Plant fiber-stalk separator

A plant fiber and separator technology, applied in the direction of raw material separation, fiber raw material processing, fine split raw material pretreatment, etc., can solve the problems of inconvenient use, affecting the quality of hemp fiber, easy to hurt users, etc., to avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

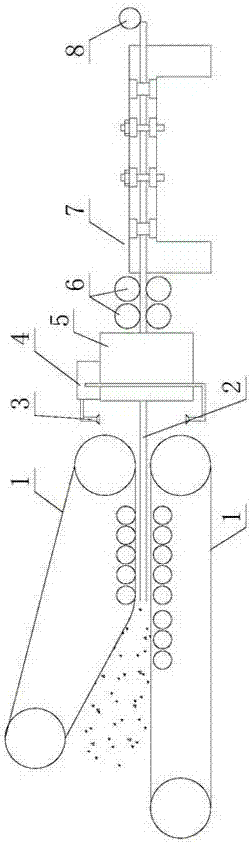

[0019] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0020] In order to achieve the above object, the present invention adopts the following technical solutions: a plant fiber stalk separator, which sequentially includes an initial pressure device 1, a softening device 4, a steam device 5, a recompression device 6, a vibrating device 7, and a collecting device according to the processing sequence. 8; the initial pressing device 1 is used to initially crush the plant stalk 2, and the initially crushed plant stalk 2 enters the softening device 4 together with the plant bast fiber; the softening device 4 is provided with two The softener nozzle 3, two softener nozzles 3 are arranged between the initial pressure device 1 and the steam device 5, the outlet of the initial pressure device 1 and the feed port of the steam device 5 are located b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com