Vibrotumbling machine

A vibration device and kinetic energy technology, which is applied to surface polishing machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of uneven grinding, disappearance of the surface, and non-flowing abrasive mixture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

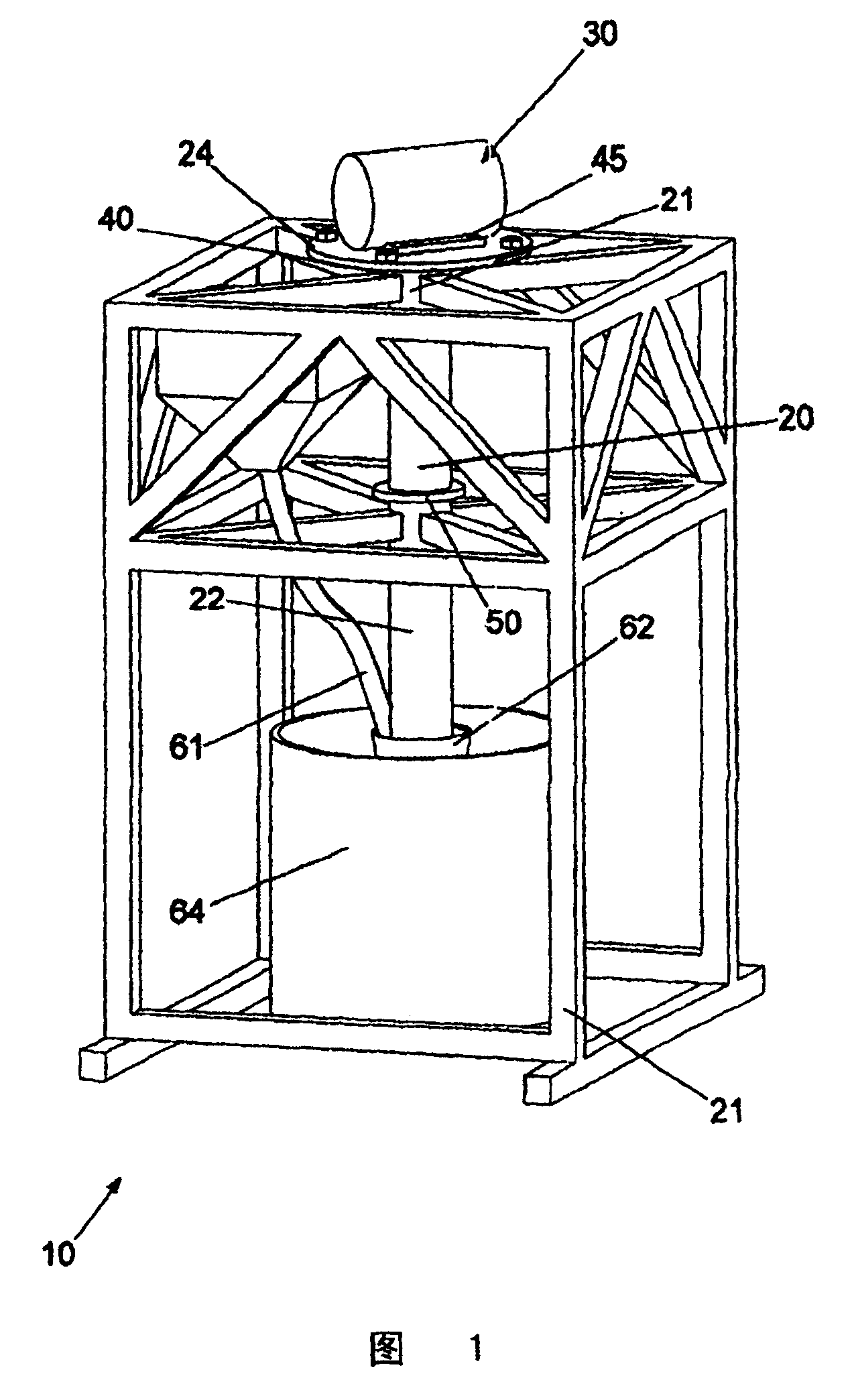

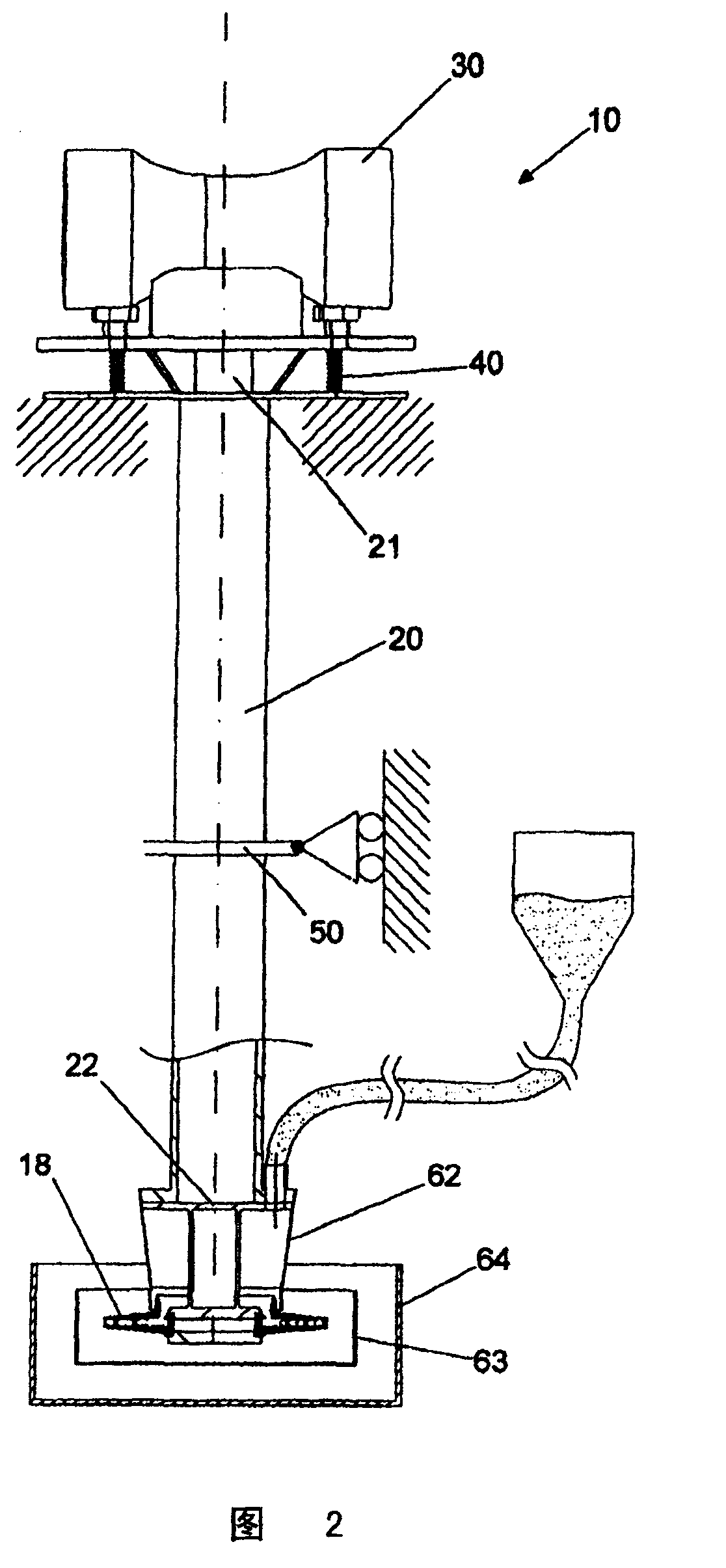

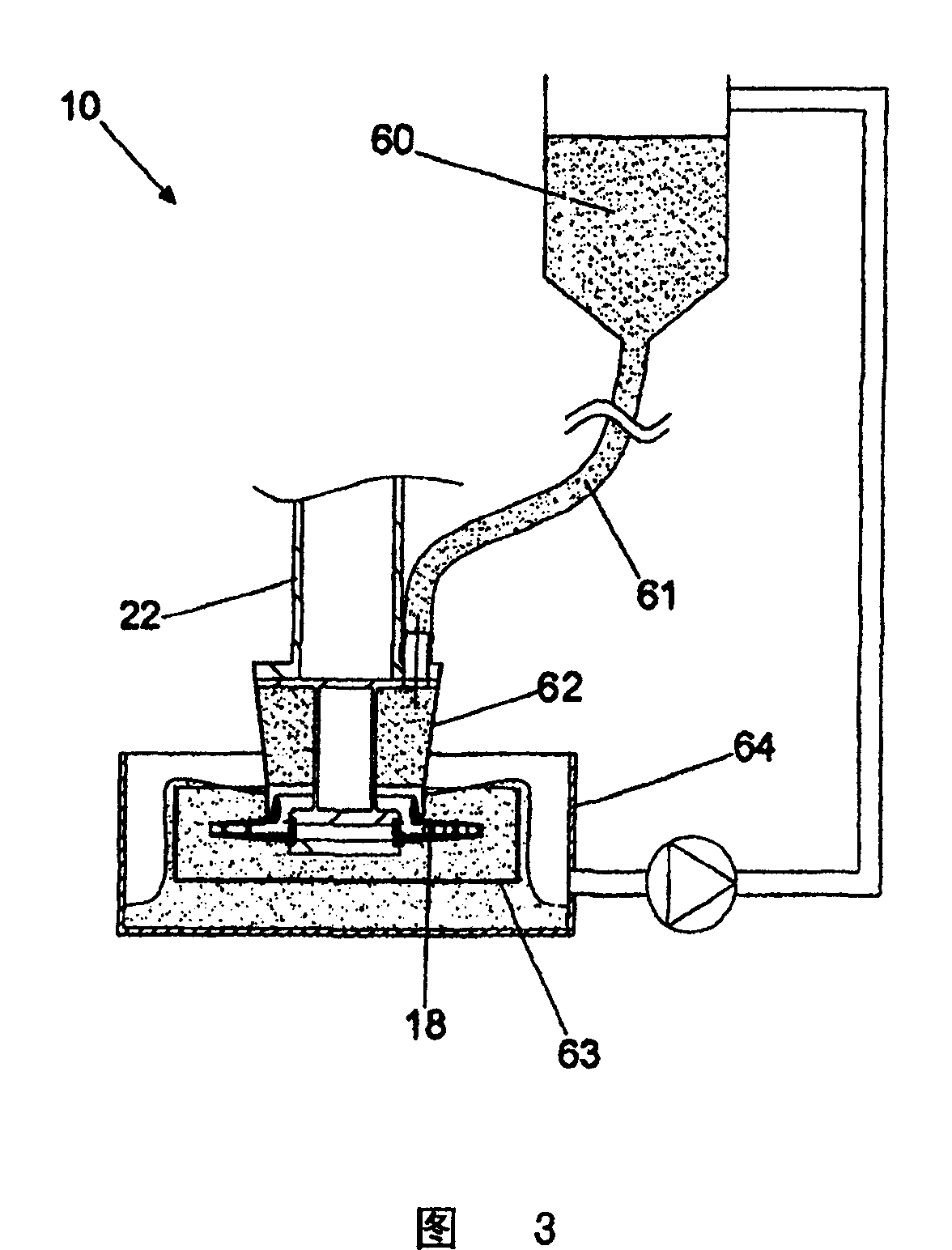

[0035] Referring to these figures, there is shown a machine 10 for vibratory tumbling of an article 18, such as a rotor, through an abrasive mixture comprising a variety of material components that are not particularly hard, abrasive particles, water, and additives.

[0036] The machine 10 includes vibratory means for inducing relative motion between the abrasive mixture and the article 18 for processing thereof.

[0037] Said vibrating means are associated with said article 18 so as to directly vibrate it and effect its treatment.

[0038] The vibrating device is preferably associated with the article 18 via a rod 20 or the vibrating device is directly connected to the article 18 .

[0039] Said machine 10 also comprises pressure means for obtaining a pressurized flow of said abrasive mixture relative to said article 18, in particular for obtaining a pressure of a pressurized flow inside at least one cavity of said article 18 device.

[0040] The pressure means preferably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com