Dough-rolling machine

A dough machine and dough feeding technology, applied in the directions of dough sheeter/roller/rolling pin, dough processing, structural components of mixing/kneading machinery, etc., can solve the problems of reduced dough efficiency and single structure, etc. To achieve the effect of improving the efficiency of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

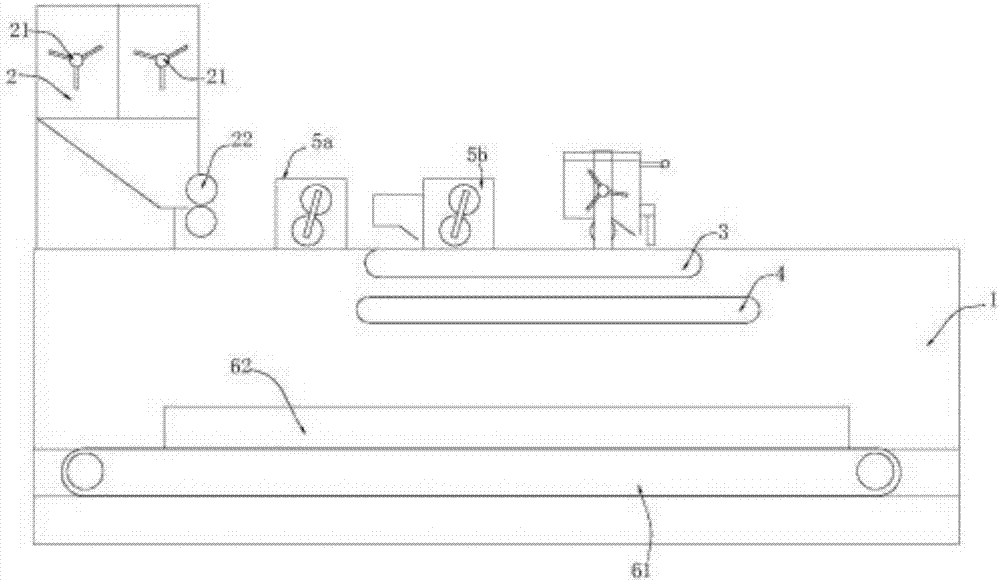

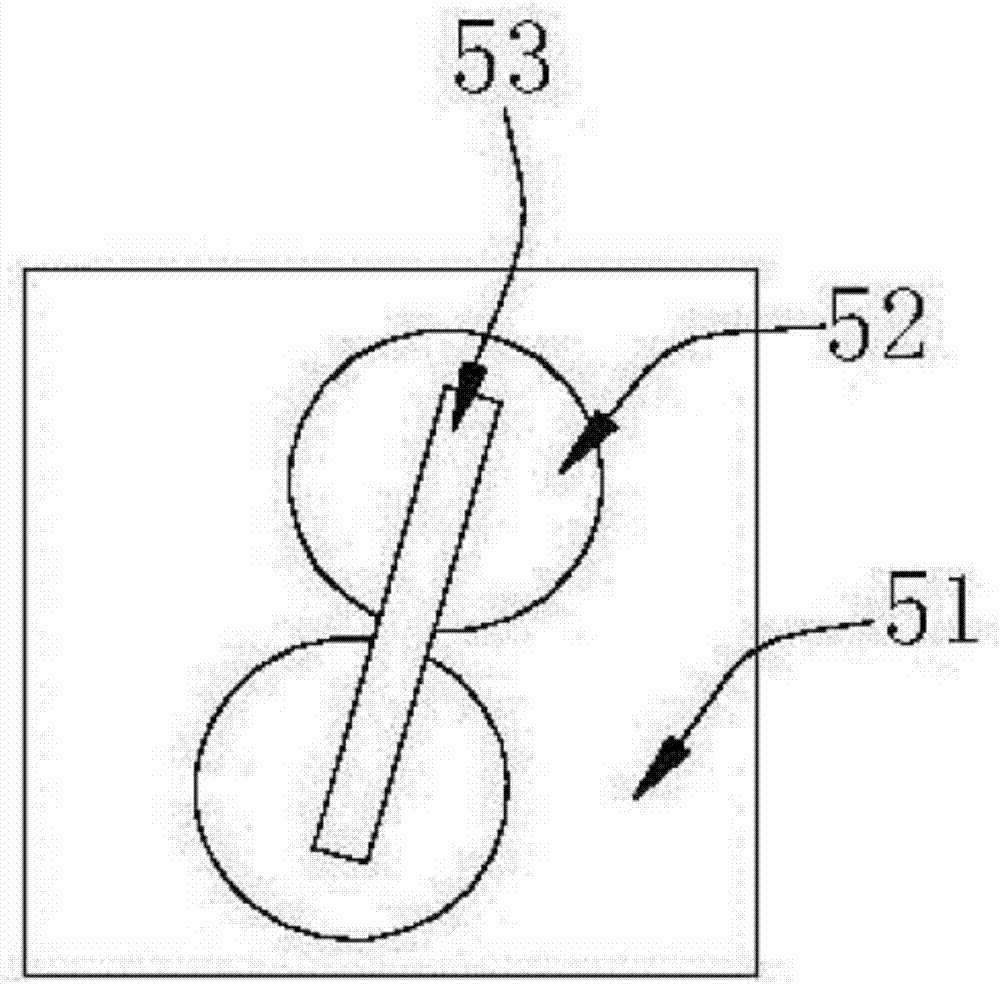

[0013] Such as Figure 1 ~ Figure 2 A kind of dough machine shown, comprises frame 1, and the feed funnel 2 that is arranged on frame 1 and the first stage sends dough belt 3. The inside of the feeding funnel 2 is provided with two stirring rods 21, and the stirring rods 21 stir the flour to achieve the effect of dough mixing and increase the toughness of the dough. The discharge end of the feeding funnel 2 is provided with a surface-exiting device, which includes two surface-exiting rollers 22 that turn in opposite directions; through the two surface-exiting rollers 22 that turn in opposite directions, the dough is pulled out. The first-level noodle-feeding belt 3 is on the frame 1 downstream of the dough-feeding device; the first auxiliary pressing device 5a is arranged between the first-level noodle-feeding belt 3 and the doug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com