Twin brush with bearing plate

A brush device and electric power technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of limited amplitude, separation of sheet parts, etc., and achieve the effect of high-quality contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

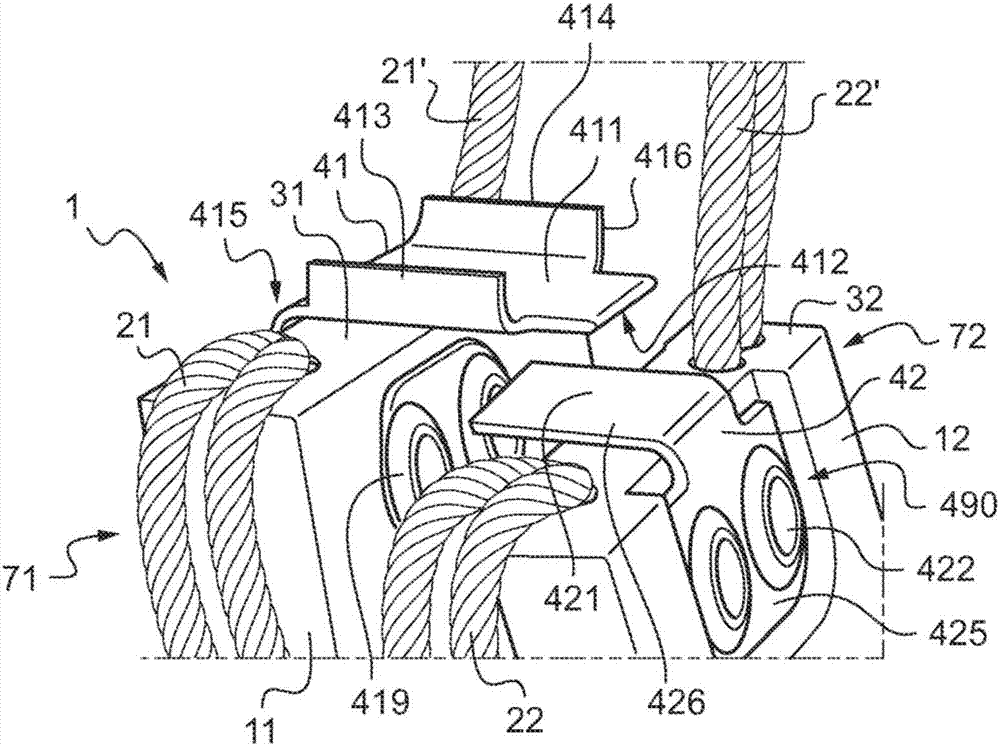

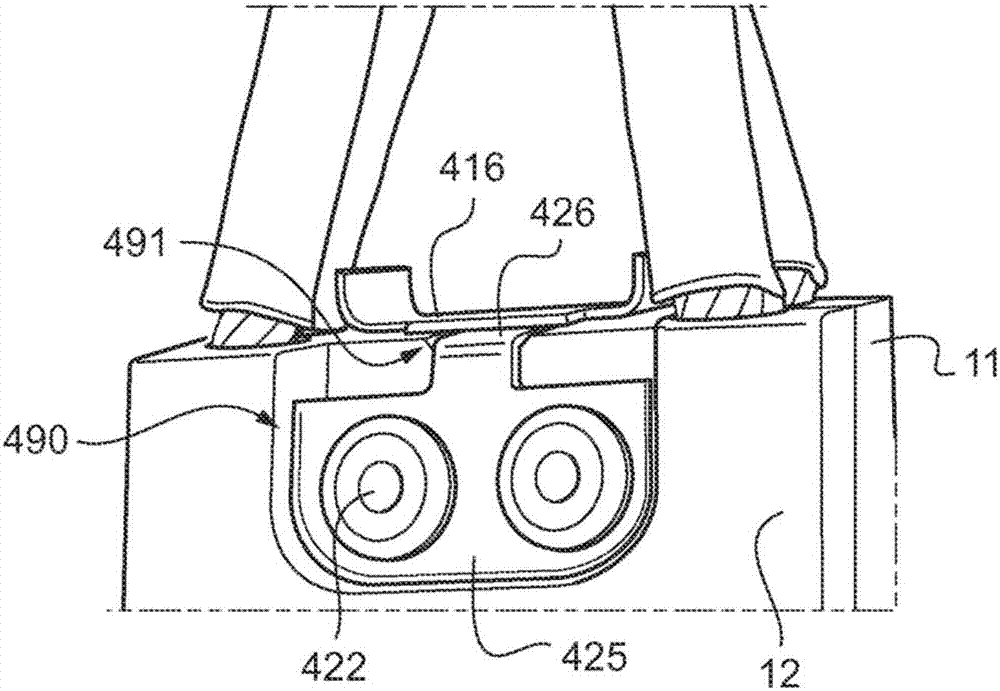

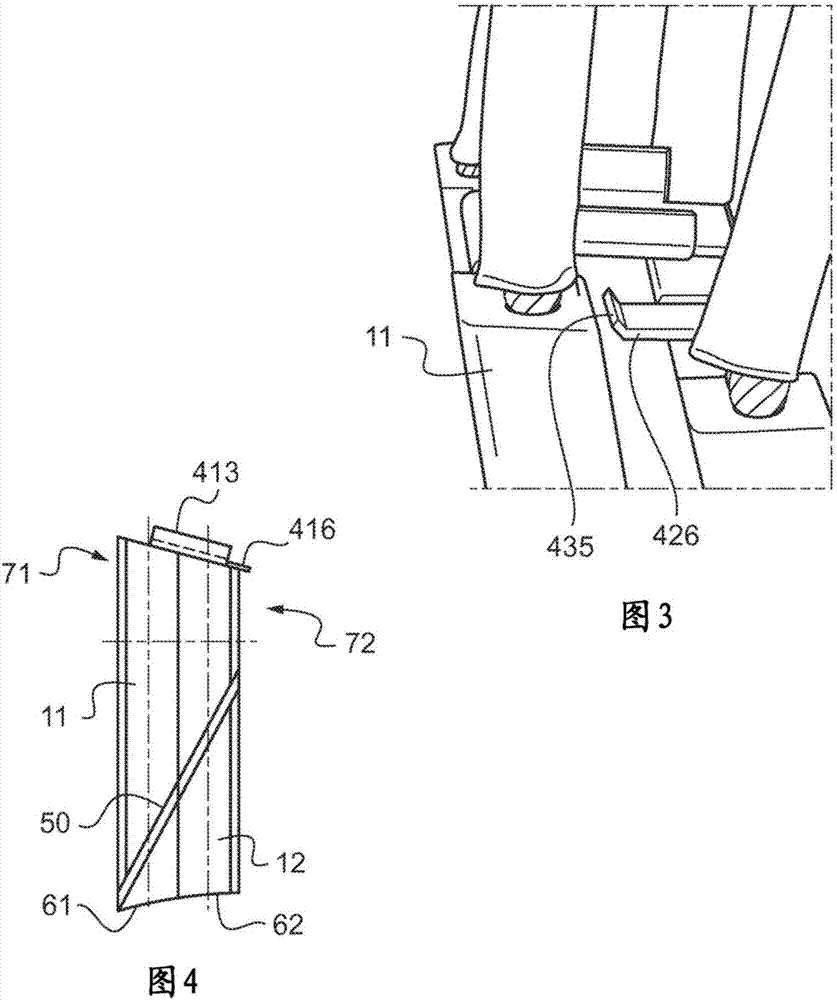

[0064] The illustrated brush arrangement is designed as a brush starter-generator for aviation applications.

[0065] Consequently, these brush arrangements, also called brushes, are subject to relatively high vibrations and, since the motor can be integral or enclosed, relatively high temperatures. These vibrations can easily cause other items to damage the motor. For example, there is a risk of detaching the brushes.

[0066] Advantageously, it can be considered to limit this risk by riveting the cable to the sheet.

[0067] There is also a risk of damaging the cable, or even the insulating sheath.

[0068] In addition, the front faces of the brushes, or sometimes even the side faces of the brushes, may wear due to friction of the brushes in the brush holder.

[0069] Finally, the contact surfaces of the brushes and the edges of the brushes are susceptible to relatively high electrical wear due to arcing caused by the brushes jumping on the commutator, especially when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com