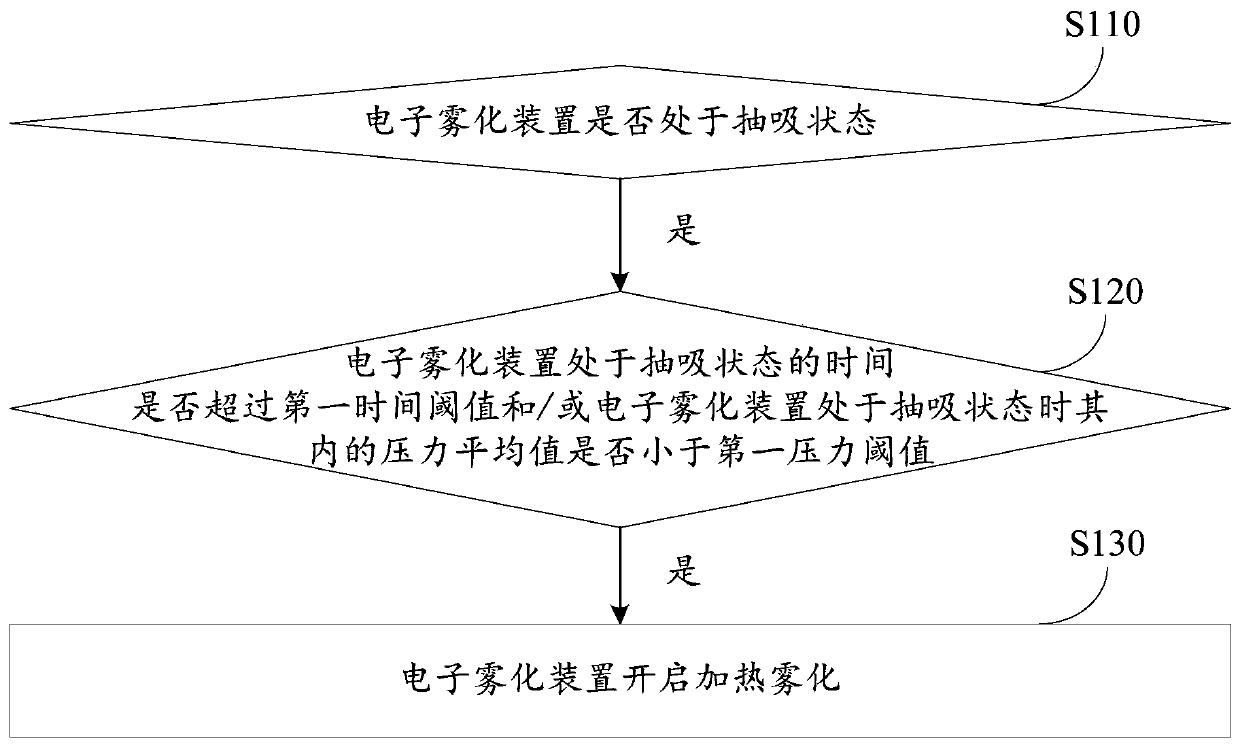

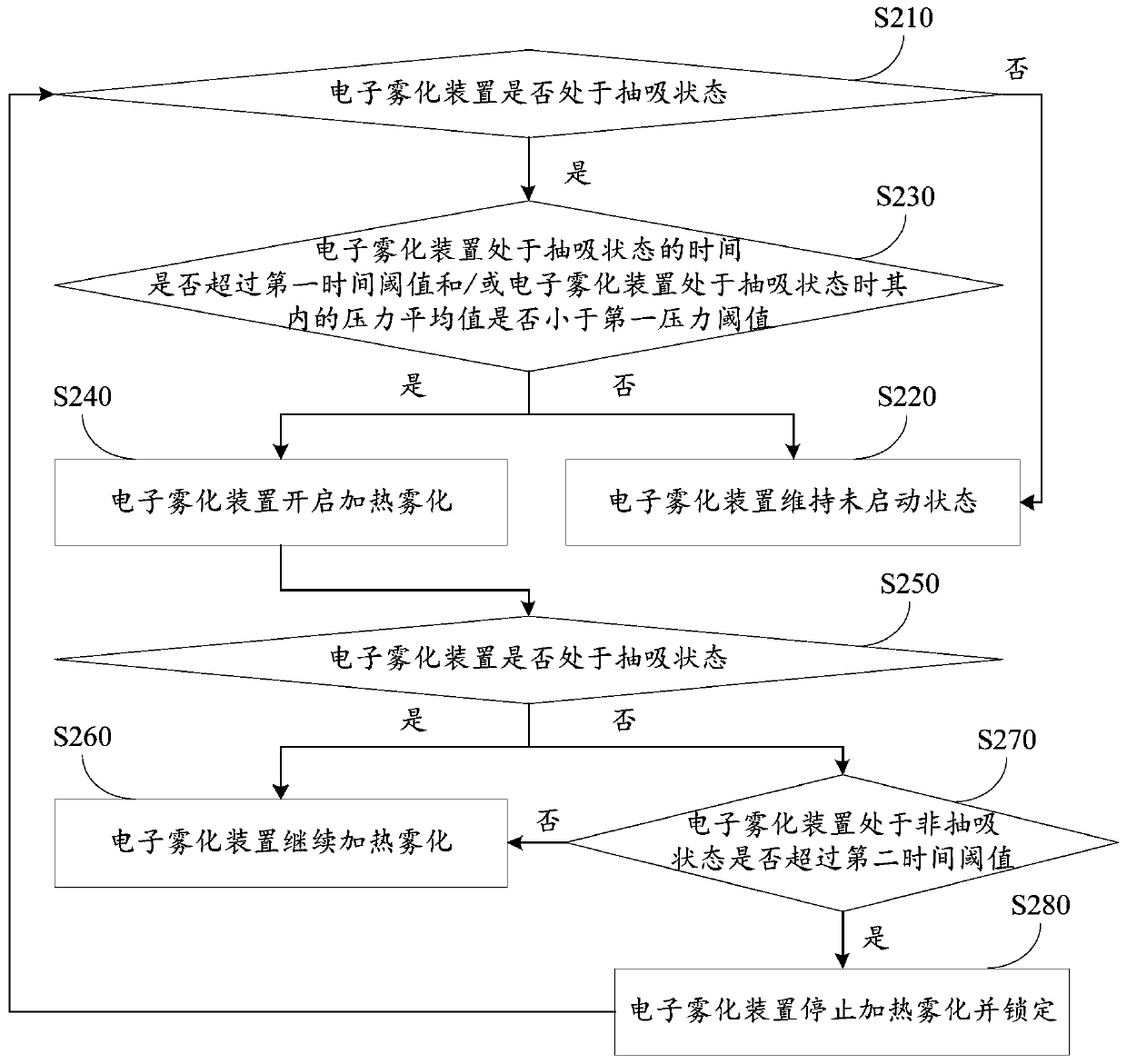

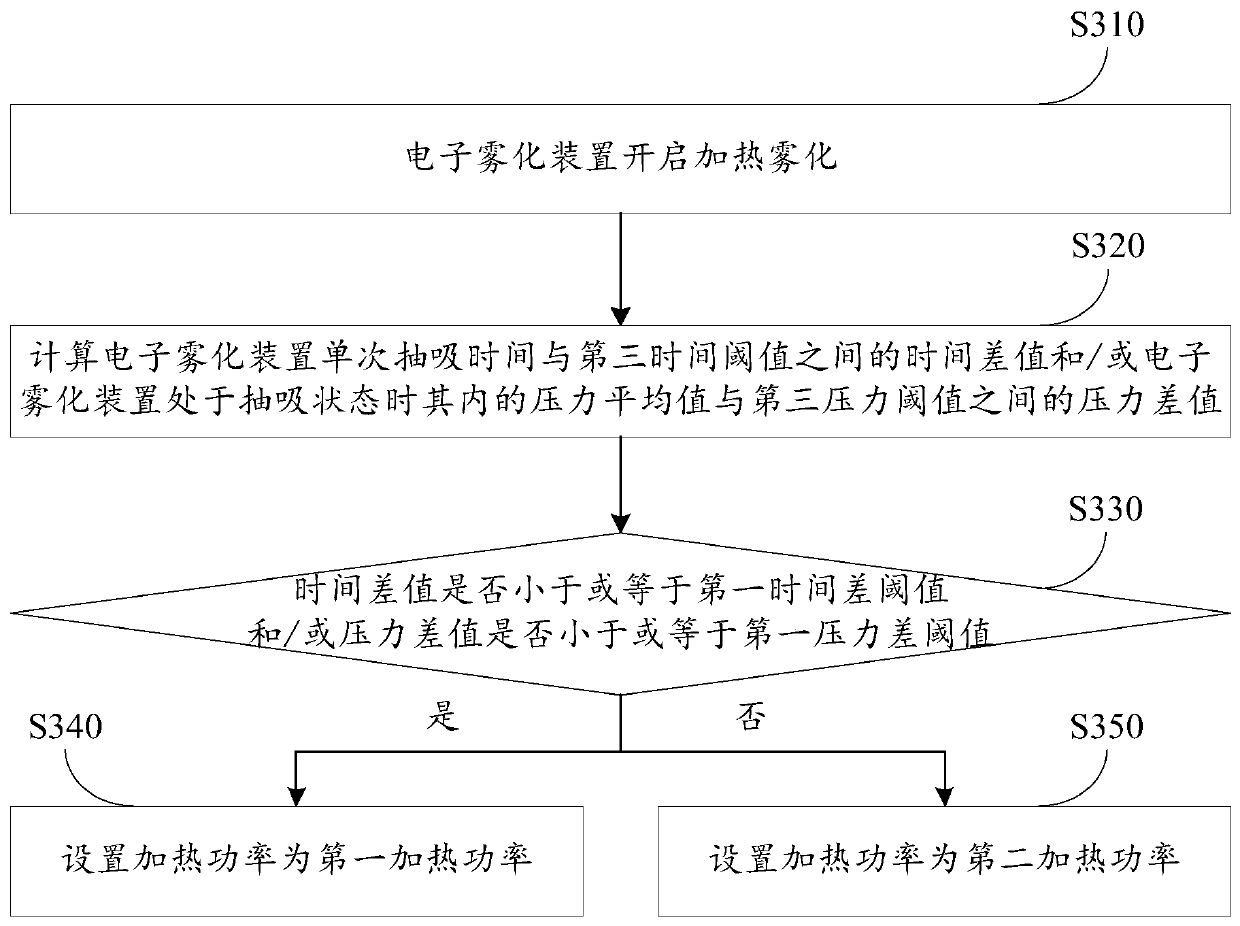

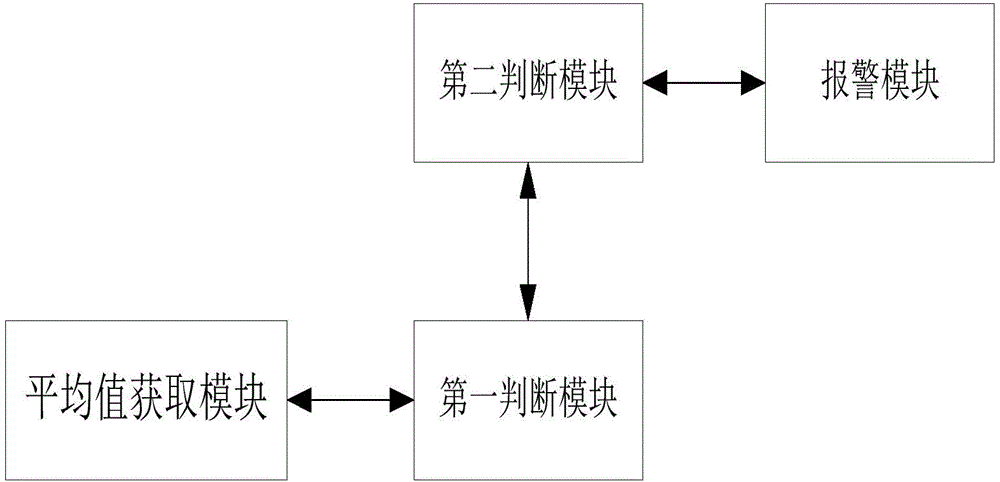

The invention discloses an electronic atomization device and a control method thereof. The control method comprises the steps that whether or not the electronic atomization device is in a suction state is judged; if yes, it is judged whether or not the time of the electronic atomization device in the suction state is more than a first time threshold and / or the average value of the pressure in theelectronic atomization device in the suction state is less than a first pressure threshold; if yes, the electronic atomization device is turned on for heating atomization. The electronic atomization device and the control method thereof have the advantages that heating atomization is started under the condition that the time of the electronic atomization device in the suction state exceeds the first time threshold and / or the average value of the pressure in the electronic atomization device in the suction state is less than the first pressure threshold, the operation process is simple, accidental contact or children's accidental suction can be avoided, and the functions of protecting the children and protecting the electronic atomization device are achieved.

Owner:SHENZHEN SMOORE TECH LTD

Method and terminal for closing application

InactiveCN104571864AAvoid misuseImprove experienceInternal/peripheral component protectionInput/output processes for data processingPressure.meanComputer terminal

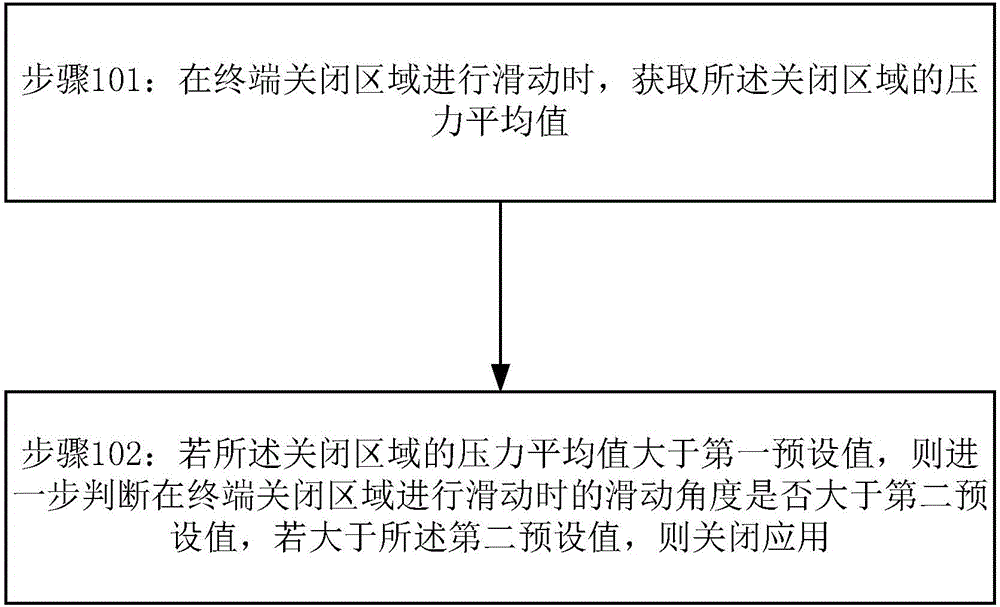

The invention belongs to the field of communication control, and particularly relates to a method and a terminal for closing an application. The method comprises the following steps: acquiring a pressure average value of a close region when sliding occurs at the terminal close region; if the pressure average value of the close region is greater than a first preset value, further judging whether the slide angle for slide at the terminal close region is greater than second preset value; if the pressure average value is greater than the second preset value, closing the application. Compared with the prior art, the method and the terminal for closing the application have the advantages that the scheme for closing the application is realized according to slide pressure and the slide angle, error operation of a user is avoided, and the user experience is greatly improved.

Owner:SHANGHAI ZHUO YOU NETWORK TECH

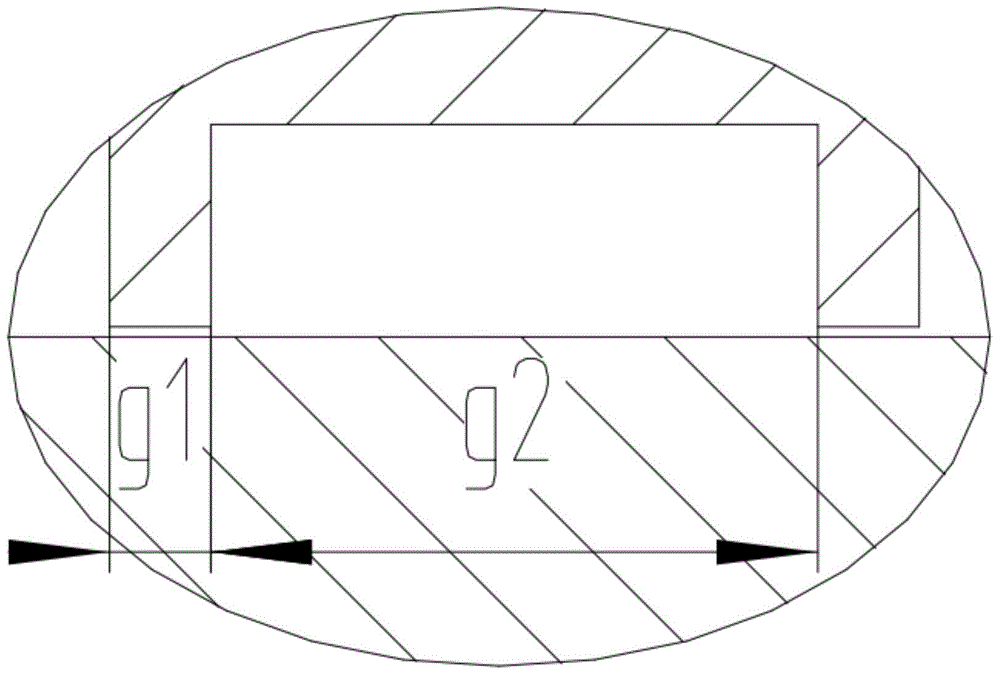

Method for determining blasting demolition order of deep foundation pit support beams

InactiveCN106055801AEnsure safetyEliminate potential safety hazardsDesign optimisation/simulationExcavationsPressure.meanOperability

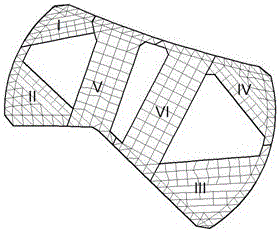

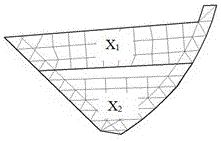

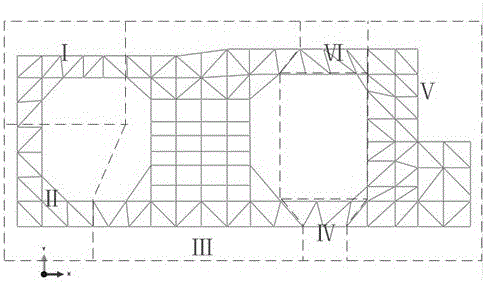

The invention relates to a method for determining a blasting demolition order of deep foundation pit support beams. According to the technical scheme, the method comprises the steps of partitioning the deep foundation pit support beams, building a deep foundation pit support beam finite element model, determining an area with the maximum average pressure value on the deep foundation pit support beams to be the finally demolished area N<M> and determining front-section ultimate compressive bearing capacity N<pressure> and front-section ultimate tensile bearing capacity N<tension> of the deep foundation pit support beams; eliminating the firstly demolished preliminary demolition scheme conforming to the condition according to the maximum displacement U of the deep foundation pit support beams, the maximal pressure f<pressure> of the deep foundation pit support beams and the maximum tension value f<tension> of the deep foundation pit support beams and employing the minimum value of the maximum displacement U of the deep foundation pit support beams as the firstly demolished preliminary demolition scheme; in a similar way, obtaining a second demolition scheme area, a third demolition scheme and a fourth demolition scheme; and finally determining the local demolition order of the areas. The method can meet the actual bearing requirements; the safety of constructors and surrounding buildings and structures can be ensured; the method conforms to the blasting construction characteristics; and the operability is high.

Owner:WUHAN UNIV OF SCI & TECH

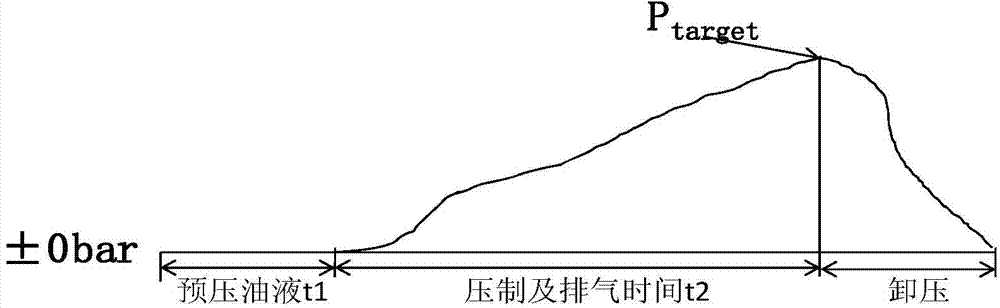

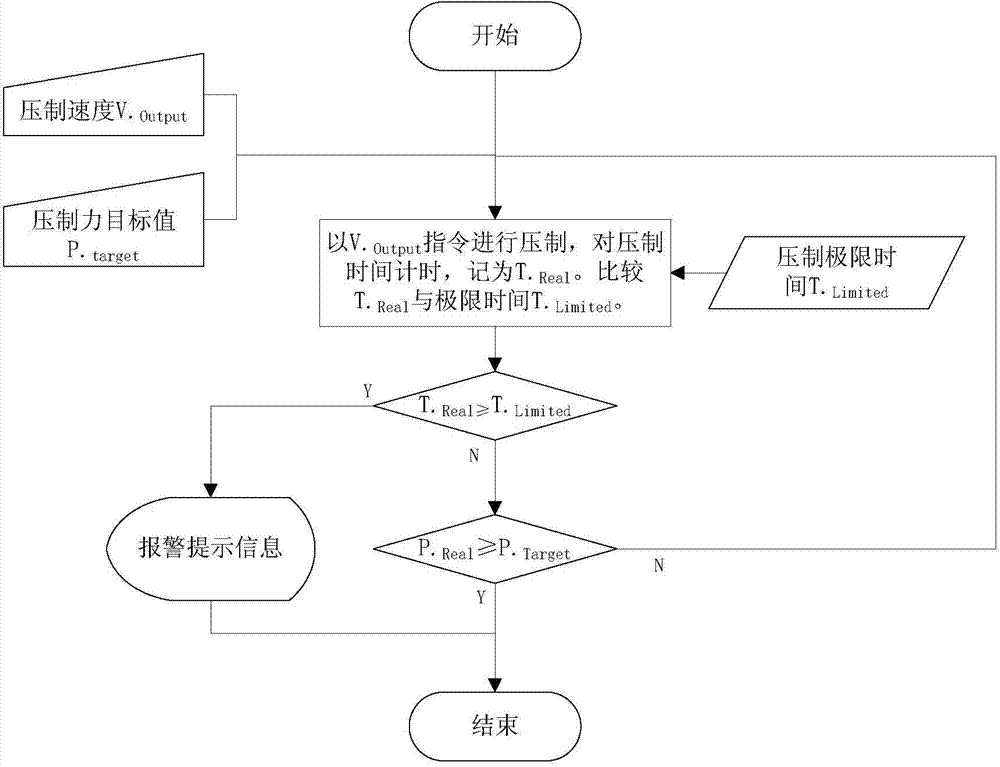

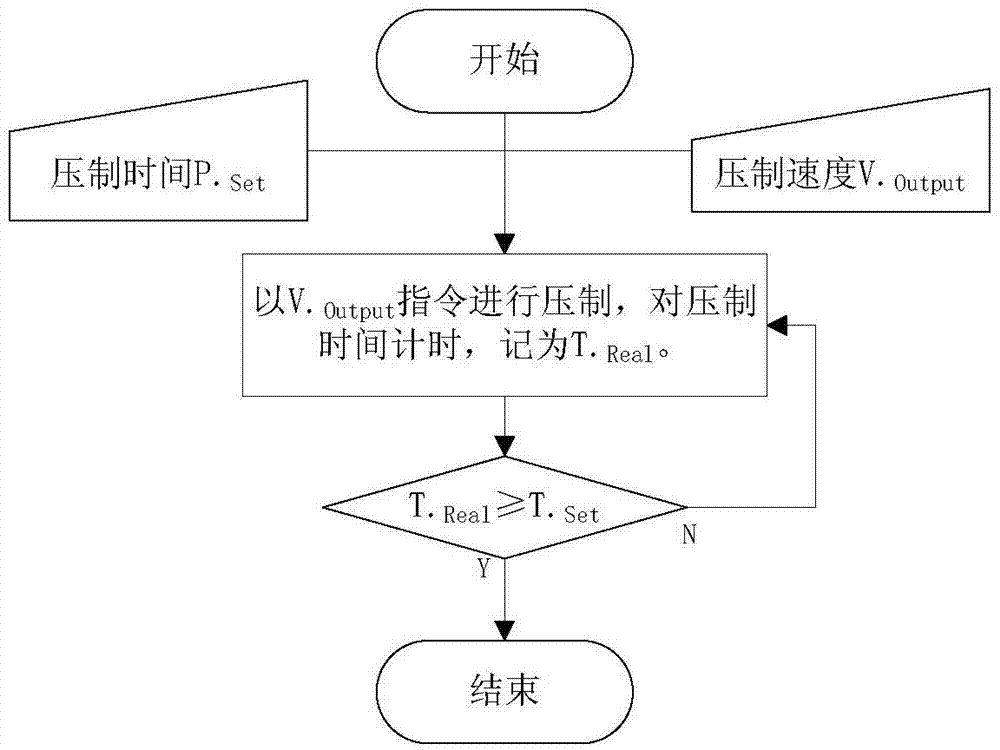

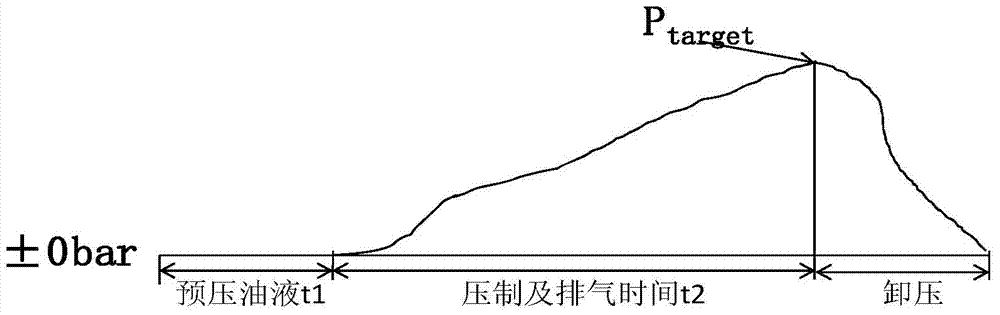

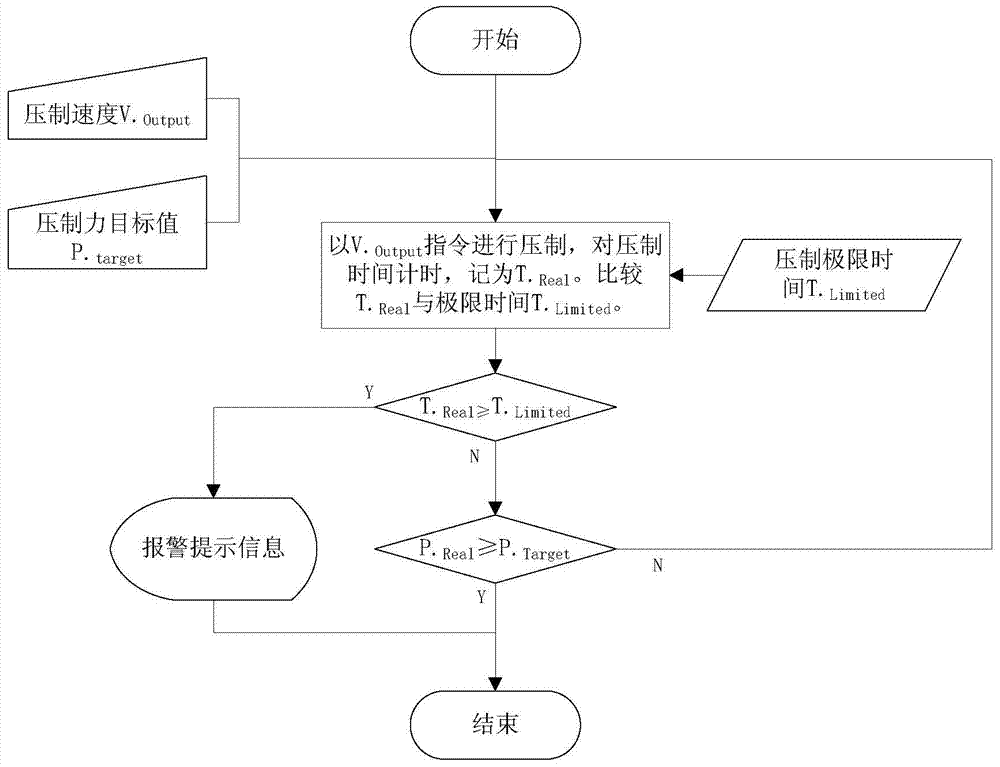

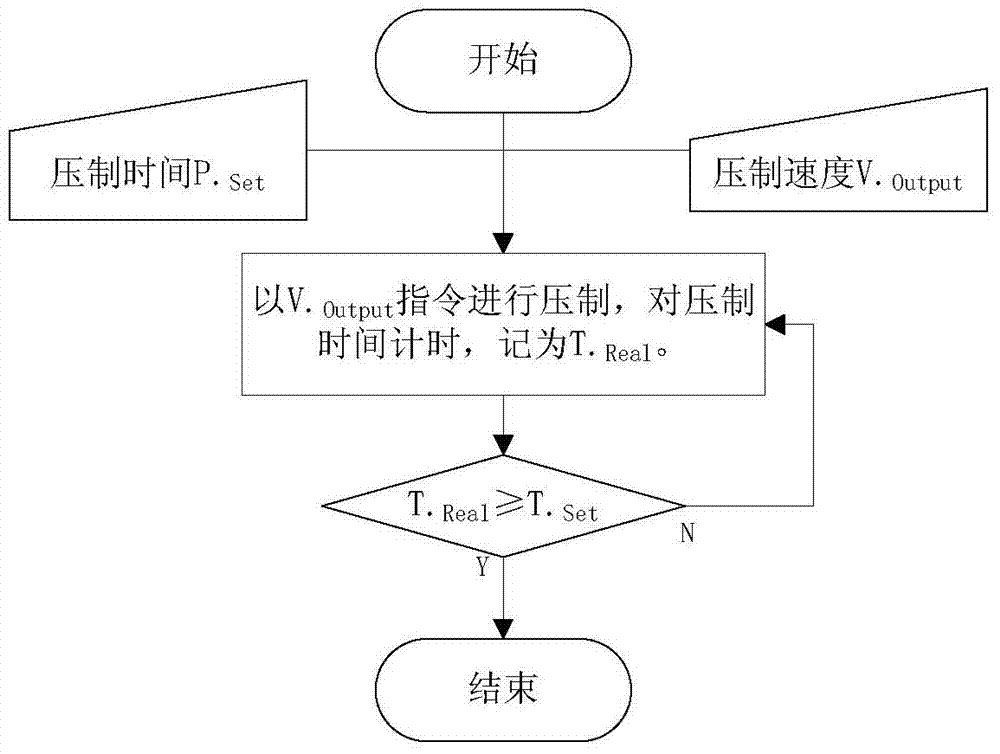

Closed-loop control method and system giving consideration to time and pressure in powder pressing process

ActiveCN104765283AImprove maneuverabilityClear control methodProgramme control in sequence/logic controllersPressure.meanClosed loop

The invention relates to a closed-loop control method and system giving consideration to both time and pressure in the power pressing process. The method comprises the steps that expected pressurizing time, a target pressing force value and a proportion coefficient input by an operator are received; the slope of time to pre-compress oil is calculated; the initial output speed of a pressurizing valve is controlled; the real-time pressing time is detected and compared with the extreme pressing time to obtain an average of pressure; the average of pressure is compared with the target pressing force value; the average of pressure is compared with the initial closed-loop pressing force; the pressure establishing time is calculated; the pressure establishing time is compared with preset standard time to calculate the pressure establishing slope; the growing average pressure value and the practical pressure slope in unit time are calculated; the difference between the practical pressure slope and the pressure establishing slope is calculated; and the second output speed of the pressurizing valve is controlled. Relation between pressure and time is displayed, the control performance of a powder forming machine is improved, and the adaptability of the powder forming machine to powder is improved.

Owner:FOSHAN HENGLITAI MACHINERY

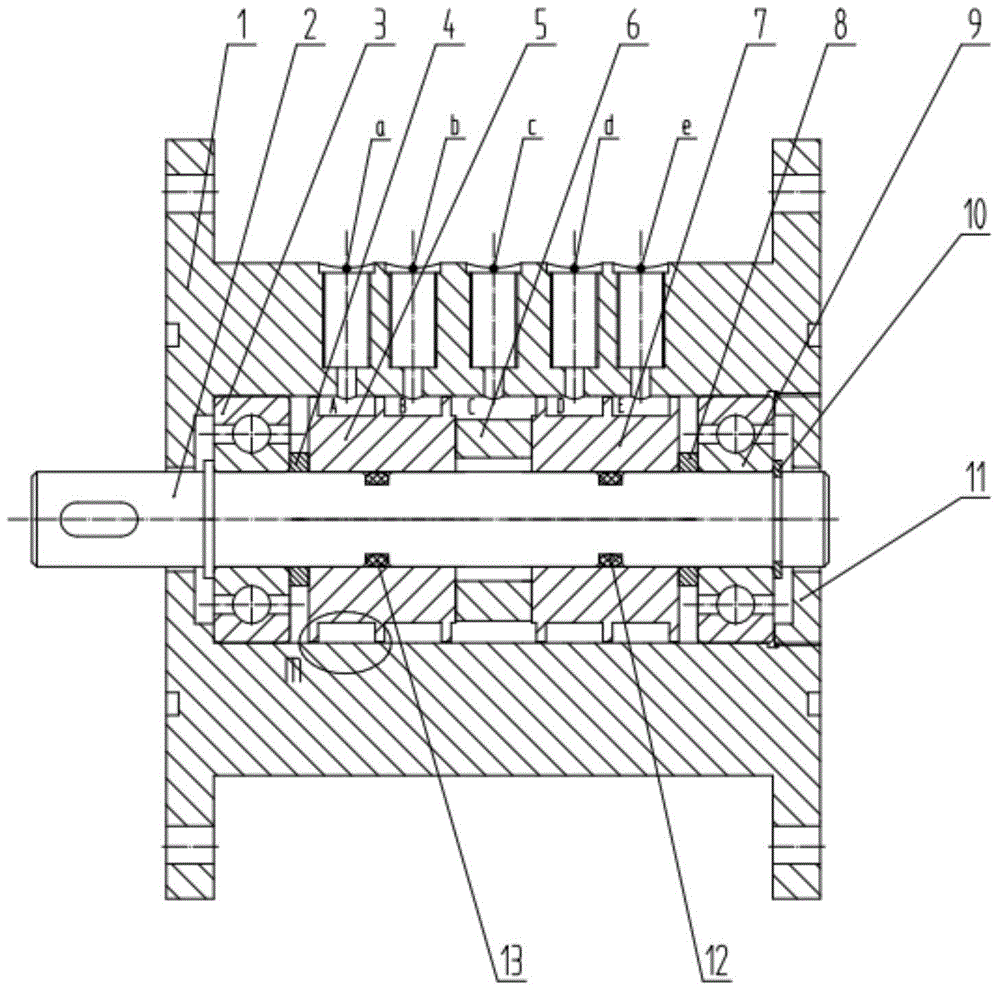

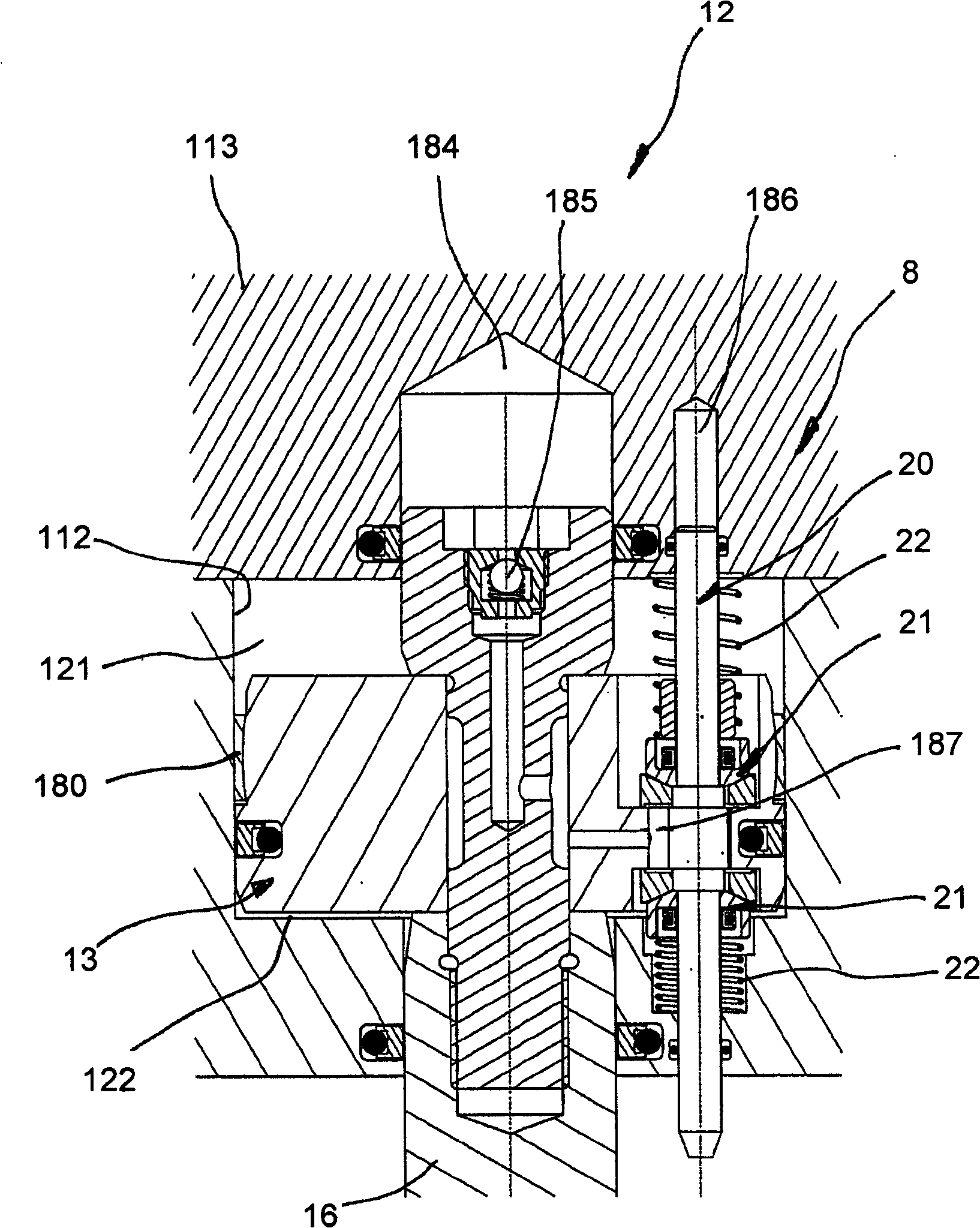

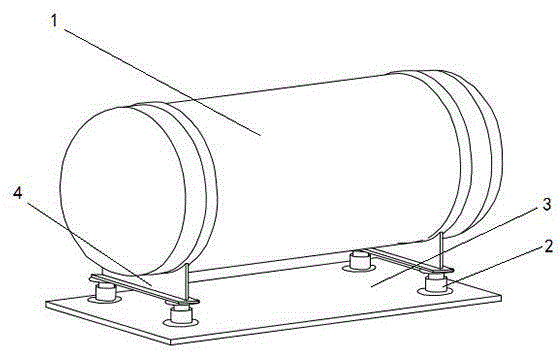

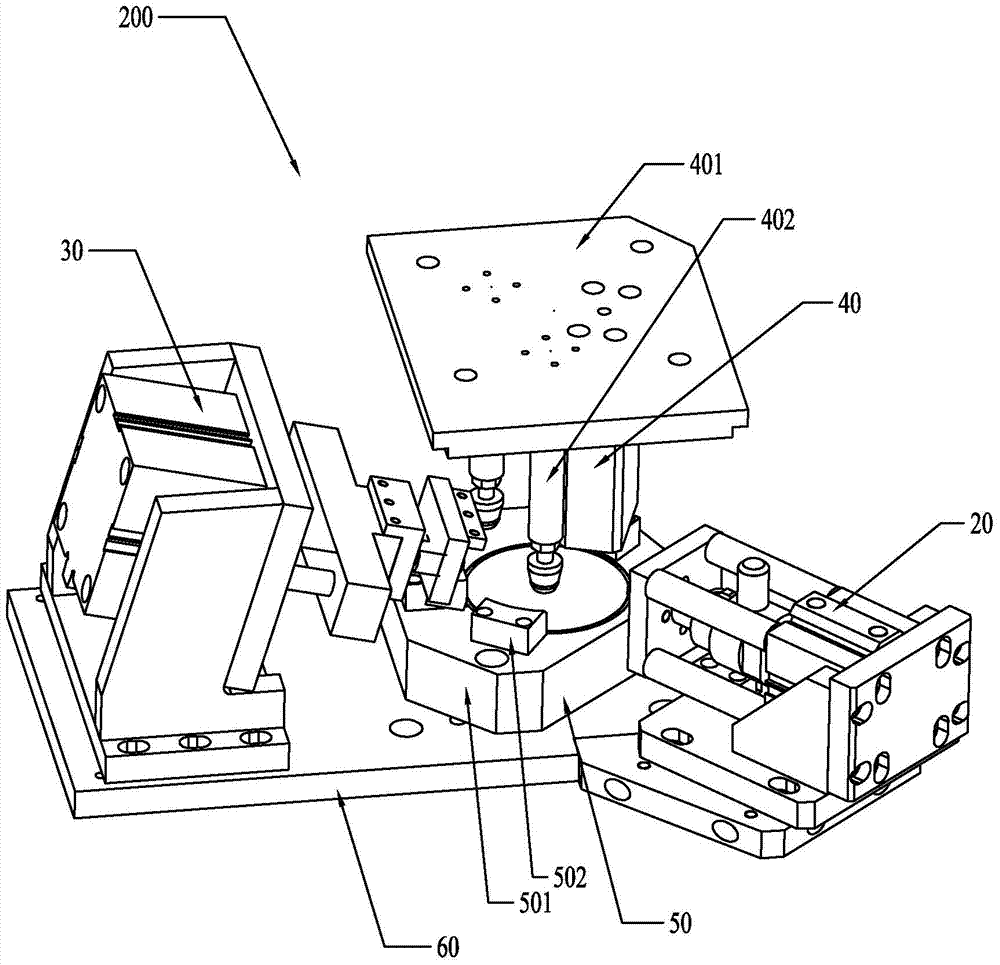

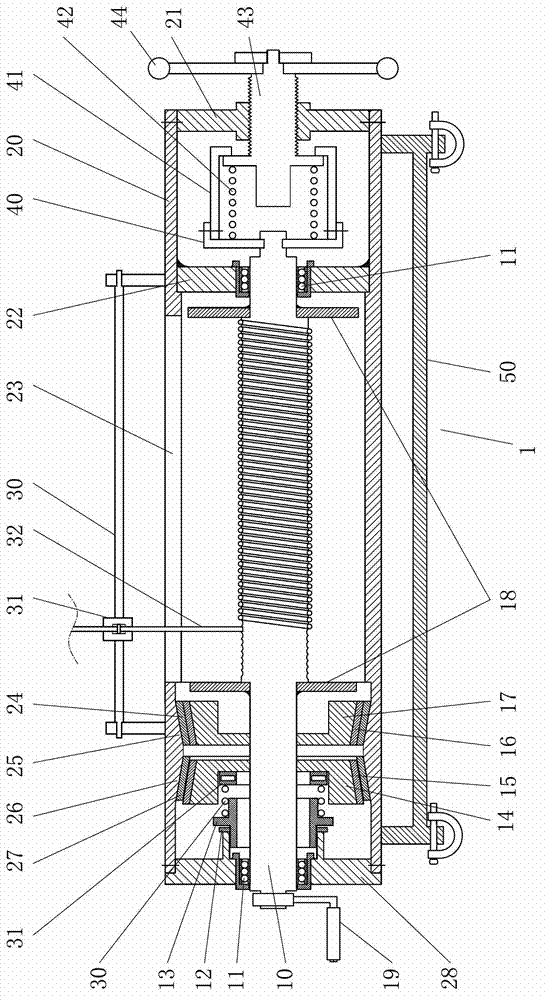

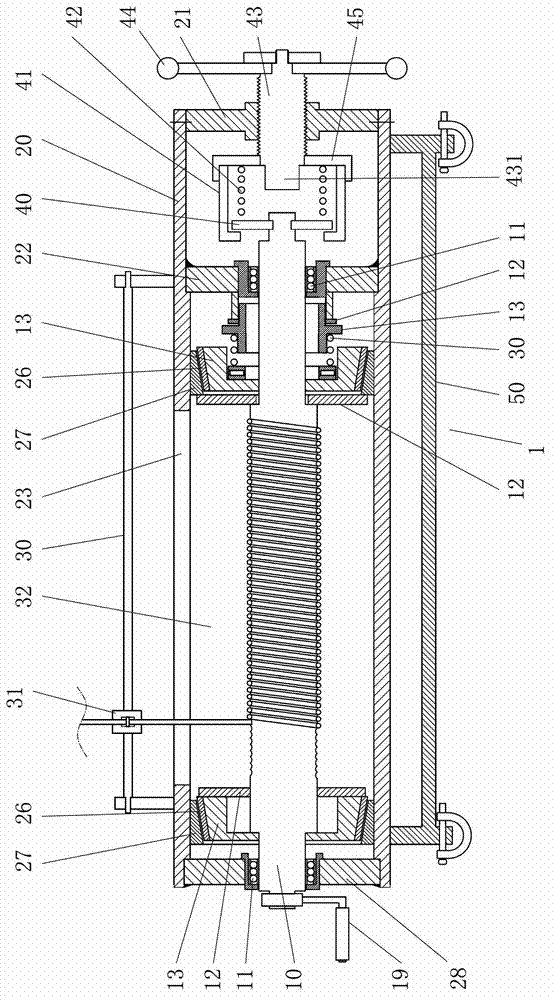

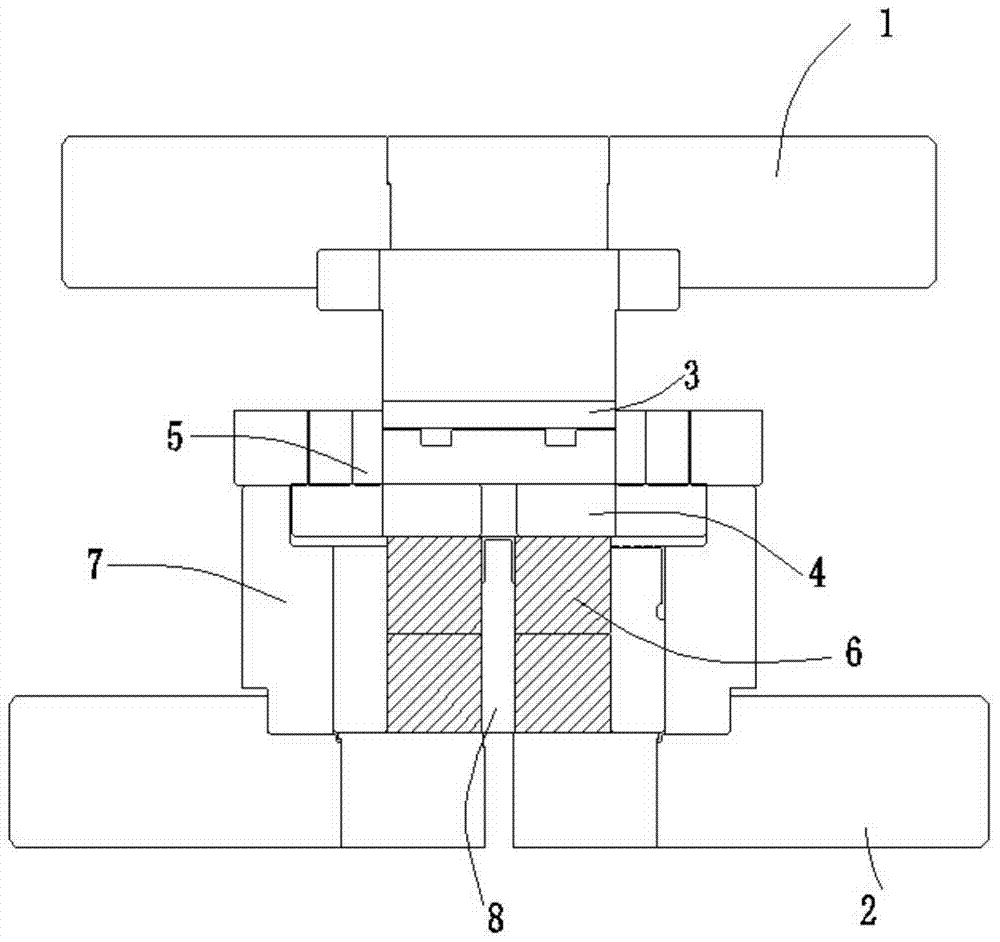

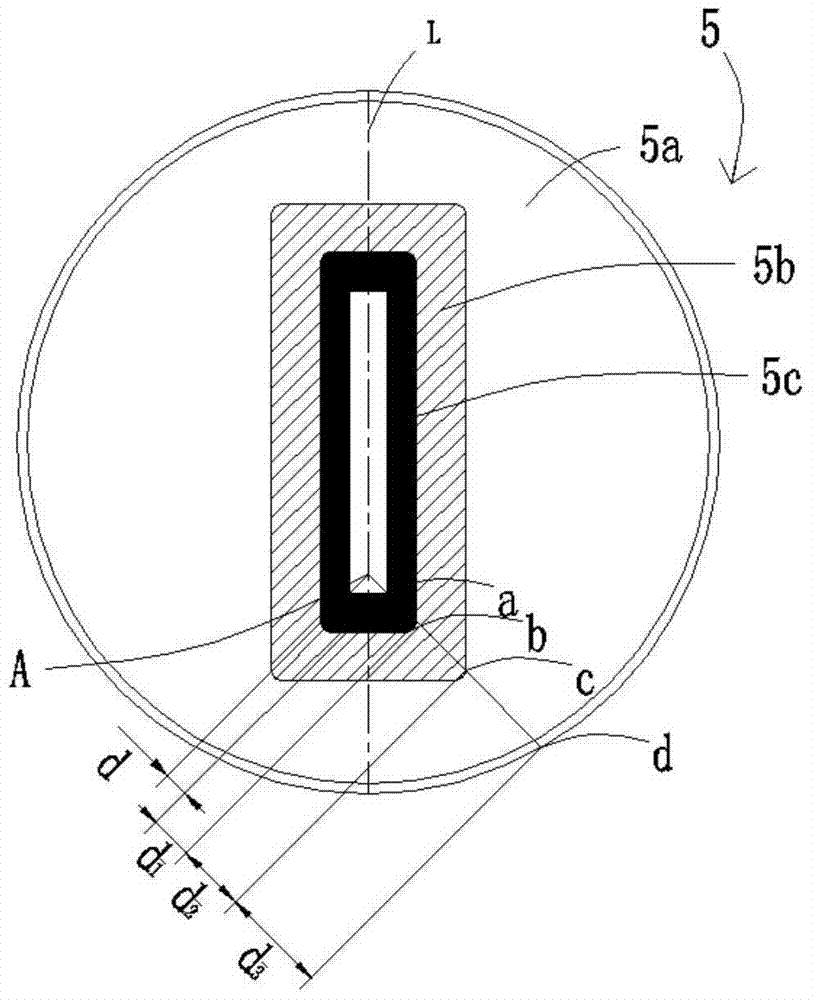

An experimental research device for the mechanism of magnetic liquid seal pressure resistance

InactiveCN103759932BRigorous structureStrong reliabilityMachine part testingPressure.meanExperimental research

The invention discloses a magnetic liquid sealing pressure-bearing mechanism experimental research device. The device is suitable for the research experiment on the magnetic liquid sealing pressure-bearing mechanism and solves the problems that the end face of an existing magnetic liquid sealing pressure-bearing mechanism experimental research device is difficult to seal, and the experiment is low in reliability. The device comprises a shell (1), a rotating shaft (2), a left bearing (3), a left magnetism separation ring (4), a left pole shoe (5), a permanent magnet (6), a right pole shoe (7), a right magnetism separation ring (8), a right bearing (9), a snap spring (10), an end cover (11), a right sealing ring (12) and a left sealing ring (13). The outer cylindrical surface of the left pole shoe (5) and the outer cylindrical surface of the right pole shoe (7) are respectively provided with pole teeth and tooth sockets. Five stepped holes are formed in the shell which is connected with a pressure gauge. The right end face of the shell is connected with a sealing cavity which has the press capacity, and magnetic liquid sealing pressure-bearing mechanism experimental research is conducted through the change of reading numbers of the pressure gauge.

Owner:BEIJING JIAOTONG UNIV

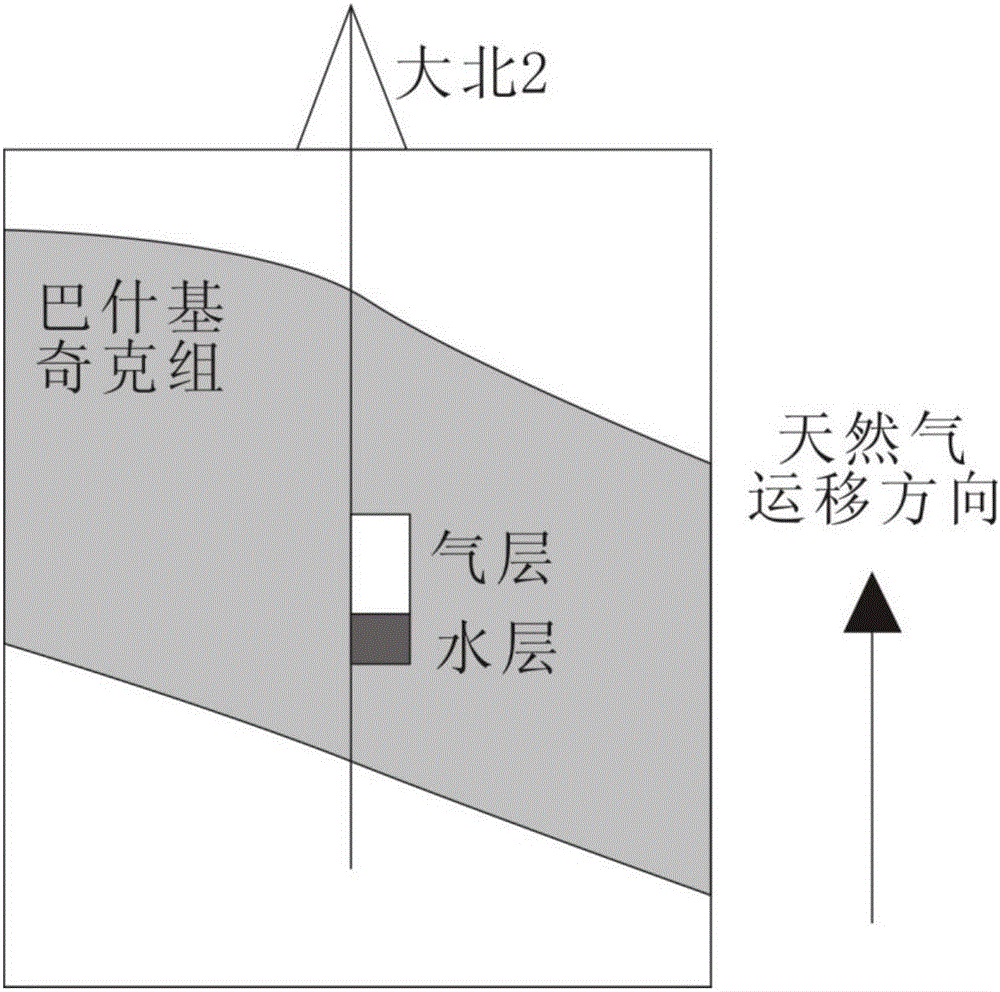

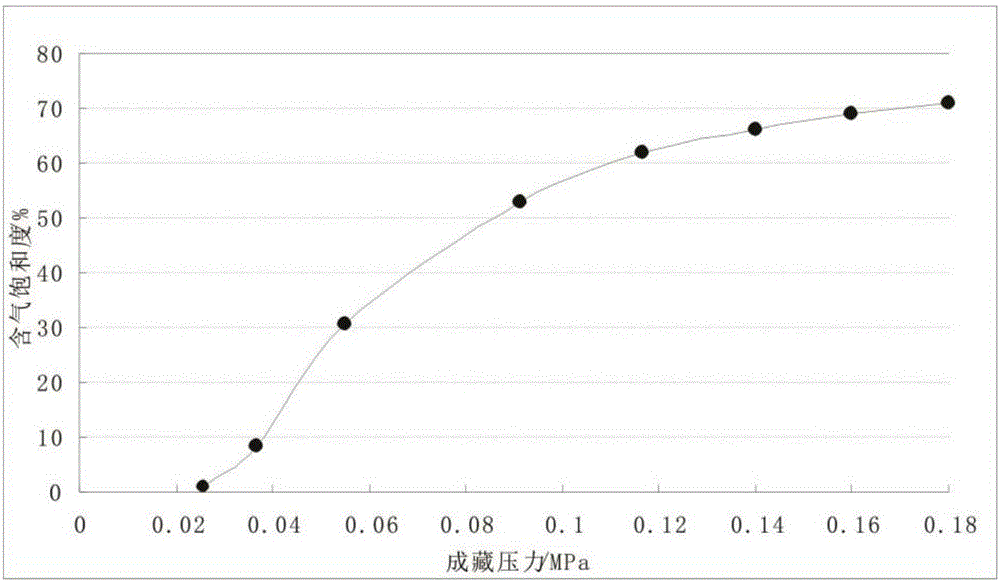

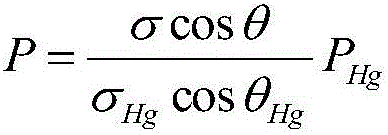

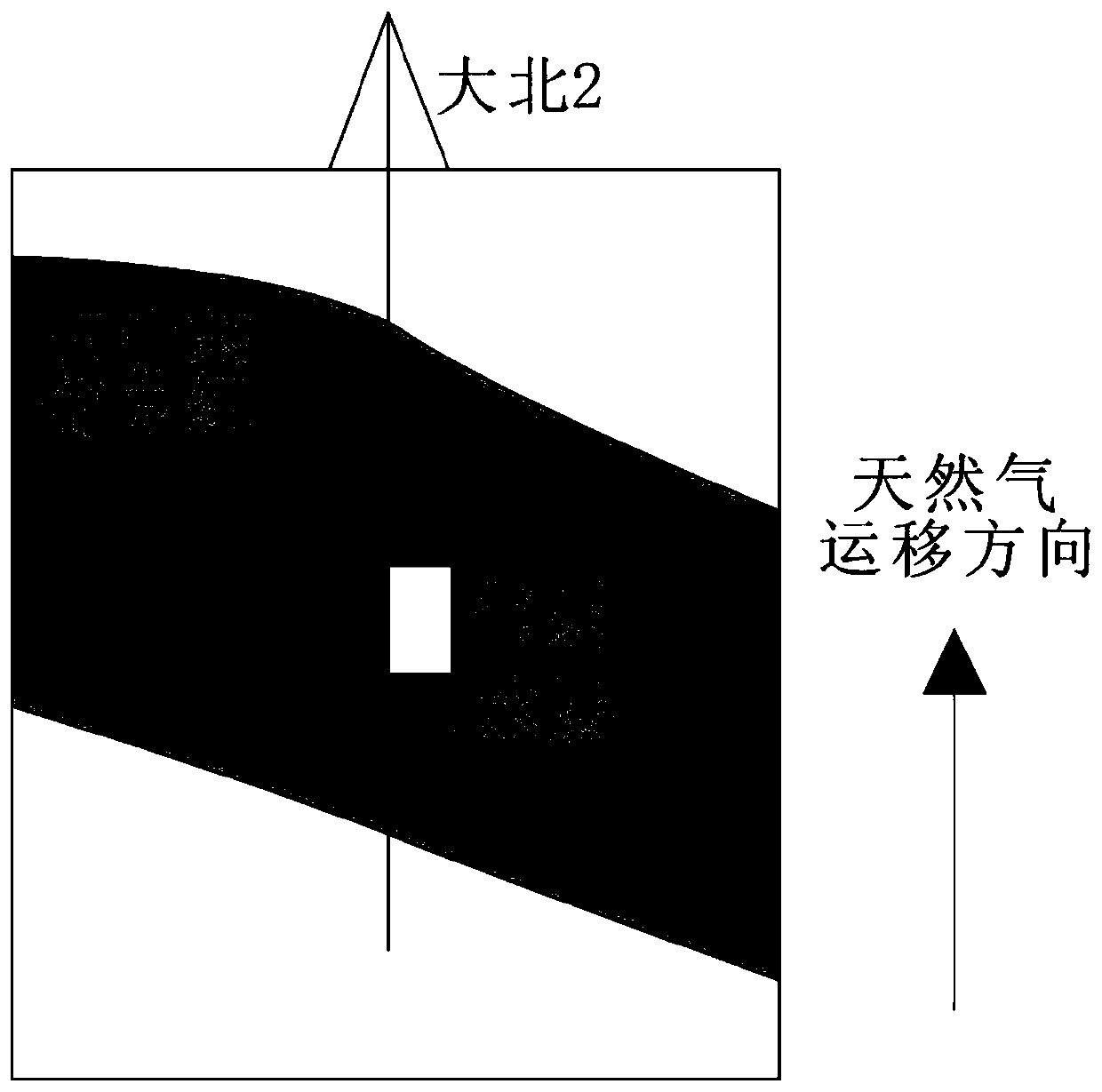

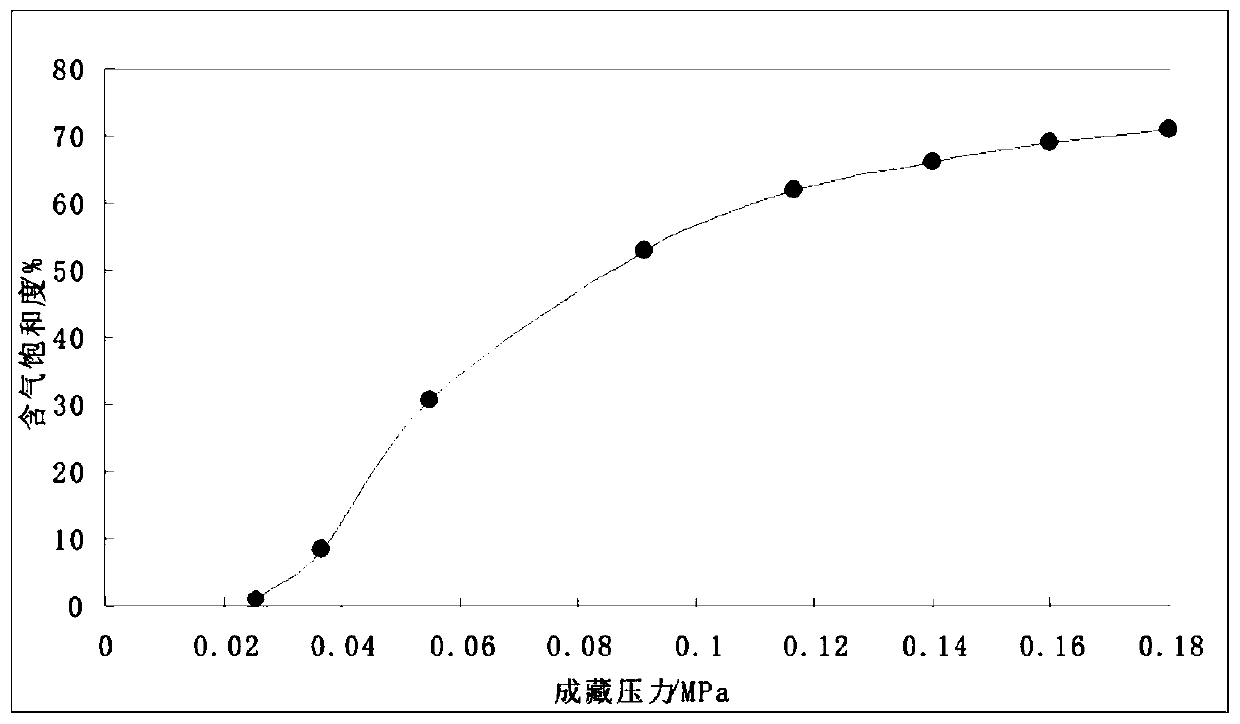

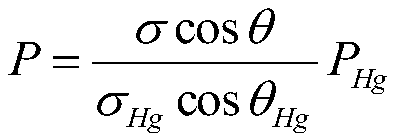

Method for determining injection pressure at natural gas pool-forming period of dense reservoir

ActiveCN106499391AAccurate dataEfficient use ofBorehole/well accessoriesPressure.meanInjection pressure

The invention provides a method for determining injection pressure at a natural gas pool-forming period of a dense reservoir. The method comprises the steps of clearly studying natural gas reservoir forming source rock of the dense reservoir and the reservoir, and regulating that the natural gas migration direction in dense reservoir natural gas reservoir forming is a source rock pointing reservoir; in the natural gas migration direction in the dense reservoir natural gas reservoir forming, determining adjacent air layers and dry layers or air layers and water layers through a natural gas reservoir forming section; obtaining mercury injection threshold pressure of the adjacent air layers and dry layers or air layers and water layers, and obtaining pressure average values thereof; and performing conversion on the dense reservoir natural gas reservoir forming capillary pressure and mercury injection threshold pressure, namely determining injection pressure at the natural gas pool-forming period of the dense reservoir. The method for determining injection pressure at the natural gas pool-forming period of the dense reservoir has data reliability and accuracy.

Owner:PETROCHINA CO LTD

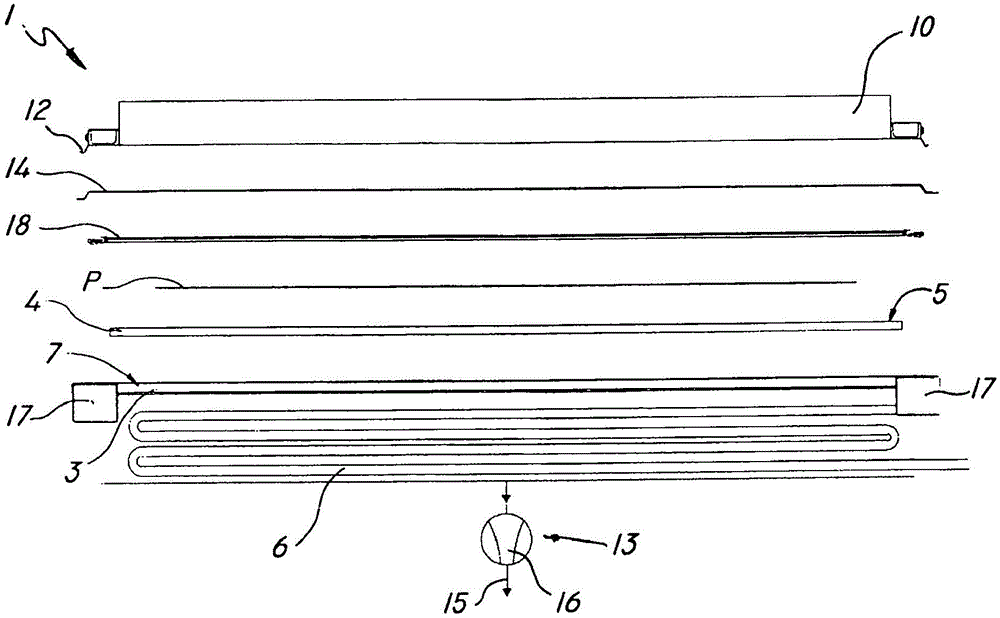

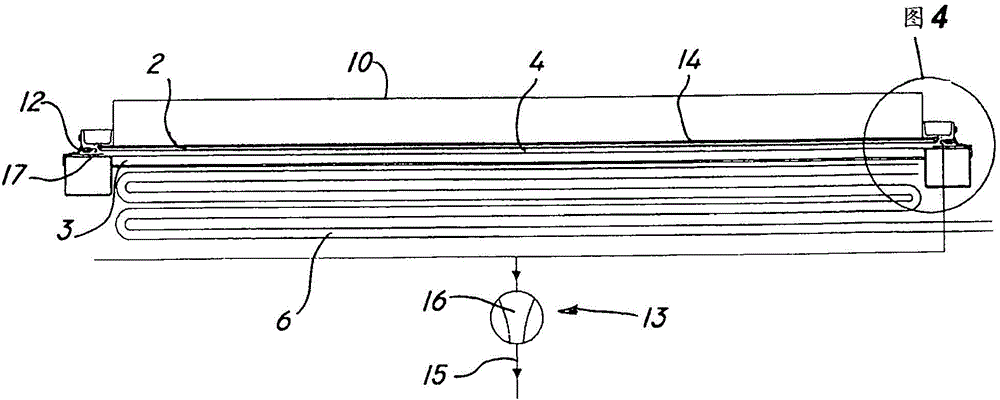

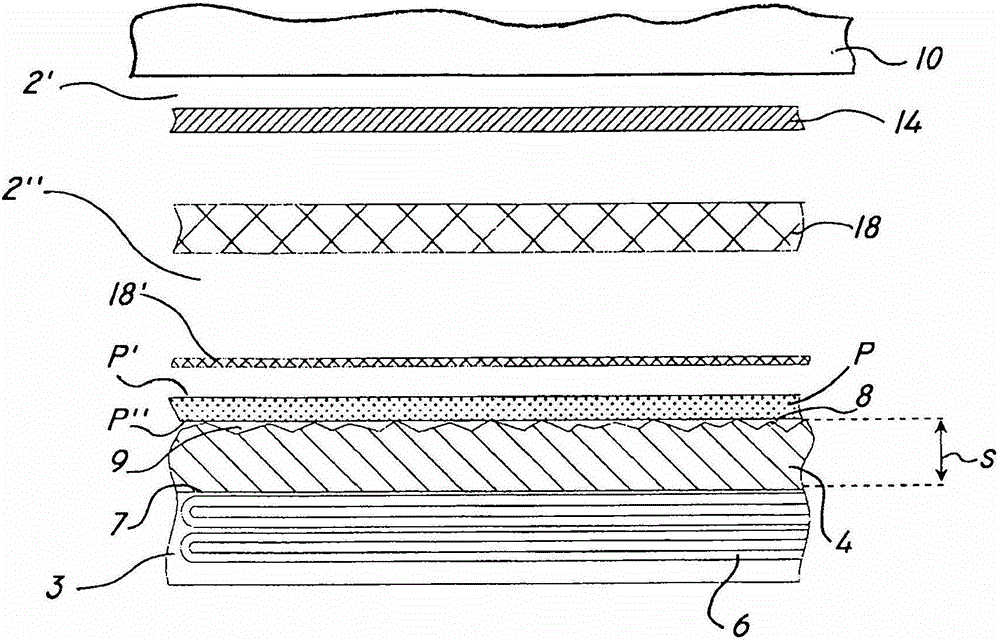

Method and plant for printing hides

ActiveCN102947469ALeather stretching/tensioningLeather surface mechanical treatmentPressure.meanVacuum pressure

A device for printing industrial hides comprises a drying chamber (2) internally housing a support surface (3) for at least one hide (P), a cover (10) placed on the top of the support surface (3) in order to define the drying chamber (2), heating means (6) associated with the support surface (3) in order to bring it to a drying temperature, an impermeable flexible membrane (14) placed on the top of the support surface (3) to divide the chamber (2) into an upper portion (21) and a lower portion (2"), pressure means (13) of vacuum type with a suction line (15) connected to the lower portion (2") of the chamber (2) in order to define a pressure difference between the portions (21, 2") of the chamber (2). The drying chamber (2) internally comprises at least one matrix (4) positioned on the surface (3) and having an upper surface (5) reproducing in negative a pattern to be printed on the hide (P). The vacuum pressure means (13) comprise one or more suction passages (17) made in the support surface (3) in a position substantially facing the cover (10) in order to fluidly connect the lower portion (2") with the suction line (15) and to promote the compression of the hide (P) on the matrix (4) for the printing of the ornamental pattern.

Owner:OFFICINE DI CARTIGLIANO SPA

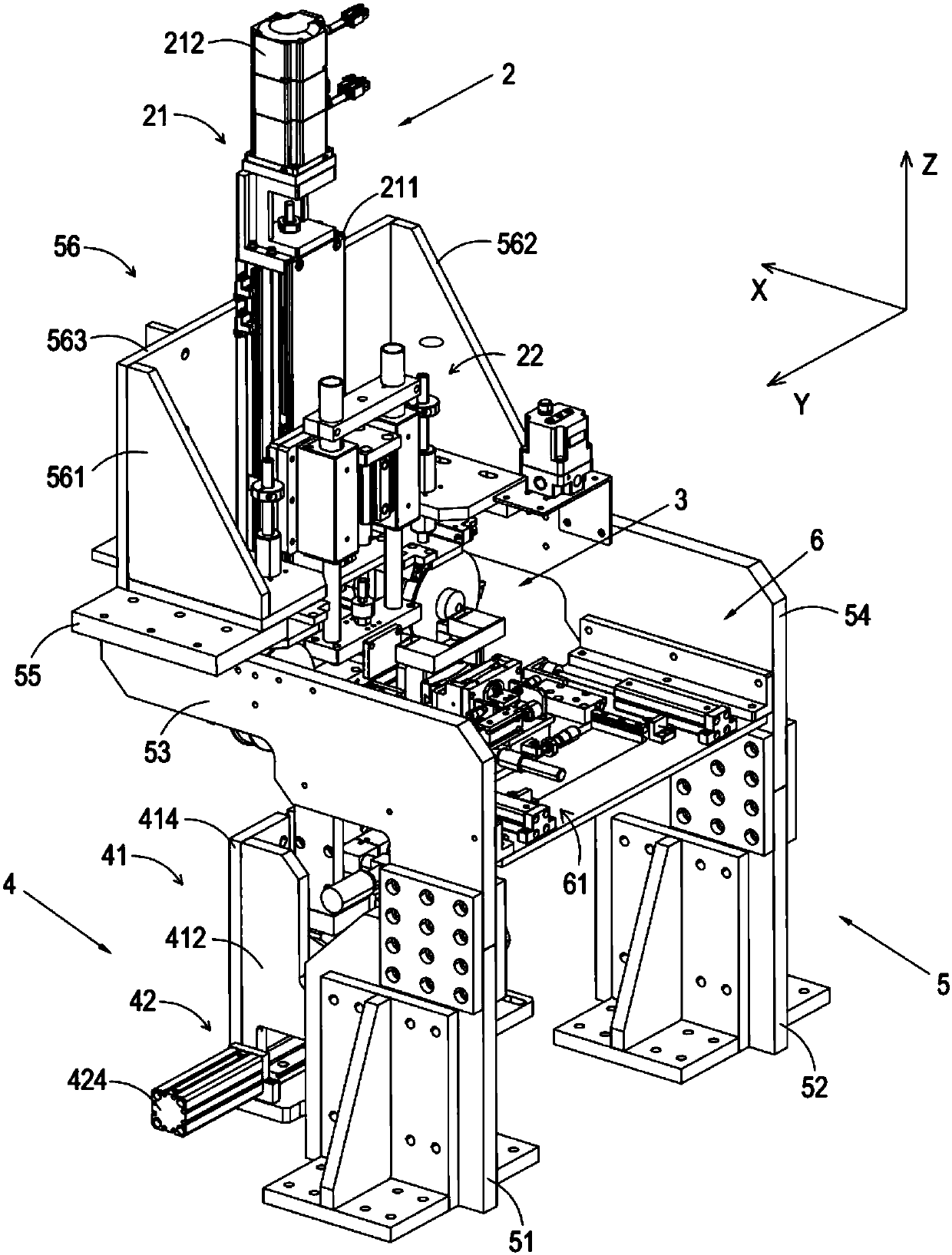

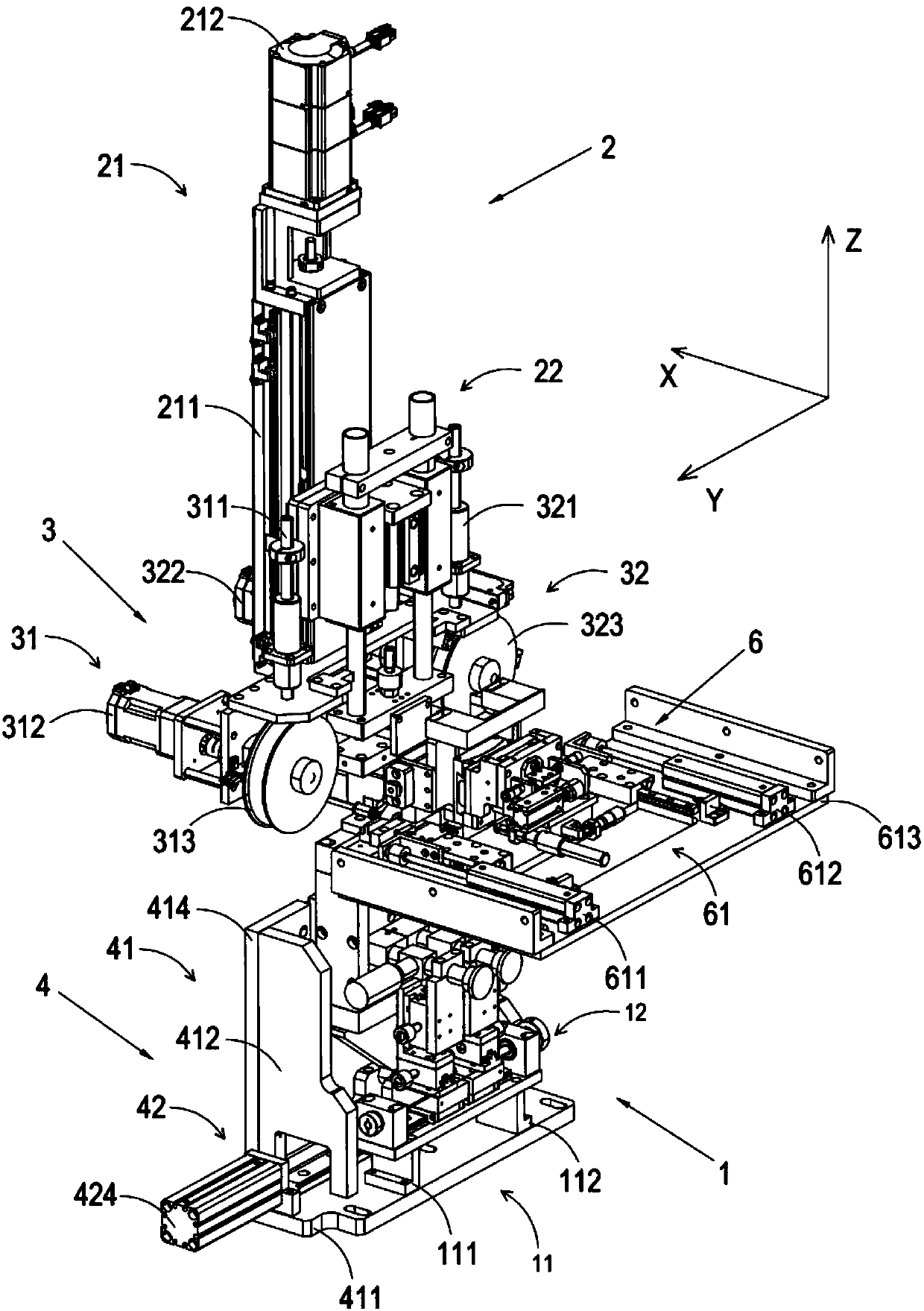

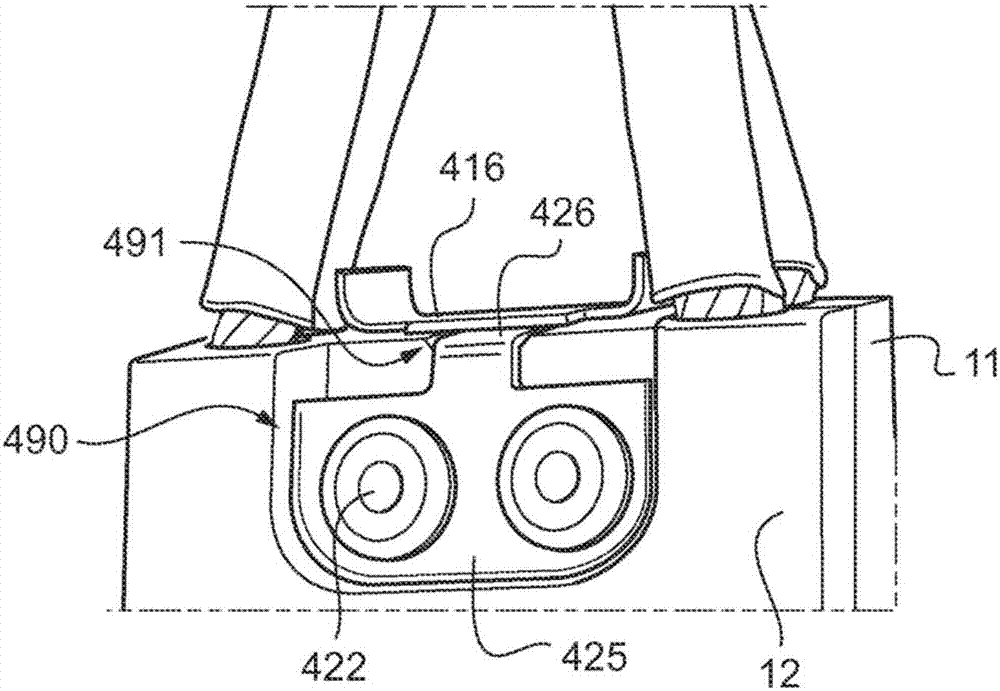

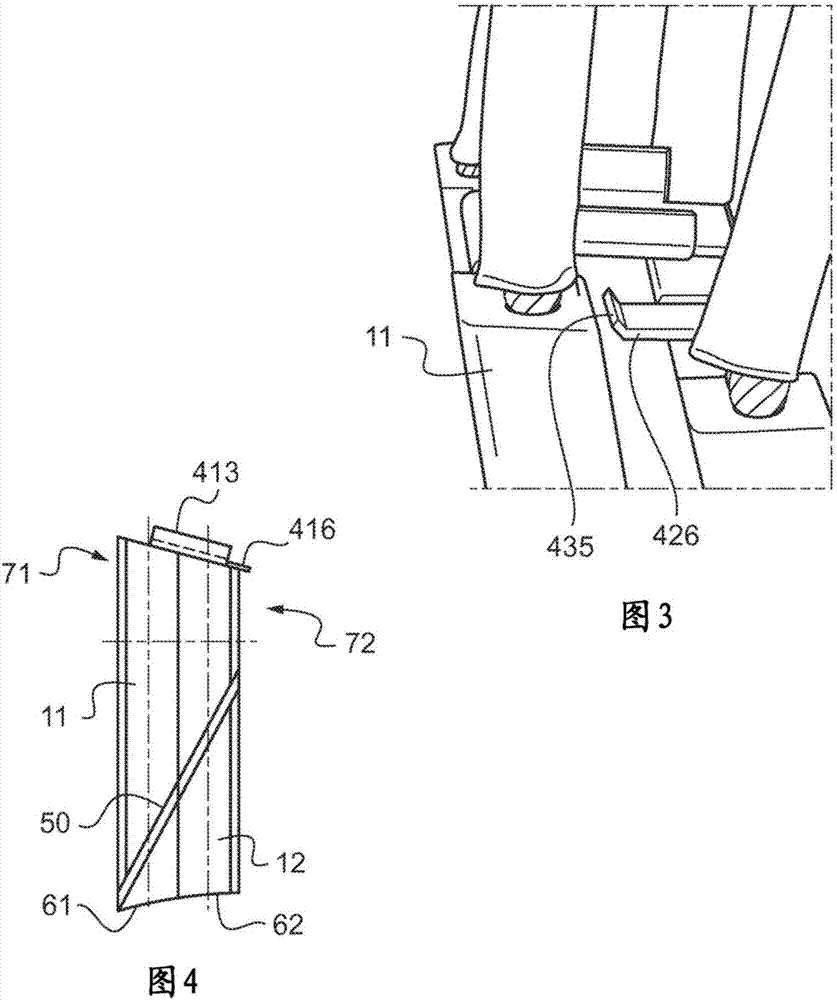

Liquid crystal display screen main pressing device

PendingCN107561741ANot easy to open glueNot easy to fall offNon-linear opticsPressure.meanLiquid-crystal display

The invention discloses a liquid crystal display screen main pressing device. The device comprises a rack with a certain internal space, a main pressing mechanism and a sucking mechanism, and the mainpressing mechanism and the sucking mechanism are arranged on the rack; the sucking mechanism is located under the main pressing mechanism and is baised on one side of the main pressing mechanism, anda lifting platform is arranged under the main pressing mechanism. The device is high in photographing positioning precision, and stable and uniform pressing pressure can be provided, so that a pressed IC is not likely to unglue and fall off, and the quality of a liquid crystal display screen is improved; a to-be-pressed product on a conveying guide rail can be conveniently and rapidly jacked up,and the pressing efficiency is improved; thermal protection and buffering protection can be provided for the surface of a Driver IC or a PCB in the main pressing process; the adjustable freedom degreecan be improved to adapt to to-be-sucked pieces in different specifications and sizes, the to-be-sucked pieces can be precisely placed, pressing errors can be reduced, and the yield is increased.

Owner:苏州富强加能精机有限公司

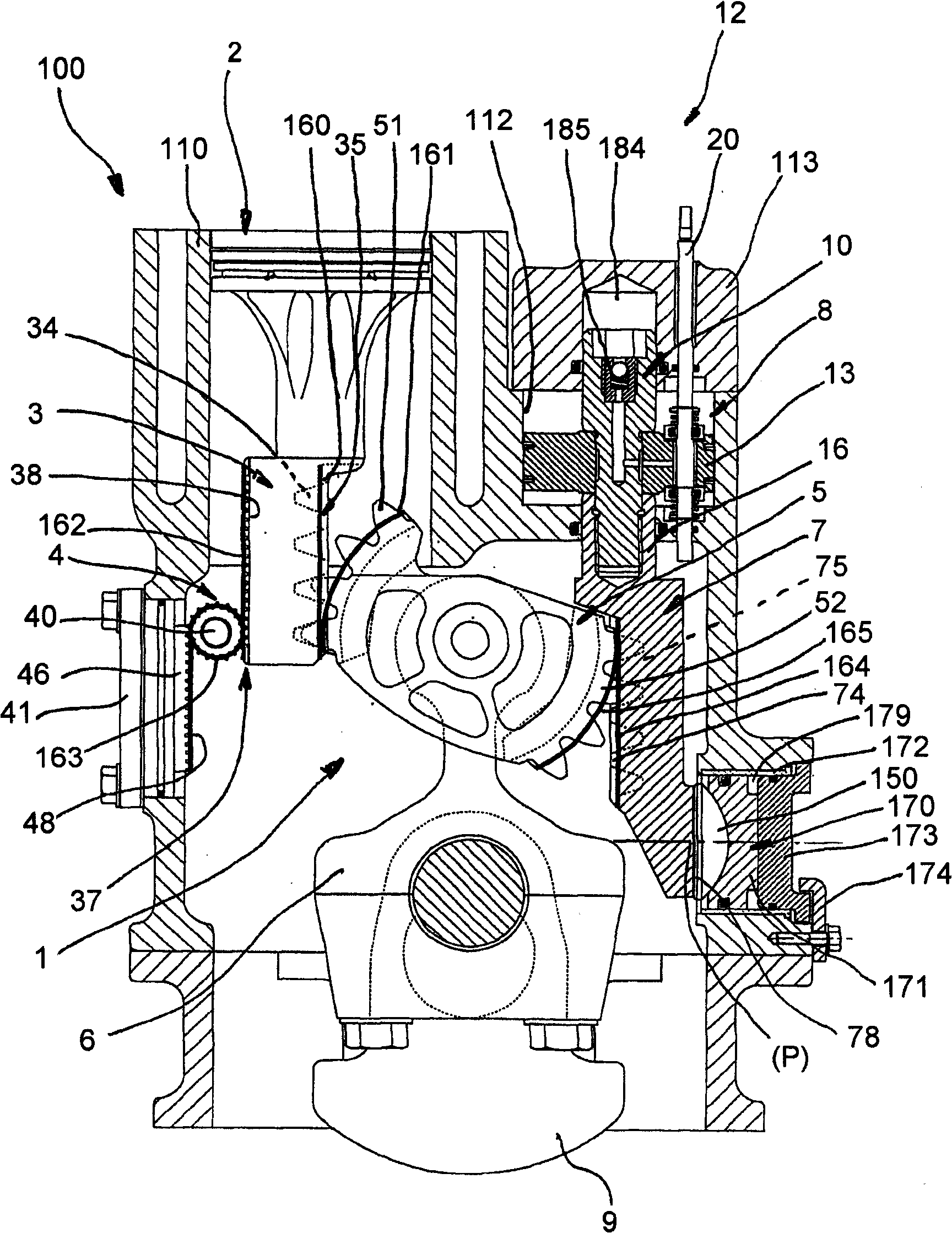

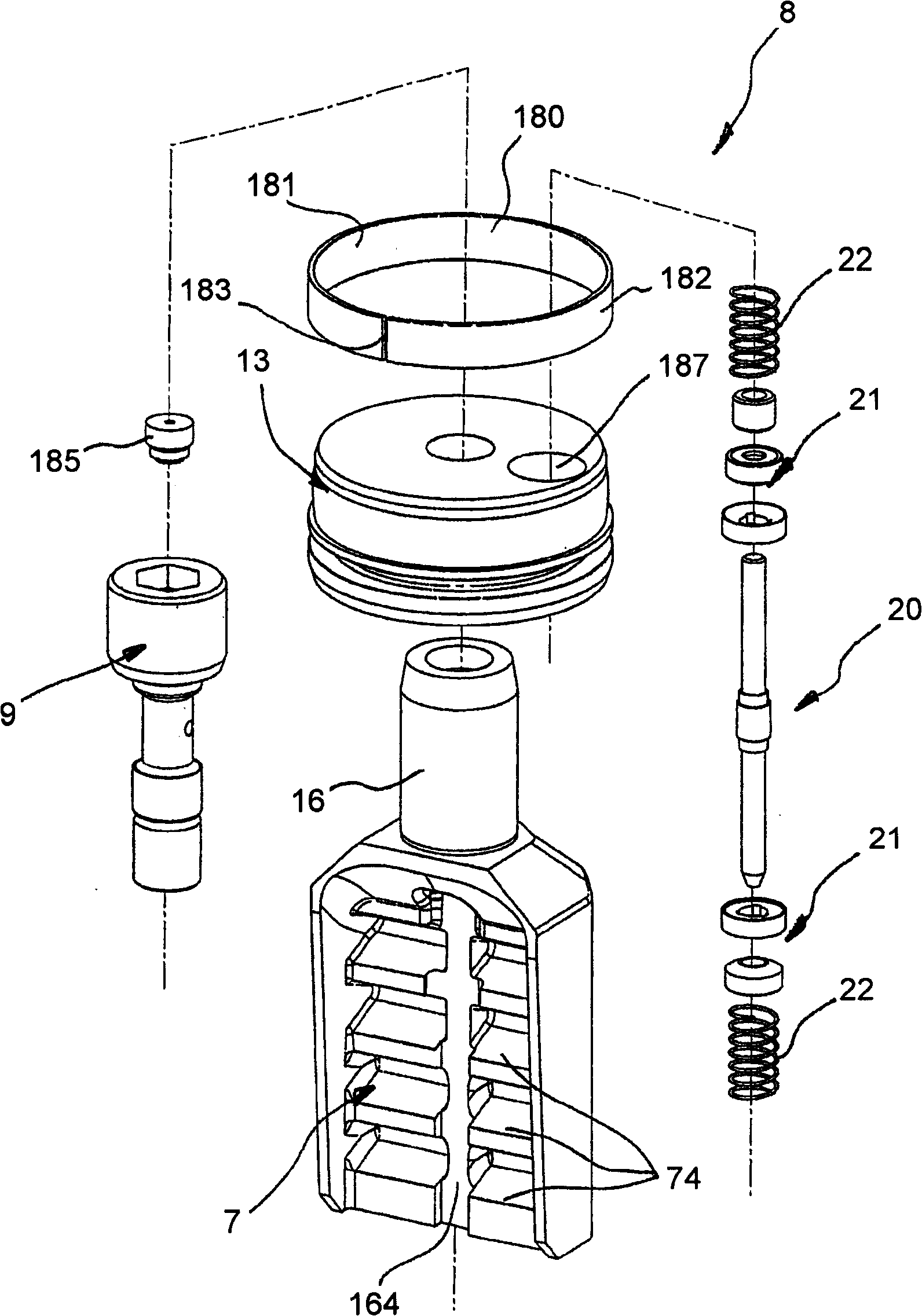

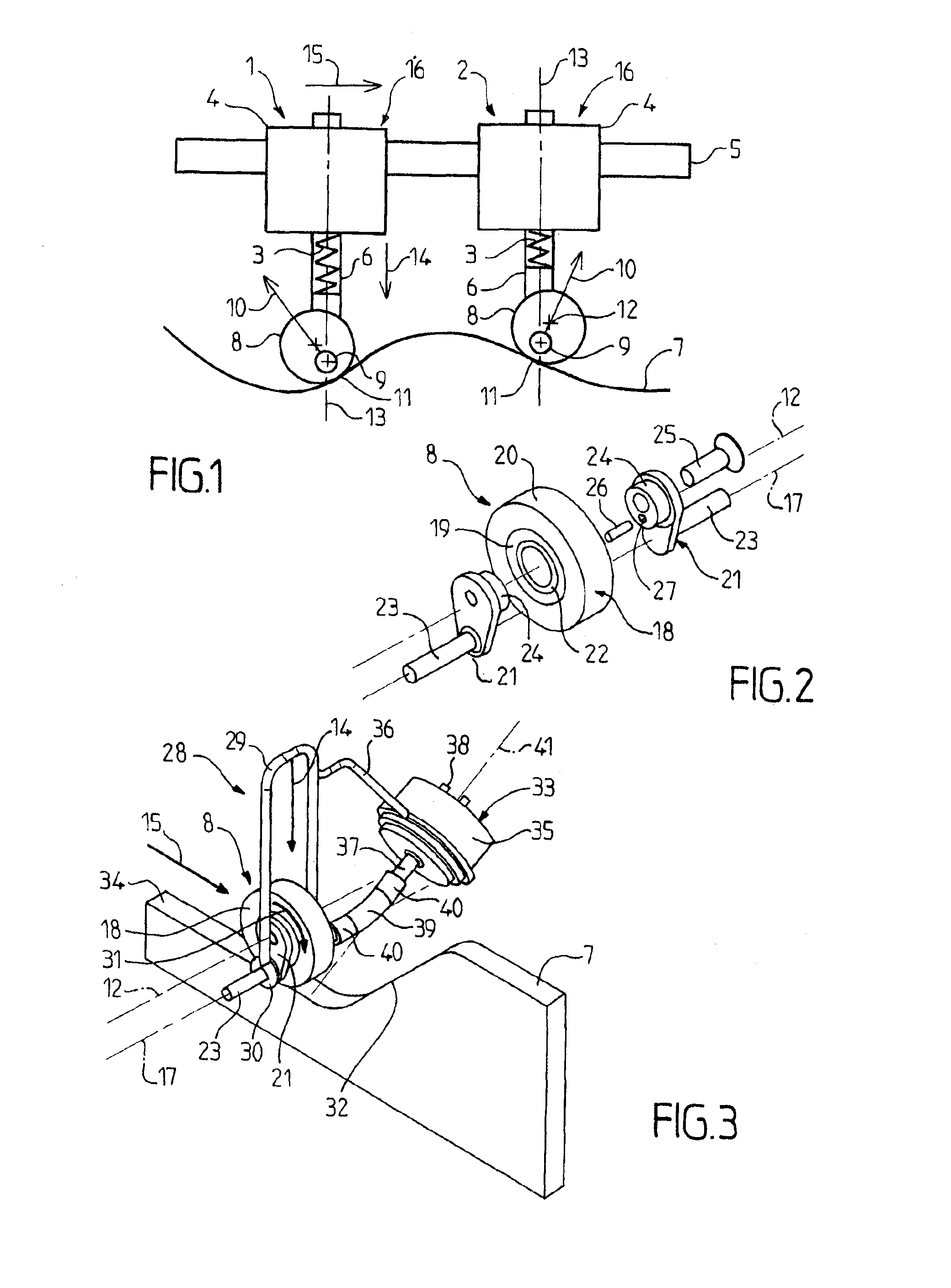

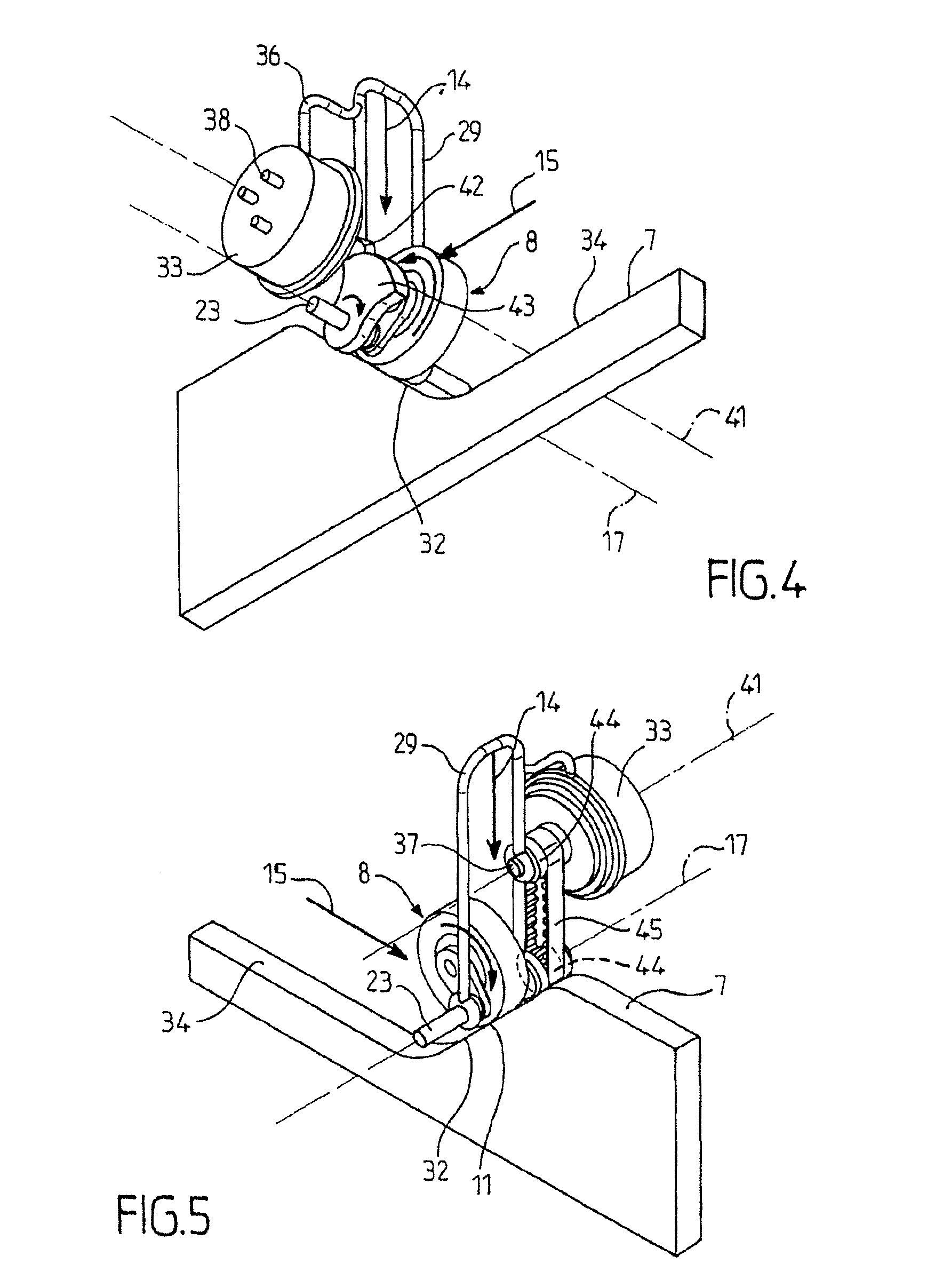

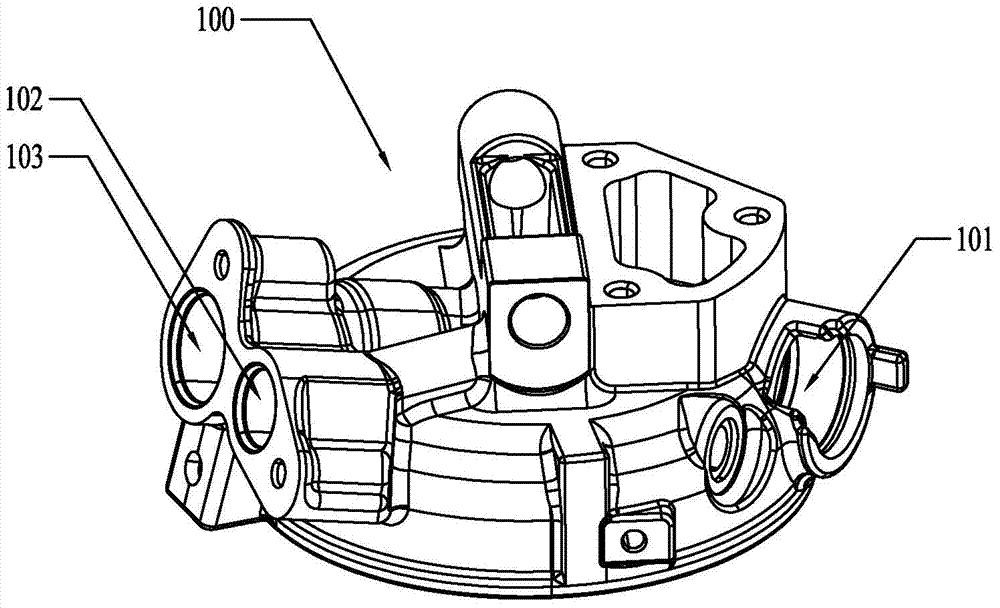

Pressure device for a variable compression ratio engine

The invention relates to a pressure device which maintains the raceways (48, 160 to 165) of the main moving components (3, 5, 7 and 40) of a variable compression ratio engine permanently in contact with one another and with the faces on which they rest in a cylinder case. The inventive device includes pressure means which are solidly connected to the cylinder case (100) and which exert a pressureforce on a control rack (7) having a toothed segment (75) formed by teeth (74). The pressure force is applied against a support surface (78) provided on the lower part of the rack (7).

Owner:维亚内·拉比 +1

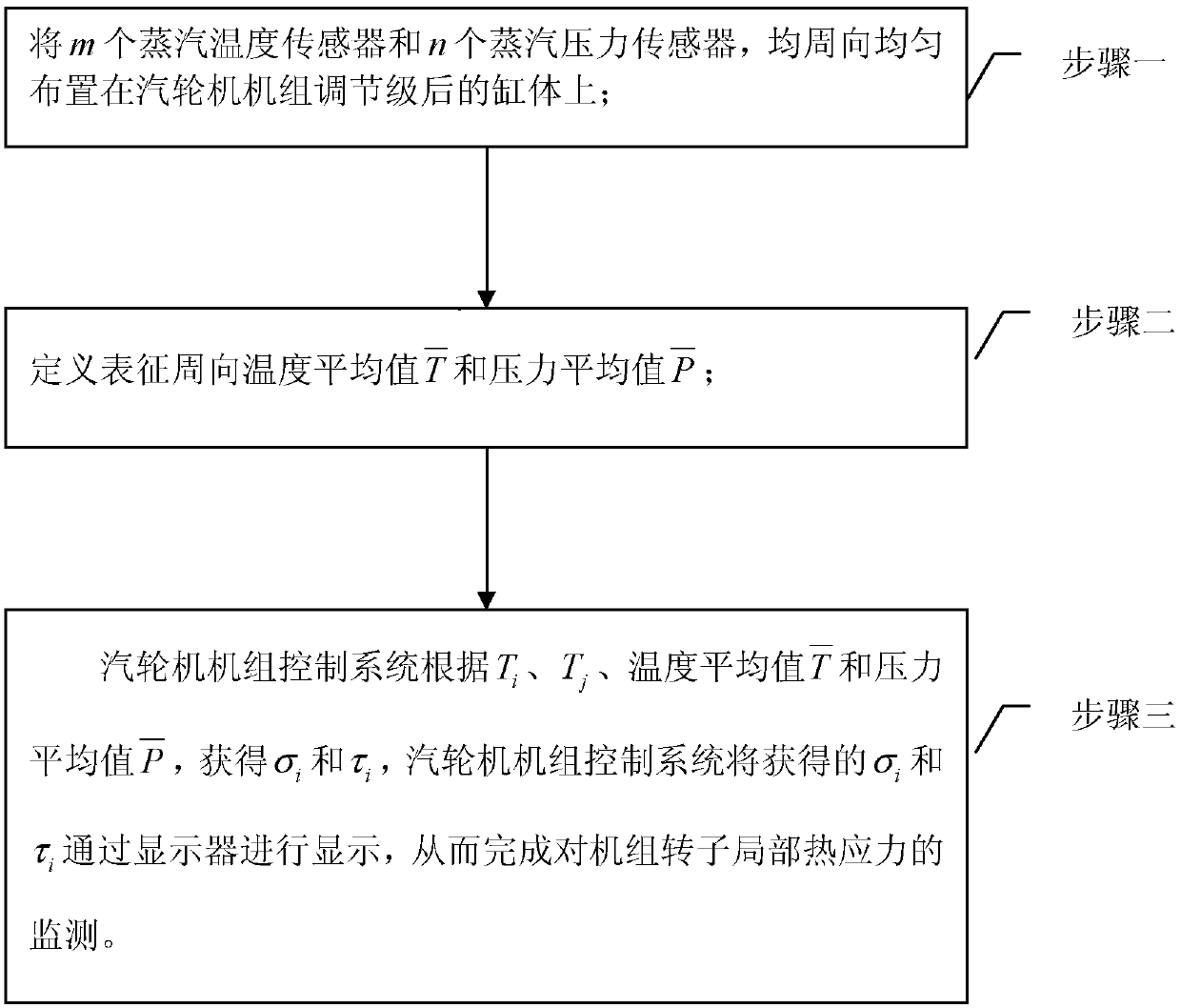

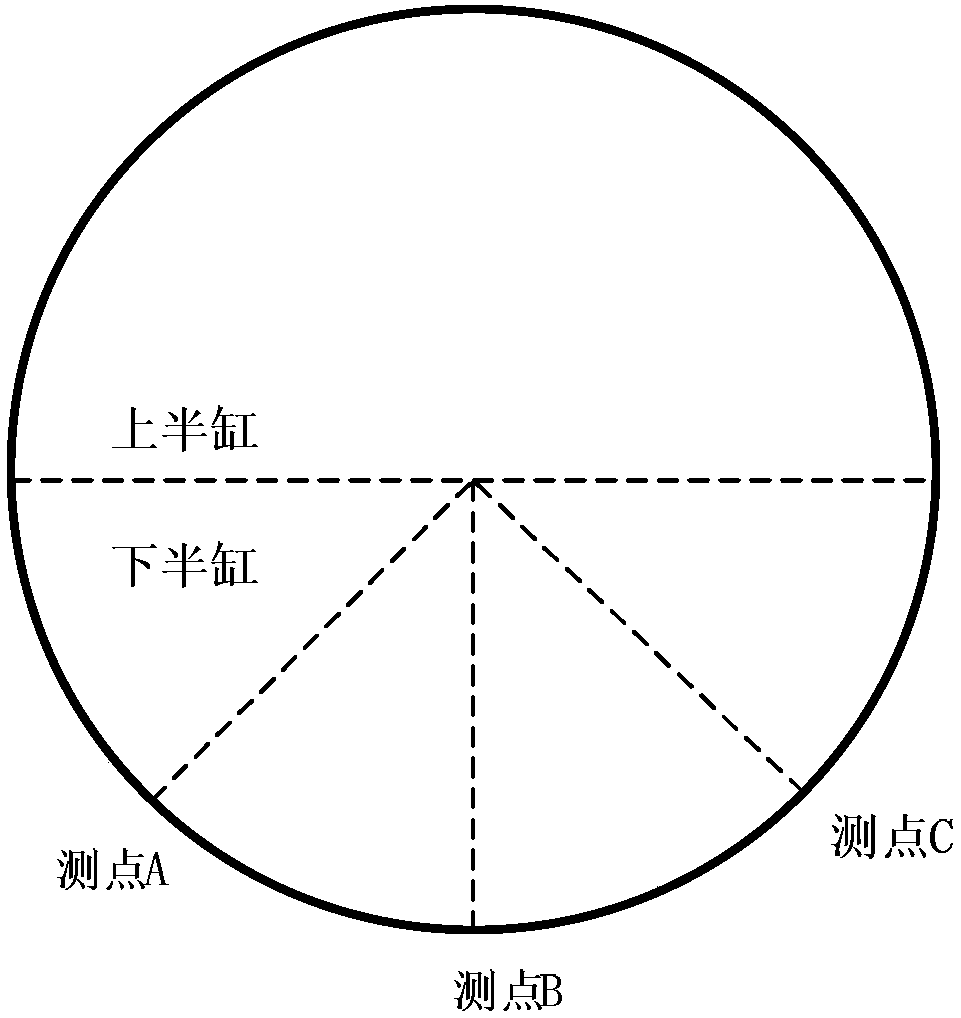

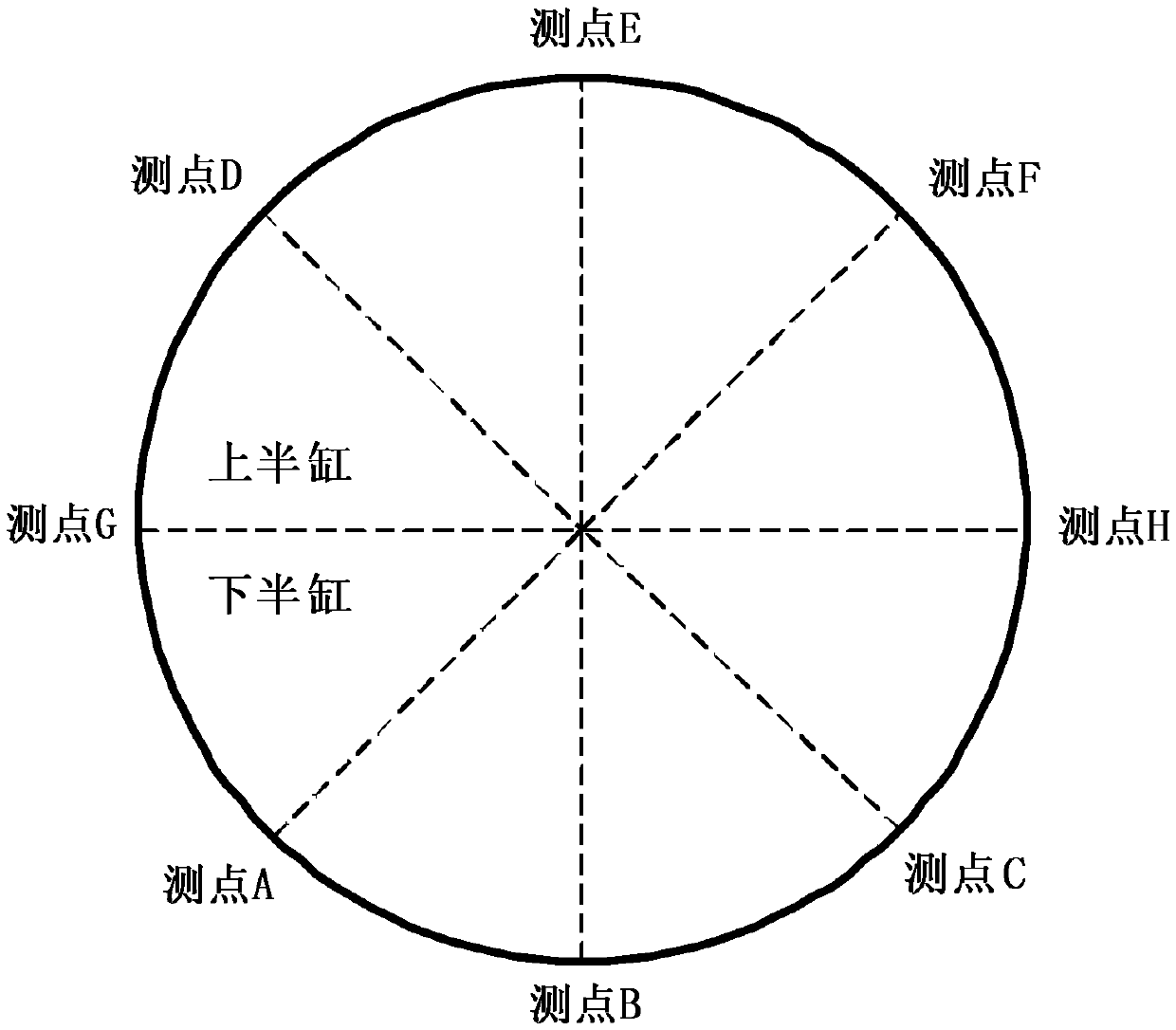

Rotor local thermal stress unevenness monitoring method of steam turbine in low load working condition

ActiveCN108590784AChange the problem of uneven circumferential distribution of thermal stressRealize monitoringEngine fuctionsMachines/enginesPressure.meanPower station

The invention relates to a rotor local thermal stress unevenness monitoring method of a steam turbine in a low load working condition, belongs to the thermotechnical field of a power plant, and solvesthe problem that conventional steam turbine rotor thermal stress monitoring means are difficult to reflect the unevenness of rotor local thermal stress in the low load working condition, in particular the problem of unevenness of the circumferential thermal stress of the rotor in the working condition. The method comprises the following steps: S1, circumferentially and uniformly arranging m steamtemperature sensors and n steam pressure sensors on a cylinder of a regulating stage of a steam turbine unit; S2, defining representative circumferential temperature mean value formula and pressure mean value formula (refer to the Specification); and S3, acquiring sigmai and taui by a steam turbine unit control system according to Ti, Tj and the temperature mean value formula and the pressure mean value formula (refer to the Specification), and displaying the acquired sigmai and taui by the steam turbine unit control system through a display so as to monitor the local thermal stress of the rotor of the unit.

Owner:HARBIN INST OF TECH +3

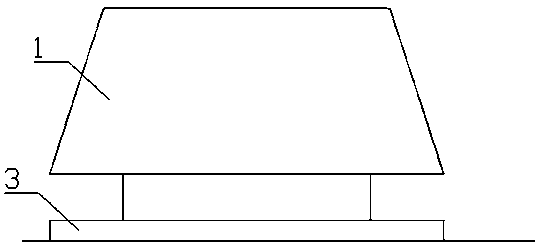

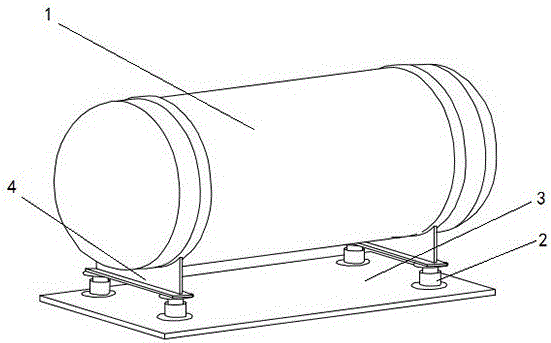

Pressure monitoring method for liquid level of vehicle-mounted liquefied natural gas tank

ActiveCN104896304APromote repairContainer filling methodsContainer discharging methodsPressure.meanProper time

The invention discloses a pressure monitoring method for a liquid level of a vehicle-mounted liquefied natural gas tank. The method is characterized in that the liquefied natural gas tank is connected with an automobile bottom plate through an elastic support, and the gravity center of the liquefied natural gas tank coincides with the rigidity center of the elastic support; a pressure sensor collects a pressure signal of the elastic support, the proper time duration is selected, time average is carried out on collected total pressure, and a pressure average value is close to mass of a system; and a processor compares the mass with the mass of the system in the no-load process of the liquefied natural gas tank so as to obtain the stock mass of liquefied natural gas, and a liquid level value is determined. According to the method, when a vehicle is static, the liquid level of the liquefied natural gas is monitored, and when the vehicle runs, the liquid level can be monitored in real time, and failure maintenance is facilitated.

Owner:江苏省特种设备安全监督检验研究院张家港分院

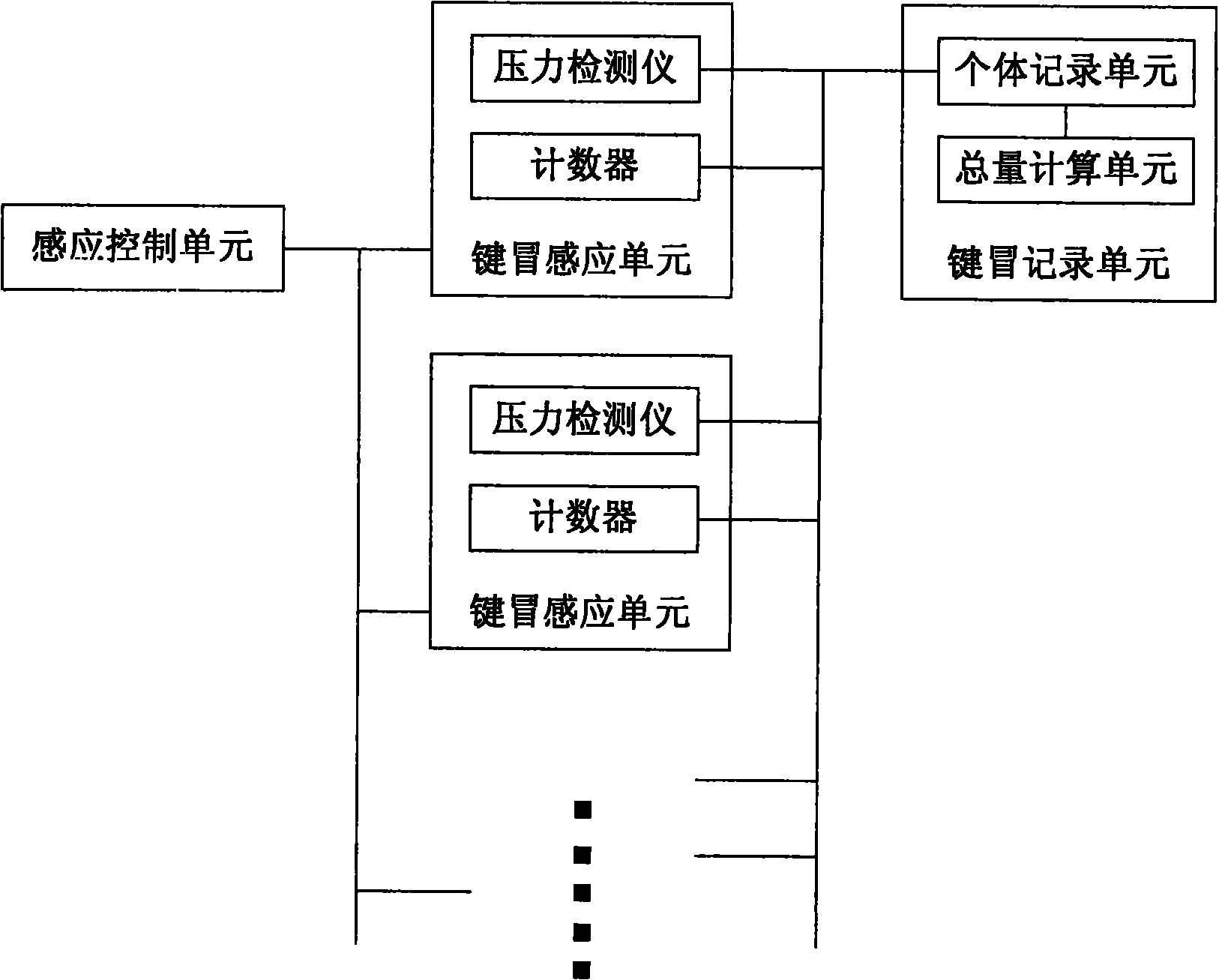

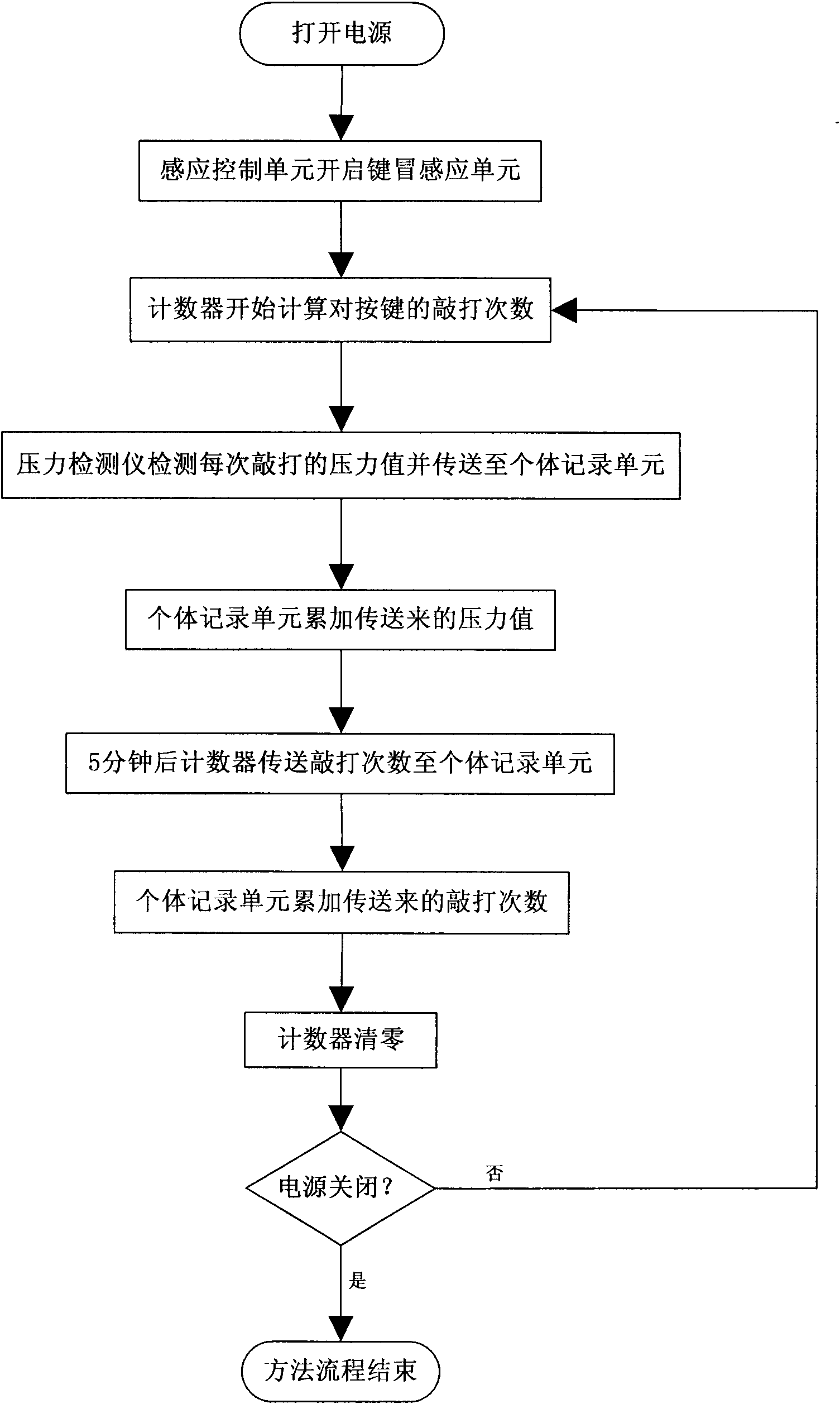

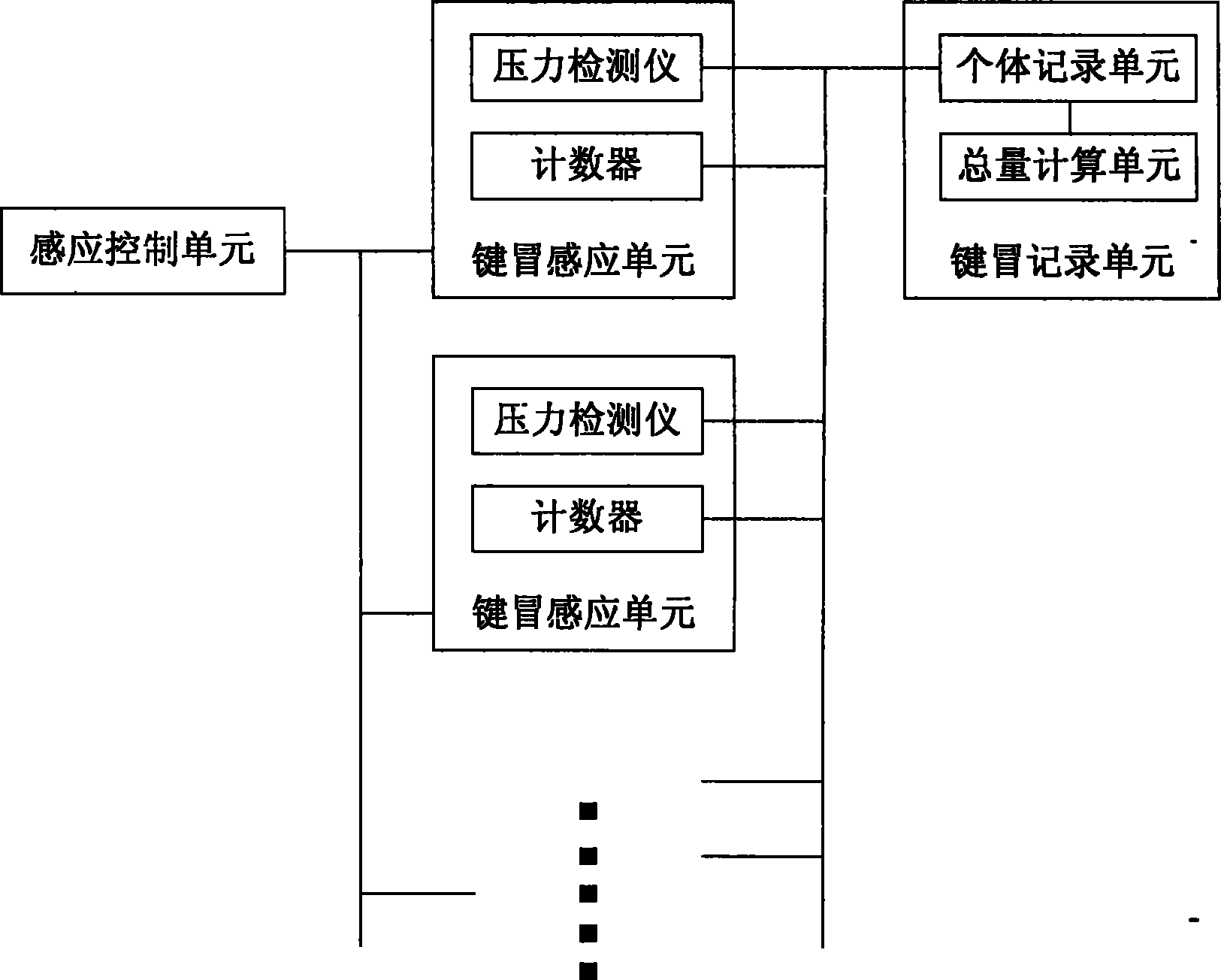

System and method for total calculation of loss and using situation of computer accessory device

InactiveCN101957869ADetailed and diverse real-time dataValid referenceData acquisition and loggingPressure.meanData acquisition

The invention discloses a system and a method for total calculation of loss and using situation of a computer accessory device. The system comprises key cap induction units, a key cap recording unit and an induction control unit, as well as a pressure detection instrument and a counter arranged in each key cap induction unit, and an individual recording unit and a total quantity calculation unit arranged on the key cap recording unit, and the key cap induction unit is particularly arranged on each key of a keyboard. The counters are used for recording the beating times of a user and saving in the individual recording unit during the process of using the keyboard of the user, the pressure detection instruments are used for detecting the pressure value during each beating of the user and transmitting into the individual recording unit, and the individual recording unit is used for converting the pressure values transmitted from the individual recording unit to average values; and the total quantity calculation unit is used for adding the beating times recorded by each counter, simultaneously adding the pressure average values recorded by the individual recording unit and saving respectively. The adoption of the method can simply and effectively carry out data acquisition and processing.

Owner:SUN YAT SEN UNIV

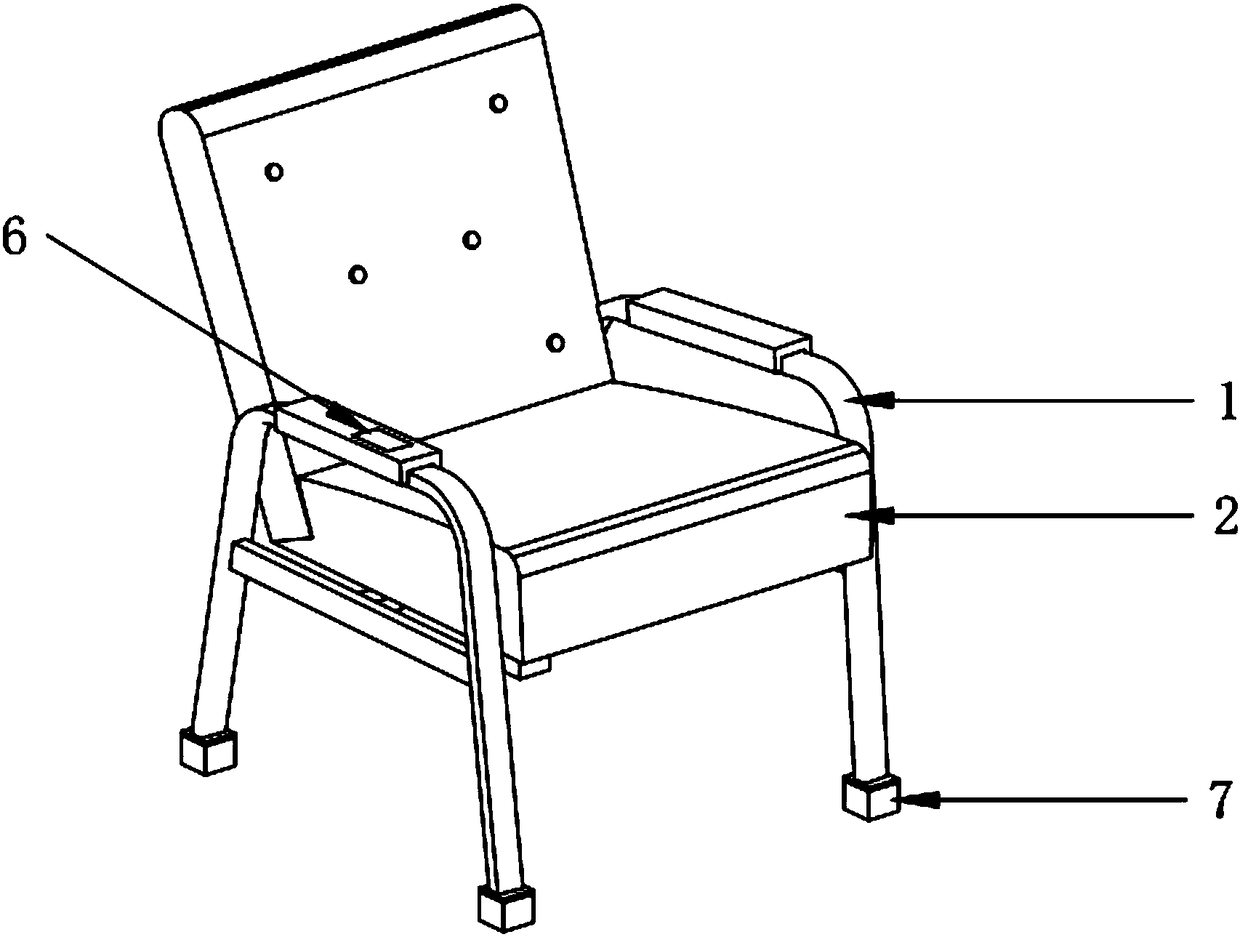

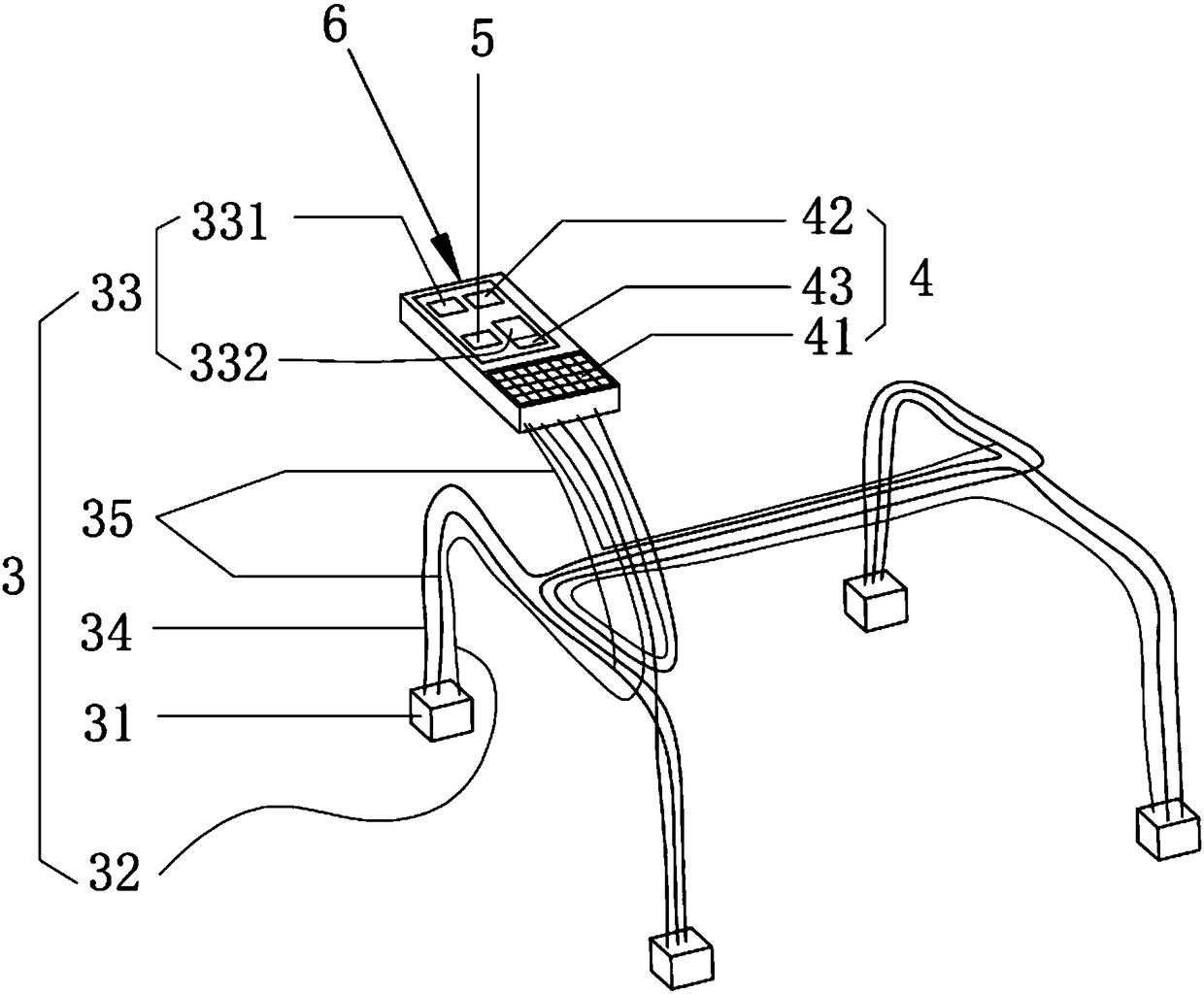

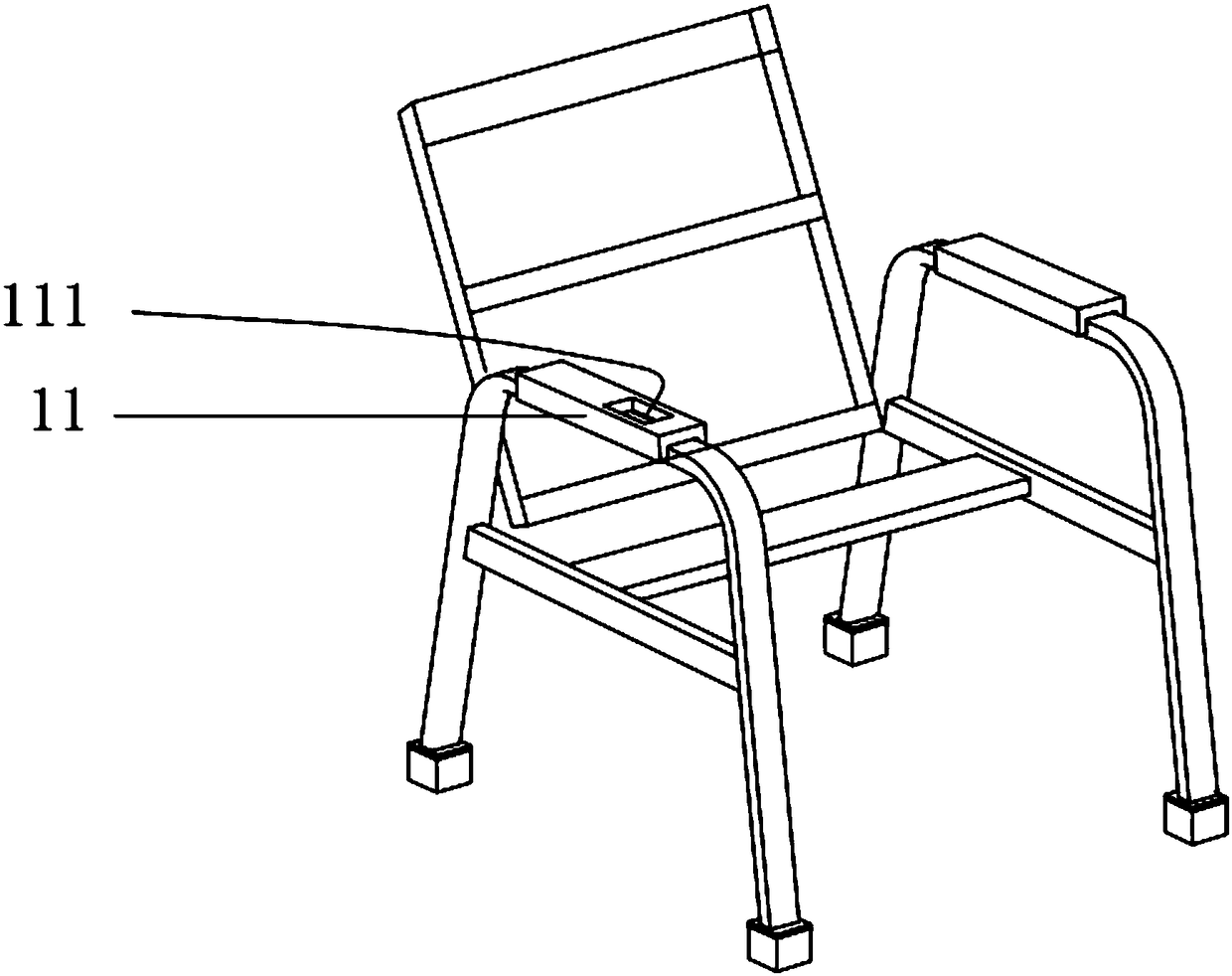

Intelligent leisure chair

InactiveCN108477903AIncreased sensitivityNumerical error is smallEvaluation of blood vesselsStoolsPressure.meanNumerical control

The invention relates to the technical field of chair, in particular to an intelligent leisure chair, which comprises a chair frame, a chair body, a weighing assembly, a blood fat and blood pressure value reference assembly, a load value reset module and a numerical control plate, wherein the weighing assembly comprises a plurality of pressure sensors, a plurality of pressure sensing wires, a bodyweight value processor and a plurality of pressure balance processors; each pressure sensor is arranged at the bottom end part of the chair frame and is in abut joint with the bearing surface for bearing the intelligent leisure chair; the body weight processor is arranged at the numerical control plate; one pressure sensor and the body weight value processor are connected through one pressure sensing wire; the two adjacent pressure sensors are connected through one pressure balance processor; through the arrangement of the pressure sensor in a position, near the bearing surface, of the bottomend of the chair frame of the intelligent leisure chair, the sensing pressure sensitivity of the intelligent leisure chair is realized; meanwhile, a pressure balancing processor is arranged the two adjacent pressure sensors; the goal of obtaining the pressure average value and lowering the value error in the inclined state of the intelligent leisure chair can be achieved.

Owner:DONGGUAN MEINAISI FURNITURE PRODS

Orientation device for orientating a sensor probe

ActiveUS9505098B2Measurement apparatus componentsMeasurement/indication equipmentsPressure.meanBiomedical engineering

Owner:GAZTRANSPORT & TECHNIGAZ

Plant fiber-stalk separator

InactiveCN107227645AAvoid damageEasy to removeDigestersFinely-divided material pretreatmentMultiplexingPressure.mean

A plant fiber stem separator, which includes the initial pressure device, softening device, steam device, compression device, vibration device, and charging device in the sequence of processing sequence;The initial crushed plant stems are connected to the softening device with this plant tough fiber; the steam device is set behind the softening device, and the compression device is set between the steam device and the vibration device.After the steam treatment, the stems are once again entering the vibration device. There are vibration tables and vibration blocks set on the upper and lower sides in the vibration device. Under the repeated vibration and pressing of vibration tables and vibration blocks, stems and stalks and stalks and stalks and stalks and stalks and stalks and stalks and stalks and stalks and stalks and stalksThe tough fiber is completely separated, and the heavier stems are vibrated and dropped, while the lighter and interrelated tough fiber parts are collected by the device.

Owner:LISHUI FEITIANREN MACHINERY DESIGN CO LTD

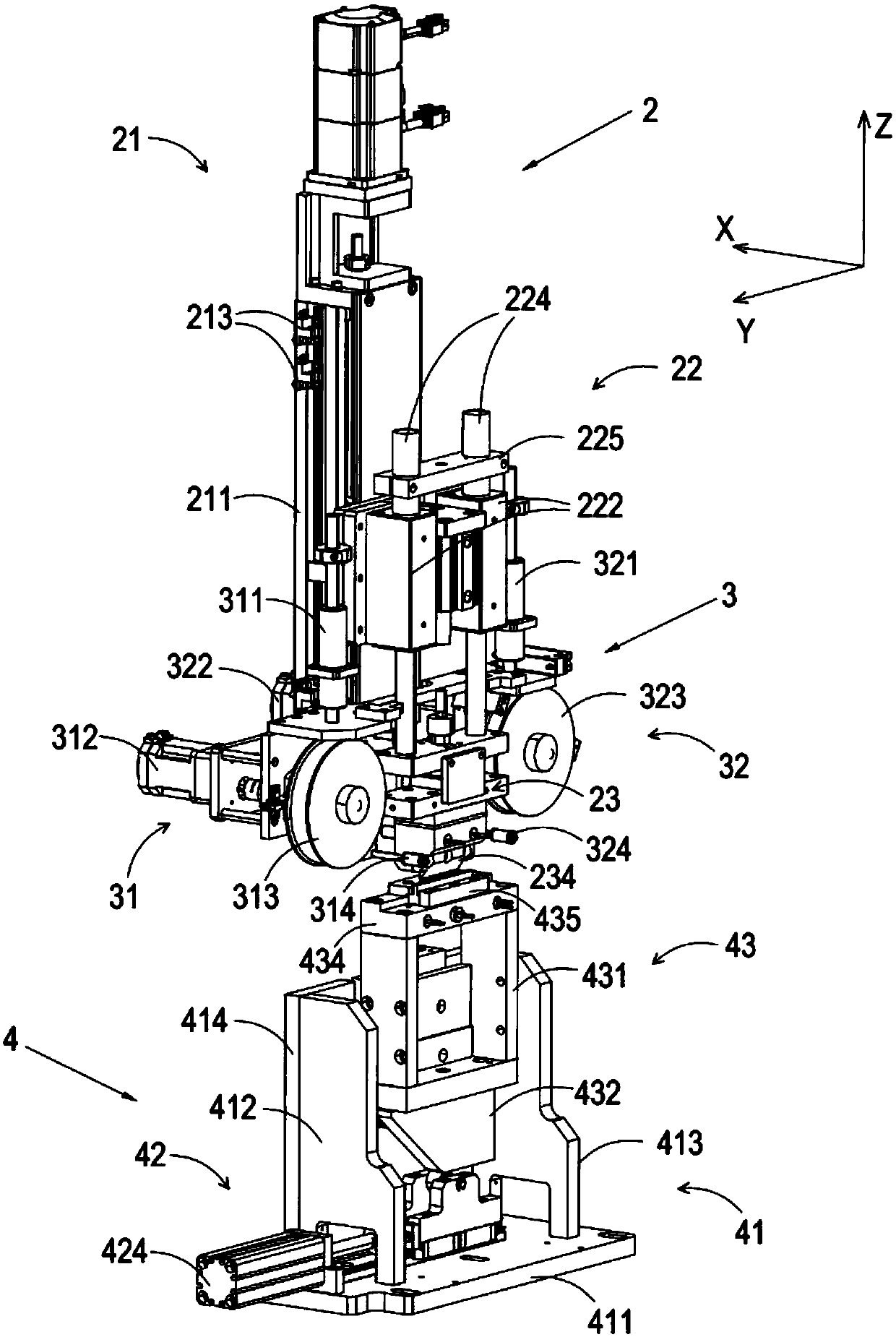

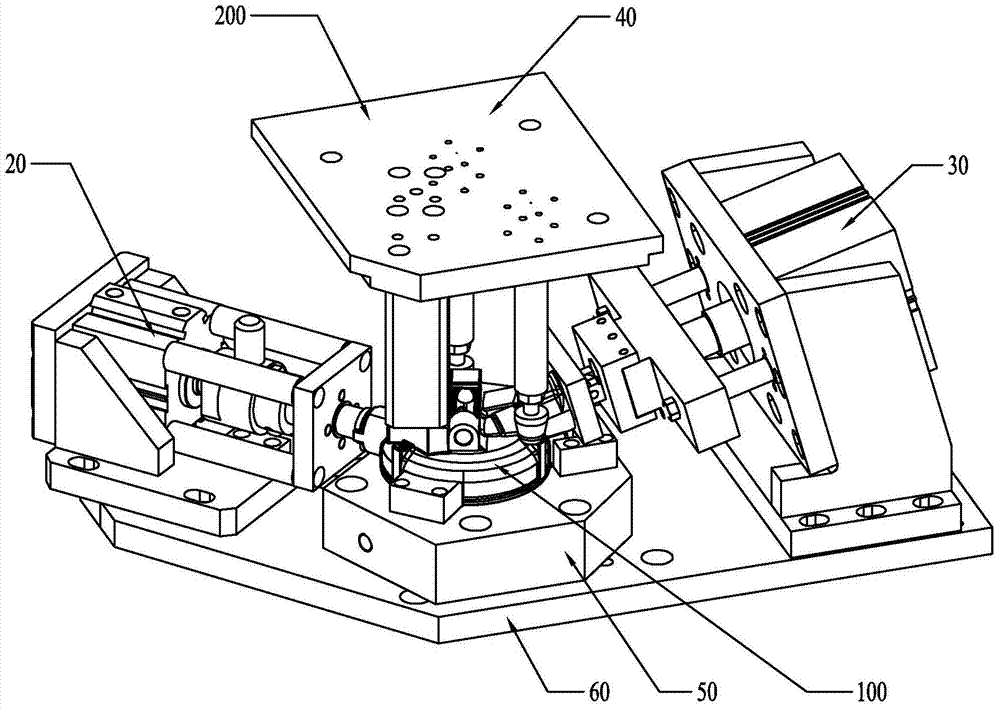

Seal leak detection device

ActiveCN104949800BEffectively fixedImprove sealingFluid-tightness measurementPressure.meanReciprocating motion

The invention discloses a sealing leak detection device, which comprises: an assembly bottom plate, an upper positioning device, a lower positioning device, a first sealing device and a second sealing device, and the upper positioning device includes: a lower pressing actuator, an upper pressing plate and more than one The positioning column, the lower positioning device includes: the lower positioning seat and the positioning block, the first sealing device includes: the first pressure actuator, the elastic member, the connecting sleeve, the stop pin, two tightening blocks, the guide sleeve and the sealing rod, the first The pressure actuator can drive the sealing rod to reciprocate. The front end of the sealing rod is provided with a first sealing ring, and the second sealing device includes: a second pressure actuator, a connecting block and a floating flap, the floating flap is hinged to the connecting block; the front side of the floating flap is provided with a sealing groove, A second sealing ring is arranged in the sealing groove; the advantage of the present invention is that the first sealing device and the second sealing device can effectively seal the hole to be inspected, the above structure is ingeniously designed, easy to implement, and the sealing effect is reliable.

Owner:NANJING CHERVON AUTOMOBILE PRECISION TECH CO LTD

A method for determining the injection pressure of tight reservoir natural gas accumulation period

ActiveCN106499391BAccurate dataEfficient use ofBorehole/well accessoriesPressure.meanInjection pressure

Owner:PETROCHINA CO LTD

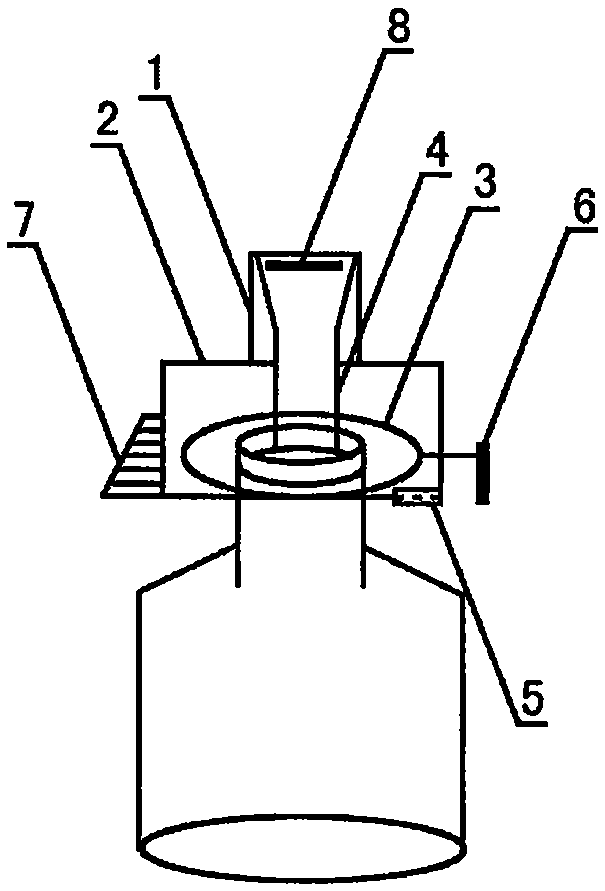

Purified water extracting device

InactiveCN107192577AReduced sampling stepsSpeed up experimentationWithdrawing sample devicesPressure.meanPackage design

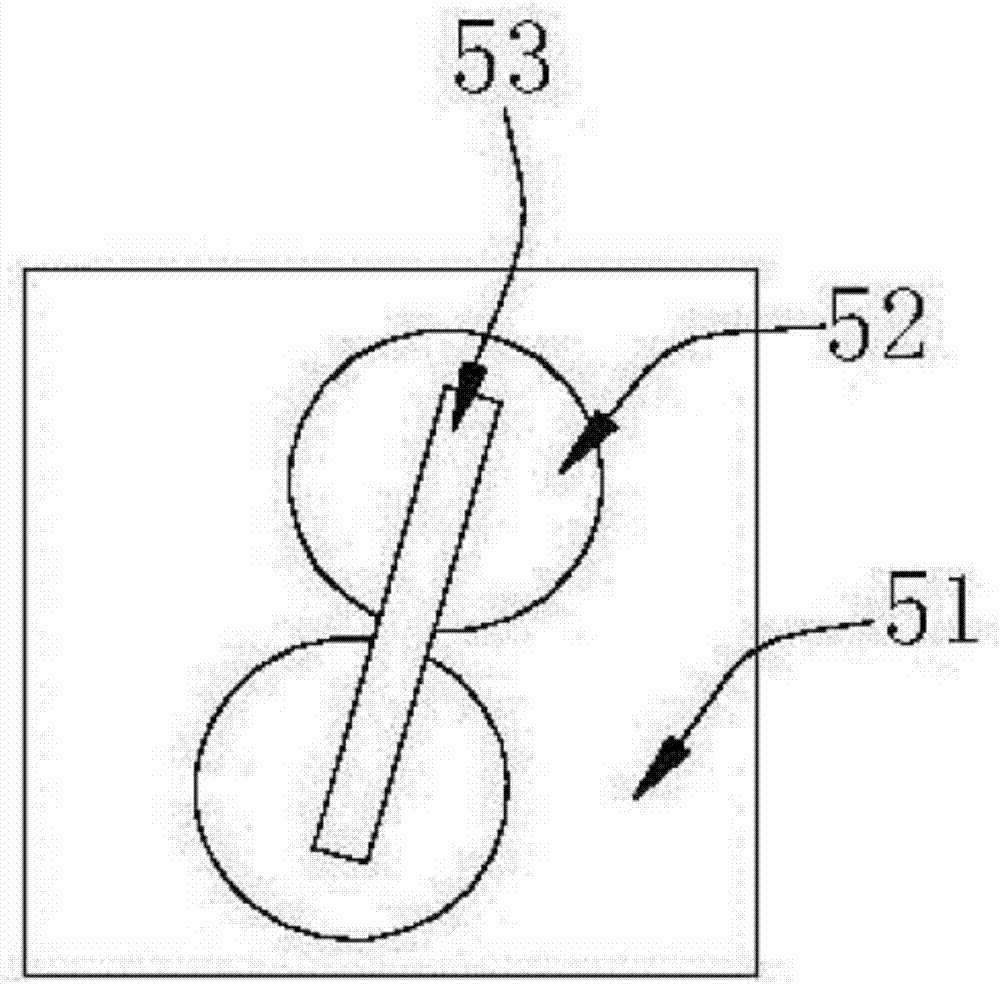

An extraction device for purified water, comprising a frame body (1), the frame body (1) is designed as a set structure as a whole, a casing device (2) is arranged on the outermost layer, an adjusting ring device (3), a hollow pipe The device (4), the filtrate structure (5), the rotating device (6) and the adjusting ring device (3) are connected for use, and the pressing device (7) is arranged on the left side of the frame body (1). The lifting device (8) is extended into the water outlet, and the collection operation is carried out after pressing the side; the filtrate structure (5) is located at the lower end of the right side of the casing device (2), and the drainage operation is carried out in case of filling; the frame body (1) It is designed with high temperature and high pressure resistance, and high temperature sterilization is required before use; it adopts the connection structure design, which can not only carry out the deployment operation according to the bottleneck of use, but also reduce the sampling steps, speed up the experimental progress, easy to operate, and has a strong practicality.

Owner:XINCHANG YULIN STREET DONGCHEN MACHINERY FACTORY

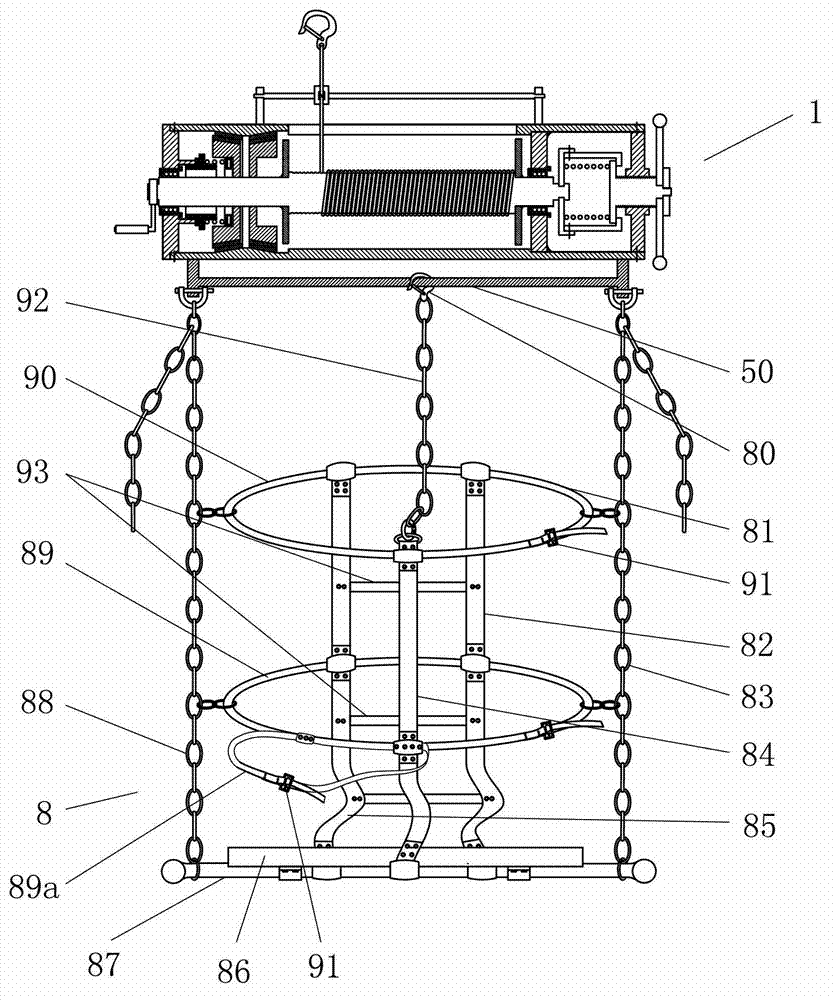

Manual adjustable pressure cone friction wheel escape device

ActiveCN102872547BEasy to operateConvenient and safe control of release rateBuilding rescuePressure.meanHigh rise

The invention belongs to the technical field of high-rise escape and relates to a manual control pressure-adjustable tapered friction wheel type escape device. The manual control pressure-adjustable tapered friction wheel type escape device comprises a rope releaser and a base basket hung on the lower side of the rope releaser, wherein the specific structure of the rope releaser is that: a through shaft which is axially and slidingly supported on two ends of a barrel is arranged on an integral axis; a rope of which one end extends out the barrel and the other end is fixed on the through shaft is wound in sequence at the middle part of the through haft; the inner wall of the barrel is fixedly provided with an outer brake disc with an annular tape; a tapered inner brake disc which cooperates with the outer brake disc to brake is fixed on the through shaft; a pre-braking force regulating device is arranged between the barrel and the through shaft; a manual brake device is arranged outside the through shaft at one side of the barrel; and a crank handle for rotating the through shaft is arranged on the through shaft at the other side of the barrel. The manual control pressure-adjustable tapered friction wheel type escape device has the advantages of multiple functions, and being flexible, fast and accurate in brake control and capable of being used for high-rise escape, entertainment, mountain climbing equipment or spider-man work.

Owner:金来兴

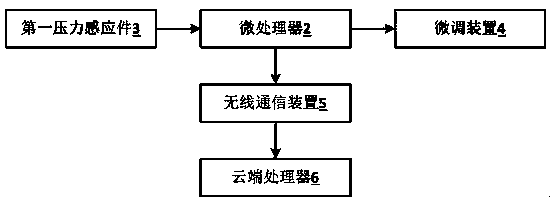

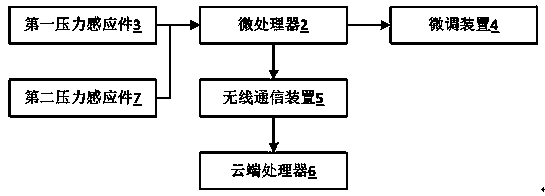

Internet-of-things-based keyboard of automatically adjusting key position spacing

ActiveCN108681406ADemand adaptationMove anywhereInput/output for user-computer interactionPressure.meanPressure sense

The invention relates to an Internet-of-things-based keyboard of automatically adjusting key position spacing. The keyboard includes: key positions, and further includes: a microprocessor, first pressure sensing pieces, a fine adjustment device, a wireless communication device and a cloud-side processor. The first pressure sensing pieces are disposed below the key positions, and are used for detecting pressure applied to the key positions. The first pressure sensing pieces and the key positions are numbered. The first pressure sensing pieces uniquely correspond to the key positions, are connected with the microprocessor, and output values of the pressure, which is applied to the key positions, to the microprocessor. The microprocessor processes the received pressure value to obtain a pressure average and uses the average as the pressure value threshold. The fine adjustment device is placed below the key and is used to adjust the position of the key. The number of the fine tuning deviceis at least one, the fine tuning device corresponds to a unique key position, and is connected with the microprocessor. The wireless communication device is connected with the cloud-side processor and the microprocessor.

Owner:东莞市尚贵电子科技有限公司

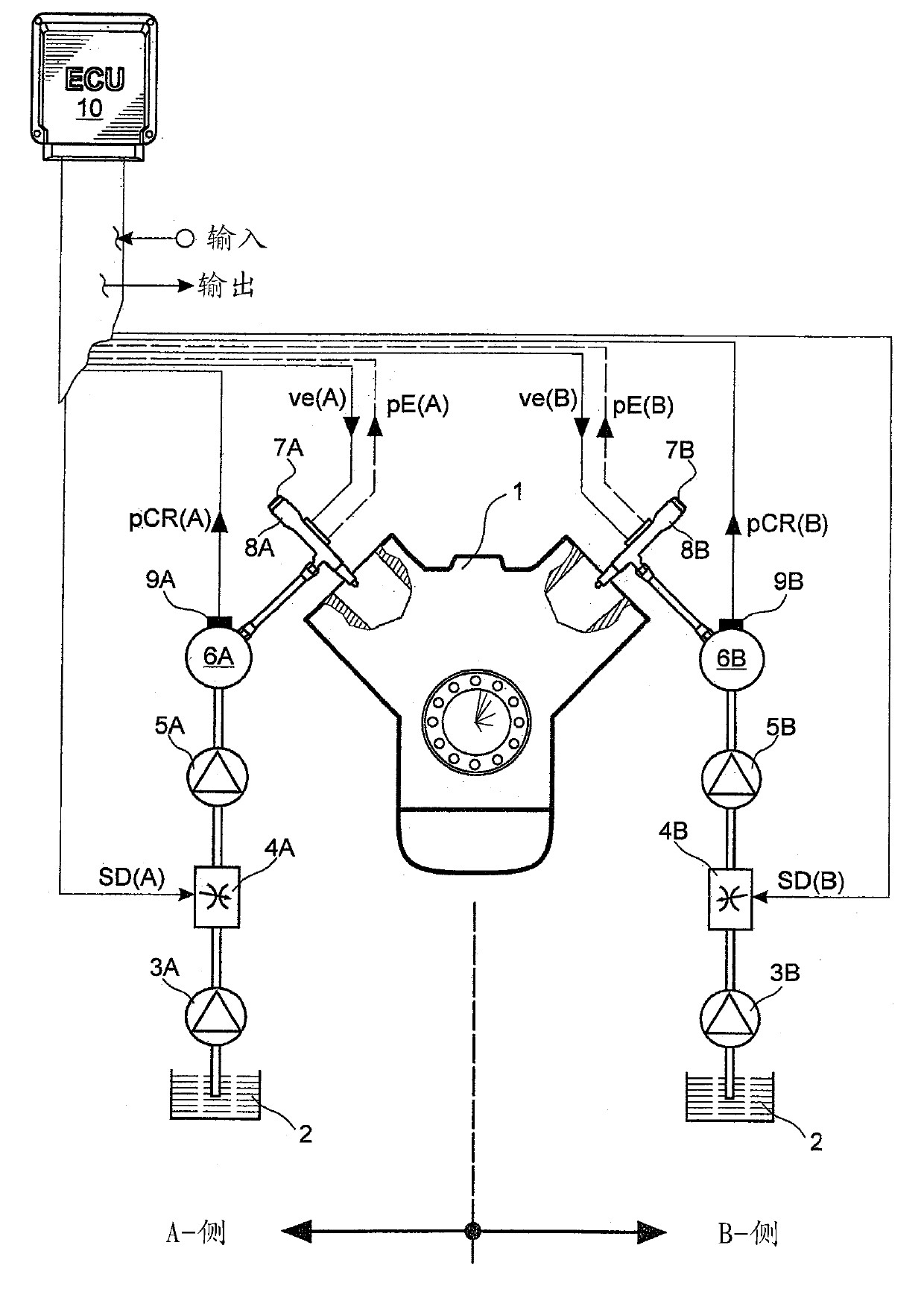

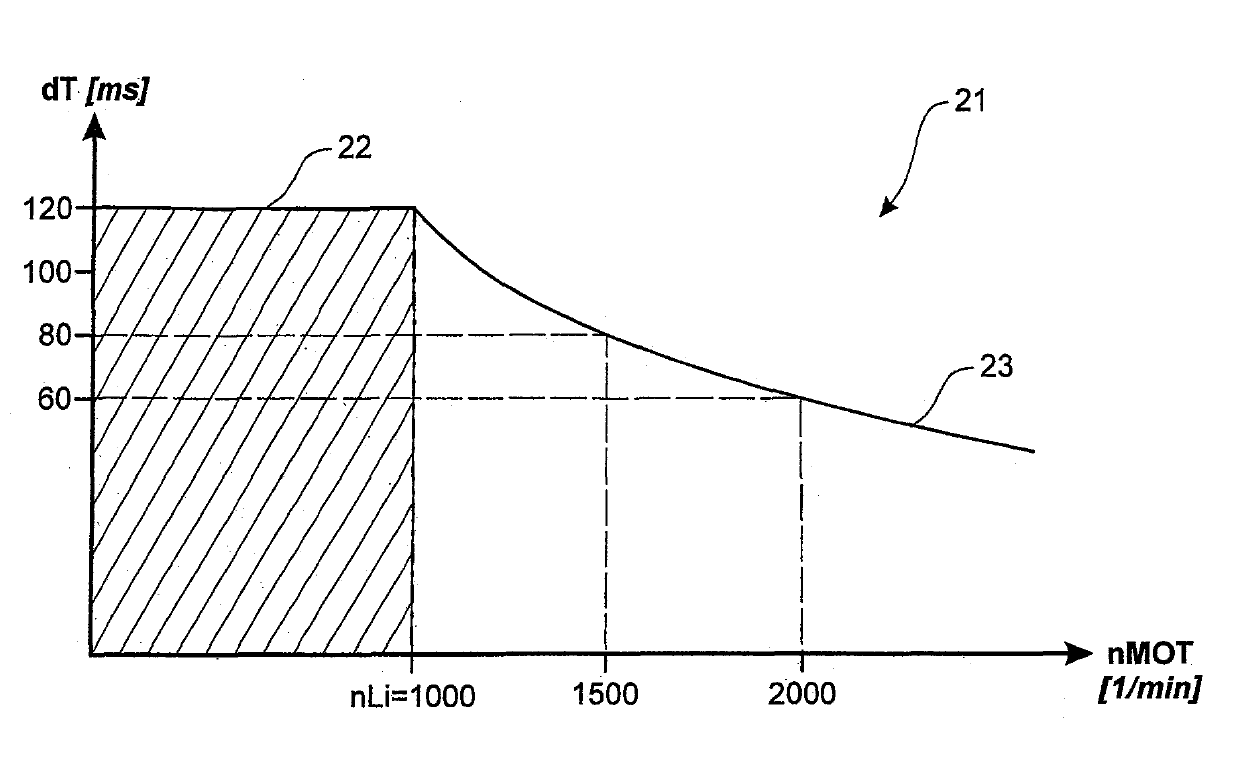

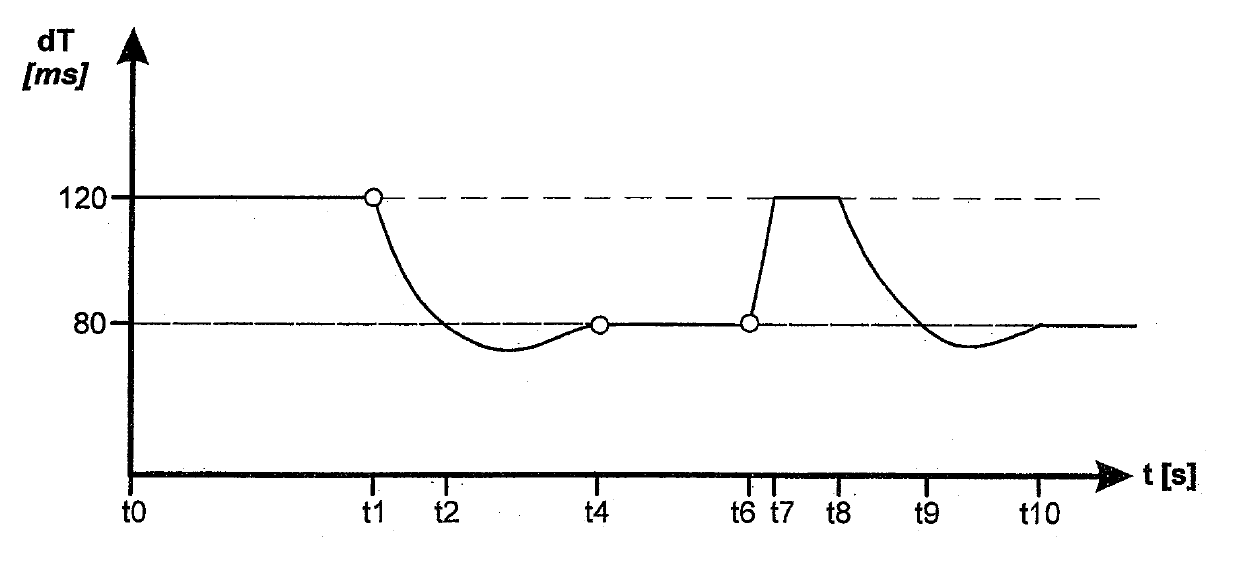

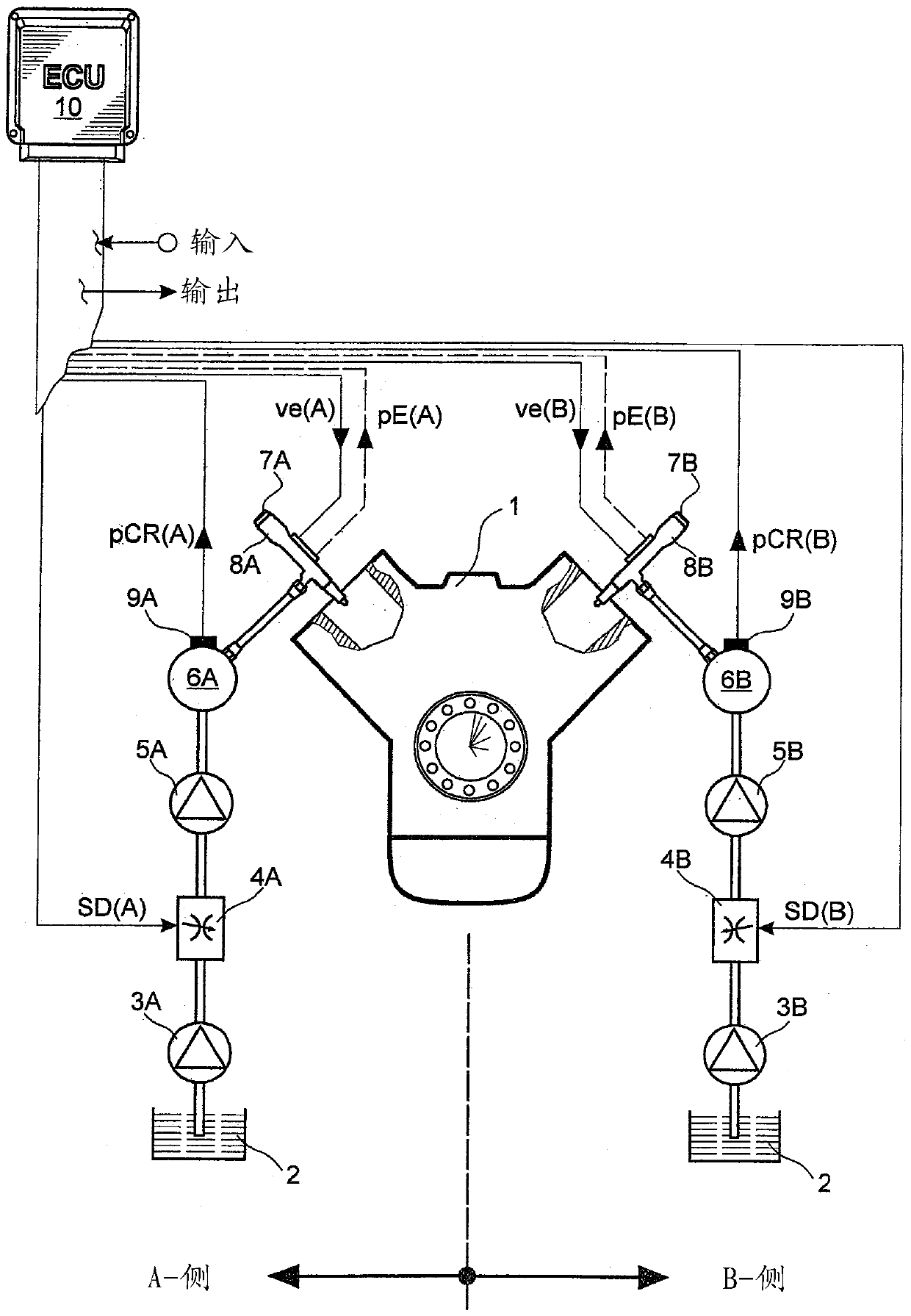

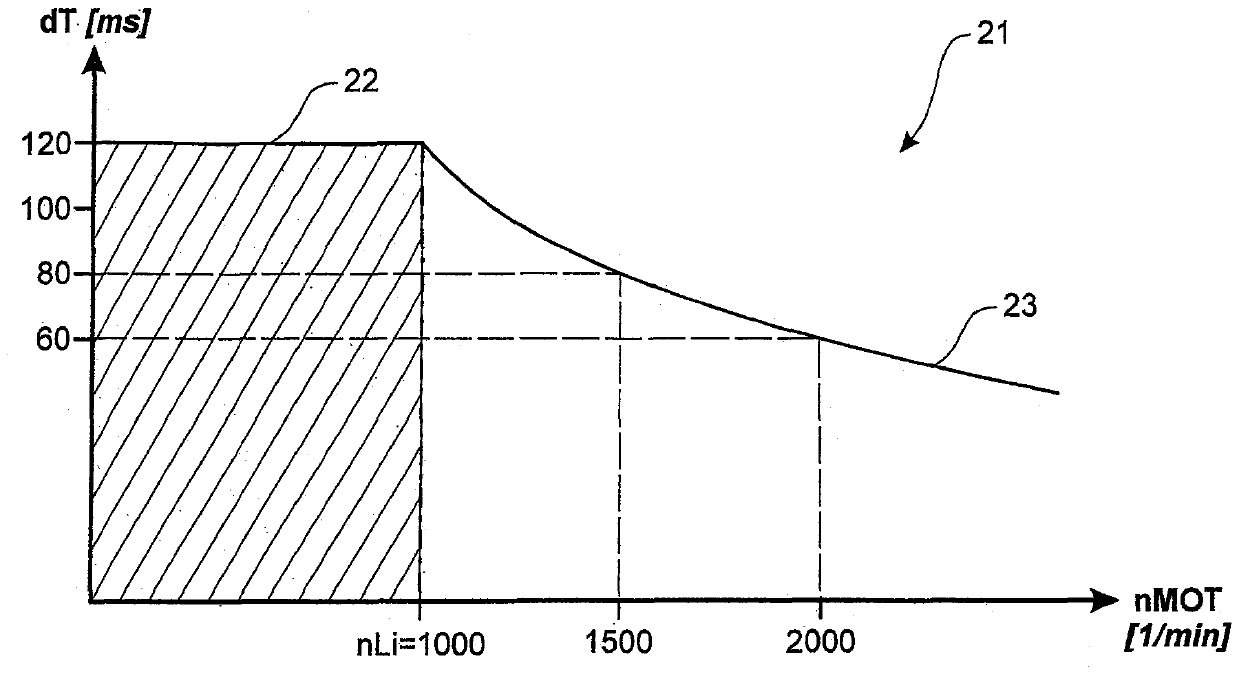

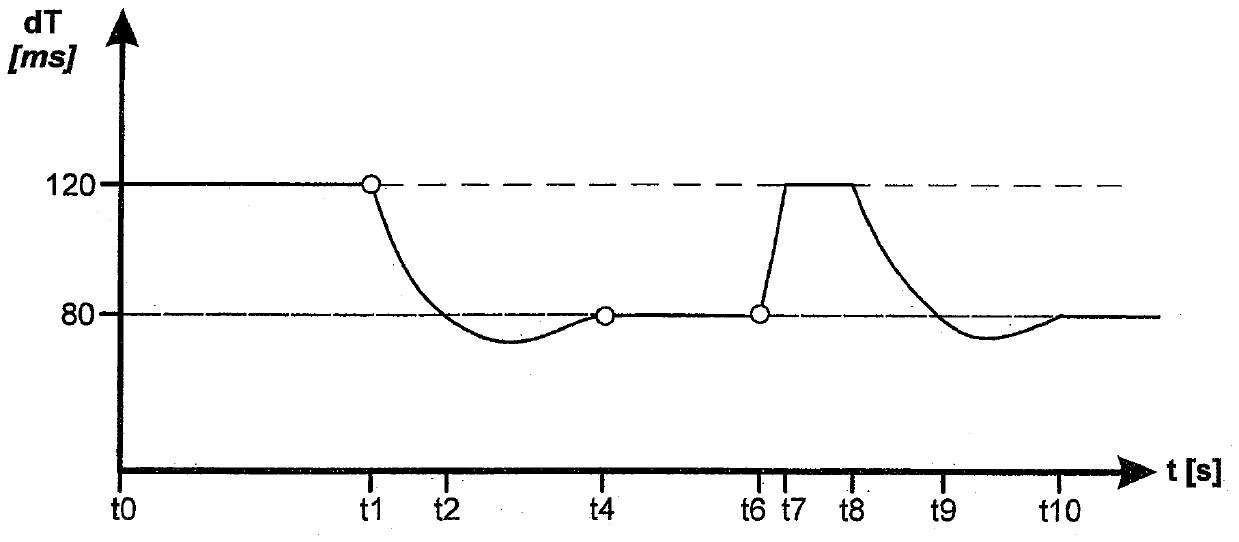

Method for controlling rail pressure

ActiveCN103748342ASatisfactory pressure regulationAchieving the meanElectrical controlMachines/enginesPressure.meanRail pressure

The invention relates to a method for controlling the rail pressure of an internal combustion engine in a V arrangement having an unequal ignition sequence, in which method an actual rail pressure is calculated from the measured rail pressure, a control deviation is determined on the basis of the actual rail pressure and a target rail pressure, and a manipulated variable for controlling a pressure actuator, in particular a suction throttle, is calculated in order to control the rail pressure. The invention is characterized in that the actual rail pressure is calculated from the measured rail pressure by means of a mean value filter, in that below a limit rotational speed (nLi) the rail pressure is averaged over a constant time and above the limit rotational speed (nLi) the rail pressure is averaged over a working cycle of the internal combustion engine.

Owner:ROLLS ROYCE SOLUTIONS GMBH

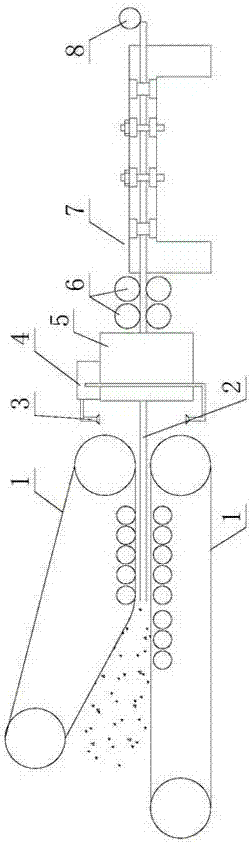

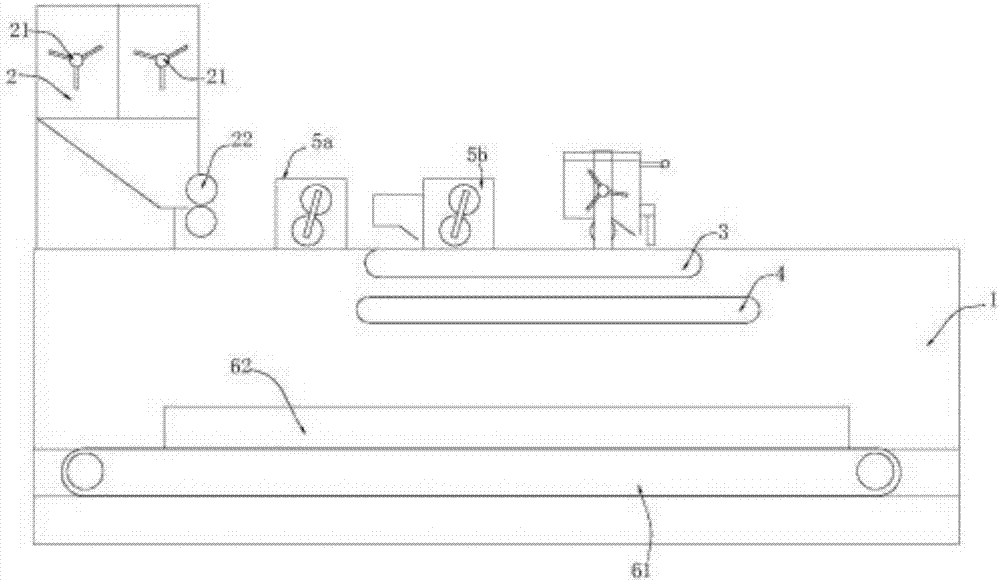

Dough-rolling machine

InactiveCN107535547AImprove appearance efficiencyMixing/kneading structural elementsDough-sheeters/rolling-machines/rolling-pinsComing outPressure.mean

The invention relates to the field of food processing equipment and discloses a dough-rolling machine. The machine includes a frame. A feeding hopper and a first-order dough-conveying belt are arranged on the frame. A dough-discharging device is arranged on the discharging end of the feeding hopper. The first-order dough-conveying belt is positioned at the frame which locates at the downstream position of the dough-discharging device. A first negative pressure device is arranged between the first-order dough-conveying belt and the dough-discharging device. A second negative pressure is arranged on the first-order dough-conveying belt. A second-order dough-conveying belt is arranged below the first-order dough-conveying belt. The conveying direction of the second-order dough-conveying beltis opposite to that of the first-order dough-conveying belt. A material-accumulating rack arranged on the frame is positioned below the second-order dough-conveying belt and a material-accumulating board is arranged on the material-accumulating rack. A driving device driving the material-accumulating rack to move back and forth is also arranged on the frame and below the second-order dough-conveying belt. According to the dough-rolling machine provided by the invention, through collecting rolled dough back and forth with the material-accumulating board, the rolled dough can be stacked layer bylayer and workers do not need to clear from time to time so as to improve the dough-discharging efficiency of the dough-rolling machine.

Owner:四川省巴中龙头食品有限公司

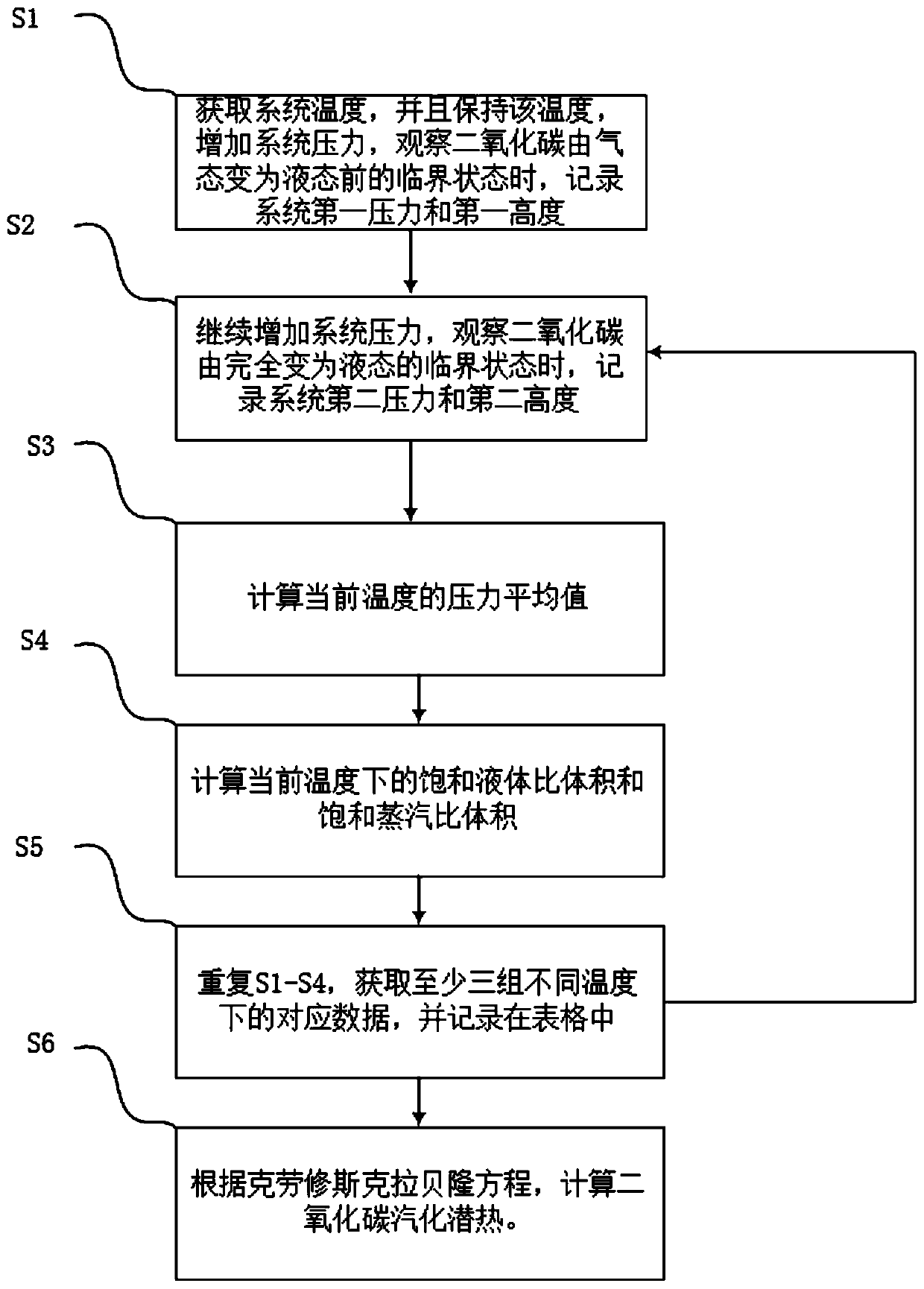

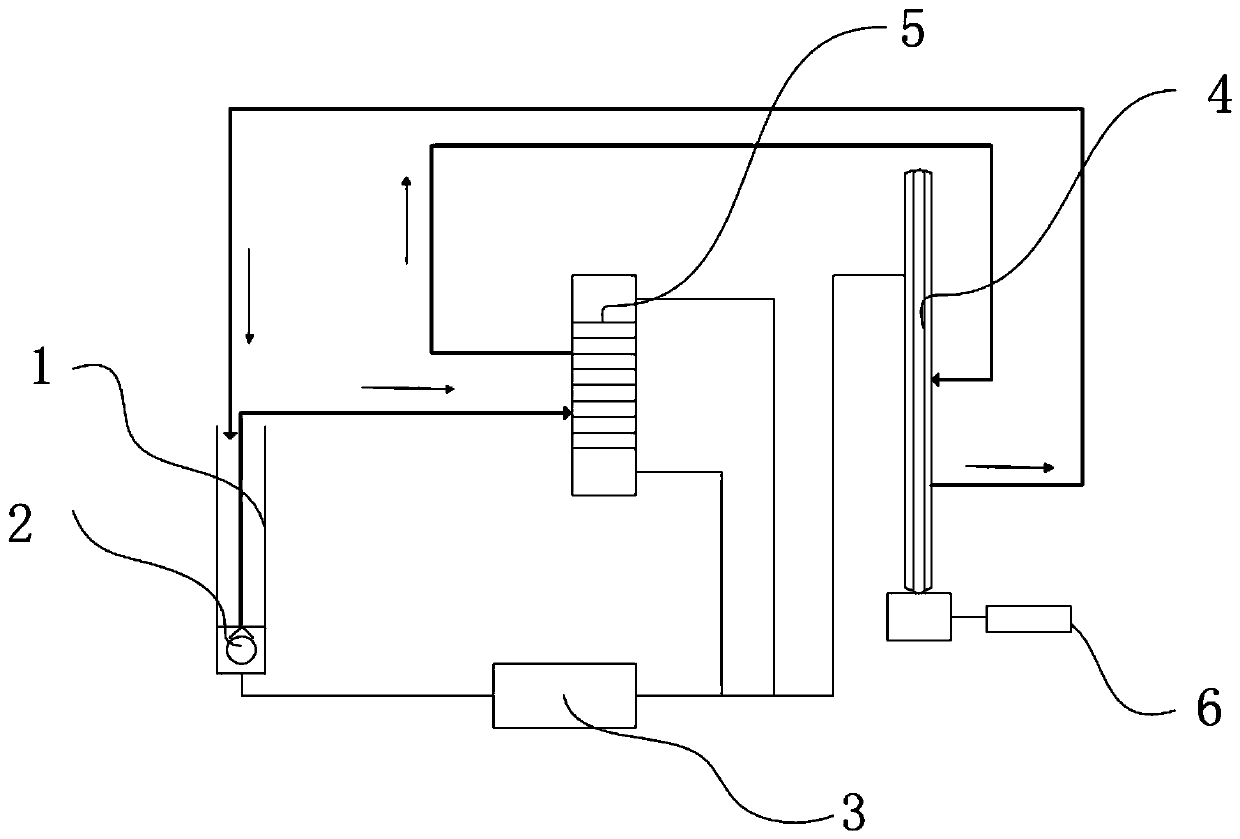

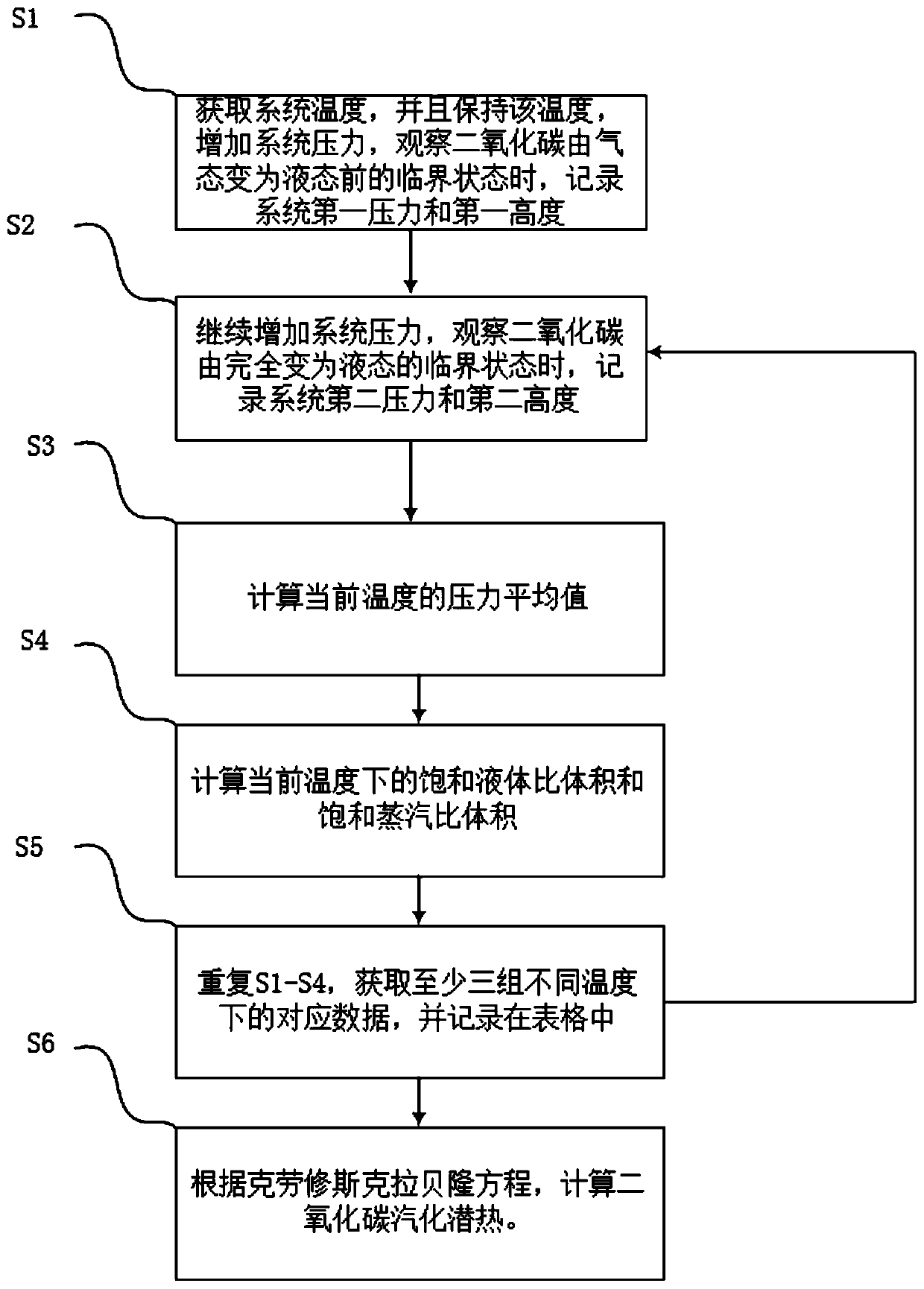

Method and system for measuring latent heat of vaporization of CO2 based on Clausius-Clapeyron equation

The invention discloses a method and system for measuring latent heat of vaporization of CO2 based on a Clausius-Clapeyron equation for teaching, and belongs to the technical field of experimental teaching. The method comprises the following steps of acquiring the current temperature of the system and maintaining the current temperature; increasing the system pressure, and when the CO2 is in a first critical state, recording the system first pressure P1 and the first CO2 height deltah1; continuing to increase the system pressure, when the CO2 is in a second critical state, recording the systemsecond pressure P2 and the second CO2 height deltah2; calculating a pressure average value at the current temperature, and according to a specific volume formula, calculating the saturated liquid specific volume V" and the saturated steam specific volume V' at the current temperature; repeating the above steps, and recording data into a table; and calculating the latent heat of vaporization of the CO2 according to the Clausius-Clapeyron equation. The method for measuring the measuring latent heat of vaporization of the CO2 based on the Clausius-Clapeyron equation provided by the invention realizes the rapid and accurate regulation of the temperature in the process of measuring the relationship between the pressure, the volume and the temperature of the CO2; and the measuring method is scientific and the operation is stable.

Owner:HARBIN INST OF TECH

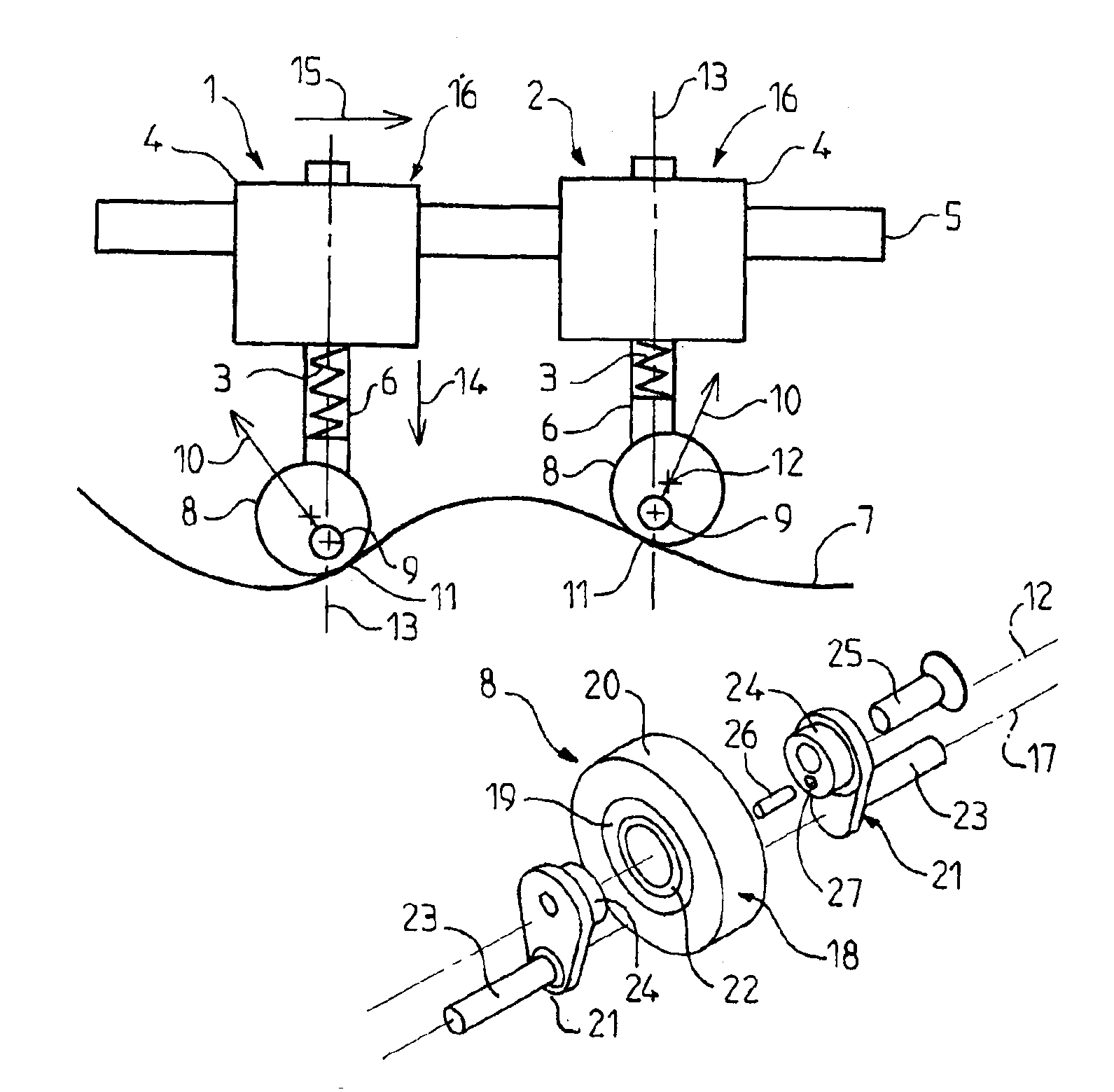

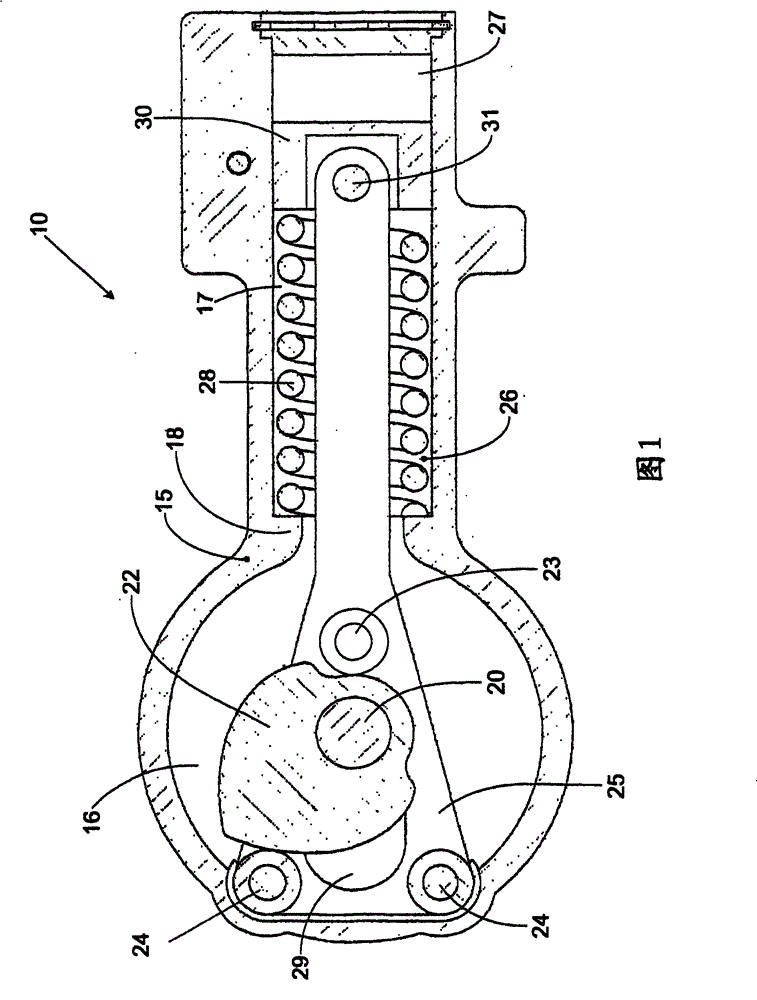

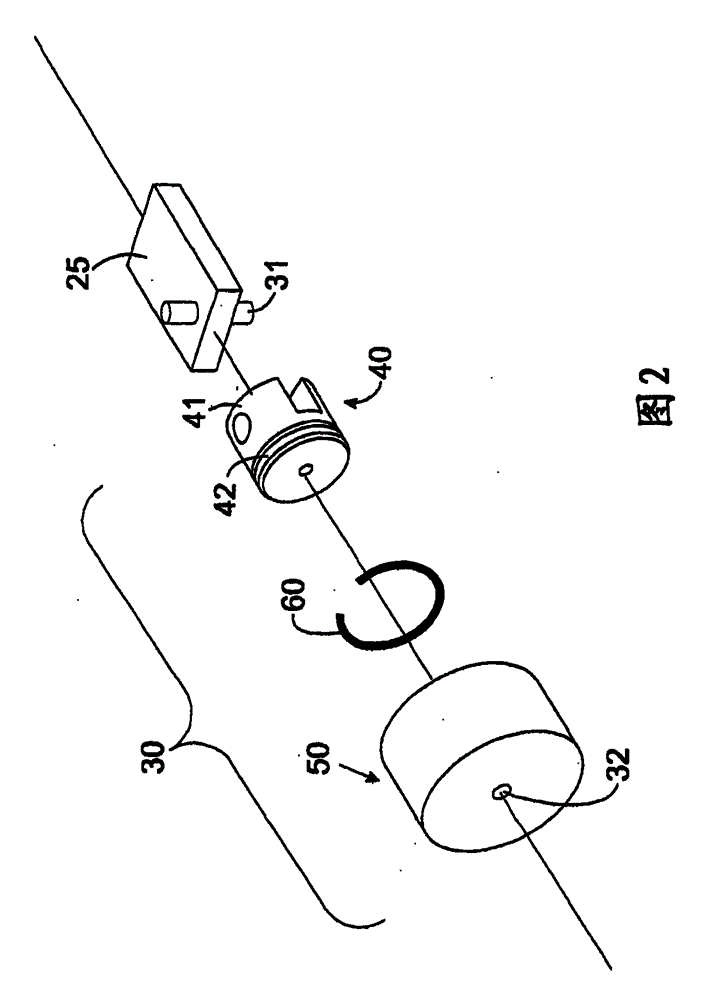

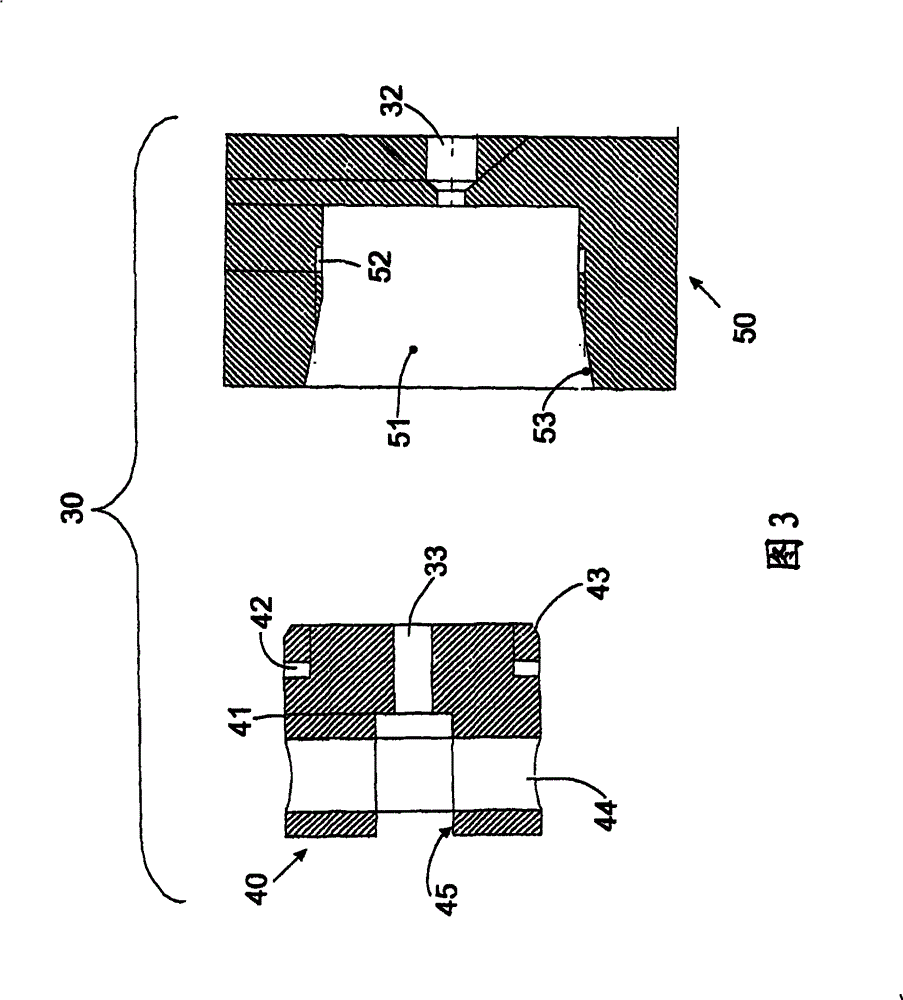

Door closer

InactiveCN101501290BSimple structureLow production costBuilding braking devicesWing accessoriesPressure.meanCoupling

The invention relates to a door closer (10) with a driving spindle (20) which is mounted in a manner such that it can be connected to and rotated by a door wing, wherein the driving spindle (20) is connected within a housing (15) to a lifting cam disc (22) which is arranged between at least one supporting means (23) and at least one pressure means (24), wherein the supporting means (23) and the pressure means (24) are located on a tab carriage (25), a piston (30) for damping is arranged in the housing (15), and the piston (30) divides the housing (15), which is filled with a pressure medium, into two pressure spaces (26, 27) and is connected to the tab carriage (25) by a spring (28) which interacts firstly with the piston (30) and secondly with the housing (15), wherein the piston (30) has a coupling element (40) and an outer element (50), and the coupling element (40) is mounted in an at least partially form-fitting manner in a receptacle (51) of the outer element (50), and the receptacle (51) and an outer surface (41) of the coupling element (40) have grooves (42, 52), wherein a snap ring (60) connects the coupling element (40) and the outer element (50) and is at least partially arranged in the two grooves (42, 52) in such a manner that it is mounted inaccessibly within the piston (30).

Owner:DORMA GMBH & CO KG

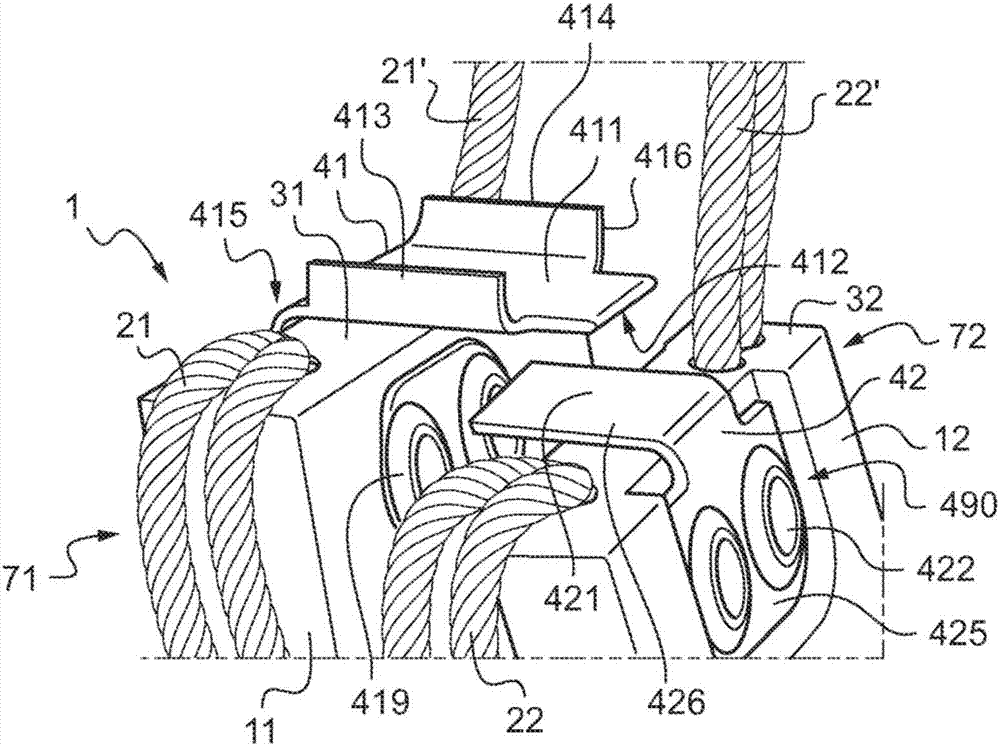

Twin brush with bearing plate

A brush device (1) comprising: a first (11) and a second (12) flange disposed side by side, each flange extending radially between a rubbing face intended to rub against a moveable element and a flange head (71, 72) intended to be connected electrically to another moveable element, a first plate (41) rigidly fixed to the first flange only and extending tangentially above the head of the second flange, in such a way as to transmit, when this first plate is loaded by pressure means, pressure forces on the second flange, a second plate (42), distinct from the first plate, rigidly fixed to the second flange only and extending tangentially above the head of the first flange in such a way as to bear on said first flange in the event of relative motion of the second flange with respect to the first flange towards the first moveable element.

Owner:MERSEN FRANCE AMIENS

Extrusion machine for automobile exhaust pipe pressure device

ActiveCN105234330BOvercome wear and tearSolve crackingForging/hammering/pressing machinesPressure.meanInterference fit

The invention relates to an extrusion machine for an automobile exhaust pipe pressure device, comprising an upper mold base, a lower mold base, an upper mold, an extrusion bottom plate, a lower mold, a load-bearing platform, a fixing plate and a thimble rod; the upper mold base and the upper The mold is fixed, the extrusion bottom plate is fixed on the load-bearing platform, the fixed plate is fixed on both sides of the load-bearing platform and the extrusion bottom plate, the lower mold base is located under the load-bearing platform, and the load-bearing platform has guide rod holes; the thimble rod is located in the middle of the lower mold base, and The lower mold base has guide rod holes, and the lower mold is fixedly connected to the extrusion base plate; the lower mold includes outer inserts, inner inserts and center inserts; the center insert is fixedly connected to the inner insert; the inner insert is fixedly set In the outer insert, the cross section of the outer insert is circular, the cross section of the inner insert is rectangular, the cross section of the central insert is rectangular, and the center part has a rectangular hollow. surplus cooperation. The invention solves the problems of easy cracking and short service life of the lower die, improves the service life of the lower die and increases working efficiency.

Owner:浙江铭锐金属制品股份有限公司

Closed-loop control method and system for both time and pressure in powder pressing process

ActiveCN104765283BImprove maneuverabilityClear control methodProgramme control in sequence/logic controllersPressure.meanLoop control

Owner:FOSHAN HENGLITAI MACHINERY

Pressure monitoring method for liquid level of vehicle-mounted liquefied natural gas tank

ActiveCN104896304BPromote repairContainer filling methodsContainer discharging methodsPressure.meanProper time

The invention discloses a pressure monitoring method for a liquid level of a vehicle-mounted liquefied natural gas tank. The method is characterized in that the liquefied natural gas tank is connected with an automobile bottom plate through an elastic support, and the gravity center of the liquefied natural gas tank coincides with the rigidity center of the elastic support; a pressure sensor collects a pressure signal of the elastic support, the proper time duration is selected, time average is carried out on collected total pressure, and a pressure average value is close to mass of a system; and a processor compares the mass with the mass of the system in the no-load process of the liquefied natural gas tank so as to obtain the stock mass of liquefied natural gas, and a liquid level value is determined. According to the method, when a vehicle is static, the liquid level of the liquefied natural gas is monitored, and when the vehicle runs, the liquid level can be monitored in real time, and failure maintenance is facilitated.

Owner:江苏省特种设备安全监督检验研究院张家港分院

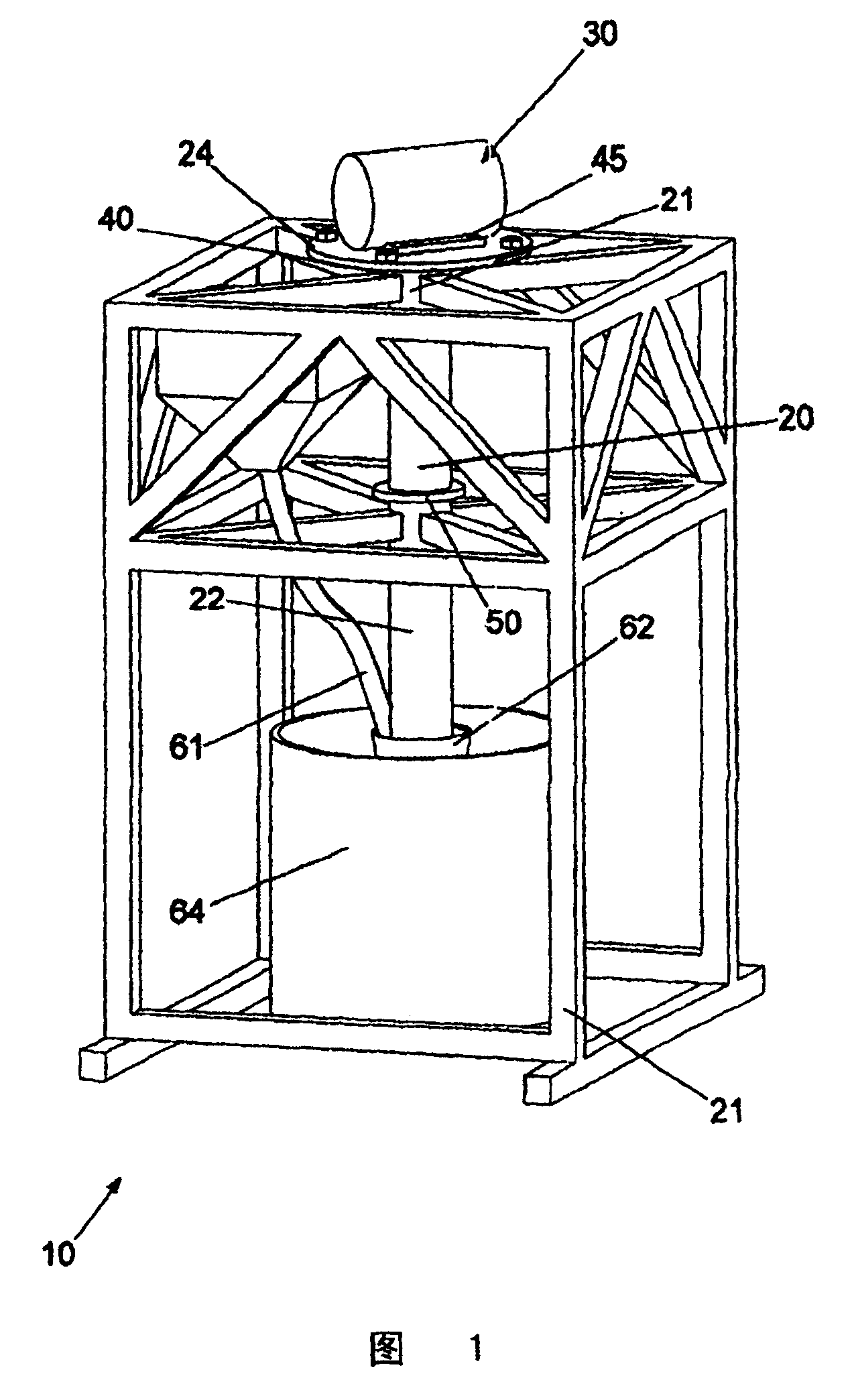

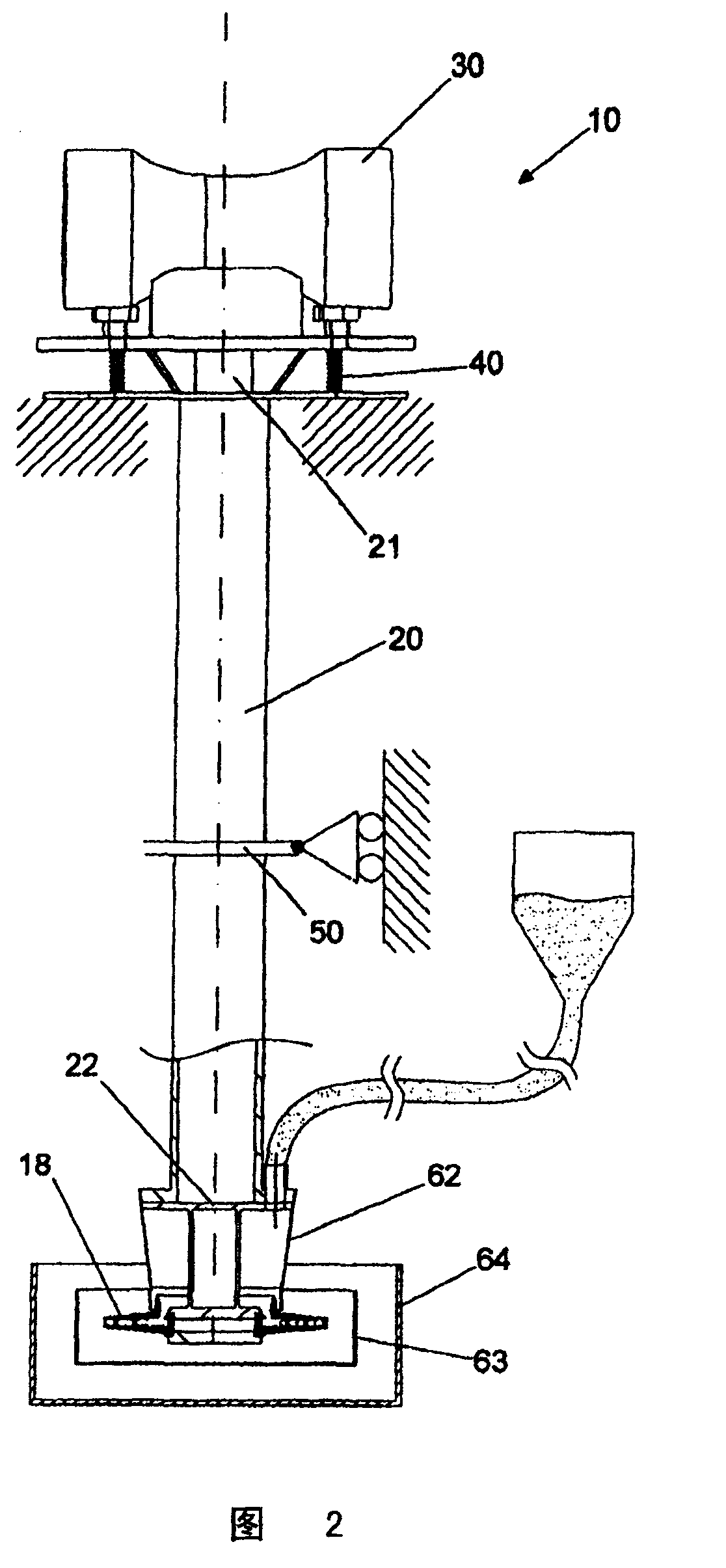

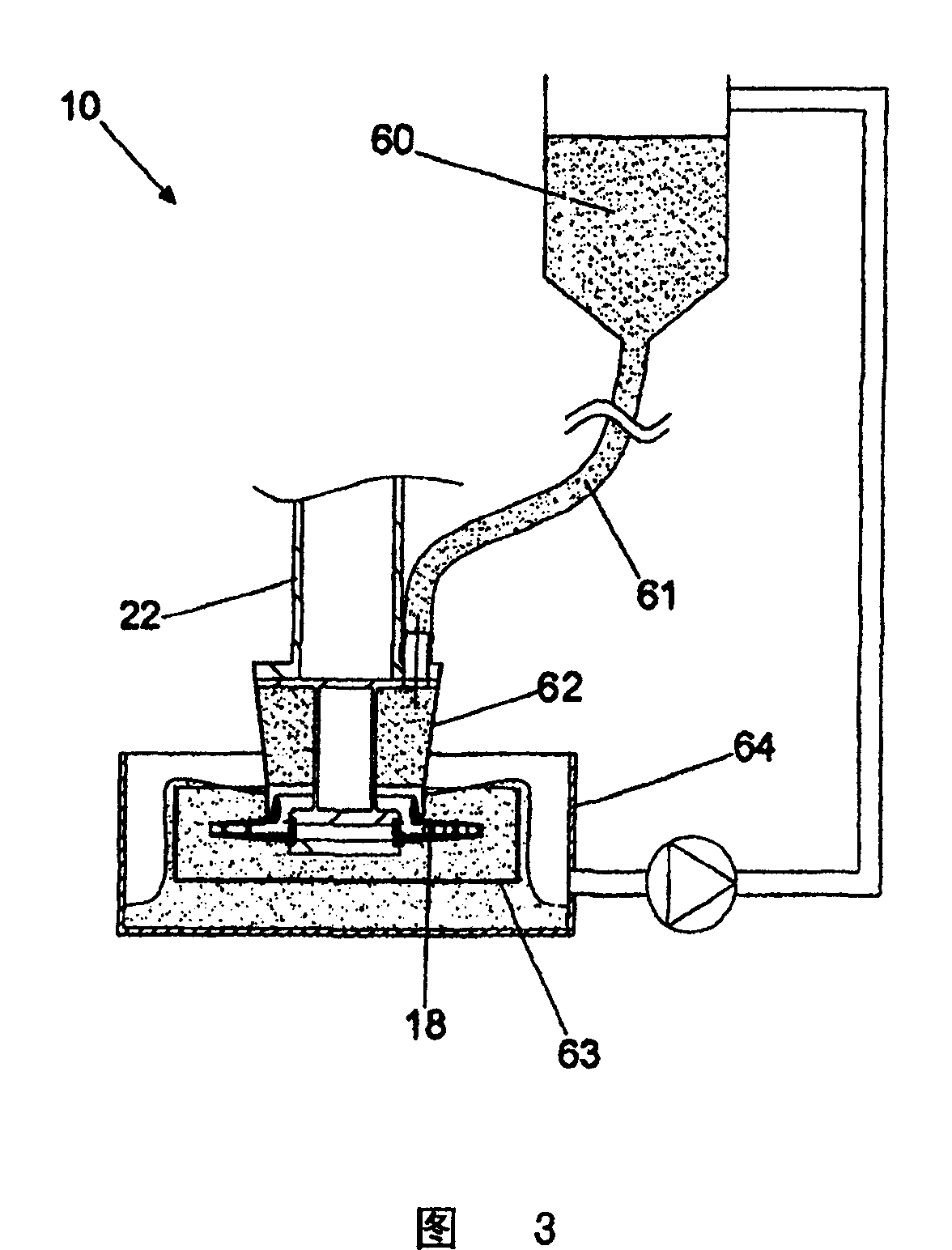

Vibrotumbling machine

The present invention provides a vibrotumbling machine (10) in particular for inner surfaces of a manufactured product (18) by means of an abrasive mix comprising several elements of not particularly hard material, abrasive particles, water and additives, the machine (10) comprises vibrating means (20,30) to cause a relative movement between the various elements of the abrasive mix and the manufactured product (18) in order to obtain a surface processing of the same, the vibrating means are associated with the manufactured product (18) to make it vibrate directly, thus obtaining the surface processing of the same. The machine (10) comprises pressure means for obtaining a forced flow of the abrasive mix with respect to the manufactured product (18), in particular for obtaining a forced flow inside at least one cavity of the manufactured product (18).

Owner:NUOVO PIGNONE TECH SRL

Method for regulating accumulator pressure

The invention proposes a method for regulating the accumulator pressure of a V-arranged internal combustion engine with different firing sequences, in which method the actual-accumulator pressure is calculated from the measured accumulator pressure, with the aid of the actual-accumulator The pressure and the theoretical rail pressure determine the control differential, and in this method a control variable for controlling the pressure regulator, in particular the suction restrictor, is calculated for regulating the rail pressure. The invention is characterized in that the actual - accumulator pressure is calculated from the measured accumulator pressure by means of an average value filter by obtaining the mean value of the accumulator pressure over a constant time below the limit speed (nLi) , and above the limiting speed (nLi) the mean value of the rail pressure over the working cycle of the internal combustion engine is obtained.

Owner:ROLLS ROYCE SOLUTIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com