Manual adjustable pressure cone friction wheel escape device

An escape device and friction wheel technology, which is applied in the field of high-rise escape, can solve the problems of unpopularity, limited application range, and inability of victims to escape in time, and achieve the effect of ingenious design and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

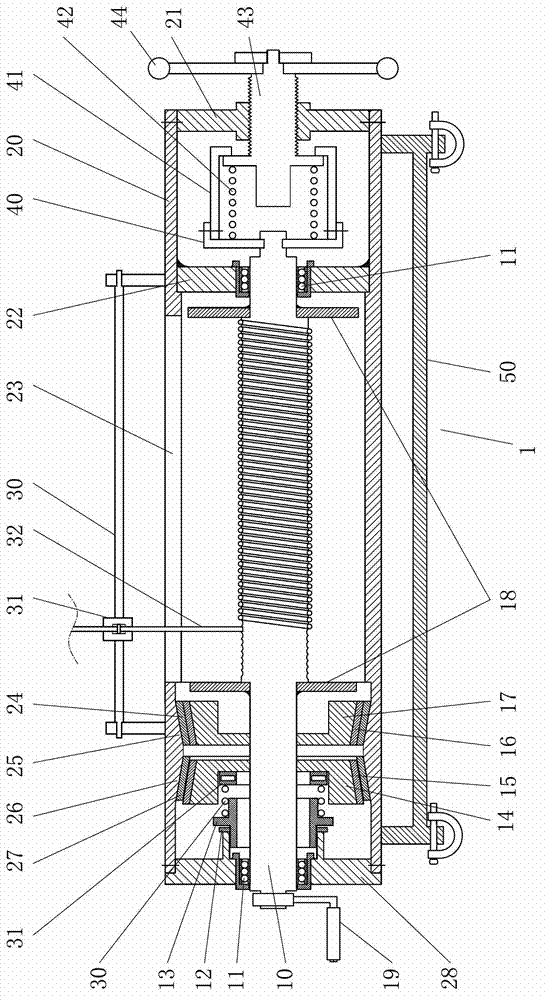

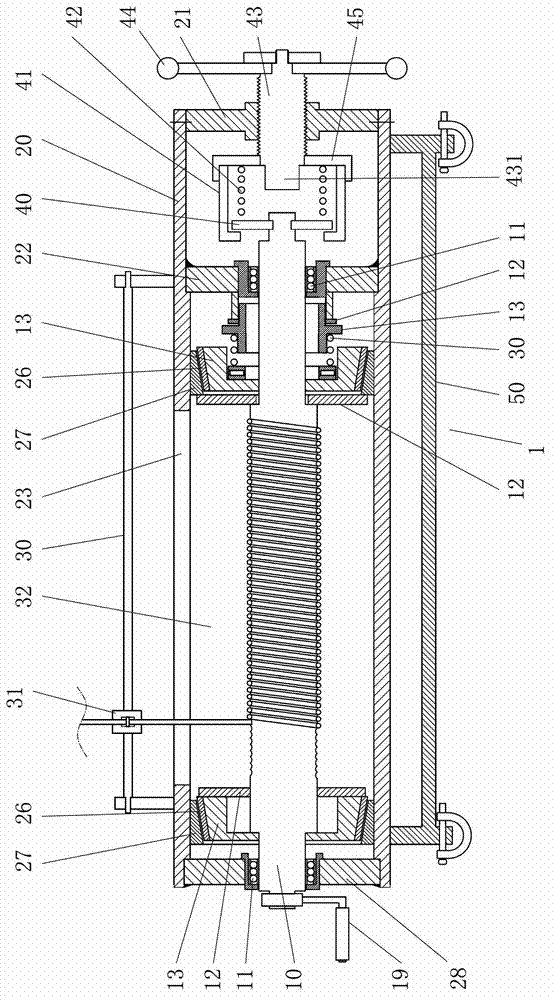

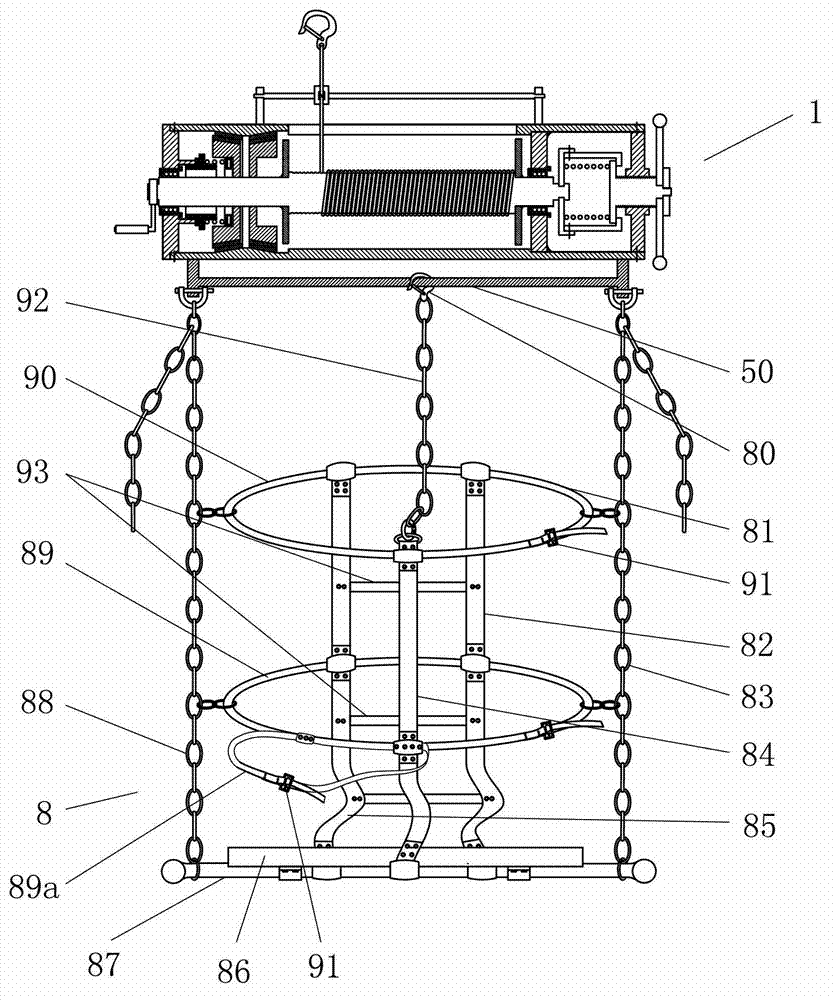

[0033] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -10:

[0034] The manual adjustable pressure conical friction wheel type escape device includes a rope releaser 1 and a seat basket 8 suspended on the lower side of the rope releaser. The specific structure of the rope releaser 1 is: There is a through shaft 10 axially slidably supported at both ends of the cylinder. The middle part of the through shaft 10 is wound sequentially with one end protruding from the cylinder 20 and a rope 32 fixed at the other end on the through shaft 10. On the inner wall of the cylinder 20 Ring-shaped outer brake discs (25, 26) are fixedly installed on the top, and the conical inner brake discs (14, 17) that cooperate with the outer brake discs (25, 26) for braking are fixed on the through shaft 10, and the cylinder body 20 A pre-braking force adjustment device is provided between the through shaft 10, a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com