Patents

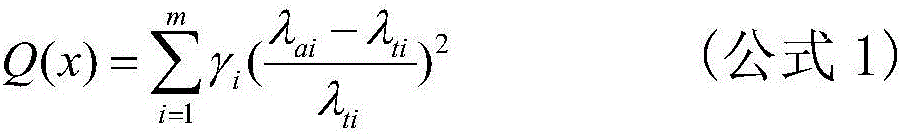

Literature

51 results about "Beam finite elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The finite element solution of a beam element is a cubic polynomial while actual beam solution is of the 4 th order. The finite element model gives a stiffer beam. It actually forces the beam in to specific modes of deflection as per the shape functions and hence gives a more stiffer beams.

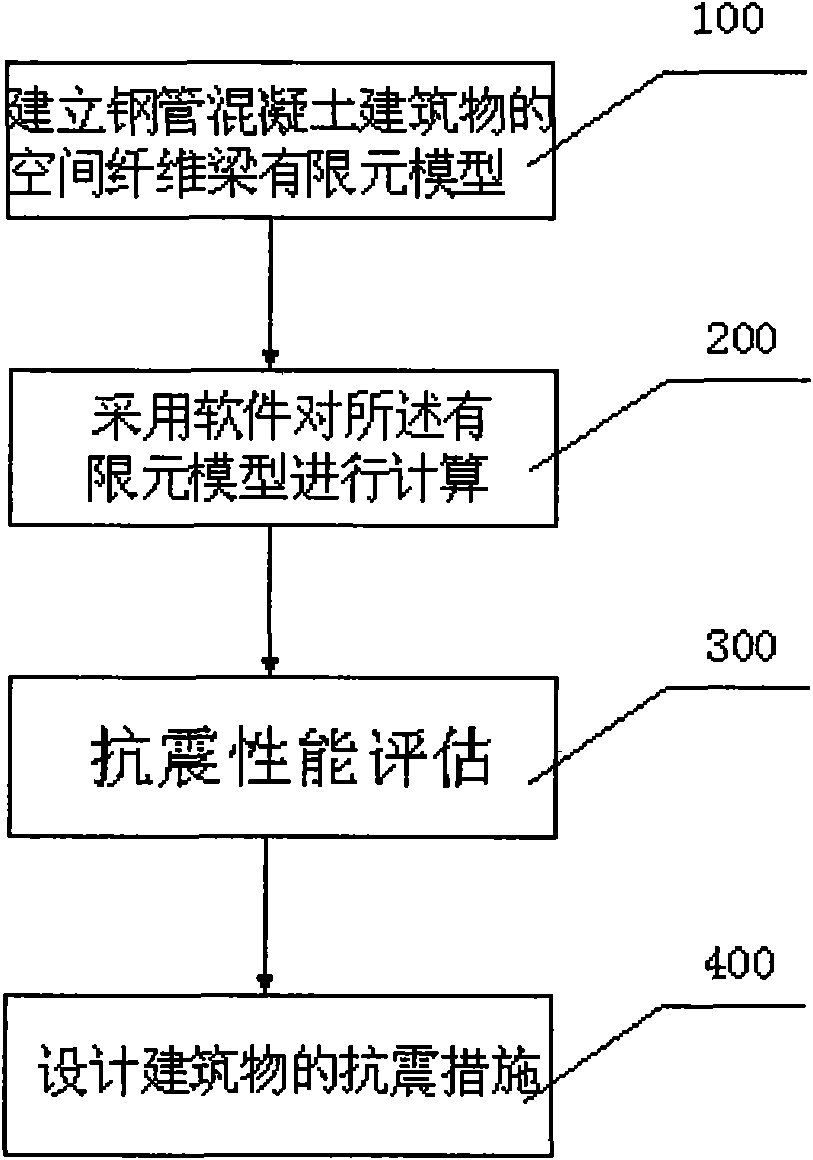

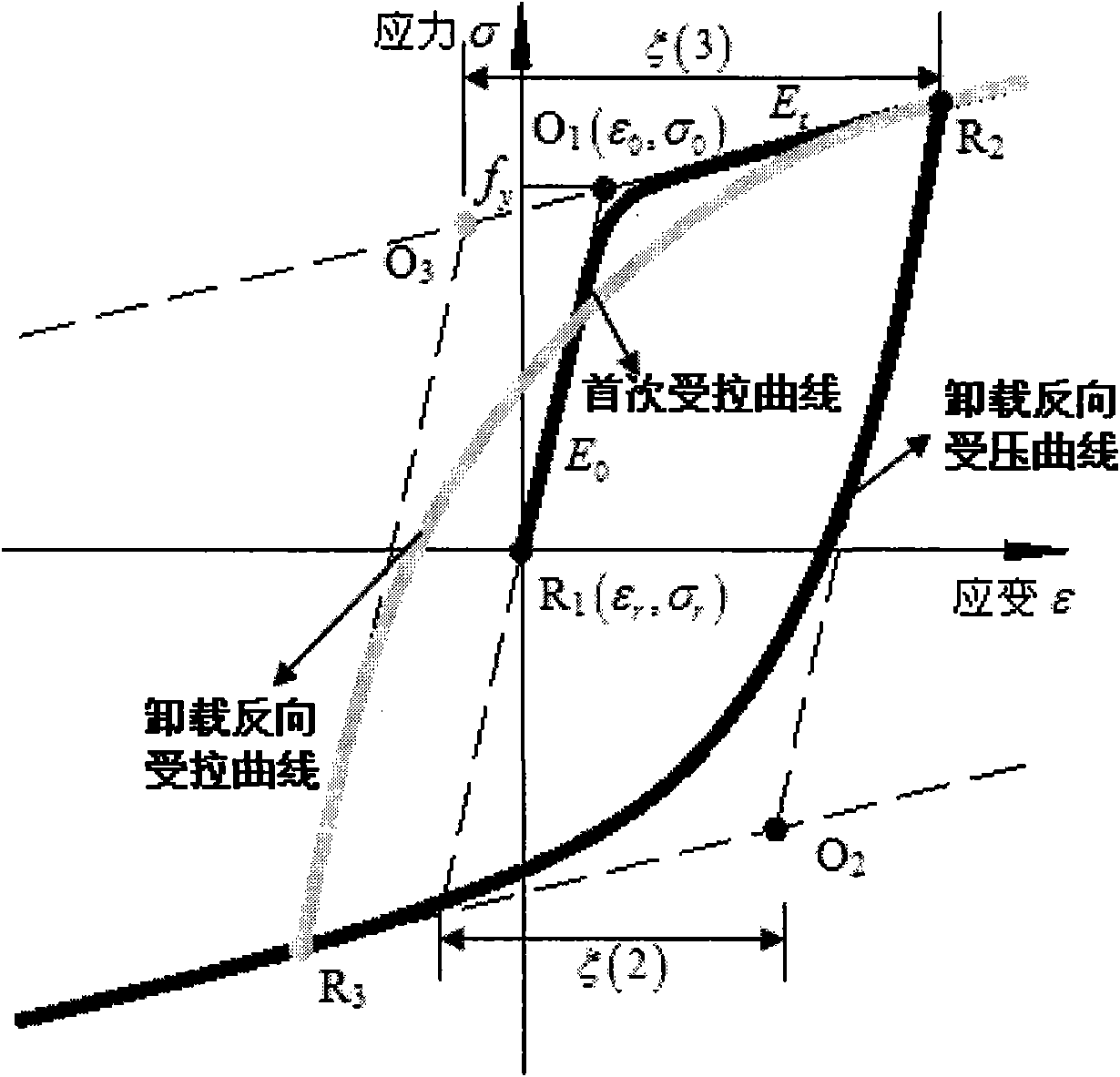

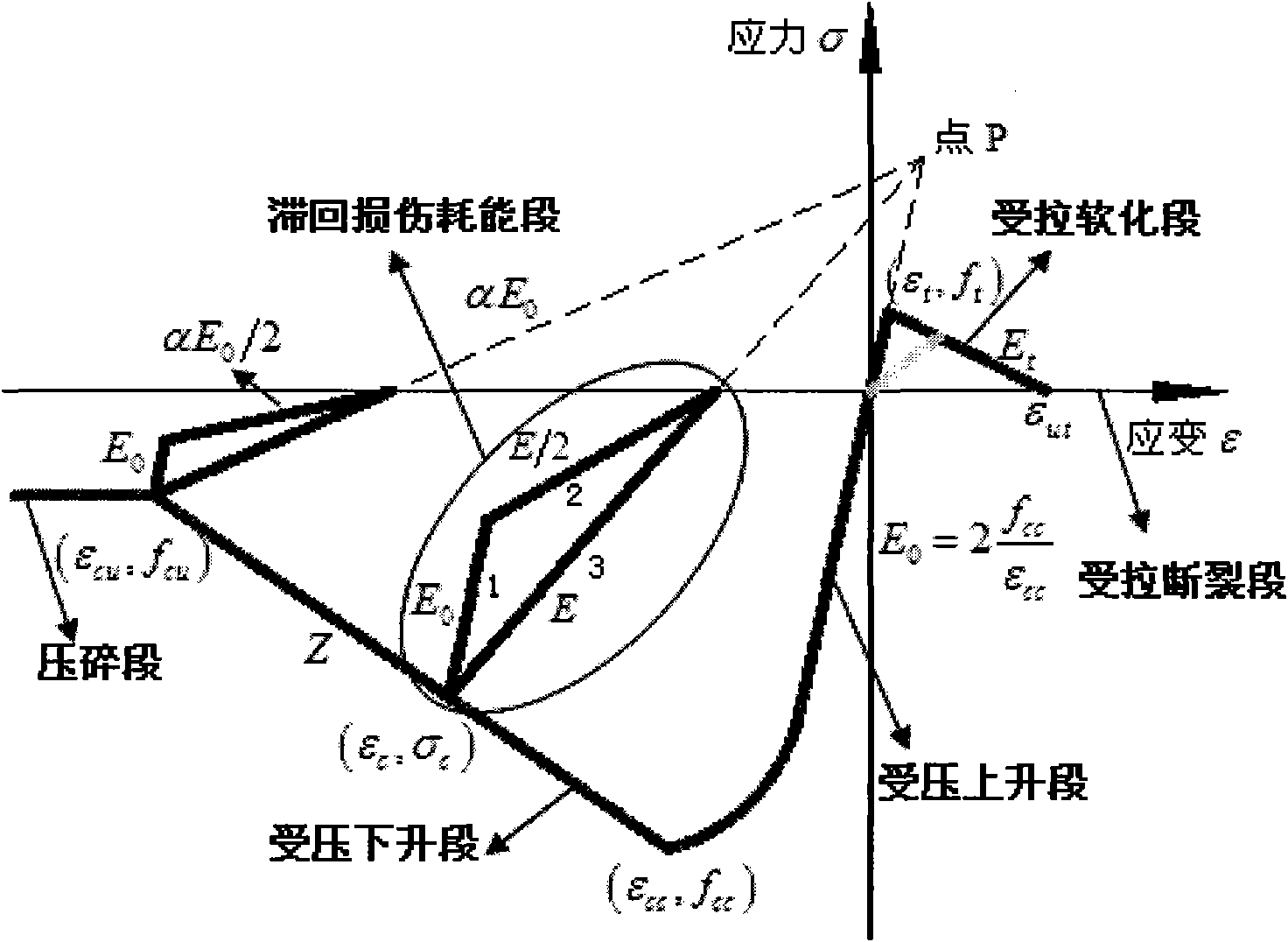

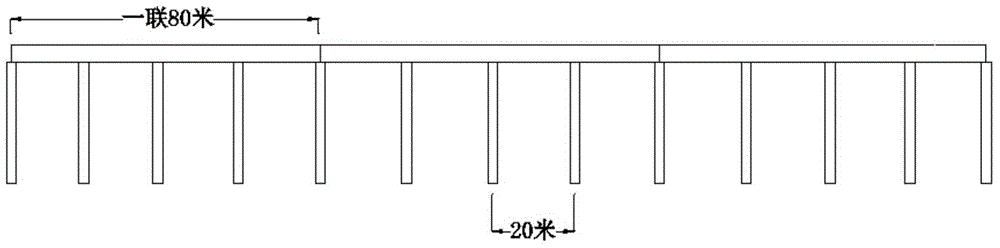

Evaluation method of earthquake resistant performance of steel tube concrete building and application

The invention relates to an evaluation method of earthquake resistant performance of a steel tube concrete building. A building support component is formed by steel tube concrete. The evaluation method comprises the following steps of establishing a space fiber beam finite element model of the steel tube concrete building, developing an analysis method suitable for a fiber beam, considering that the confinement effect and the material characteristic of the elasto-plasticity under earthquake cyclic loading damage a constitutive model and a corresponding subprogram, calculating the finite element model by adopting a software and combining with the material subprogram, evaluating the earthquake resistant performance, and designing the earthquake resistant measure of the building. In the provided evaluation method of the earthquake resistant performance of the steel tube concrete building, the earthquake resistant performance of the building is evaluated on the basis of the maximum inter-story displacement angle limit value required by a steel tube concrete structure by establishing the space fiber beam finite element model of the steel tube concrete building, developing the analysis method suitable for the fiber beam, considering that the confinement effect and the material characteristic of the elasto-plasticity under earthquake cyclic loading damage the constitutive model, calculating the finite element model by adopting the software and obtaining the maximum inter-story displacement angle of the building, and building earthquake resistant measures are planed according to the evaluation result of the earthquake resistant performance of the building.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Bridge finite element model modifying method

InactiveCN104133959AImprove correction efficiencyAvoid the drawbacks of repeated iterative calculations that take too longSpecial data processing applicationsTest designUniform design

The invention discloses a bridge finite element model modifying method, which comprises the following steps that: 1, an entity finite element model of a whole bridge is built by universal finite element calculation software ANSYS; and 2, the entity finite element model of the whole bridge is subjected to primary modification by a uniform design method. The bridge finite element model modifying method has the following advantages that the uniform design method is used as a test optimization design method with obvious superiority, and the application of the uniform design method to the bridge structure finite element model modification is feasible; on the basis of the uniform design method, a more correct result can be found in a very short time by the uniform design method in the efficiency aspect, and the bridge large-scale finite element model modification efficiency is improved; a response surface method is used as a test design and mathematical statistics combined mathematical analysis method, and the application of the response surface method to the finite element model modification of a large-scale complicated bridge structure is feasible; and higher modification efficiency and higher modification precision can be ensured at the same time.

Owner:NORTHEASTERN UNIV LIAONING

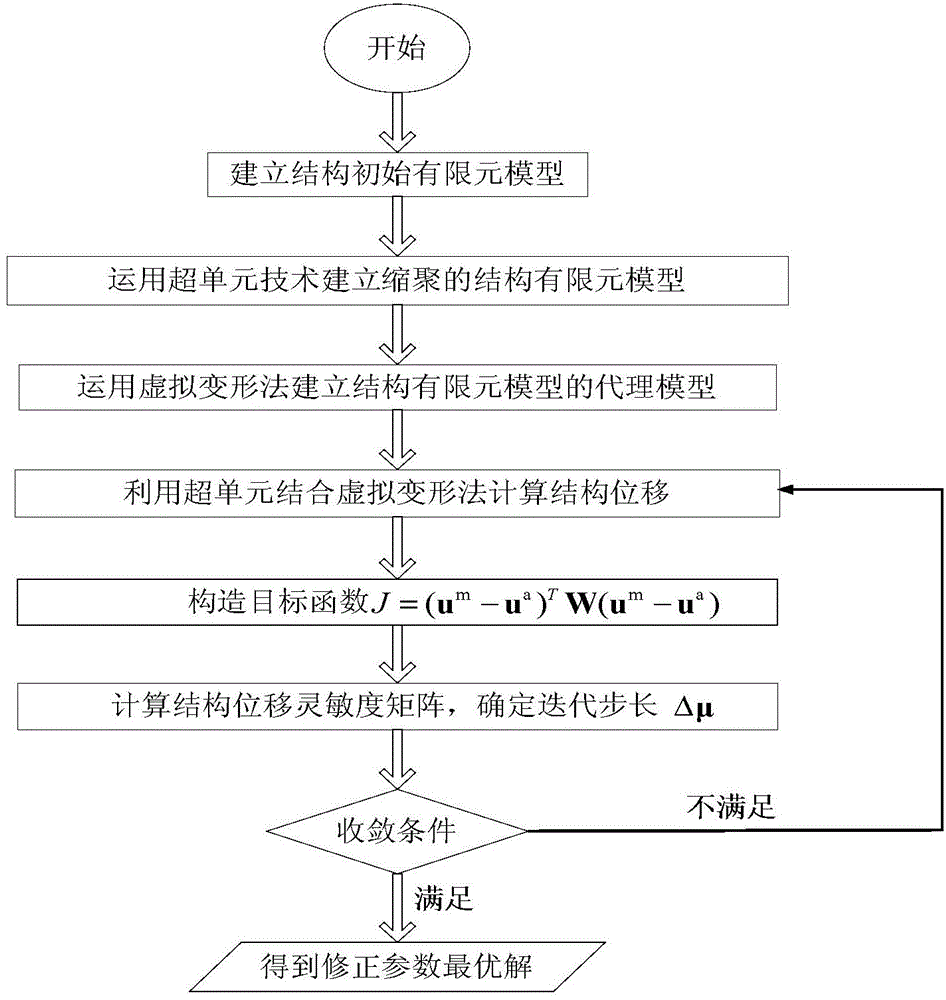

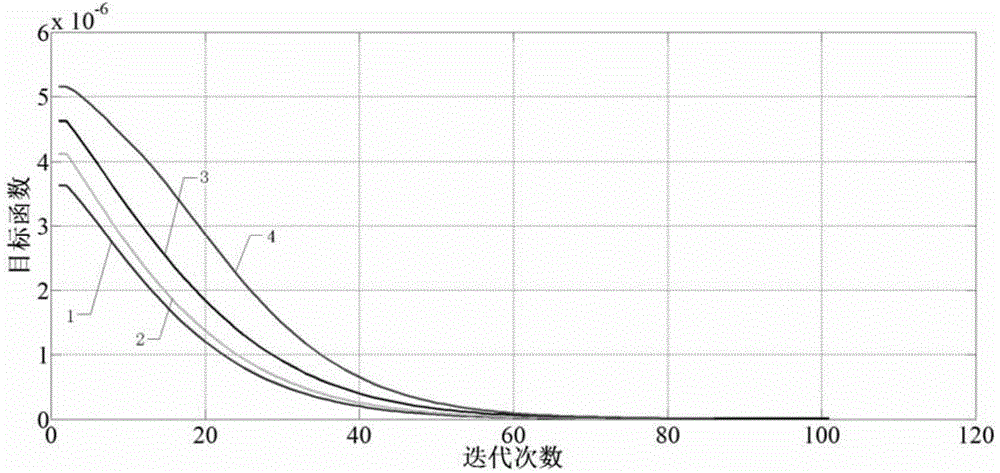

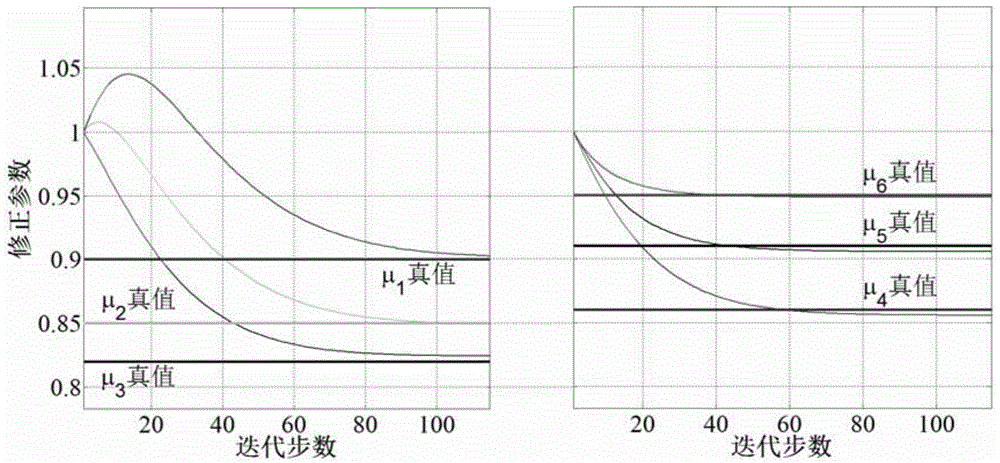

Bridge static force finite element model correcting method based on super-element combination virtual deformation method

ActiveCN104091033ASmall scaleGuaranteed calculation accuracySpecial data processing applicationsElement modelSuper element

The invention relates to a finite element correcting method for an actual operation bridge structure of static force information, in particular to a bridge static force finite element model correcting method based on a super-element combination virtual deformation method to solve the problems that the correcting efficiency of a finite element model of an existing bridge structure is low, and the requirement for correcting a large and complex bridge finite element model cannot be met. The correcting method specifically comprises the steps that shrinking is carried out on an initial finite element model of the bridge structure through the super-element technology, and the shrunk bridge structure finite element model is obtained; an agent model of the bridge structure finite element model is established through the combination with the virtual deformation method; the bridge structure finite element model based on the static force information is corrected. The method is used for correcting the actual operation bridge structure finite element model based on static force information.

Owner:HARBIN INST OF TECH

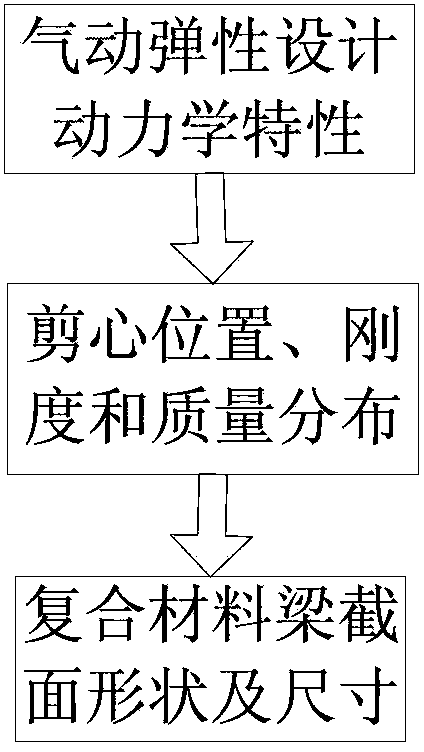

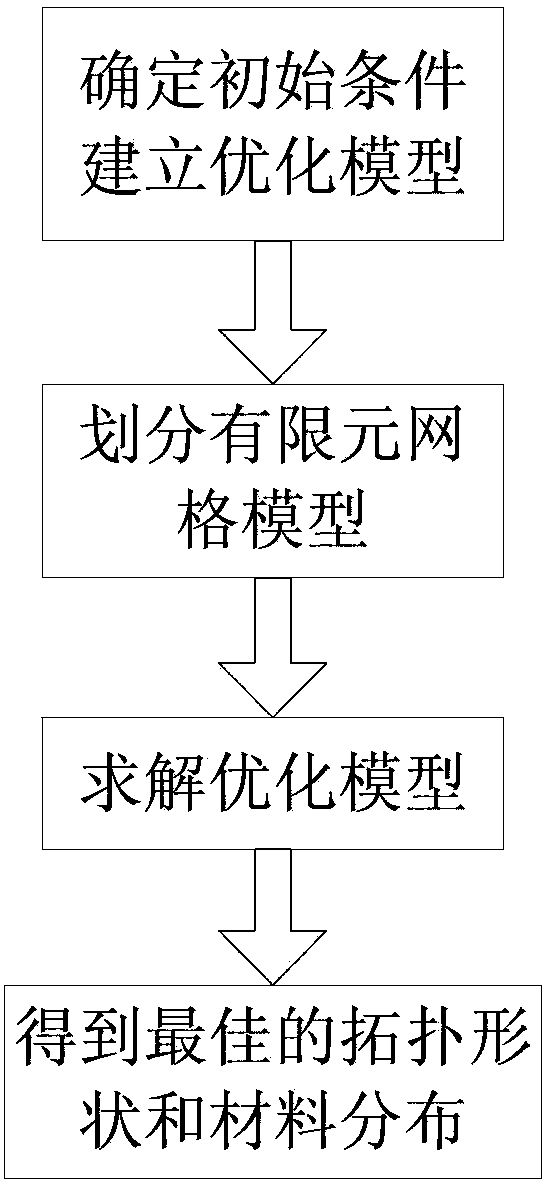

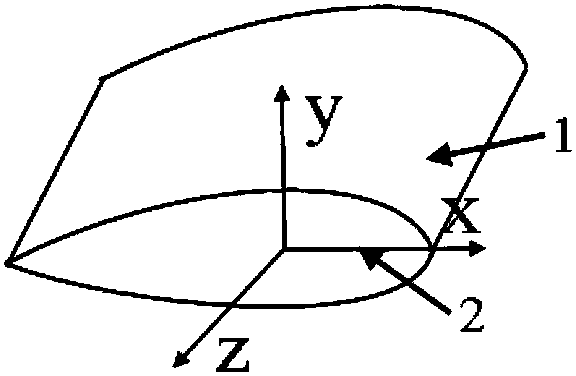

Method for designing composite material beam for helicopter and fixed-wing aircraft

ActiveCN103366070AOptimal distribution lawImprove performanceSpecial data processing applicationsLinear programming algorithmElement model

The invention discloses a method for designing a composite material beam for a helicopter and a fixed-wing aircraft, and belongs to the field of designing an aircraft structure. The method comprises the steps of firstly establishing a composite material beam optimal design model according to the general design performance of the helicopter or the fixed-wing aircraft, wherein a design variable is a volume fraction of each material at each unit; then establishing a composite material beam profile finite element model by finite element software; optimally designing the composite material beam profile finite element model by the composite material beam optimal design model through a volume fraction filtering method or a sensitivity filtering method, and updating the volume fraction based on a sequential linear programming algorithm to obtain material distribution rules of the beam profiles; and finally obtaining a topological structure of the beam profile according to the material distribution rules. The method for designing the composite material beam profiles can be applied to profile design of various helicopter rotors and fixed-wing aircraft wings.

Owner:BEIHANG UNIV

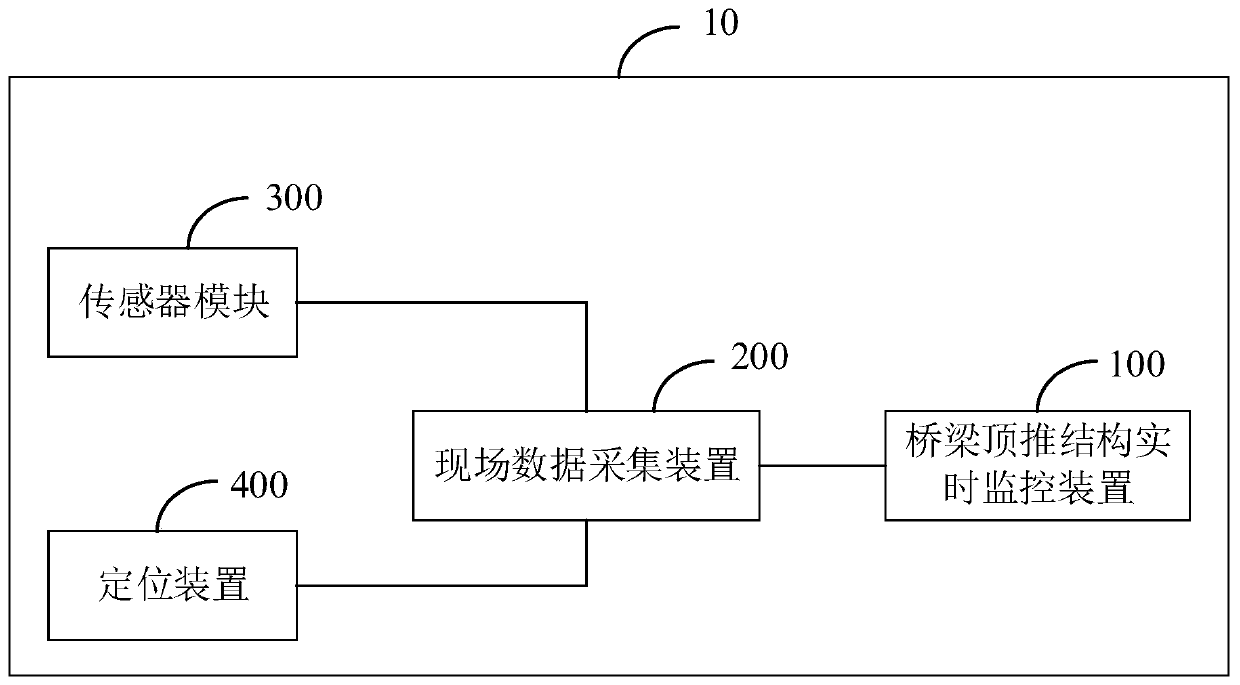

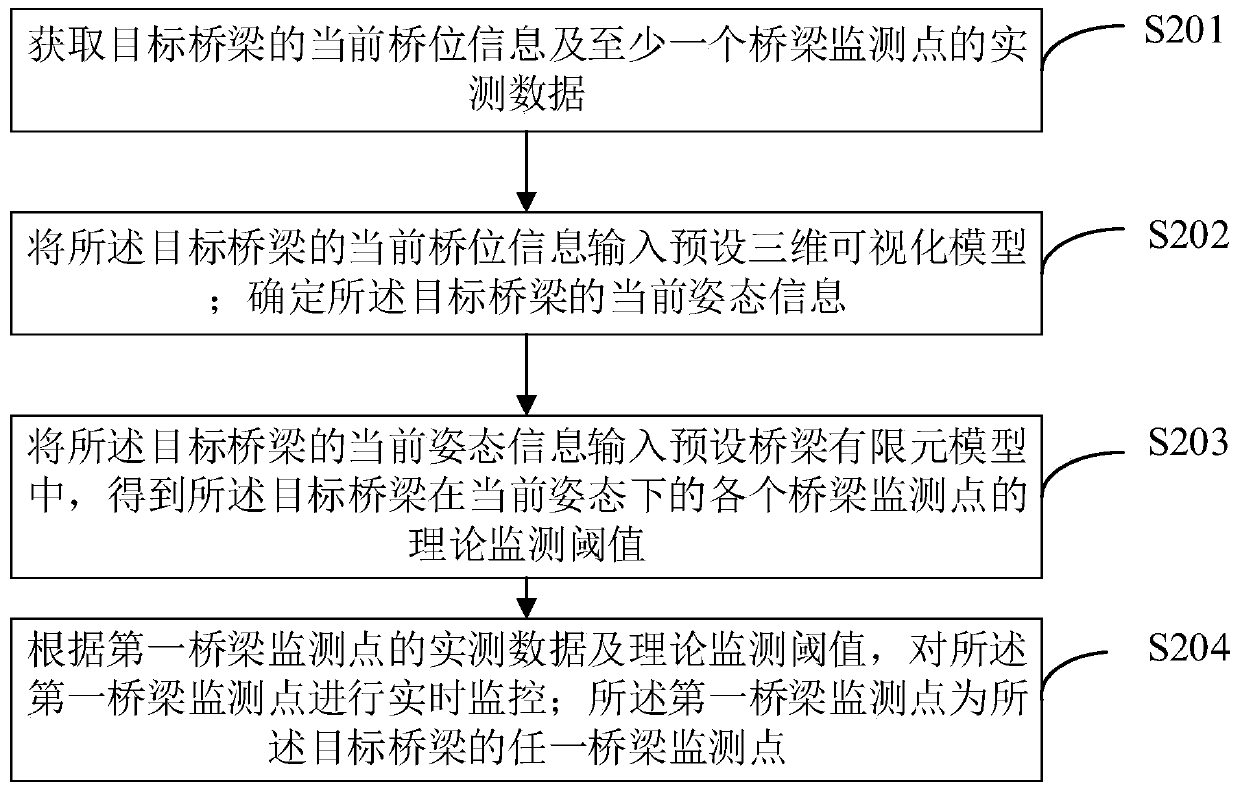

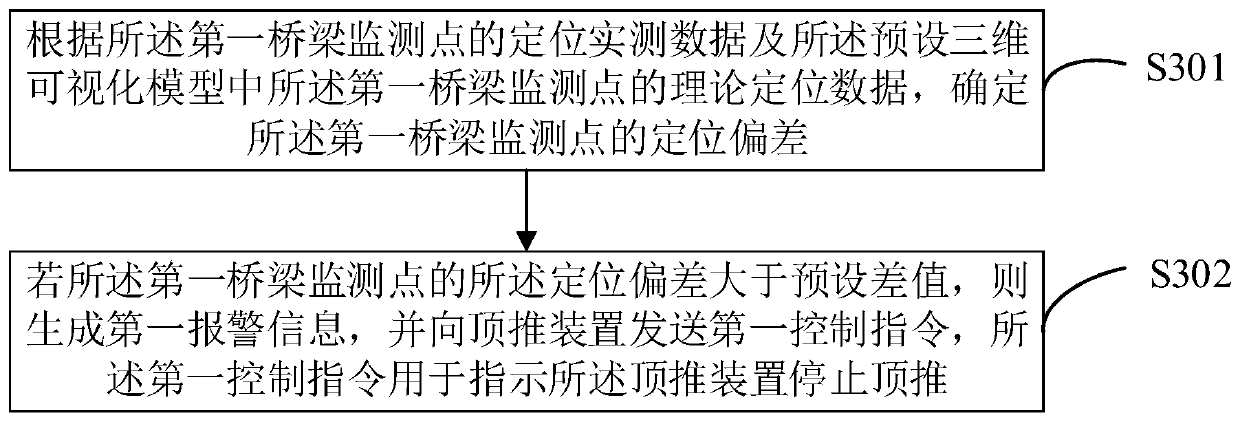

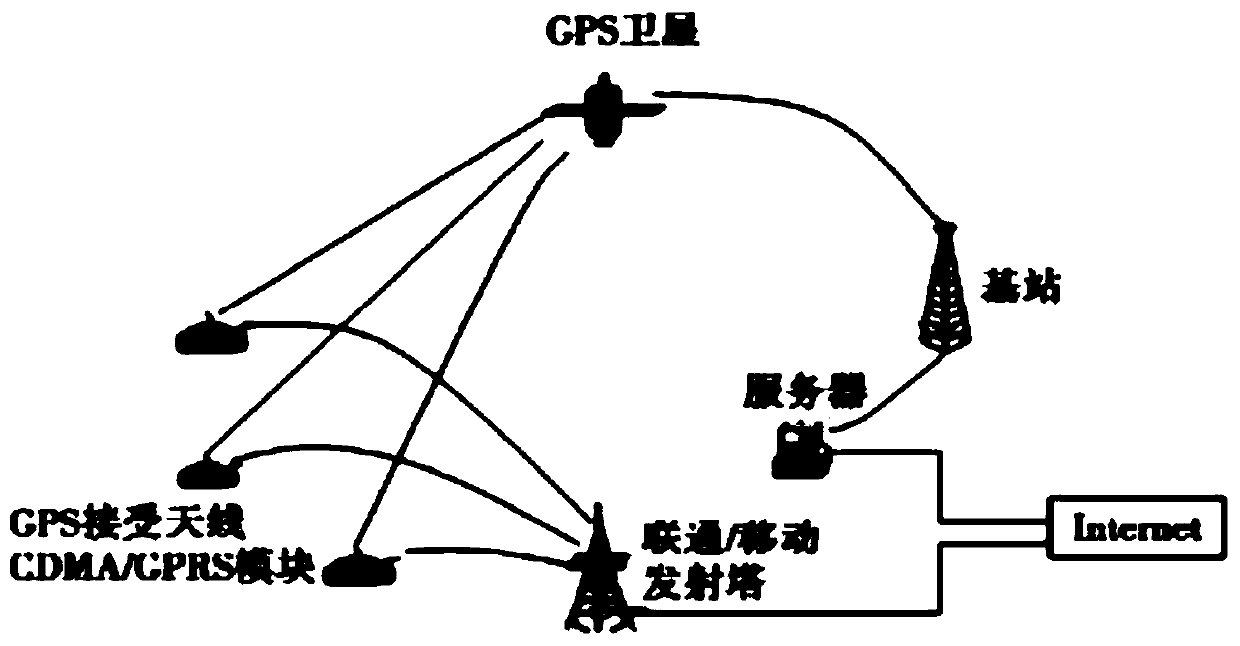

Real-time monitoring method, device and system for bridge pushing structure

ActiveCN111324923AReal-timeAccurate realizationGeometric CADMeasurement devicesMonitoring siteElement model

The invention is suitable for the technical field of bridge construction, and provides a real-time monitoring method, device and system for a bridge pushing structure, and the method comprises the steps: obtaining the current bridge position information of a target bridge and the actual measurement data of at least one bridge monitoring point; inputting the current bridge position information of the target bridge into a preset three-dimensional visualization model; determining current attitude information of the target bridge; inputting the current attitude information of the target bridge into a preset bridge finite element model to obtain a theoretical monitoring threshold of each bridge monitoring point of the target bridge under the current attitude; and monitoring the first bridge monitoring point in real time according to the measured data of the first bridge monitoring point and the theoretical monitoring threshold. By comparing the measured data with the theoretical monitoringthreshold, whether the pushing mechanism has errors or not can be determined in real time, so that real-time monitoring and deviation rectification of the bridge pushing mechanism are realized, and the monitoring efficiency of the bridge pushing mechanism is improved.

Owner:SHIJIAZHUANG TIEDAO UNIV

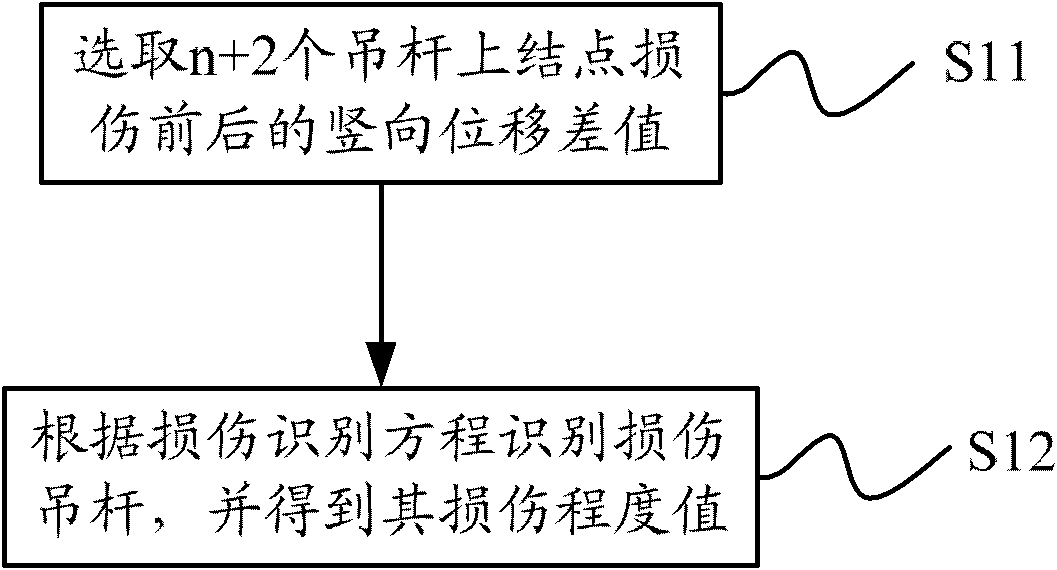

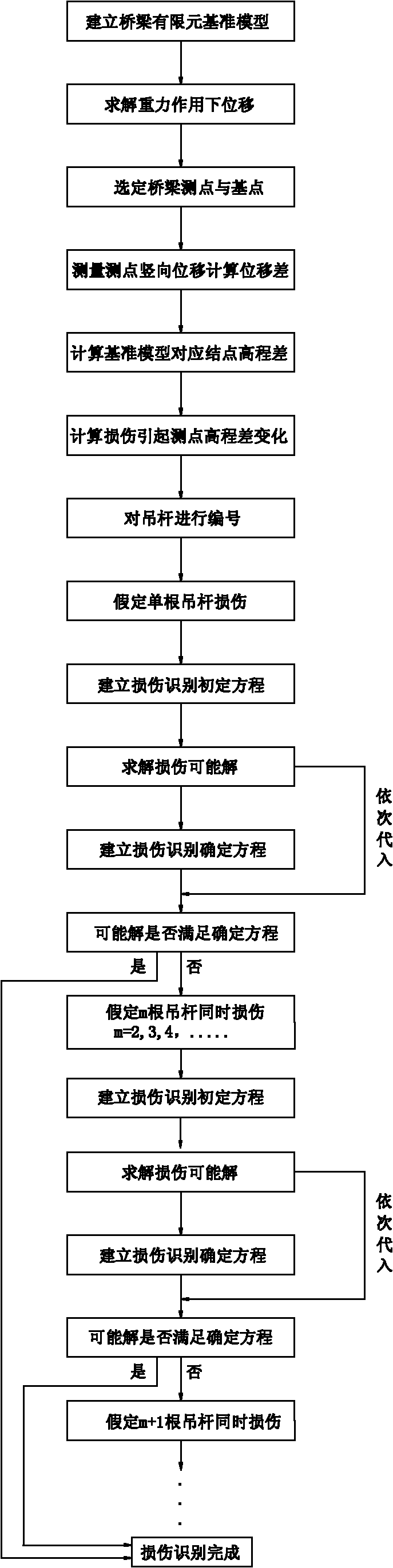

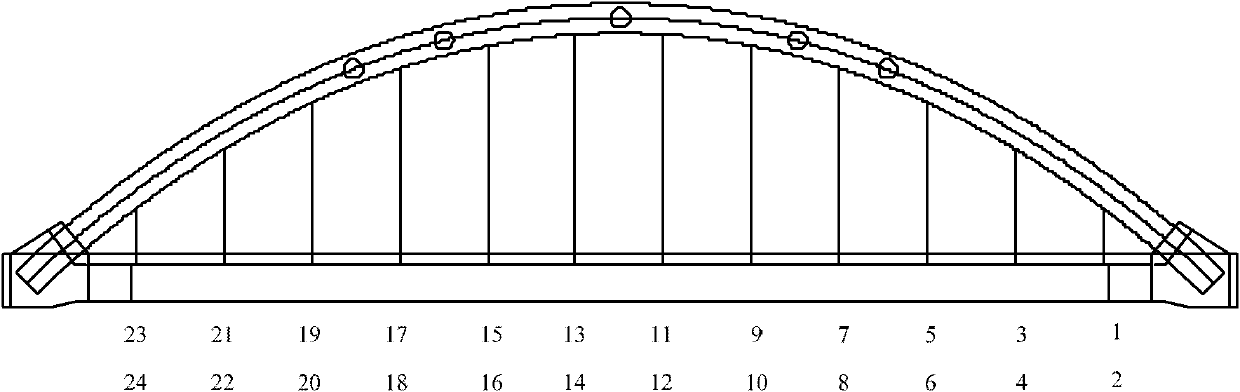

Suspender damage identification method for half-through and through arch bridges

InactiveCN102230927AAccurate identification of damagePractical methodMaterial analysisReference modelFirst order perturbation

The invention discloses a suspender damage identification method for half-through and through arch bridges, and the method comprises the following steps: when n suspenders are damaged, selecting n+2 nodes; and by using one of the n+2 nodes as a basic point and the other n+1 nodes as measuring points, constructing n+1 damage identification equations in accordance with the changes of the vertical displacement differences between each measuring point and the basic point before and after the suspenders are damaged, wherein when all the damage identification equations are tenable, epsilon i is thedamage value of the ith suspender, and the damage identification equation is shown in the specification, wherein ({X}j-{X}1) is the vertical displacement difference between the measuring point and the basic point after the suspender is damaged, ({X0}j-{X0}1) is the vertical displacement difference between the measuring point and the basic point before the suspender is damaged, the specification is the first-order perturbation of a suspender system finite element stiffness matrix caused by the damage to the ith suspender after order expansion is defined in the specification, and an inverse matrix of a bridge finite element reference model stiffness matrix under the initial conditions is defined in the specification. By identifying medium and small damages to the suspenders based on the changes of the vertical displacement differences among the nodes, the method disclosed by the invention is practical and ensures higher precision.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

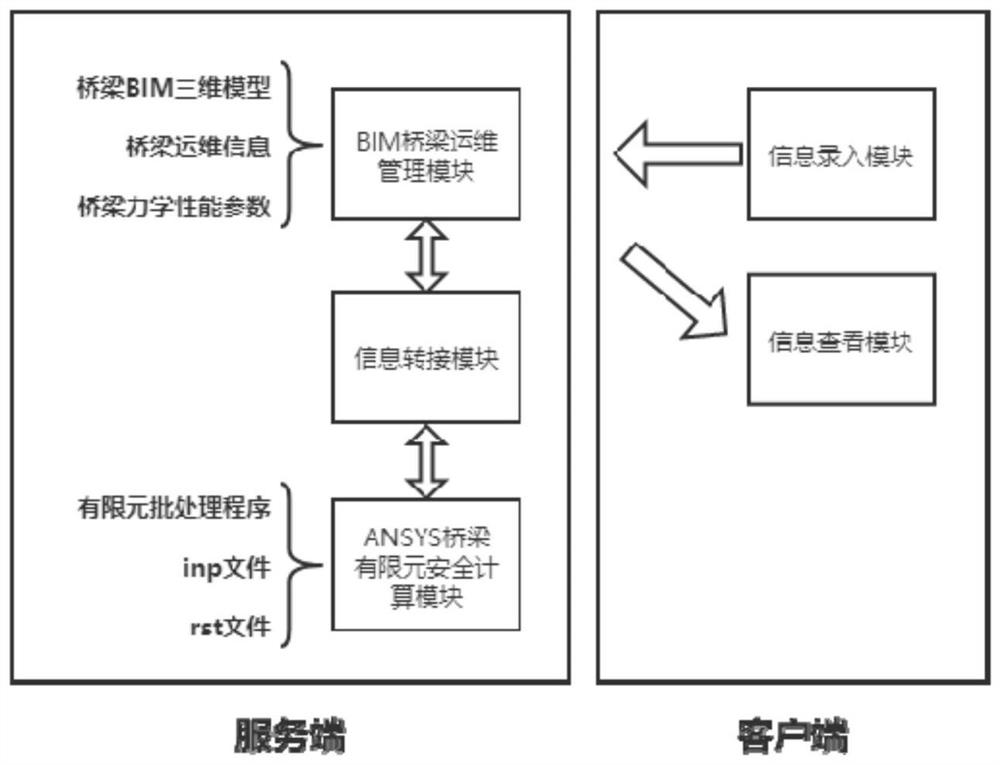

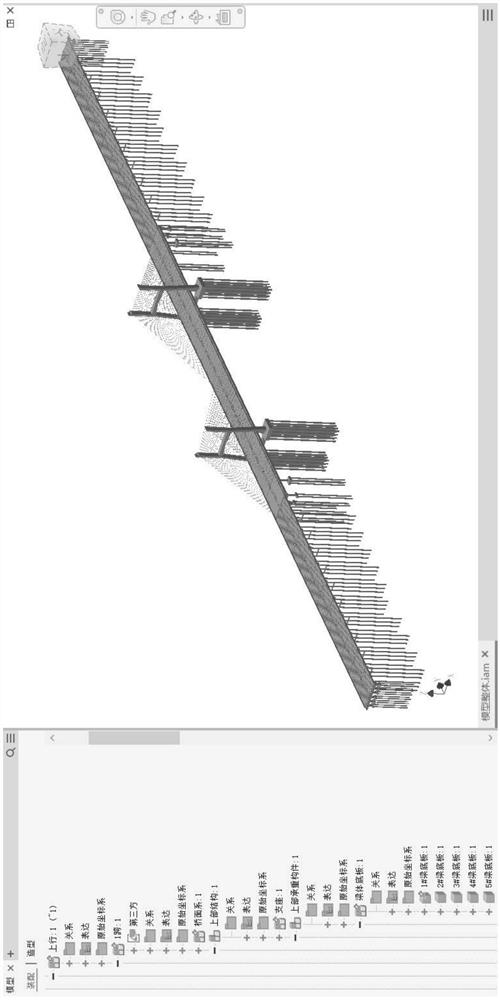

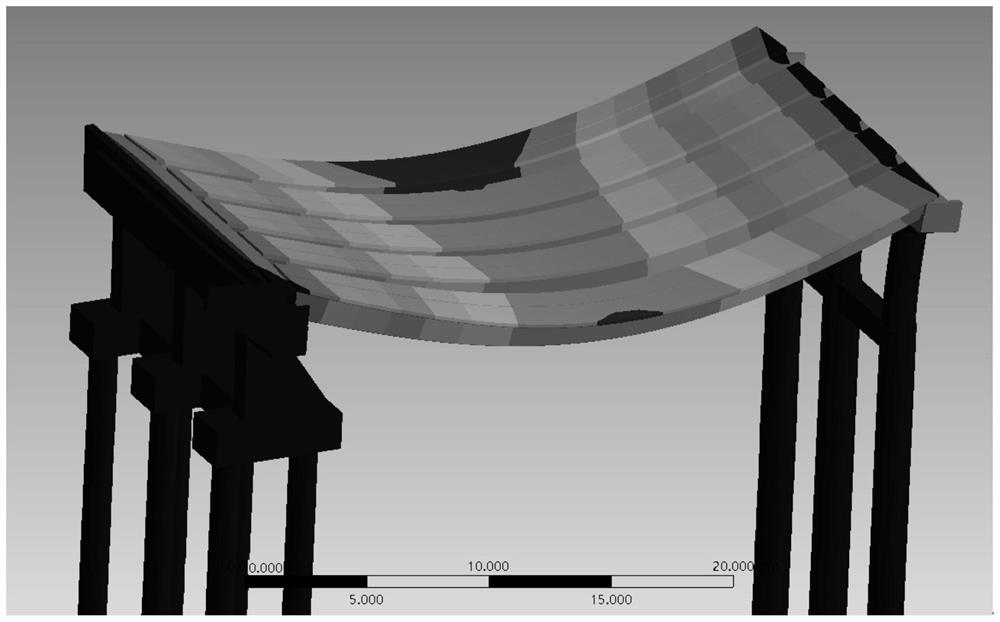

BIM-FEM-based bridge health assessment system and health assessment method

PendingCN111611634AMeet the need for a health assessmentGeometric CADDesign optimisation/simulationBeam finite elementsStructural safety

The invention discloses a BIM-FEM-based bridge health assessment system and health assessment method, and the system comprises: a BIM bridge operation and maintenance management module which is used for classifying and storing related information generated in a bridge operation and maintenance process; an ANSYS bridge finite element safety calculation module which is used for calculating the stress state of the bridge; an information transfer module which is used for realizing information mutual feedback between the BIM bridge operation and maintenance management module and the bridge finite element safety calculation module; an information viewing module which is used for viewing the operation and maintenance management information and the structural stress deformation state of the bridge; and an information input module which is used for inputting basic engineering data and operation and maintenance management information of the bridge. According to the method, the problem that the BIM information model lacks effective structure safety analysis in the bridge operation and maintenance process can be solved, the advantages of visualization, coordination and simulation of the BIM technology are combined with the calculation advantages of finite element analysis software, and a reliable bridge safety evaluation function and convenient visual experience are provided for bridge operation and maintenance.

Owner:上海深物控智能科技有限公司

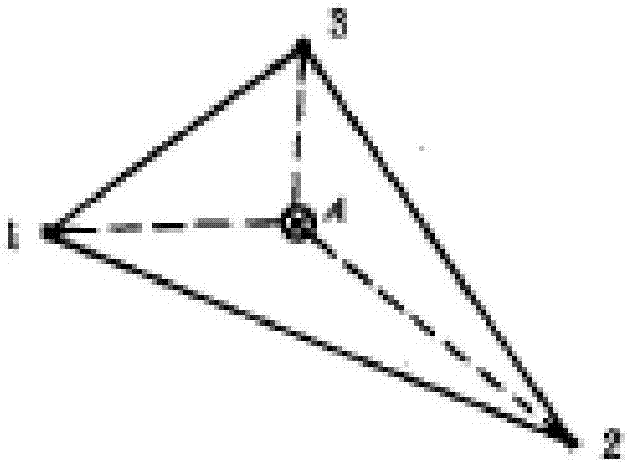

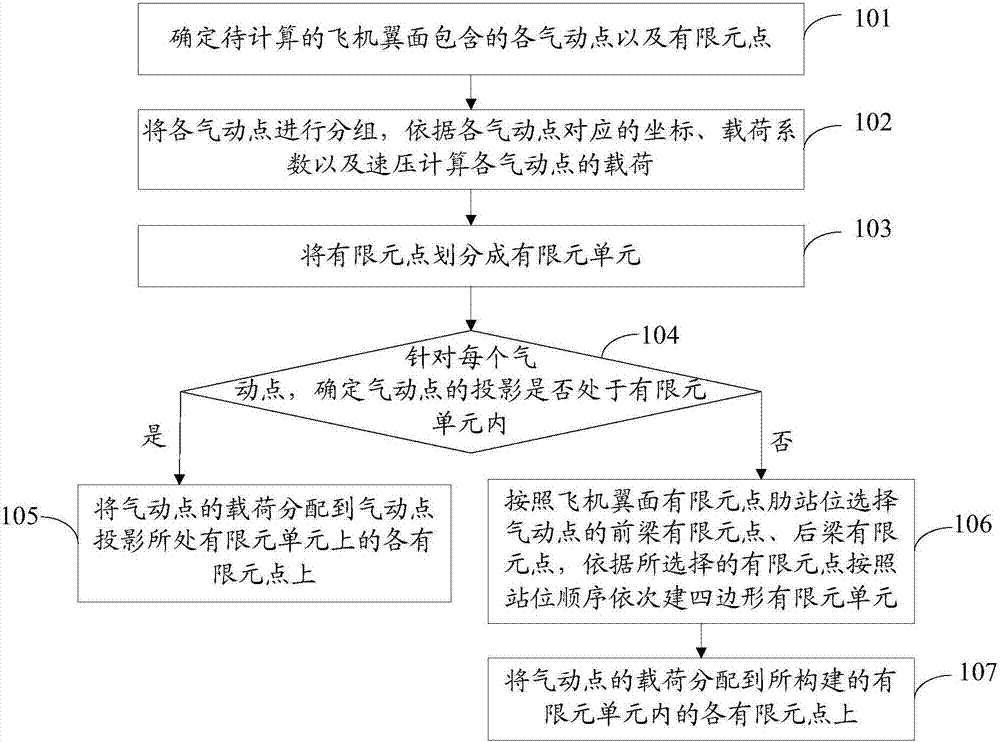

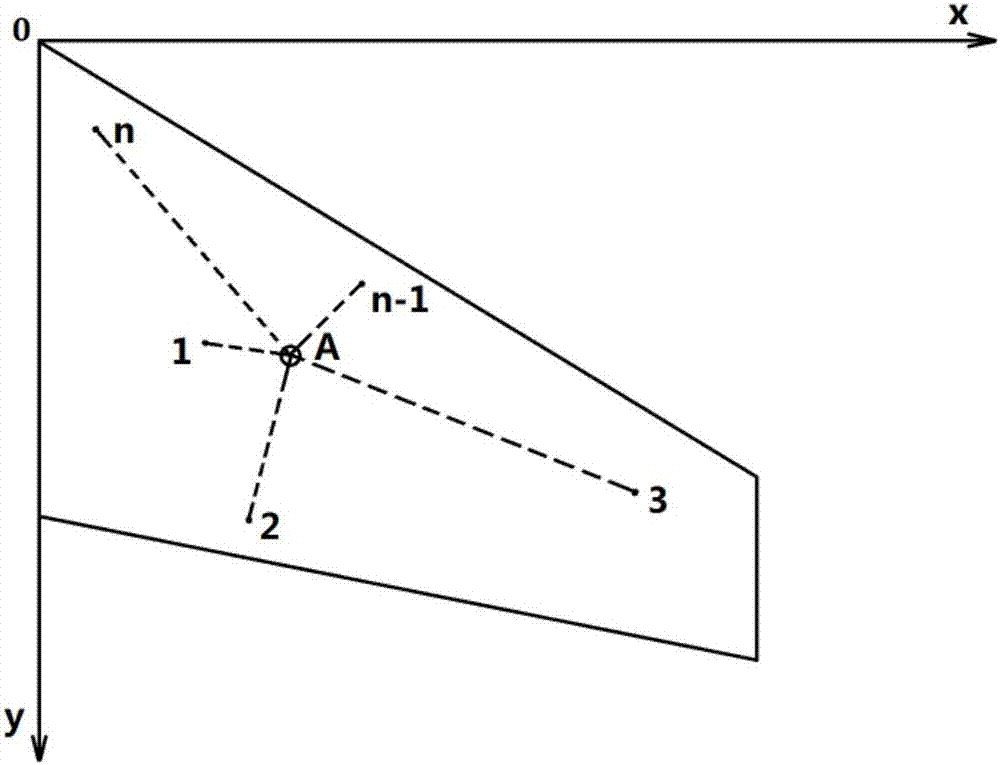

Method and device for determining finite element point load distribution in aircraft wing

ActiveCN107038296AImprove accuracyPracticalGeometric CADDesign optimisation/simulationEngineeringLoad distribution

The invention provides a method and a device for determining finite element point load distribution in an aircraft wing. The method comprises the steps that all pneumatic points and finite element points contained in the aircraft wing to be calculated are determined; all the pneumatic points are grouped, and loads of all the pneumatic points are calculated according to coordinates, load coefficients and velocity pressure corresponding to all the pneumatic points; the finite element points are divided into finite element units; whether a projection of each pneumatic point is in one finite element unit is determined; if yes, the loads of the pneumatic points are distributed to all the finite element points on the finite element units where the projections of the pneumatic points are located; if not, front-beam finite element points and back-beam finite element points of the pneumatic points are selected according to rib stances of the finite element points in the aircraft wing, and quadrilateral finite element units are sequentially constructed according to the order of the stances and the selected finite element points; and the loads of the pneumatic points are distributed to all the finite element points in the constructed finite element units. Through the load distribution method, the accuracy of a calculation result is high.

Owner:SHANGHAI GONGFANG SOFTWARE CO LTD

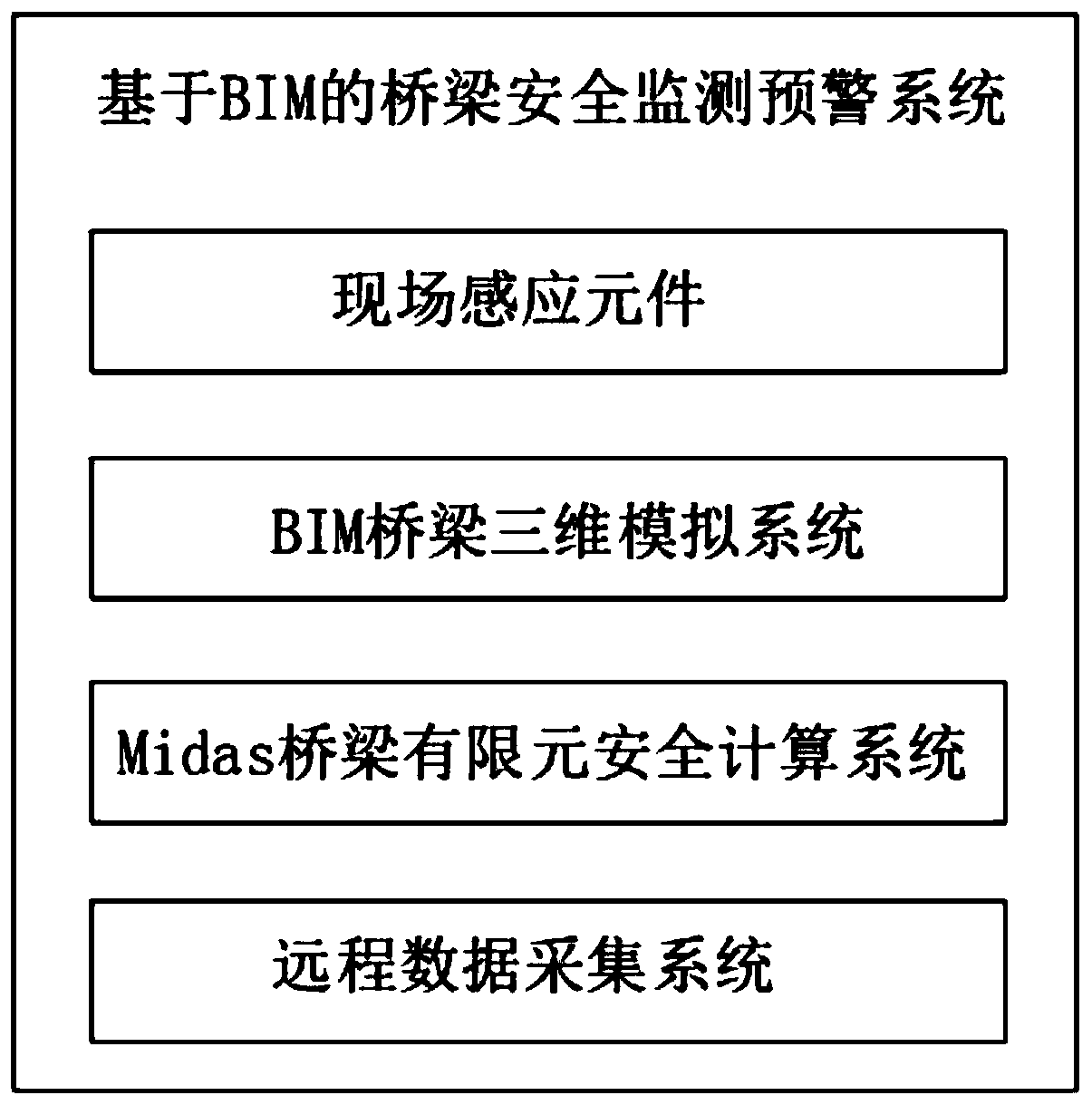

Bridge safety monitoring and early warning system based on BIM

ActiveCN110263461ASave manpower and material resourcesGeometric CADDesign optimisation/simulationThree dimensional simulationElement model

The invention discloses a bridge safety monitoring and early warning system based on a BIM. The bridge safety monitoring and early warning system comprises an on-site sensing element, a BIM bridge three-dimensional simulation system, a Midas bridge finite element safety calculation system and a remote data acquisition system; the on-site sensing element is used for collecting stress-strain real-time data of a bridge on-site stress point; the remote data acquisition system is used for receiving stress-strain real-time data of a bridge on-site stress point acquired by the on-site sensing element; the Midas bridge finite element safety calculation system is used for analyzing the stress condition of the bridge; and the BIM bridge three-dimensional simulation system carries out critical touch on a Midas bridge finite element model. According to the invention, technical support can be provided for real-time performance and visualization of bridge safety monitoring and early warning; when unpredictable deformation and cracks happen to the bridge under the load condition, personnel can be maintained or evacuated in time, the damaged part is clear through visualization, detection is conducted through reduced manpower and material resources, and therefore the best opportunity of maintenance is prevented from being delayed.

Owner:IANGSU COLLEGE OF ENG & TECH

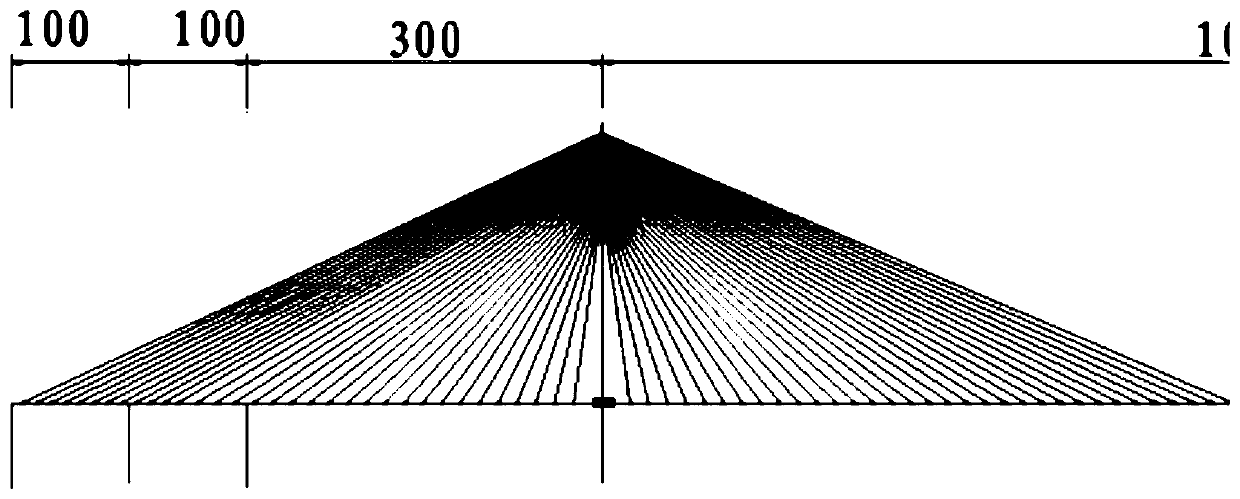

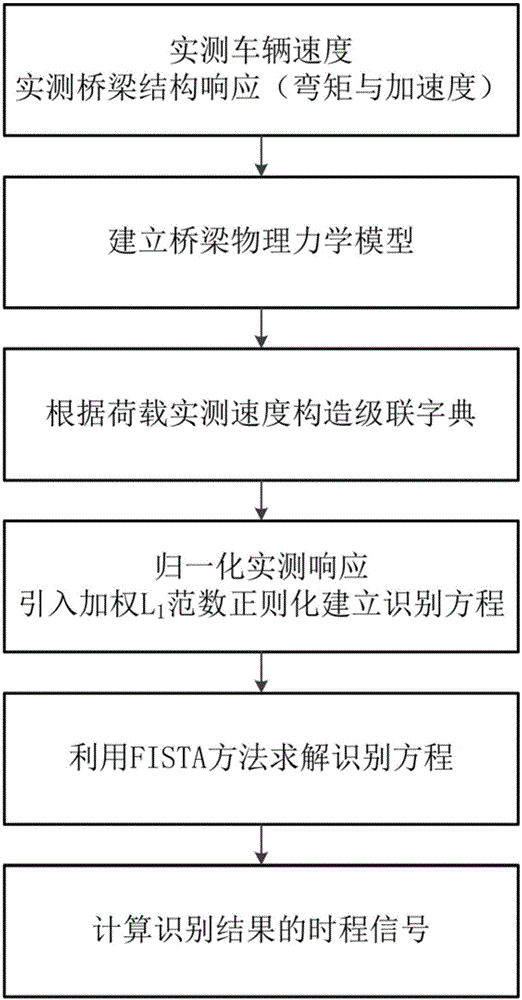

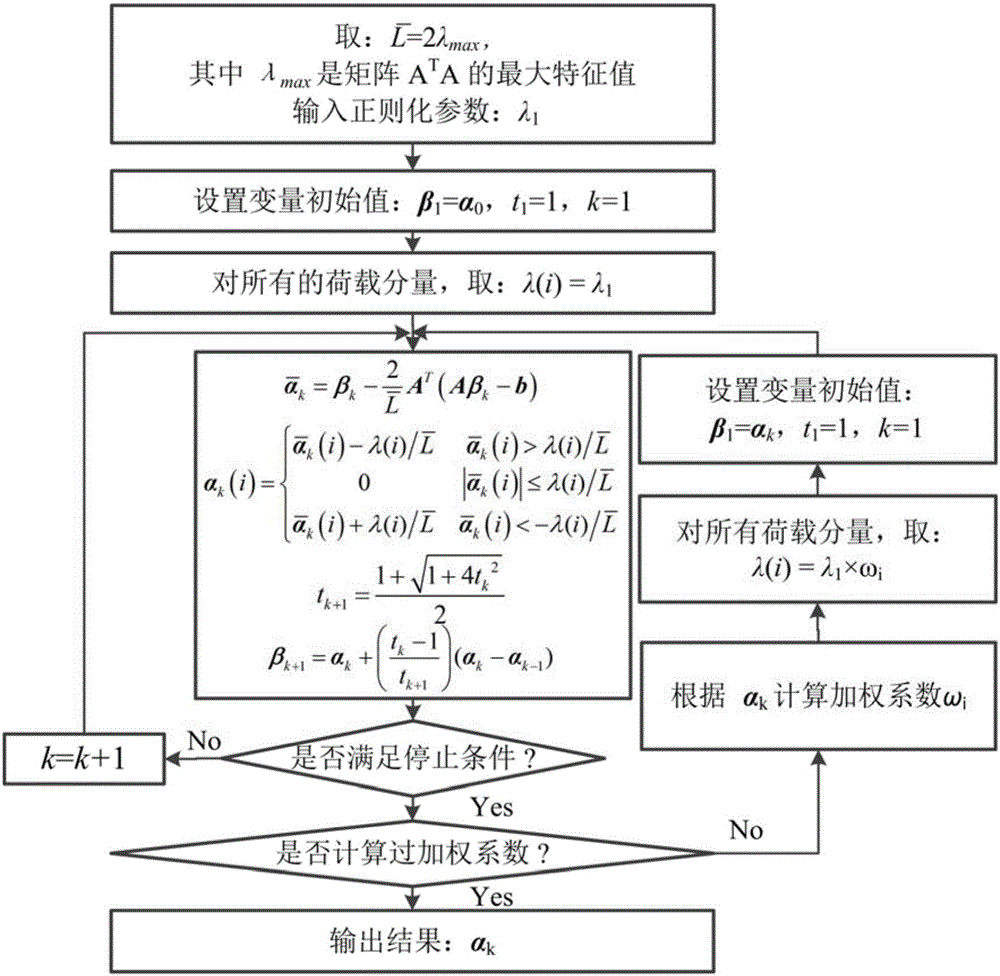

Bridge moving load identification method based on cascaded dictionaries and sparse regularization

ActiveCN106503730AInnovativeAccurate identificationCharacter and pattern recognitionMobile vehicleElement model

The invention discloses a bridge moving load identification method based on cascaded dictionaries and sparse regularization. The method mainly includes the following steps: 1) arranging a speed measuring device on a bridge to be used for measuring vehicle speed, and arranging a plurality of strain and acceleration sensors on the bridge for actual measurement of bridge response; 2) building a bridge finite element model; 3) adopting cascaded dictionaries formed by a discrete trigonometric function and a discrete rectangular function to expand an unknown moving load; 4) normalizing actual measurement response, and introducing a weighted L1 norm regularization method to build an identification equation; and 5) utilizing a fast iterative shrinkage-thresholding algorithm (FISTA) to solve the equation, and calculating a corresponding time interval signal. The method provided by the invention can accurately identify a bridge moving load, including a slowly-changing integral signal and local impact signal in bridge moving vehicle load signals, has strong noise robustness, and is particularly suitable for field utilization of bridge response to estimate gross vehicle weight.

Owner:JINAN UNIVERSITY

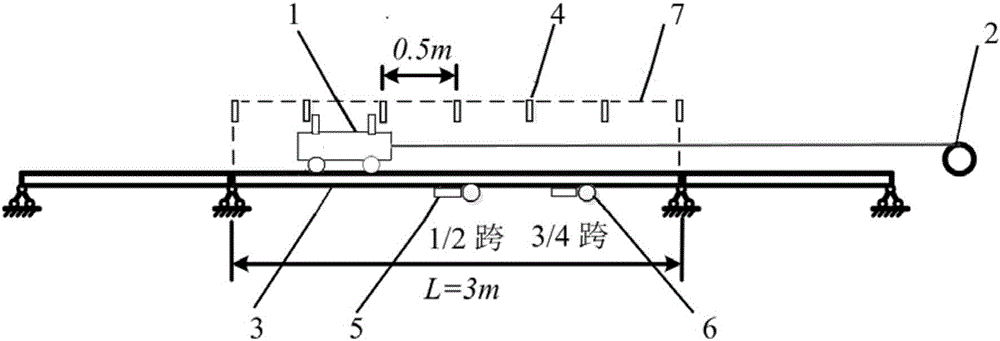

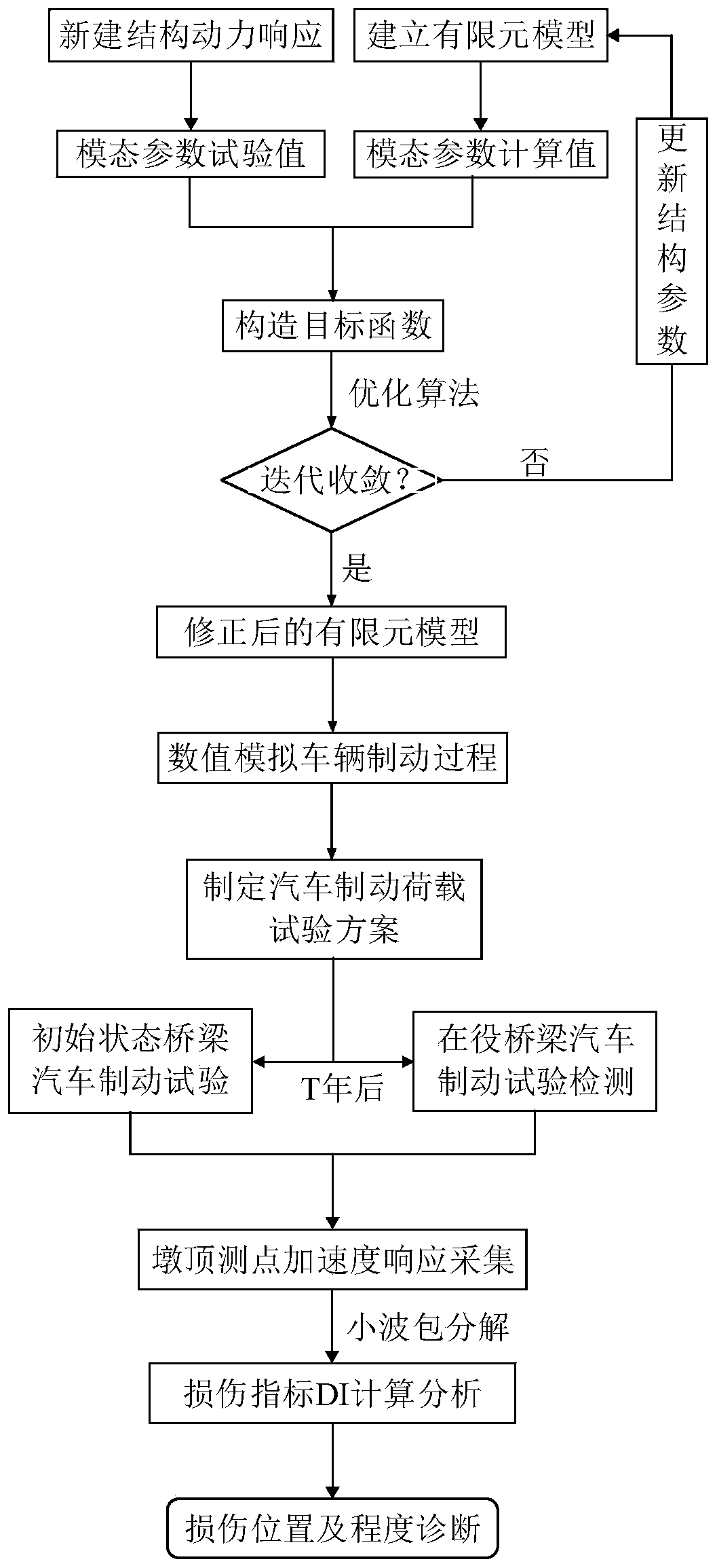

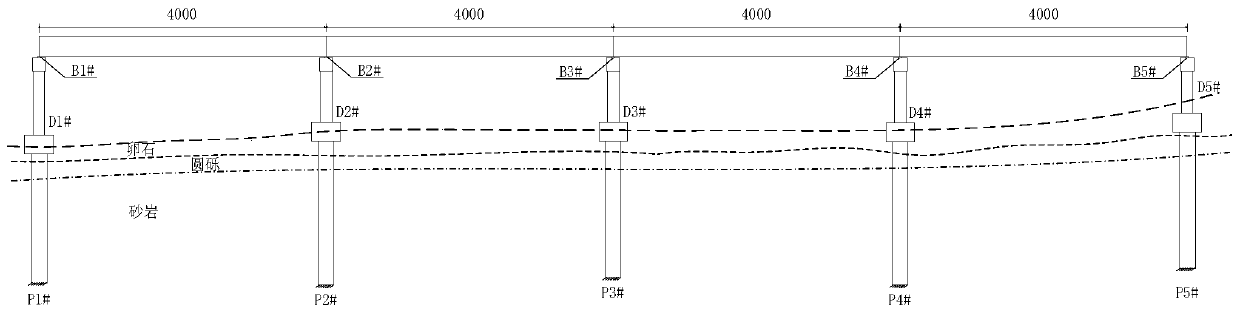

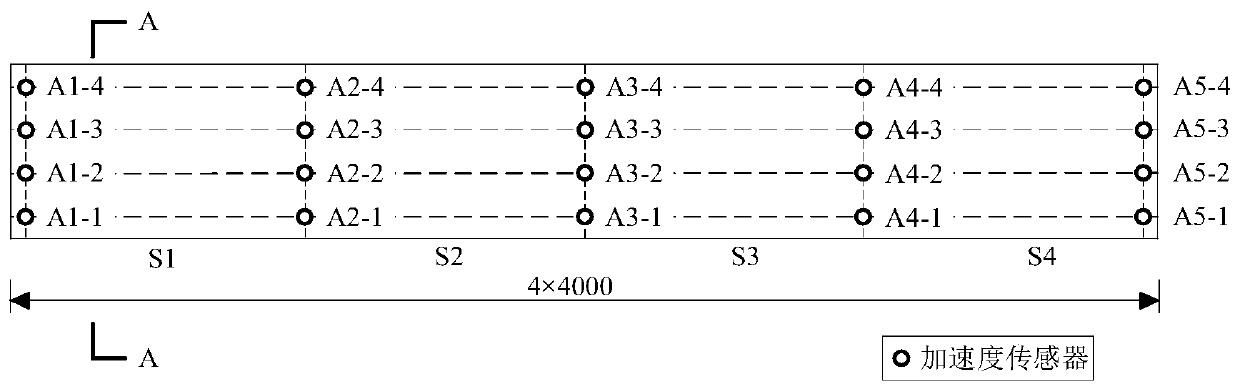

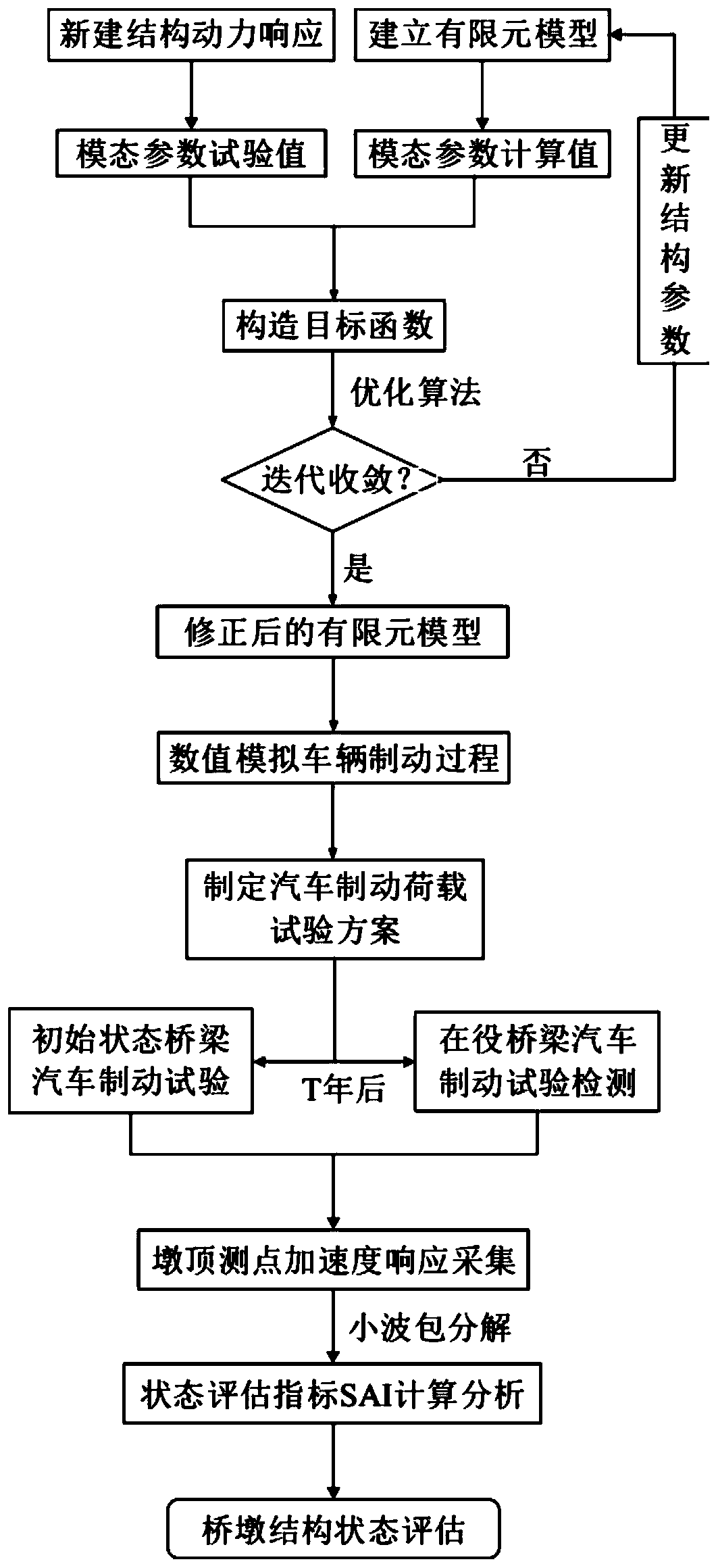

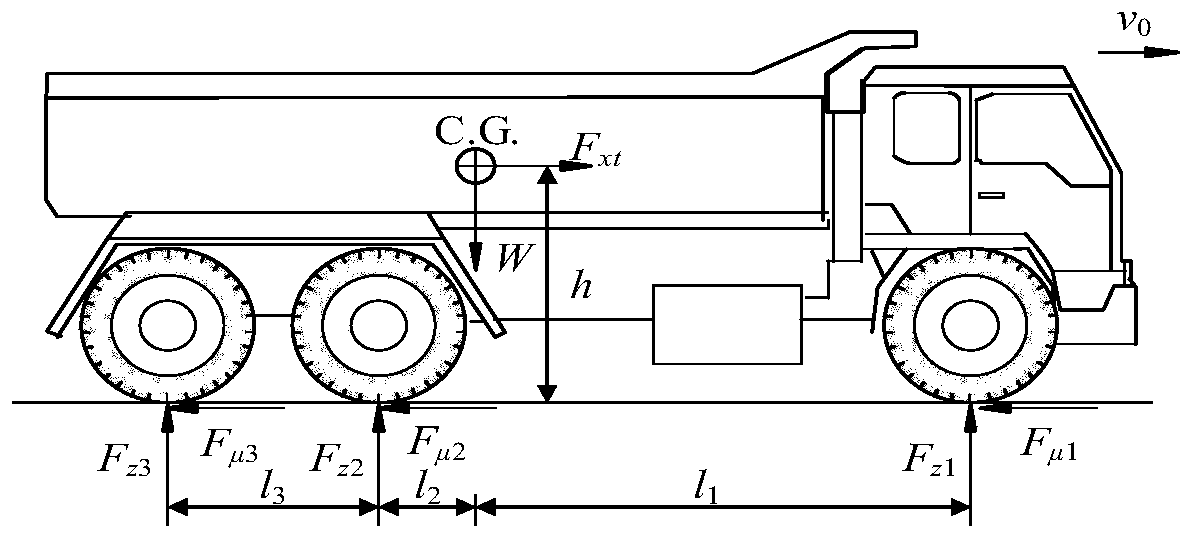

In-service bridge support damage diagnosis method based on vehicle braking effect

ActiveCN110543706AObvious vibration along the bridge directionEnsure safe operationSpecial data processing applicationsElement modelDecomposition

The invention discloses an in-service bridge support damage diagnosis method based on a vehicle braking effect, and belongs to the technical field of bridge support damage diagnosis. The objective ofthe invention is to solve the problems that an existing in-service bridge support damage diagnosis method cannot accurately perform structural damage positioning and is not high in measurement precision. According to the invention, the accurate bridge finite element model is established by using a model correction method, and a vehicle brake numerical simulation method is provided, so that a braketest scheme suitable for the bridge to be detected can be formulated more accurately. A proper wavelet basis function decomposition level is selected by utilizing a cost function, wavelet packet decomposition is performed on a free attenuation signal acquired at the pier top of the pier, and a damage index is constructed to diagnose the damage position and degree of the support. The method is simple to operate, economical and practical, has certain robustness and noise immunity, and does not greatly influence the bridge structure.

Owner:HARBIN INST OF TECH

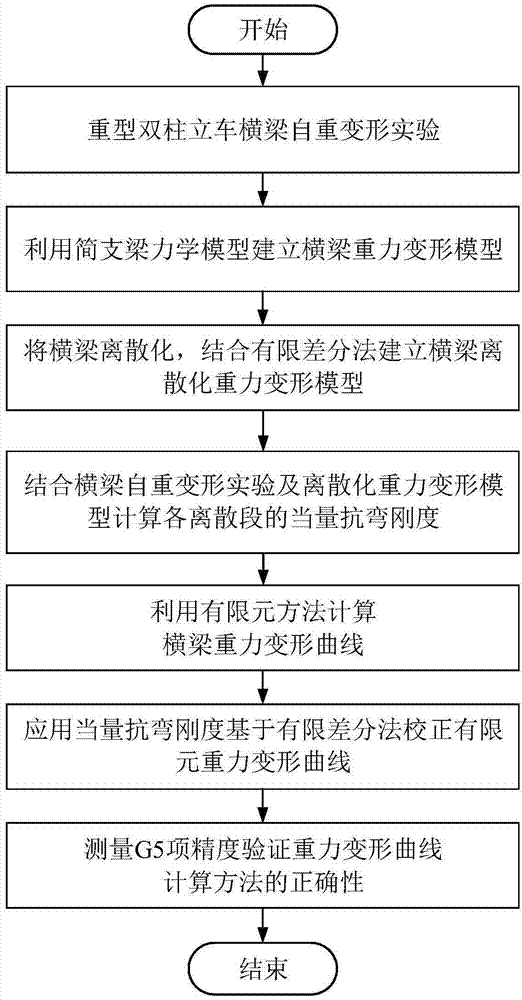

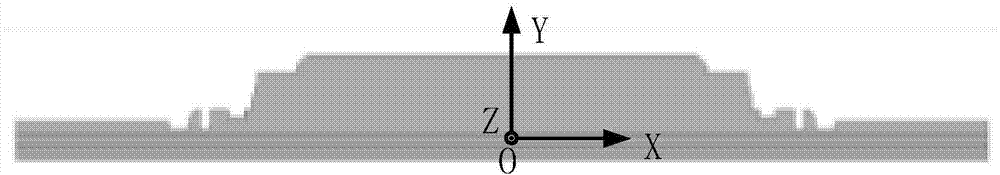

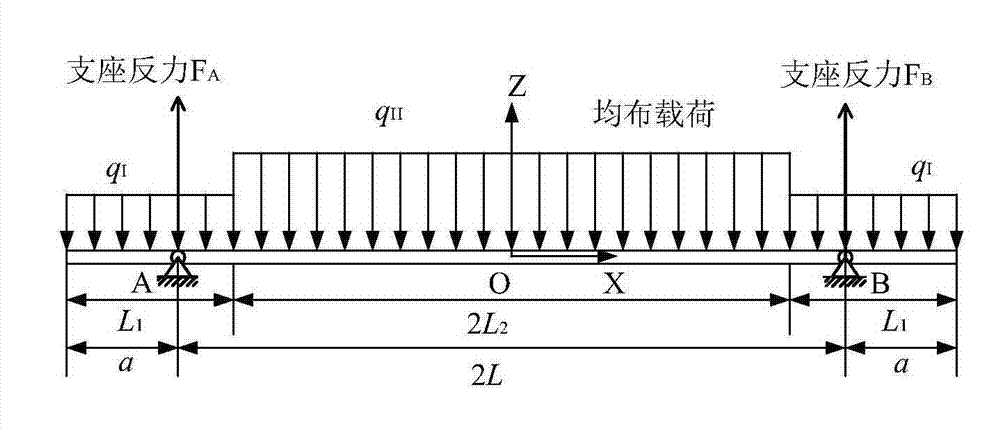

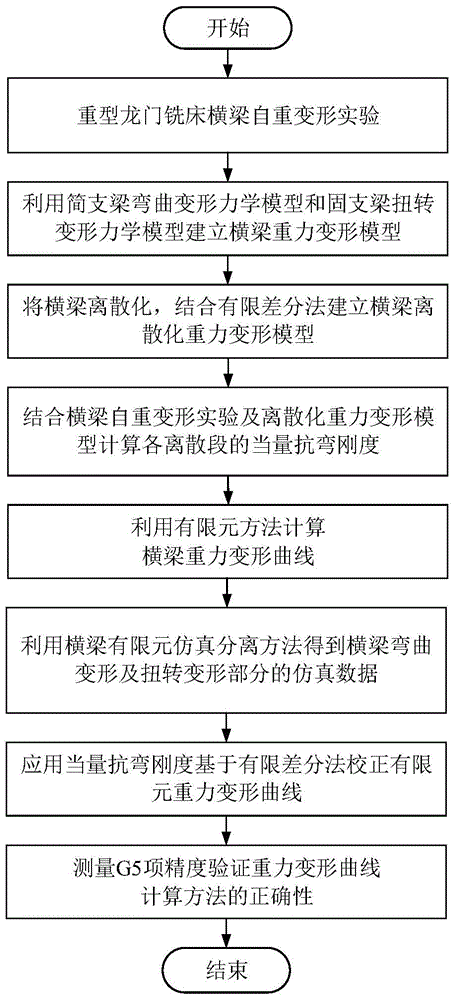

Heavy double-column vertical lathe cross beam gravity deformation prediction method based on finite difference method

ActiveCN104714478AReduce the number of disassembly and assemblySolve the problem of inaccurate finite element analysis resultsProgramme controlComputer controlMechanical modelsElement analysis

The invention relates to a heavy double-column vertical lathe cross beam gravity deformation prediction method based on a finite difference method. Due to the fact that an existing finite element analysis computing method cannot accurately calculate a cross beam gravity deformation curve on the condition that actual materials have not uniform attributes, the calculation result much differs from an actual deformation value. The heavy double-column vertical lathe cross beam gravity deformation prediction method based on the finite difference method comprises the steps that actual assembling conditions are simulated to design a heavy machine tool cross beam self-weight deformation experiment to obtain a self-weight deformation curve. By means of the material mechanical theory, a cross beam is simplified into a simply supported beam mechanical model and then made into micro segments through discretization, and a cross beam gravity deformation discretization model is built on the basis of the finite difference method; the equivalent weight bending rigidity of each discrete micro segment is calculated; the cross beam finite element gravity deformation curve is calculated; the equivalent weight bending rigidity is utilized for correcting the cross beam finite element gravity deformation curve on the basis of the finite difference method to obtain a final cross beam gravity deformation curve. The heavy double-column vertical lathe cross beam gravity deformation prediction method is applied to heavy double-column vertical lath cross beam gravity deformation curve calculation.

Owner:HARBIN INST OF TECH

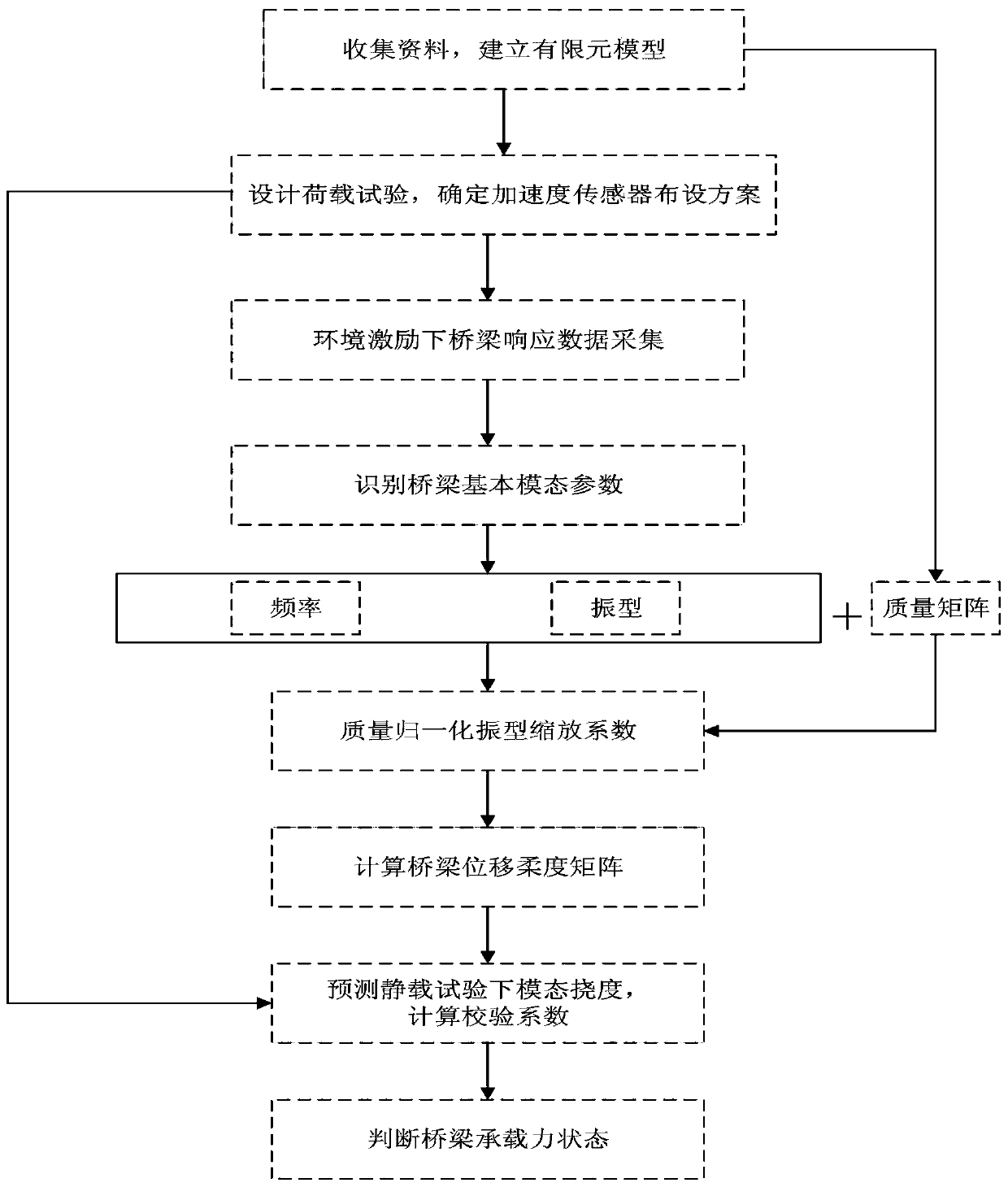

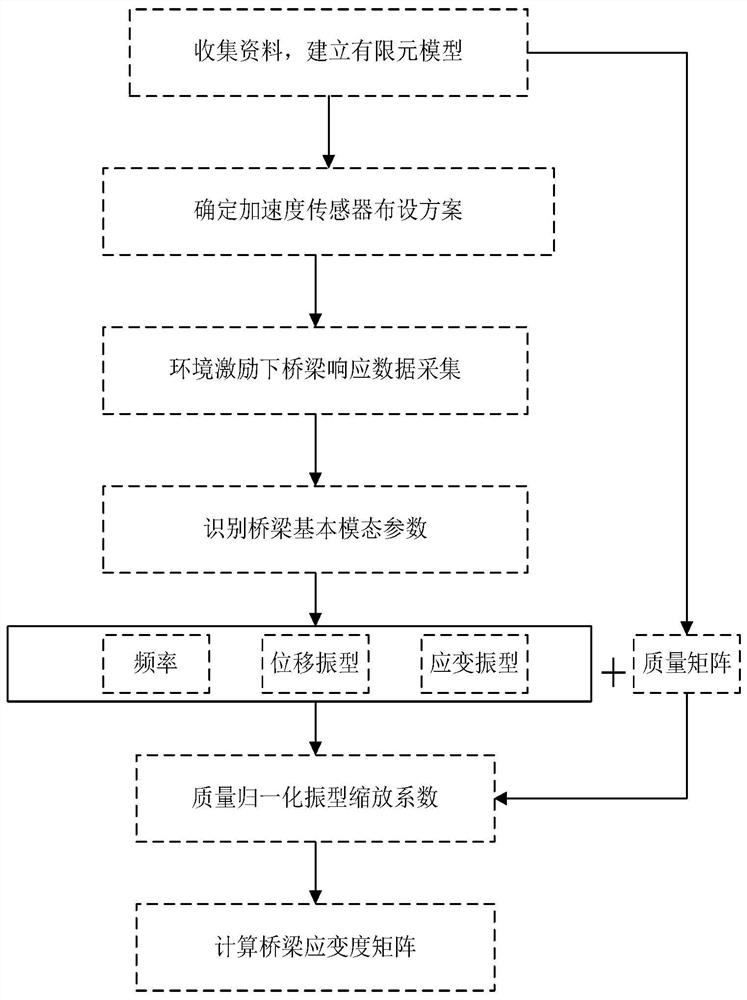

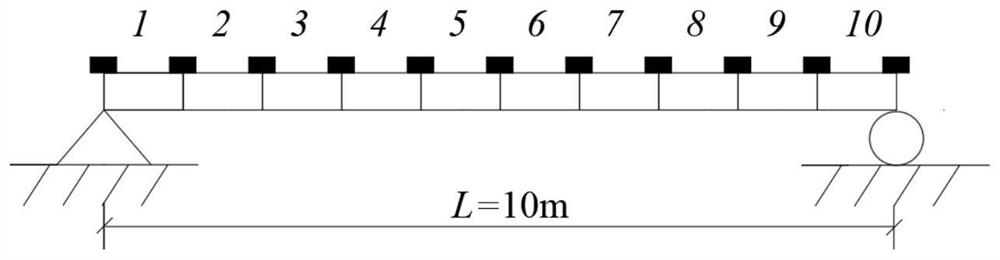

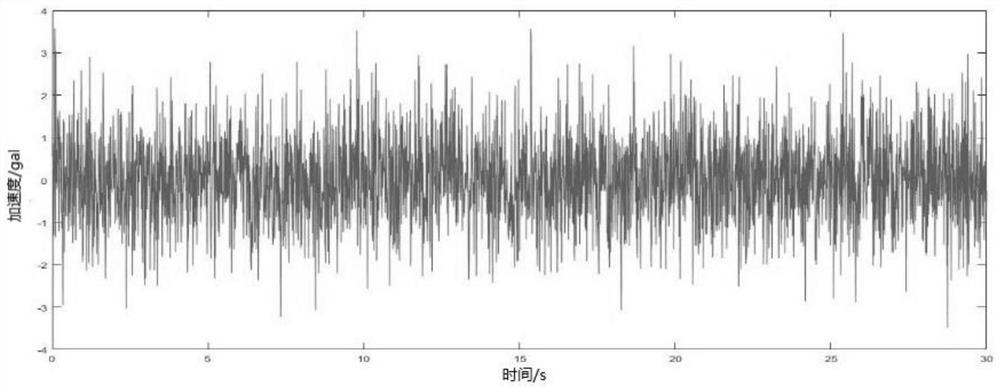

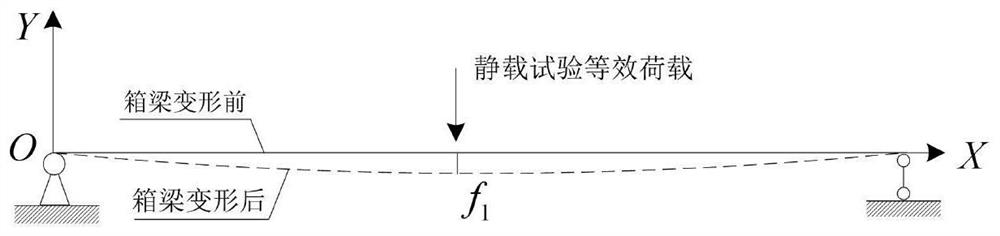

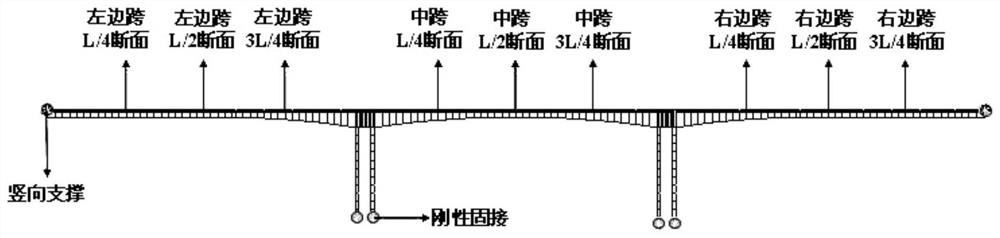

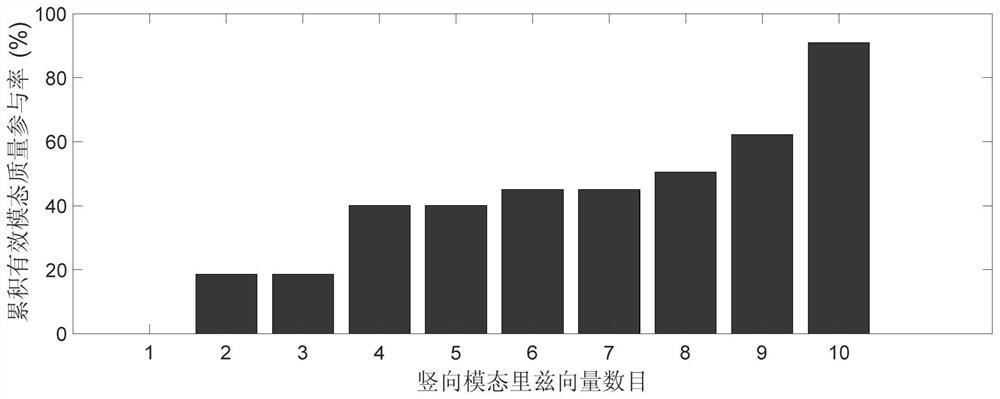

Bridge static load test method based on environmental excitation

PendingCN111353252AEasy to operateSave human and financial resourcesGeometric CADDesign optimisation/simulationElement modelVibration acceleration

The invention discloses a bridge static load test method based on environmental excitation. The method comprises the steps: establishing a bridge finite element model according to a bridge completiondrawing, and extracting a centralized mass matrix of a bridge from the bridge finite element model; designing a load test scheme and an acceleration sensor arrangement scheme according to related specifications and the actual state of the bridge; acquiring vibration acceleration response of the bridge under environmental excitation by using an acceleration sensor arranged on the bridge; identifying basic modal parameters of the bridge through a modal identification method; calculating a mass normalized vibration mode scaling coefficient of the bridge structure by utilizing the concentrated mass matrix extracted by the bridge finite element model and the identified bridge basic modal parameters; and then performing quality normalization on the actually-measured vibration mode, calculating an actually-measured flexibility matrix of the bridge by utilizing the normalized vibration mode, further predicting modal deflection of the bridge under the working condition of the static load test,comparing the modal deflection with theoretically-calculated deflection, calculating a static load test verification coefficient and judging the bearing capacity of the bridge. The method is convenient to operate, and traffic does not need to be closed.

Owner:SHANDONG HI SPEED GRP CO LTD +1

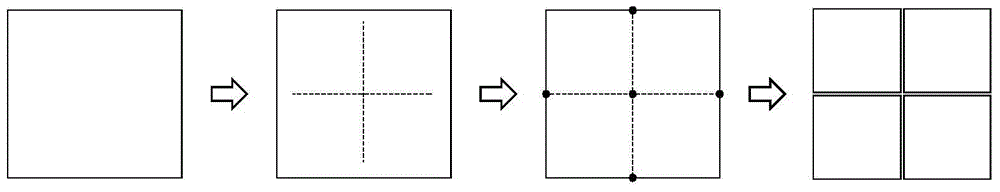

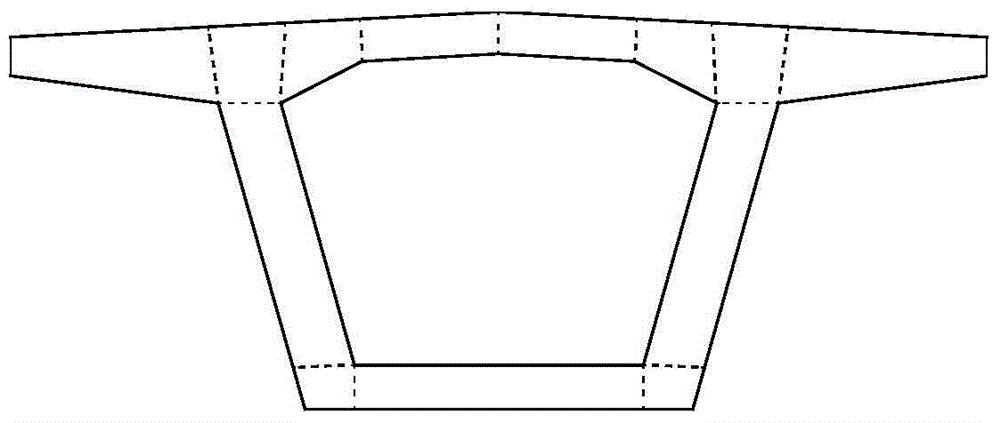

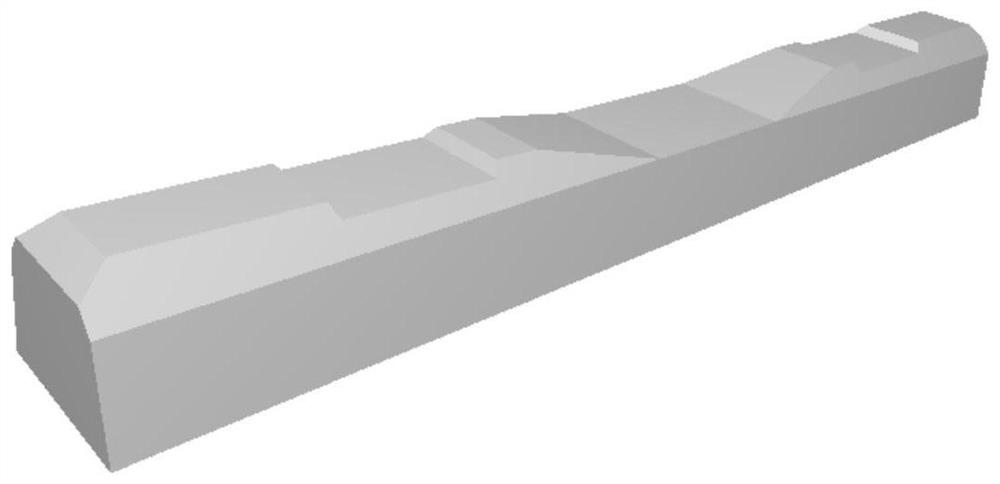

Fracture surface pre-processing method for variable cross-section beam finite element model

ActiveCN105224748AGuaranteed matchImprove division efficiencySpecial data processing applicationsLine segment intersectionEngineering

The invention provides a fracture surface pre-processing method for a variable cross-section beam finite element model, and solves a problem cross section matching in variable cross-section beam modeling. The method comprises two steps of fracture surface auxiliary mesh generation and automatic cross section matching. The main process comprises: first, segmenting in advance to form cross section blocks and automatically generating nodes and units, segmentation of the cross section blocks being completed by manpower, when the fracture surface of a variable cross-section beam is processed, region segmentation of each pair of cross sections having a similar structure; adjusting size of the cross sections and matching the units and the nodes in the cross section according to a minimum distance principle; after node matching is completed, according to the unit and node number of a reference cross section, numbering the units and nodes of a target cross section again, and finally obtaining a pair of matched cross sections. A method for determining whether segment is intersected is also provided, and line segment intersection point coordinates can be calculated. The method can be suitable to be used for various types of cross section forms in practical engineering, and can simplify modeling flow and prevent modeling mistakes.

Owner:重庆大学建筑规划设计研究总院有限公司

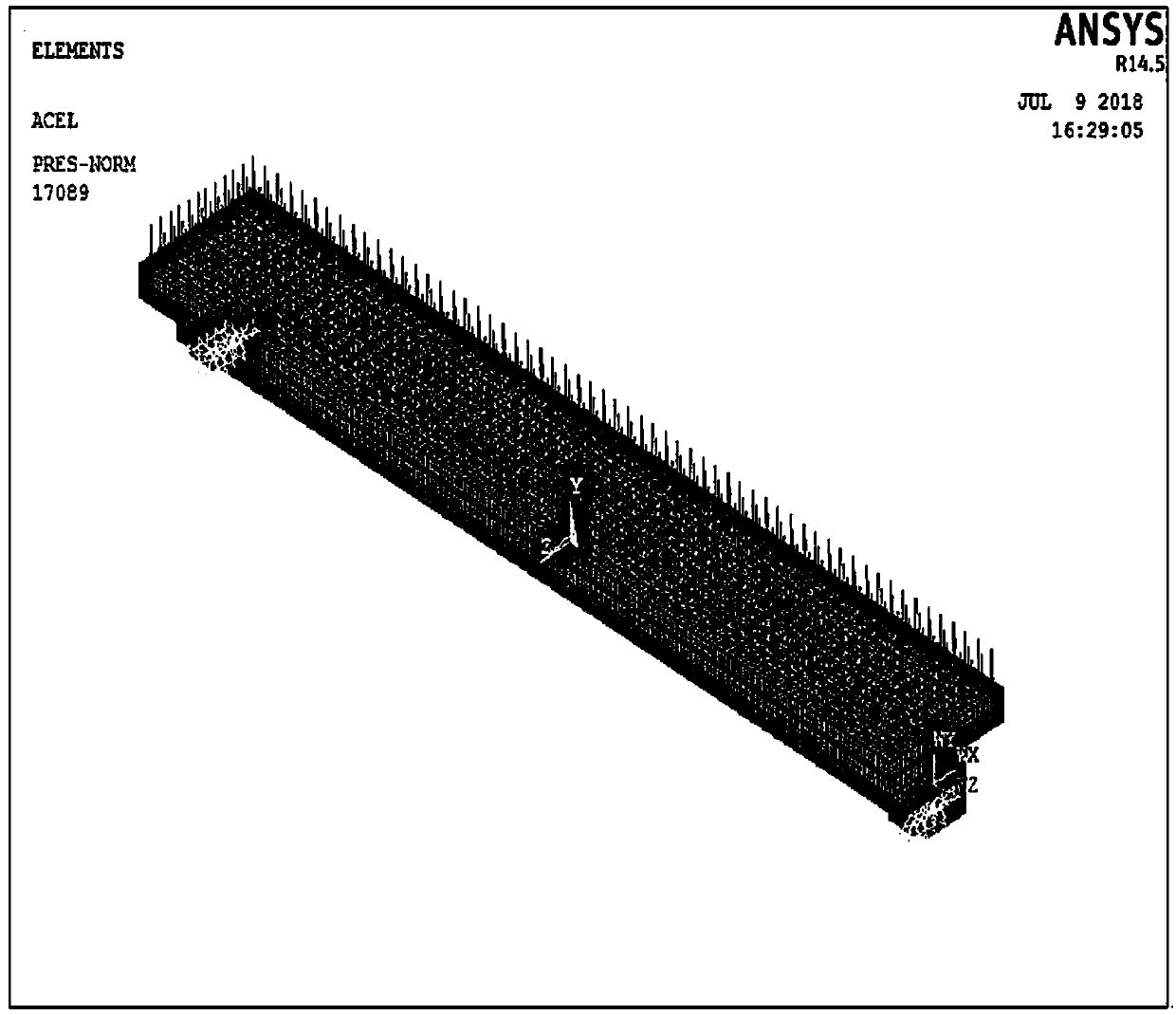

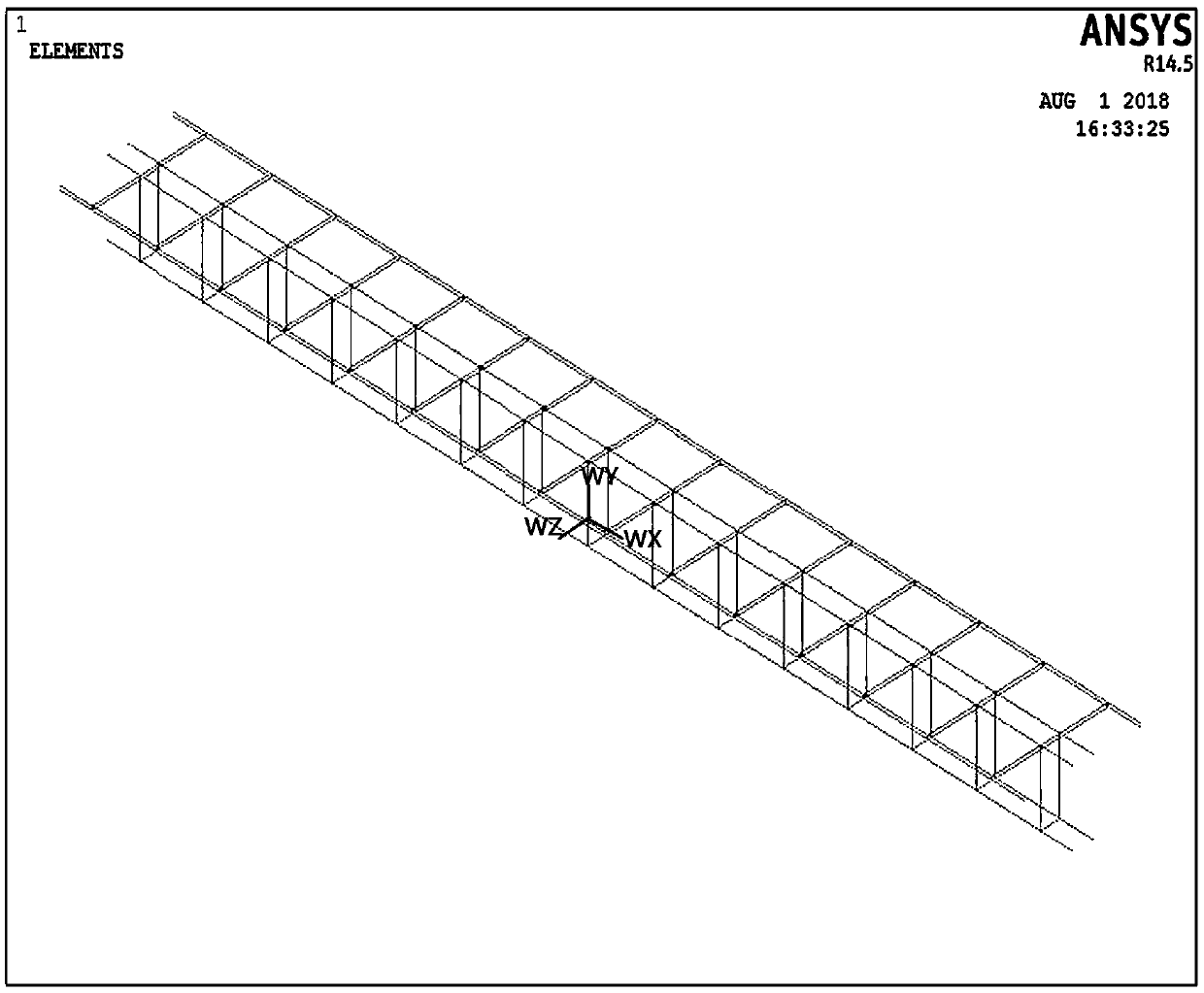

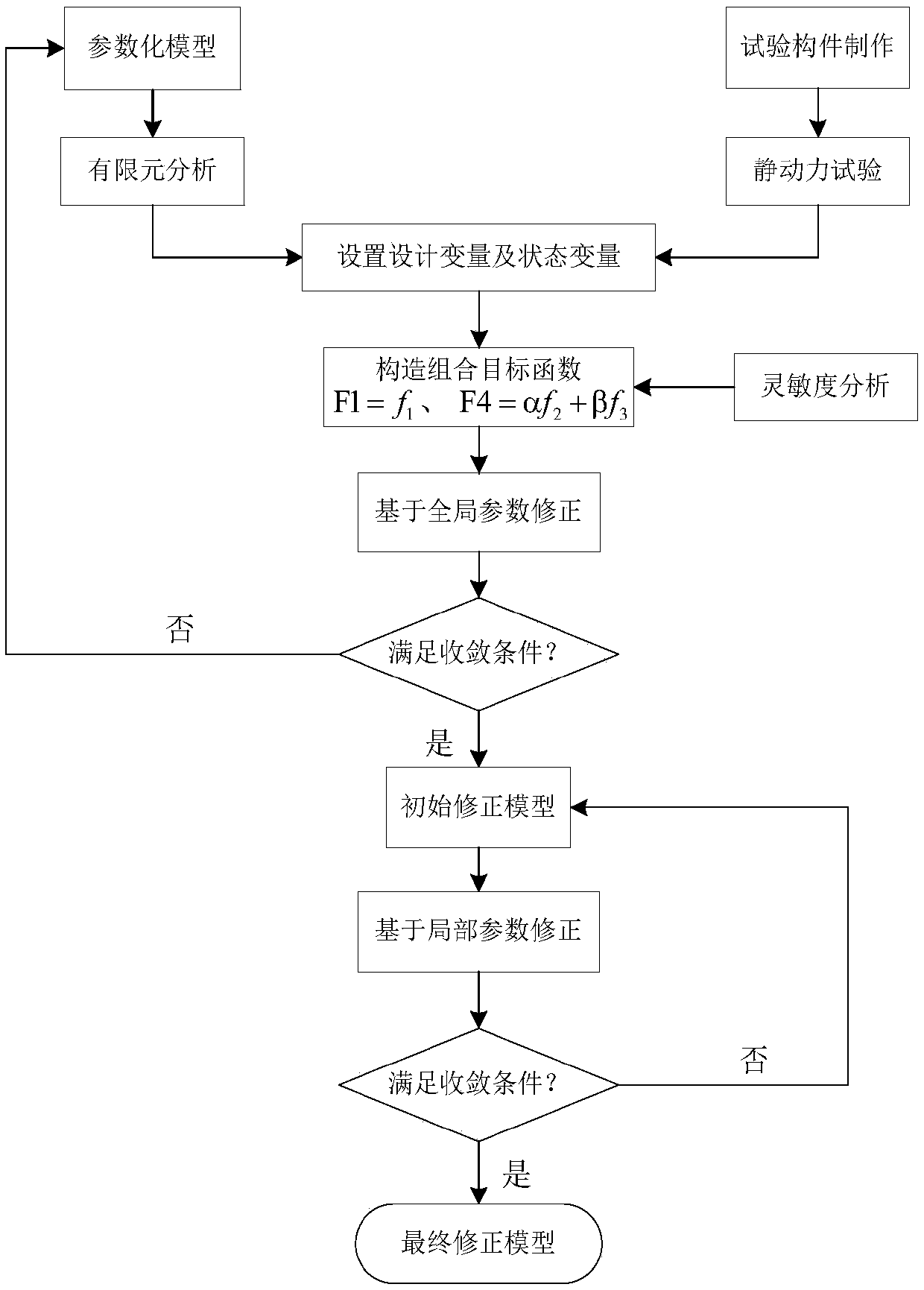

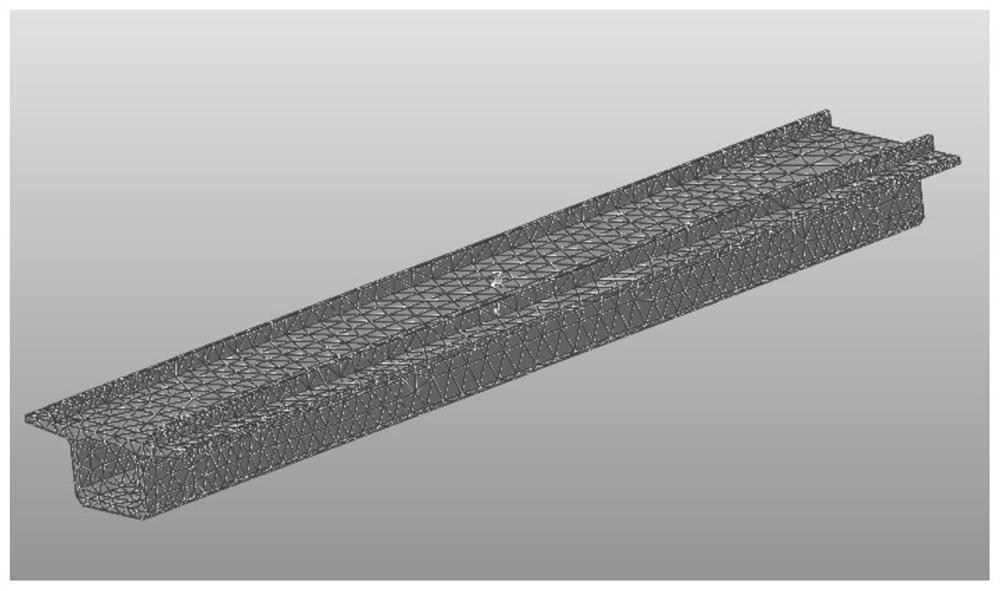

Parameter classification-step model correction method based on sensitivity analysis

InactiveCN109657289AReduce mutual constraintsReduce interactionGeometric CADSpecial data processing applicationsReinforced concreteThree-dimensional space

The invention relates to a Parameter classification-step model correction method based on sensitivity analysis. The invention discloses a step-by-step model correction method, belongs to the technicalfield of model correction, and solves the problem of model correction of a reinforced concrete T-shaped section simply supported beam comprehensively considering static and dynamic responses. The method comprises the following steps: S1, establishing a simply supported beam finite element model: establishing a three-dimensional space model by using a separated modeling method; S2, selecting correction parameters, including the following steps: S21, parameter primary selection; and S22, sensitivity analysis. S3, parameter classification based on sensitivity analysis. The step-by-step correction strategy comprises the following small steps: S31, global correction; and S32, local correction. According to the method, mutual restriction and mutual influence of different response residual termsin the correction process are reduced to a great extent, the corrected model can accurately reflect the static and dynamic response of the real structure, and the corrected physical parameters and boundary conditions are basically consistent with the real structure.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

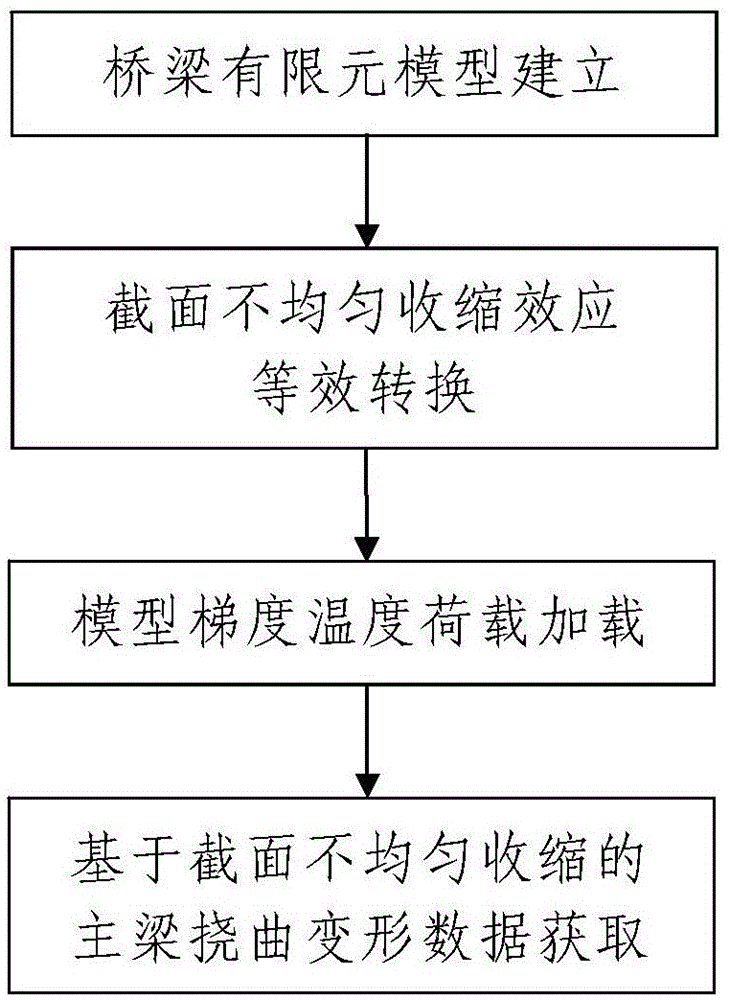

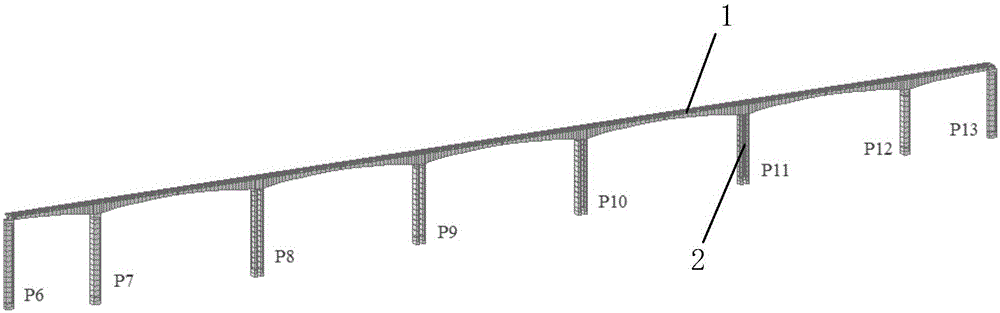

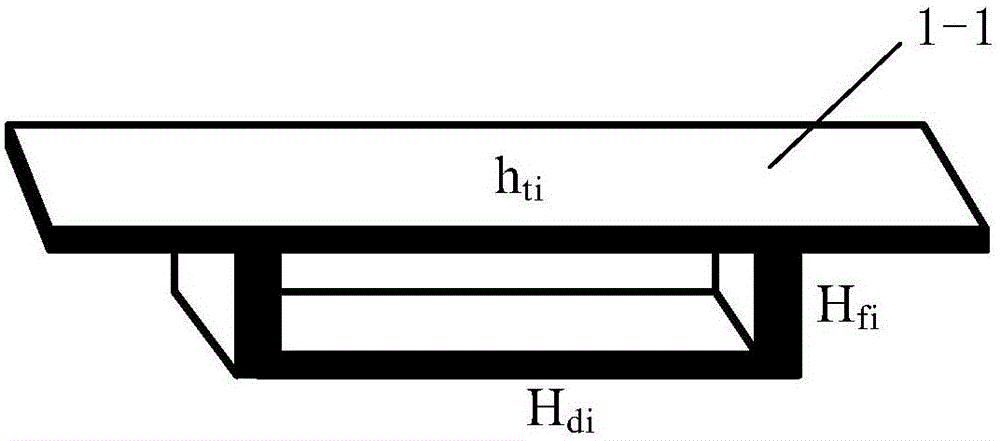

Section uneven shrinkage effect-based girder flexural deformation predicting method

InactiveCN105117510AThe method steps are simpleReasonable designSpecial data processing applicationsElement modelElement analysis

The invention discloses a section uneven shrinkage effect-based girder flexural deformation predicting method. The method comprises the following steps: I, establishment of a bridge finite element model: dividing a girder to be analyzed into N girder units, wherein the girder to be analyzed is a PC box girder; II, equivalent conversion of the section uneven shrinkage effect: respectively carrying out equivalent conversion on the section uneven shrinkage effect of each girder unit at a t moment to obtain the equivalent gradient temperature of each girder unit, wherein the equivalent conversion process comprises the selection of sections to be analyzed, the calculation of top plate shrinkage strain and bottom plate shrinkage strain and the calculation of the equivalent gradient temperature, and the equivalent gradient temperatures of N girder units form equivalent gradient temperature load information; III, loading of the model gradient temperature load; IV, obtaining of girder flexural deformation data on the basis of section uneven shrinkage. The method provided by the invention is simple in steps, reasonable in design and good in using effects; and a finite element analysis method is used to predict the girder flexural deformation by also considering the influence factors of the section uneven shrinkage, so that the prediction precision is high and the prediction is convenient to realize.

Owner:XIAN HIGHWAY INST

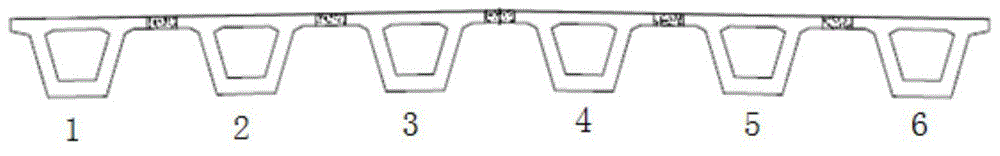

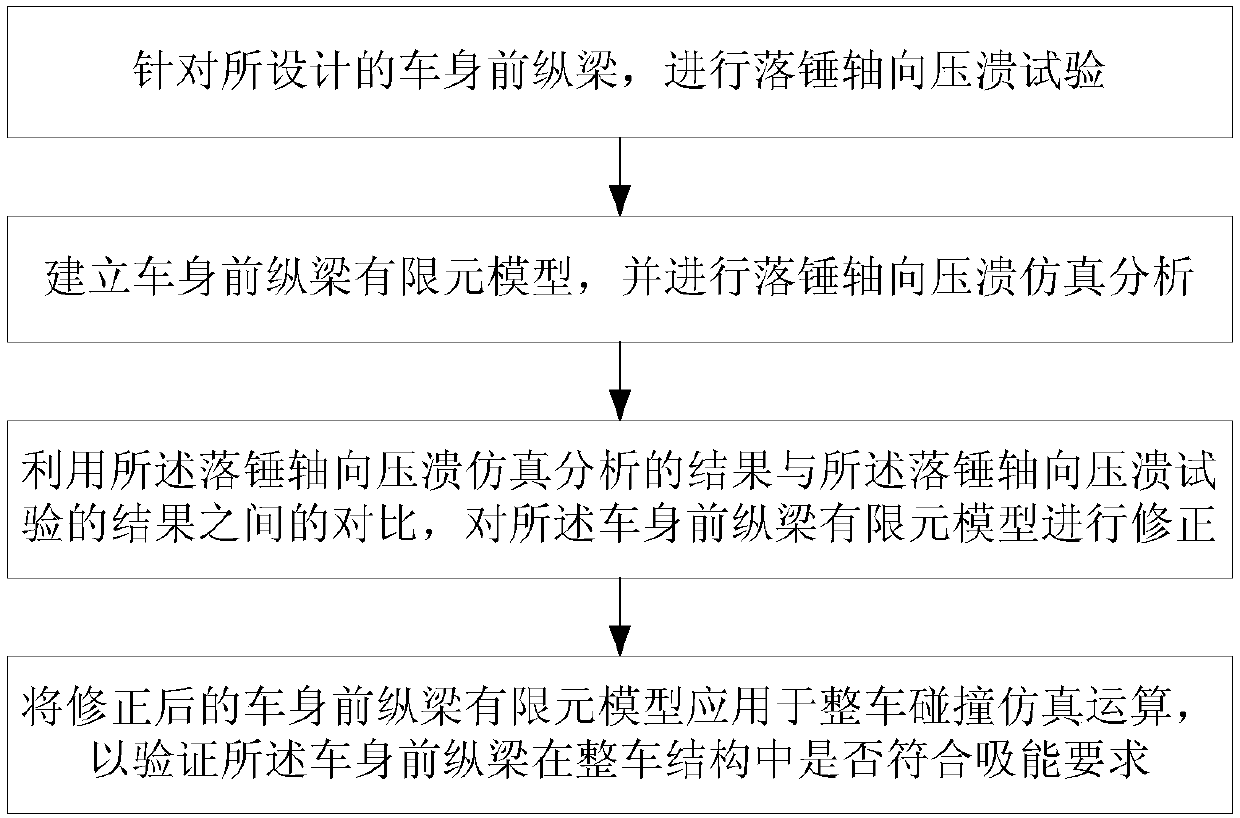

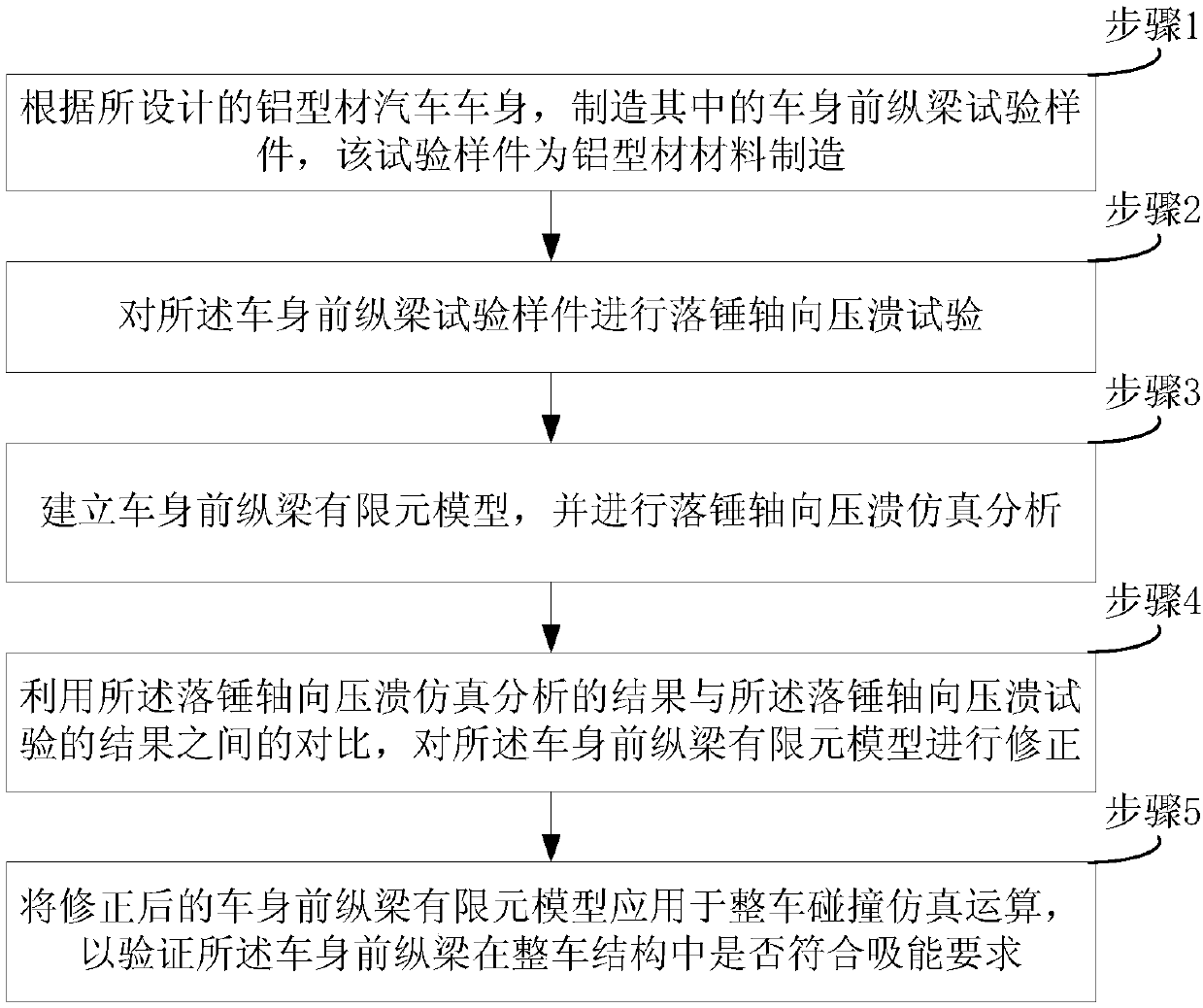

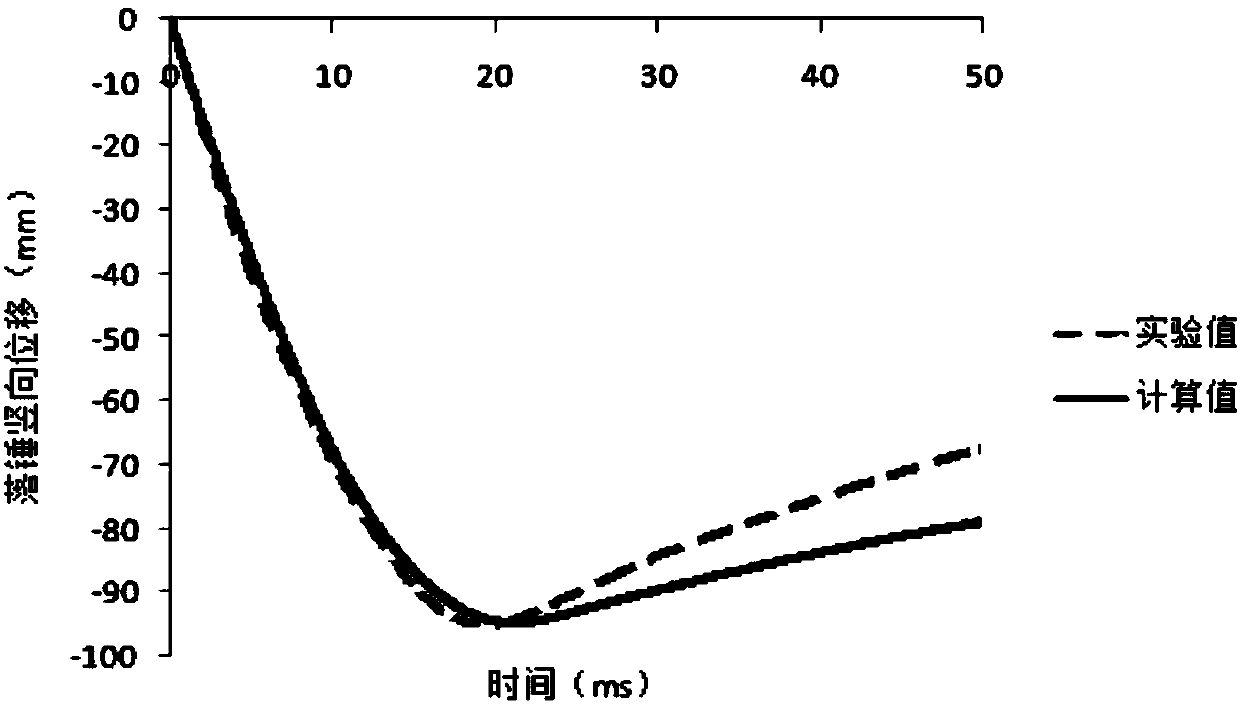

Car body front longitudinal beam test method

InactiveCN107609215AGuaranteed accuracyEasy to optimizeSpecial data processing applicationsElement modelEnergy absorption

The invention provides a car body front longitudinal beam test method. According to the method, first, a drop hammer axial crushing test is performed on a designed car body front longitudinal beam toobtain actual test data, then the actual test data is utilized to establish a relevant finite element model, the finite element model is utilized to perform simulation analysis on the car body front longitudinal beam and is corrected, and the finite element model of the car body front longitudinal beam after correction is applied to whole-car crash simulation operation to verify whether the car body front longitudinal beam meets an energy absorption requirement in a whole car structure. Through the method, simulation operation is adopted to replace a large quantity of actual tests, and by useof the advantages of being repetitive, convenient to improve, high in result acquisition speed and the like of simulation operation, a large amount of investment consumed in an actual test is saved, and research and development time is shortened. Meanwhile, the finite element model of the car body front longitudinal beam is corrected through comparison of the simulation analysis result and the actual drop hammer axial crushing test result, so that the accuracy of a simulation calculation result is guaranteed.

Owner:CH AUTO TECH CORP CO LTD

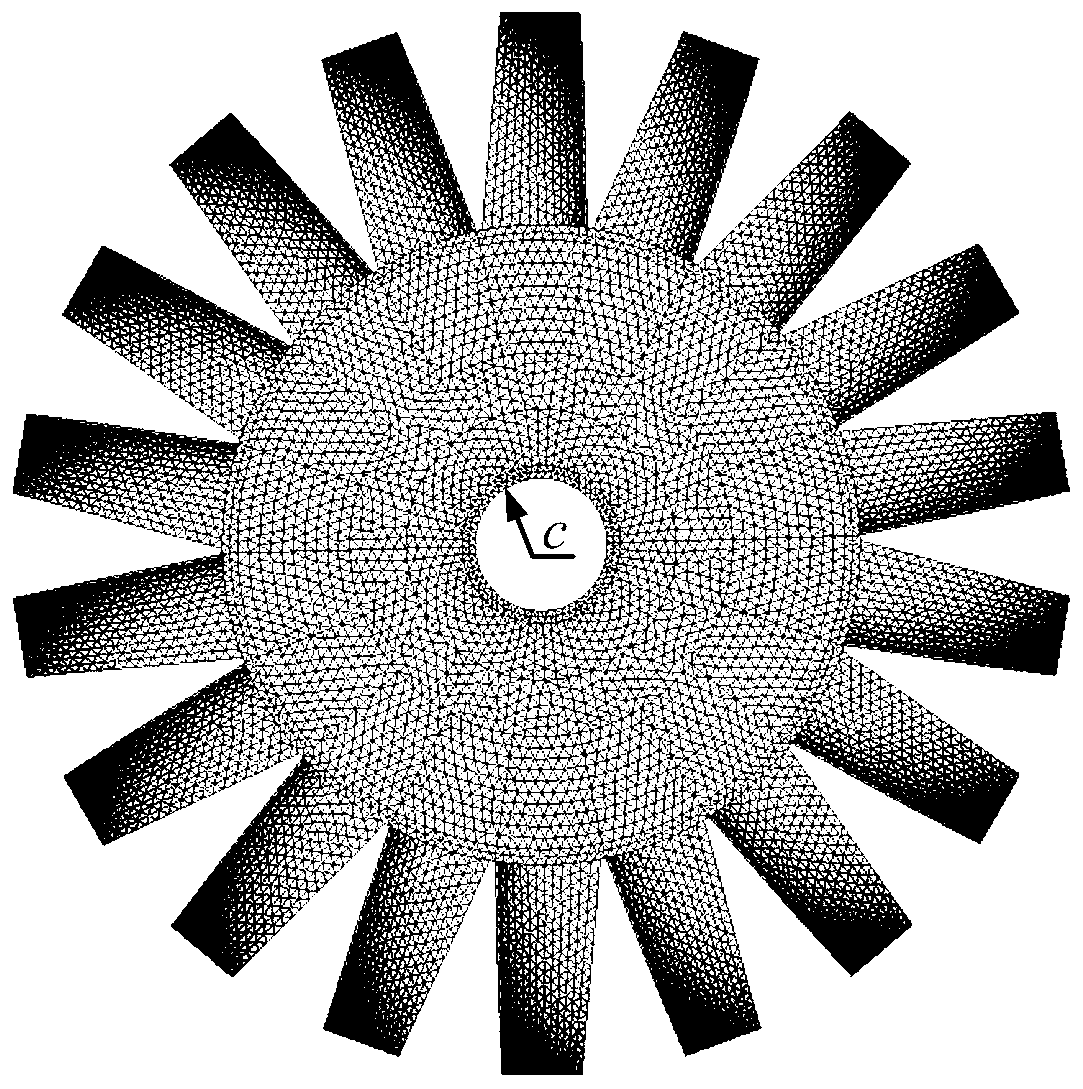

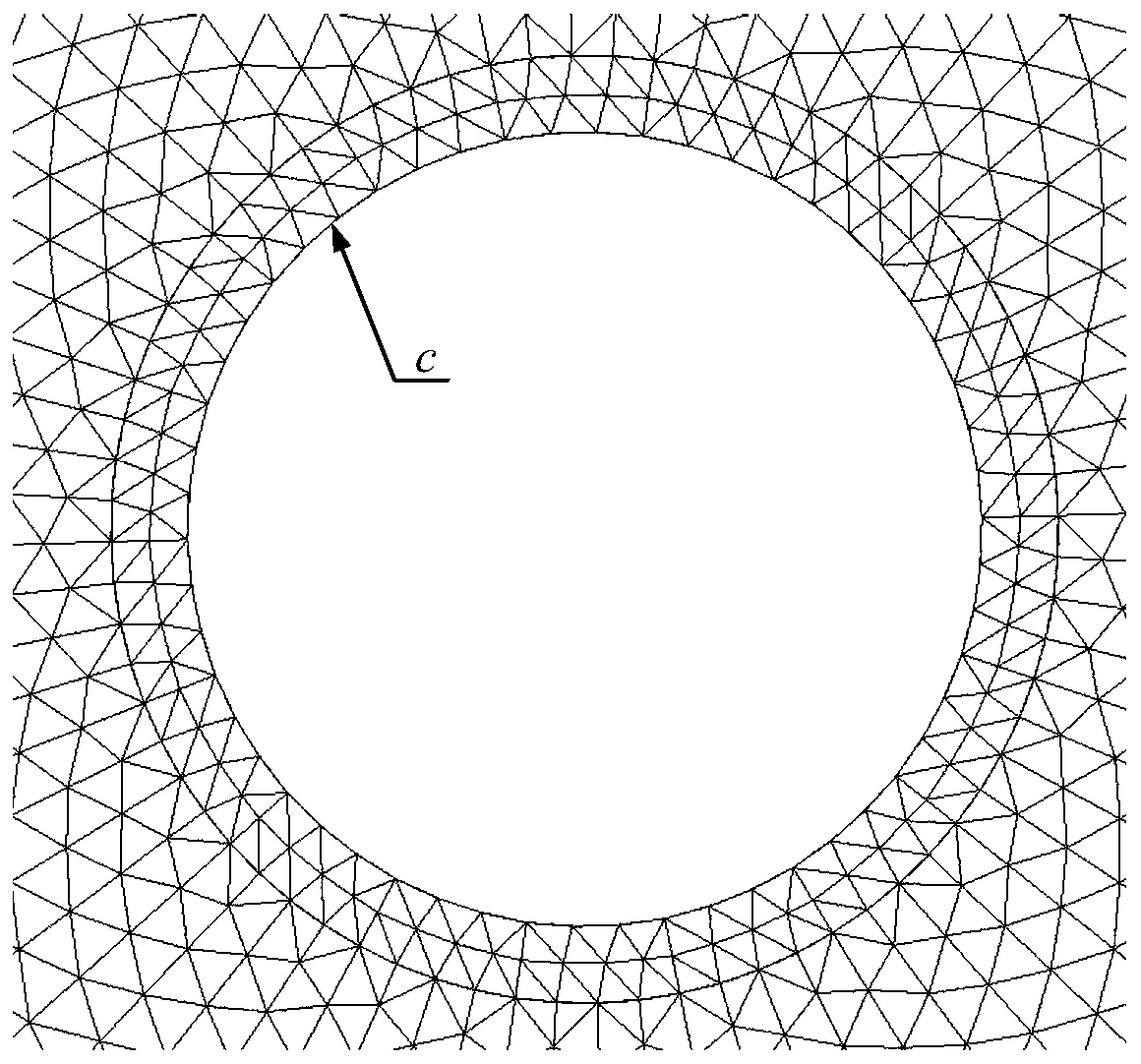

Efficient quantitative modeling method for impeller-bearing-rotor system

PendingCN111209639AEnable accurate modelingRealize quantitative analysisGeometric CADDesign optimisation/simulationElement modelAlgorithm

The invention discloses an efficient quantitative modeling method for an impeller-bearing-rotor system, and the method comprises the steps: 1, respectively building a rotating shaft kinetic model andan impeller kinetic model through an iron-wood-octane beam finite element model and a three-dimensional entity finite element model, and building a kinetic model of a rolling bearing through a five-degree-of-freedom lumped parameter model; 2, establishing at least two six-degree-of-freedom virtual main nodes on a common connection interface of an impeller and a rotating shaft in the impeller dynamic model; 3, constructing non-matching displacement coordination transformation from the entity node to the virtual main node; and 4, performing order reduction on the impeller model by adopting a fixed interface modal synthesis method, and integrating the impeller model, the rotating shaft model and the bearing model to obtain an order reduction model of the whole impeller-bearing-rotor system. According to the method, the analysis efficiency of the rotor kinetic model can be improved, the order of the model is reduced, and a technical support is provided for modeling, analyzing and solving work of large rotating machinery.

Owner:HEFEI UNIV OF TECH

Method for determining blasting demolition order of deep foundation pit support beams

InactiveCN106055801AEnsure safetyEliminate potential safety hazardsDesign optimisation/simulationExcavationsPressure.meanOperability

The invention relates to a method for determining a blasting demolition order of deep foundation pit support beams. According to the technical scheme, the method comprises the steps of partitioning the deep foundation pit support beams, building a deep foundation pit support beam finite element model, determining an area with the maximum average pressure value on the deep foundation pit support beams to be the finally demolished area N<M> and determining front-section ultimate compressive bearing capacity N<pressure> and front-section ultimate tensile bearing capacity N<tension> of the deep foundation pit support beams; eliminating the firstly demolished preliminary demolition scheme conforming to the condition according to the maximum displacement U of the deep foundation pit support beams, the maximal pressure f<pressure> of the deep foundation pit support beams and the maximum tension value f<tension> of the deep foundation pit support beams and employing the minimum value of the maximum displacement U of the deep foundation pit support beams as the firstly demolished preliminary demolition scheme; in a similar way, obtaining a second demolition scheme area, a third demolition scheme and a fourth demolition scheme; and finally determining the local demolition order of the areas. The method can meet the actual bearing requirements; the safety of constructors and surrounding buildings and structures can be ensured; the method conforms to the blasting construction characteristics; and the operability is high.

Owner:WUHAN UNIV OF SCI & TECH

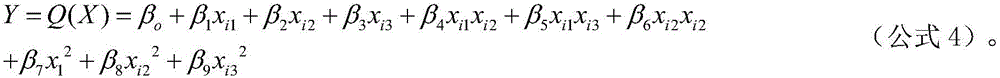

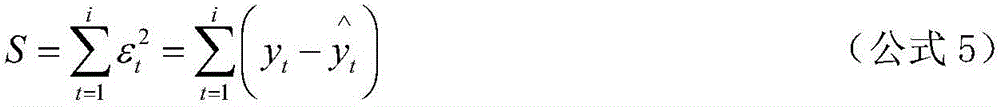

Correction method for bridge finite element model

InactiveCN106257541AReduce the number of calculationsHigh precisionGeometric CADDesign optimisation/simulationUniform designElement model

The invention discloses a correction method for a bridge finite element model. Preliminary parameter optimization is completed by using an orthogonal design method, and then primary parameter correction is completed by using a uniform design method on the basis of the preliminarily optimized parameters. The method is less in finite element calculation frequency and can obtain the high-precision correction result so that the defect of excessively long time consumption of repeated iterative calculation in the correction process of a large finite element model can be avoided, and the efficiency of the correction work of the large finite element model can be enhanced. Then secondary correction is performed on the primary correction parameters by a response surface method, the primary correction result is further optimized, and the correction efficiency of the large finite element model of the bridge can be greatly enhanced by finite times of calculation. The response surface method acts as a mathematical analysis method of combination of experimental design and mathematical statistics and is feasible to be applied to correction of the finite element model of the large complex bridge structure so that high correction efficiency and correction precision can also be guaranteed.

Owner:CHANGAN UNIV

Heavy planomiller beam gravity deformation predicting method based on finite difference method

ActiveCN104636543AStrong complementaritySolve the problem of inaccurate finite element analysis resultsSpecial data processing applicationsBeam finite elementsFlexural rigidity

The invention provides and relates to a heavy planomiller beam gravity deformation predicting method based on the finite difference method. The heavy planomiller beam gravity deformation predicting method aims at solving the problems that by means of an existing finite element analyzing and calculating method, the beam gravity deformation curve can not be accurately calculated under the condition that actual material properties are not uniform and then the difference between the calculation result and the actual deformation value is large. The method includes the steps of firstly, obtaining the beam gravity deformation curve; secondly, simplifying the beam gravity deformation curve into a beam gravity deformation model and a beam torsional deformation model; thirdly, establishing a beam gravity deformation discrete model; fourthly, calculating the equivalent flexural rigidity; fifthly, obtaining a beam finite element gravity deformation curve; sixthly, separating the finite element gravity deformation curve; seventhly, obtaining the final beam gravity deformation curve. The method is applied to the prediction of the heavy planomiller beam gravity deformation.

Owner:HARBIN INST OF TECH

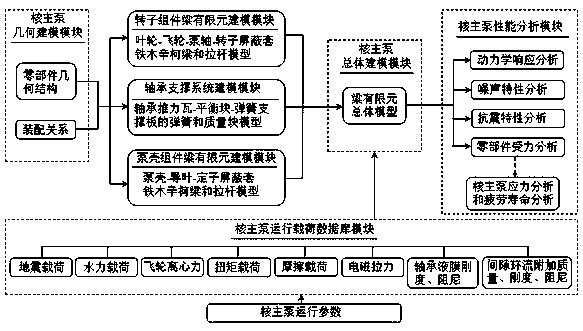

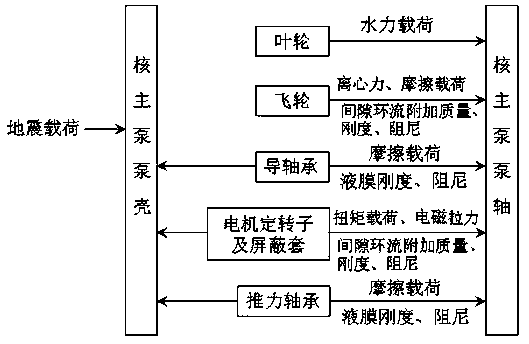

Method for constructing shielded nuclear main pump digital prototype based on beam finite element model

ActiveCN110598316AMeet performance simulation needsAccurate assessment of kinetic responseSpecial data processing applicationsSupporting systemInformation support

The invention discloses a method for constructing a shielded nuclear main pump digital prototype based on a beam finite element model, and belongs to nuclear reactor coolant pump design and manufacturing. The method comprises the following construction steps: 1, generating a nuclear main pump geometric modeling module according to a nuclear main pump part geometry and assembly relationship; 2, onthe basis of the nuclear main pump geometric model, generating a rotor assembly beam finite element modeling module, a bearing support system modeling module and a pump shell assembly beam finite element modeling module; 3, integrating a rotor assembly model, a bearing support system model and a pump shell assembly model, establishing a beam finite element overall model, generating a nuclear mainpump overall modeling module, and constructing a nuclear main pump three-dimensional digital prototype by taking an operation load database module under nuclear main pump operation parameters as information support; and 4, the nuclear main pump performance analysis module receiving the three-dimensional digital prototype, calling beam finite element overall model calculation data as input, and outputting simulation results of nuclear main pump dynamic response and noise analysis, anti-seismic analysis and part stress analysis. The method has the advantage of accurate analysis of nuclear main pump dynamic characteristics.

Owner:DALIAN UNIV OF TECH

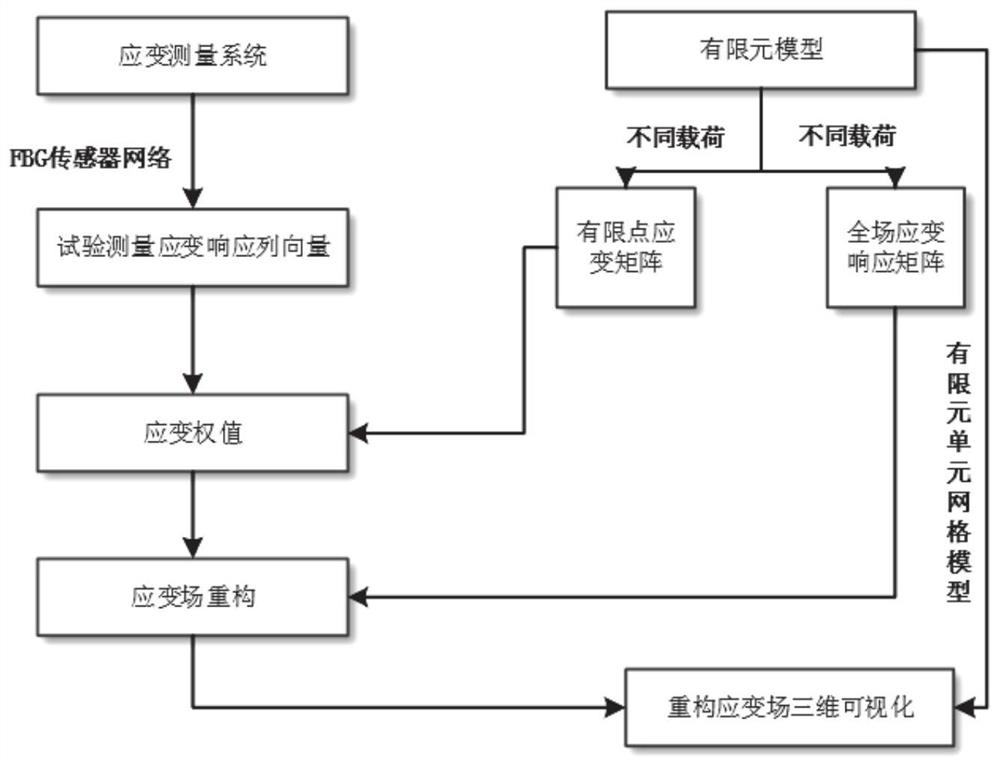

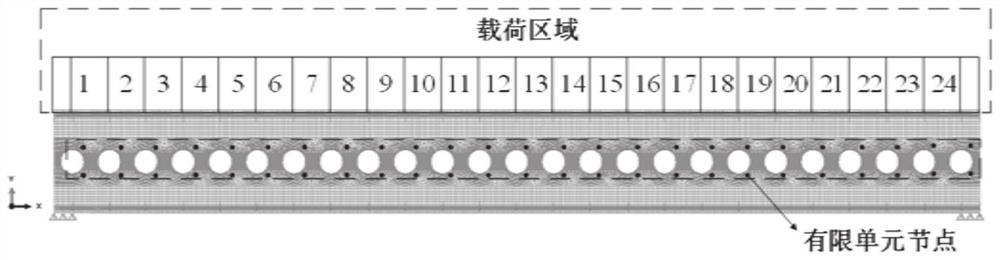

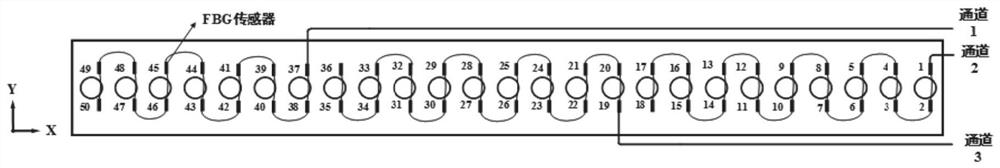

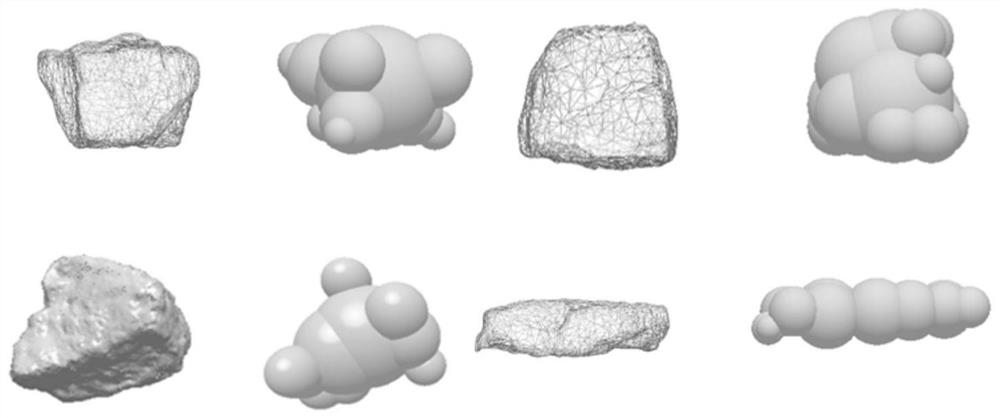

Strain field reconstruction visualization method and system based on load strain linear superposition

ActiveCN112989491AStrain field reconstruction is accurateApplicable to strain state monitoringGeometric CADDesign optimisation/simulationFull field strainEngineering

The invention provides a strain field reconstruction visualization method and system based on load strain linear superposition. The method comprises the following steps: acquiring beam parameter data and beam surface strain data; obtaining a full-field strain value according to the obtained data, and mapping the full-field strain value to a unit grid node of the beam finite element model, wherein the calculation of the full-field strain value comprises the following steps: obtaining a strain response column vector according to the surface strain data of the cross beam; obtaining a strain response matrix of finite element nodes and a structural full-field strain response matrix according to the obtained beam parameter data; obtaining a strain weight according to the strain response column vector and the strain response matrix of the finite element node; and obtaining a full-field strain value under the static load working condition according to the full-field strain response matrix and the strain weight. According to the method, a load and strain reconstruction model is established by extracting mechanical parameters such as strain on the basis of an elastic mechanics principle by applying a linear superposition means, and accurate reconstruction of the cross beam structure is realized.

Owner:SHANDONG UNIV

Construction method of ballast track-bridge dynamic coupling model

PendingCN111797459AImprove calculation accuracyHigh precisionGeometric CADDesign optimisation/simulationElement modelTrackway

The invention discloses a construction method of a ballast track-bridge dynamic coupling model. The method comprises the steps that a ballast track bed discrete element model reflecting the complex shape and the contact relation of a railway ballast is established through a discrete element method, and the model is used for representing a particle unit accumulation structure, the contact force between particles and coupling surfaces and an equivalent node transplantation load; a continuous medium sleeper finite element model and a bridge finite element model are established by utilizing a multi-body finite element method, wherein the models are used for representing a continuum grid structure, node displacement deformation, surface node position coordinates and an element connection relationship; and a ballast track-bridge dynamic coupling model is constructed based on a discrete element and multi-body finite element coupling method. According to the method, the irregular shape and themutual meshing and stacking relation of the ballasts on the mesoscopic level are fully considered, meanwhile, the interaction between the macroscopic ballast bed and the upper and lower structures can be reflected, and refined simulation of the complex mechanical behaviors of the ballast track on the bridge under the train load effect is achieved.

Owner:BEIJING JIAOTONG UNIV

Pier structure state evaluation method based on variable-speed vehicle excitation and wavelet packet analysis

ActiveCN110532657AIncreased sensitivityImprove accuracySustainable transportationSpecial data processing applicationsBeam finite elementsDecomposition

The invention discloses a pier structure state evaluation method based on variable-speed vehicle excitation and wavelet packet analysis, and belongs to the technical field of bridge working state detection and evaluation. The invention provides a pier structure state evaluation method based on variable-speed vehicle excitation and wavelet packet analysis in order to improve the accuracy of pier structure detection and identification. According to the invention, the accurate bridge finite element model is established by using a model correction method, and a vehicle brake numerical simulation method is provided, so that a brake test scheme suitable for the bridge to be detected can be formulated more accurately. A proper wavelet basis function decomposition level is selected by using a costfunction, a pier top free attenuation section signal is used as a research object, and feature information with high sensitivity to damage is acquired through a wavelet packet decomposition signal processing mode. Indexes with high damage sensitivity and robustness are constructed, then the damage position and degree of the pier are recognized, and the performance state of the pier structure is evaluated.

Owner:HARBIN INST OF TECH

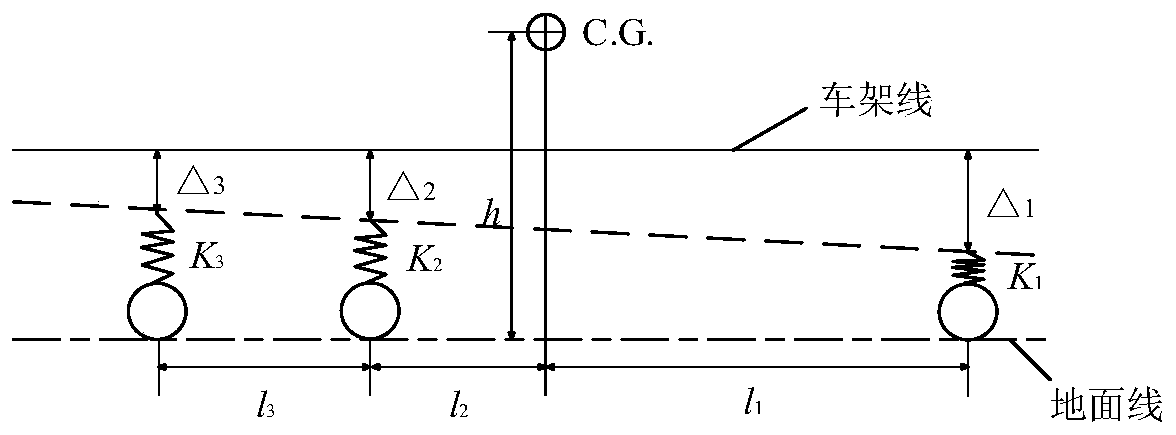

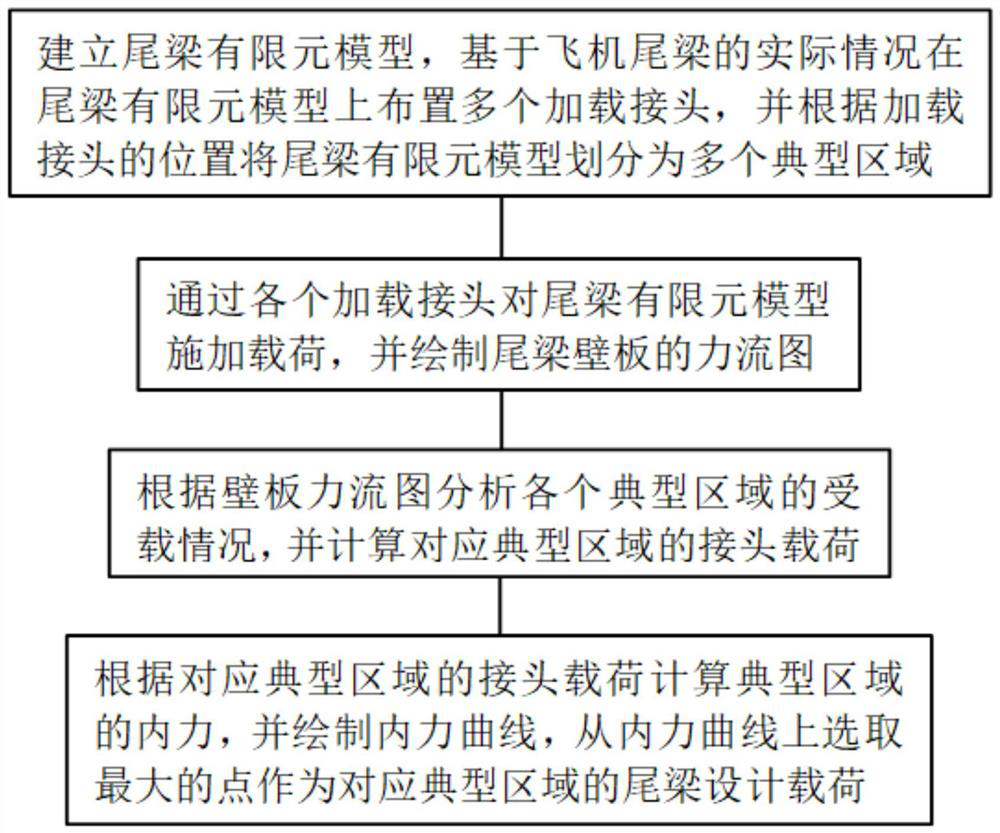

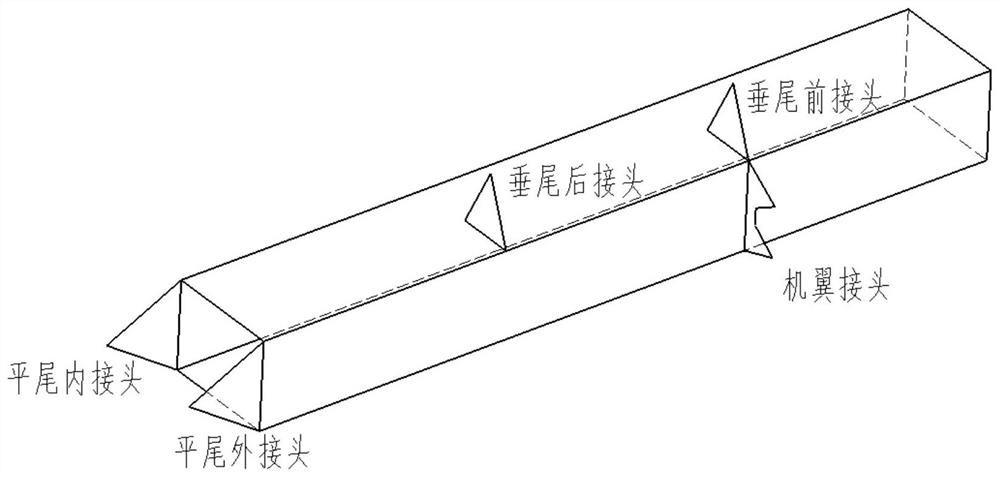

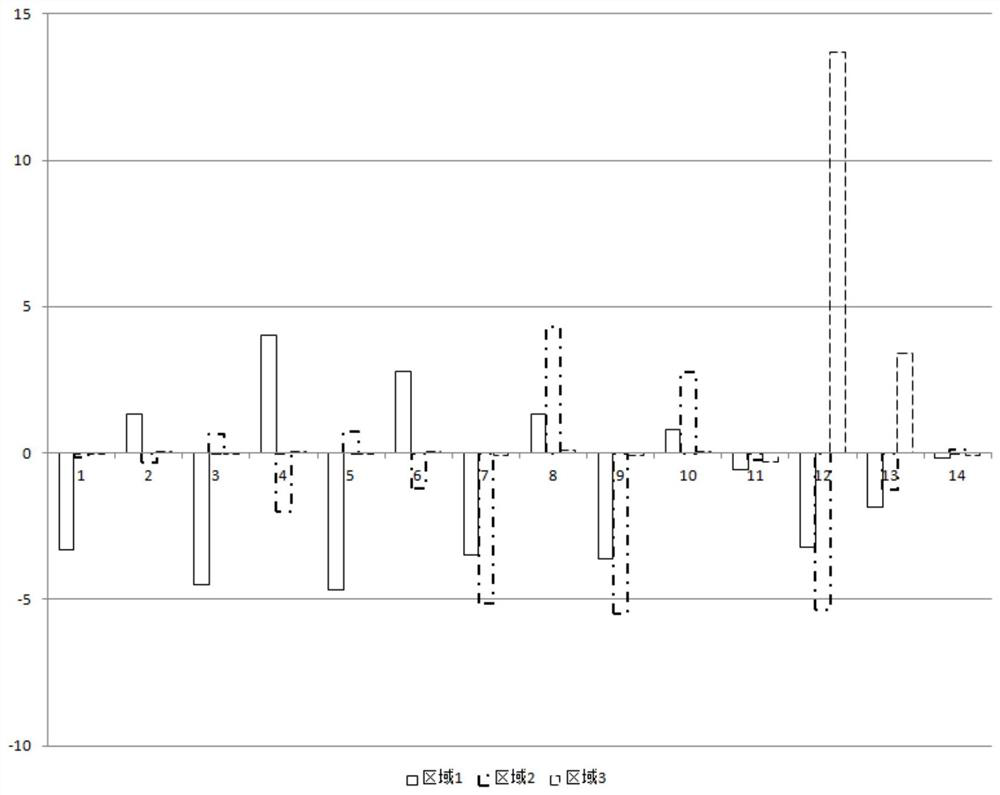

Airplane tail beam structure design load screening method

ActiveCN112632701AEnsure safetySmall amount of calculationGeometric CADDesign optimisation/simulationDesign loadControl theory

The invention belongs to the field of airplane loading tests, and particularly relates to an airplane tail beam structure design load screening method. The method comprises: 1, establishing a tail beam finite element model, arranging a plurality of loading connectors on the tail beam finite element model based on the actual situation of the aircraft tail beam, and dividing the tail beam finite element model into a plurality of typical areas according to the positions of the loading connectors; 2, applying a load to the tail beam finite element model through each loading joint, and drawing a force flow diagram of the tail beam wallboard; 3, analyzing the loading condition of each typical region according to the wallboard force flow diagram, and calculating the joint load of the corresponding typical region; and 4, calculating the internal force of the typical region according to the joint load of the corresponding typical region, drawing an internal force curve, and selecting the maximum point from the internal force curve as the tail beam design load of the corresponding typical region. The tail beam design load can be rapidly screened out from thousands of load conditions, and design input is provided for tail beam structure design.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Method for testing bridge strain flexibility matrix

PendingCN113639941AStrain predictionStrain accurateGeometric CADDesign optimisation/simulationVertical vibrationElement model

The invention discloses a method for testing a bridge strain flexibility matrix, which comprises the following steps of: establishing a finite element model according to a design drawing of a bridge, designing an acceleration sensor arrangement scheme, acquiring vertical vibration acceleration response of the bridge under environmental excitation by using an acceleration sensor arranged on the bridge, identifying basic modal parameters such as a vibration mode and a frequency of a bridge by applying a modal identification method, acquiring a concentrated mass matrix of a structure according to the bridge finite element model, calculating a vibration mode mass normalization coefficient, then normalizing an actually measured vibration mode, calculating a strain vibration mode and a strain flexibility matrix of the bridge by utilizing the normalized vibration mode, and predicting the modal strain of the bridge so that the target of conveniently and quickly measuring the actual strain of the bridge is achieved.

Owner:SHANDONG JIANZHU UNIV +1

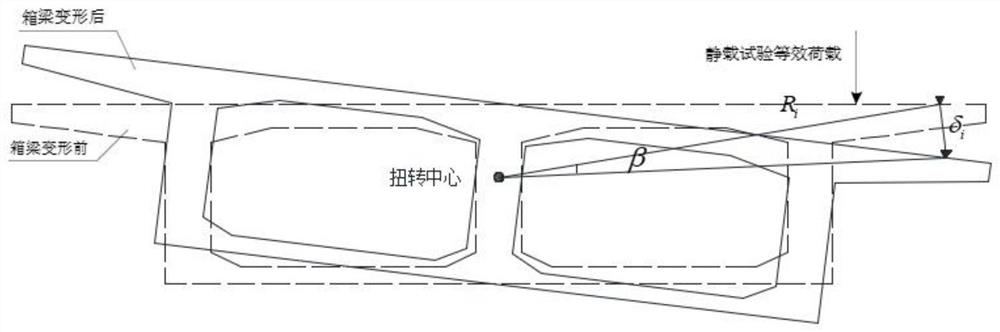

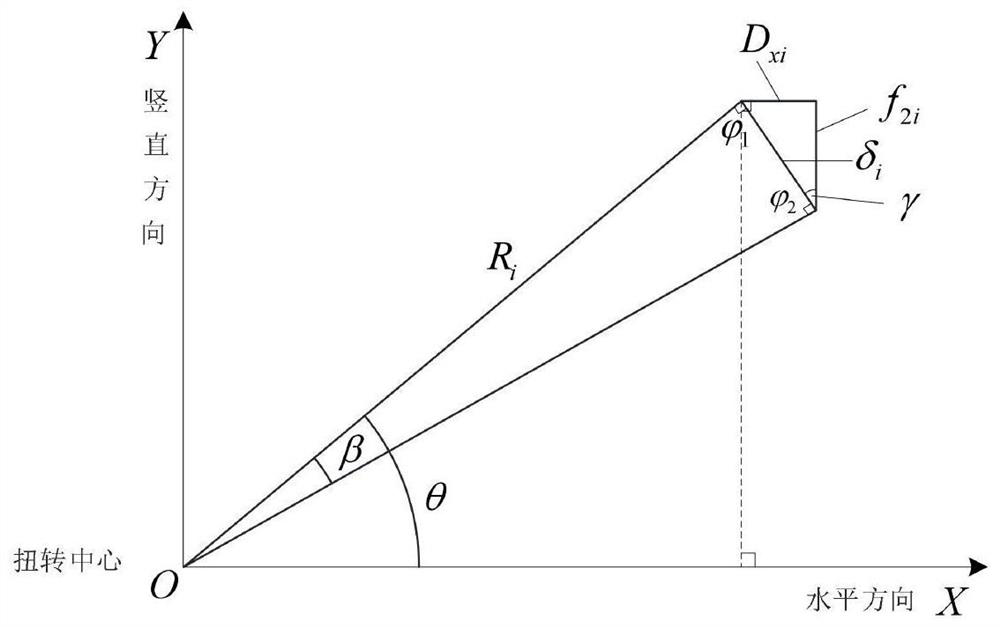

Test method for determining unbalance loading deflection of box girder bridge based on single-girder finite element model

ActiveCN111859768AOvercoming economyOvercome needsGeometric CADDesign optimisation/simulationElement modelArchitectural engineering

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +2

Bridge Dynamic Deflection Monitoring Method Based on Optimal Arrangement of Inclinometers

ActiveCN110319990BAccurate predictionAvoid wastingGeometric CADDesign optimisation/simulationElement modelData set

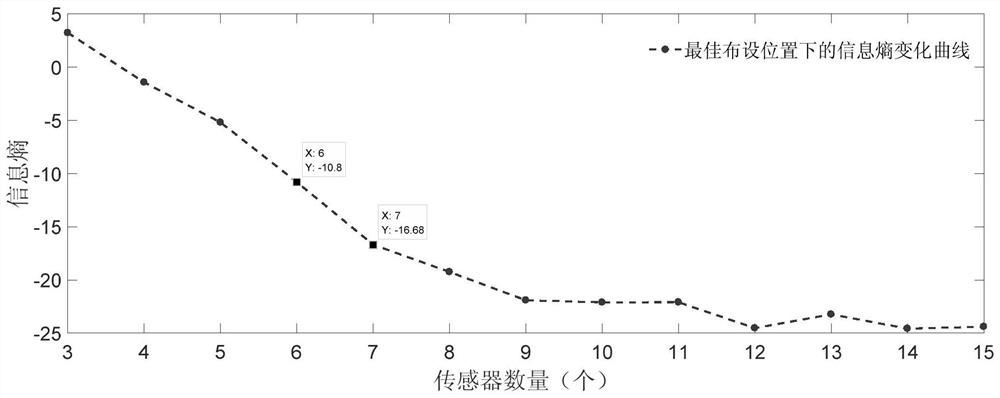

The present invention proposes a bridge dynamic deflection monitoring method based on the optimized arrangement of inclinometers, which includes: establishing an inclination-dynamic deflection conversion equation, simulating bridge deck passing vehicles in the bridge finite element model, and extracting the inclination time of candidate nodes for inclinometer layout The process data and the displacement time history data of key bridge sections are used as the data set for genetic algorithm optimization training. In the optimization process, information entropy is used as the fitness function, so as to obtain the optimal layout position of the inclinometer under a fixed number and the corresponding information entropy. The critical information entropy is determined with the relative error of the time-history displacement of the key section of the bridge in the predicted finite element model equal to 5% as the limit, and the information less than or equal to the critical information is found in the information entropy corresponding to the number of sensors under the optimal arrangement of the inclinometer. The minimum value of the number of sensors in the entropy is the optimal number of sensors, and the optimal layout position corresponding to the optimal number of sensors is the layout position of the inclinometer. This method can accurately predict the dynamic deflection of the bridge.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +1

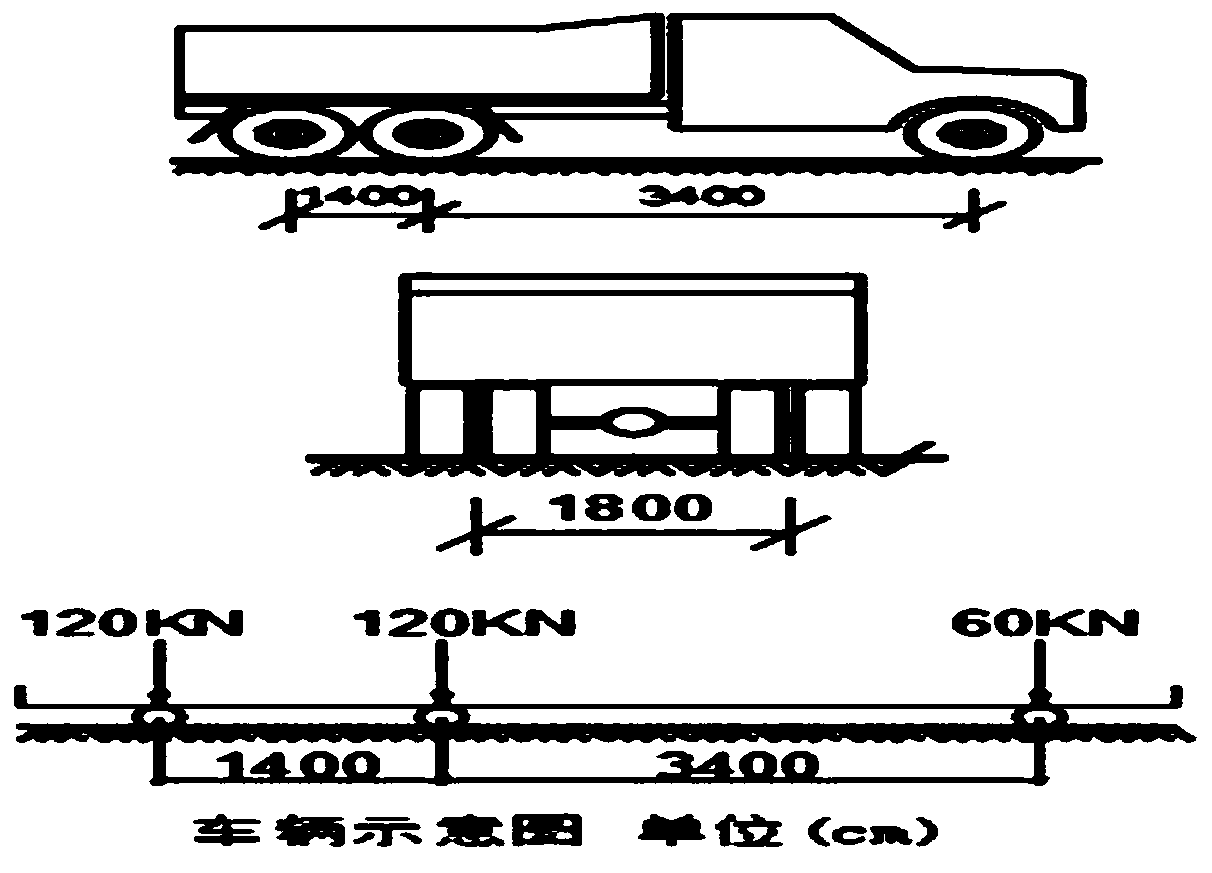

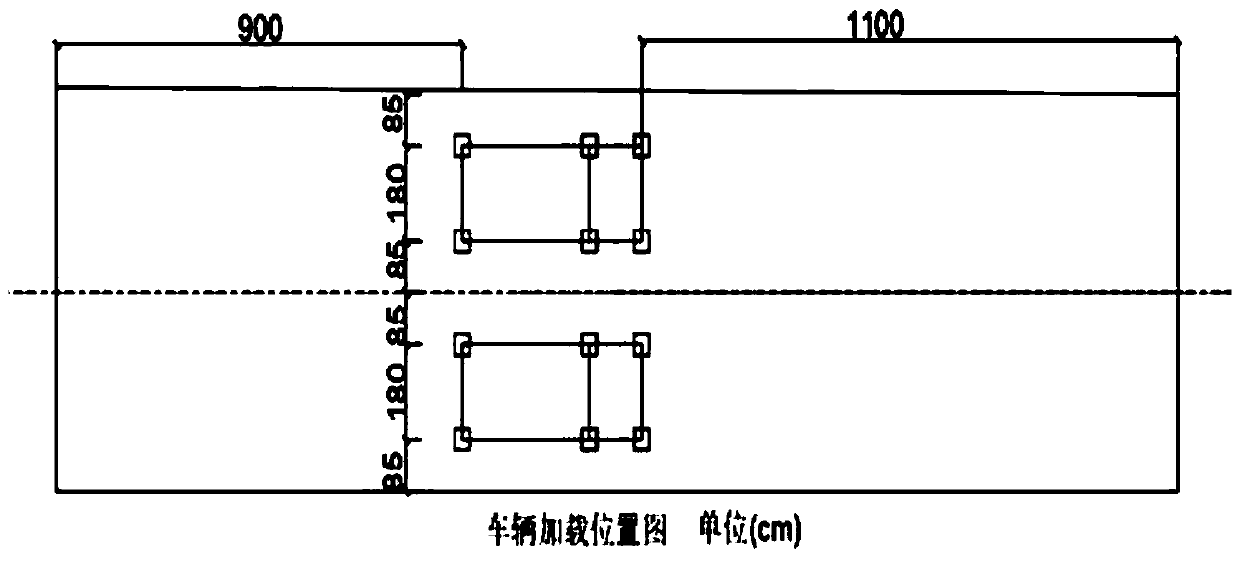

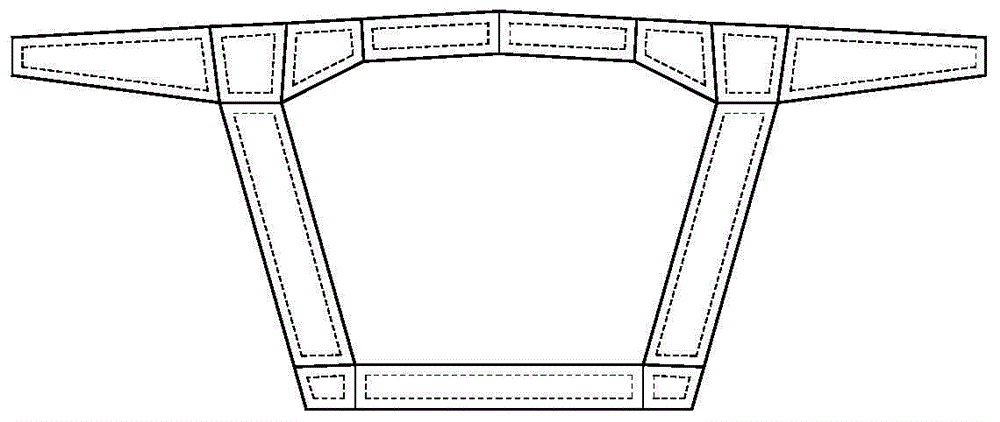

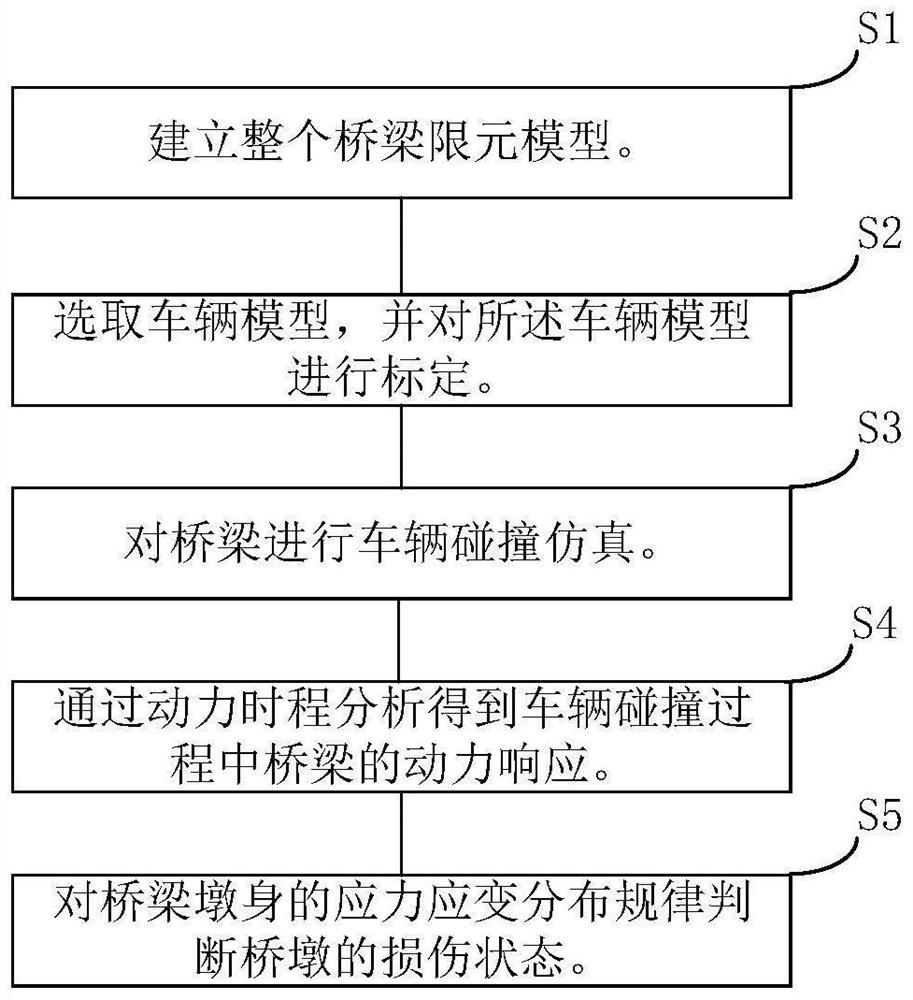

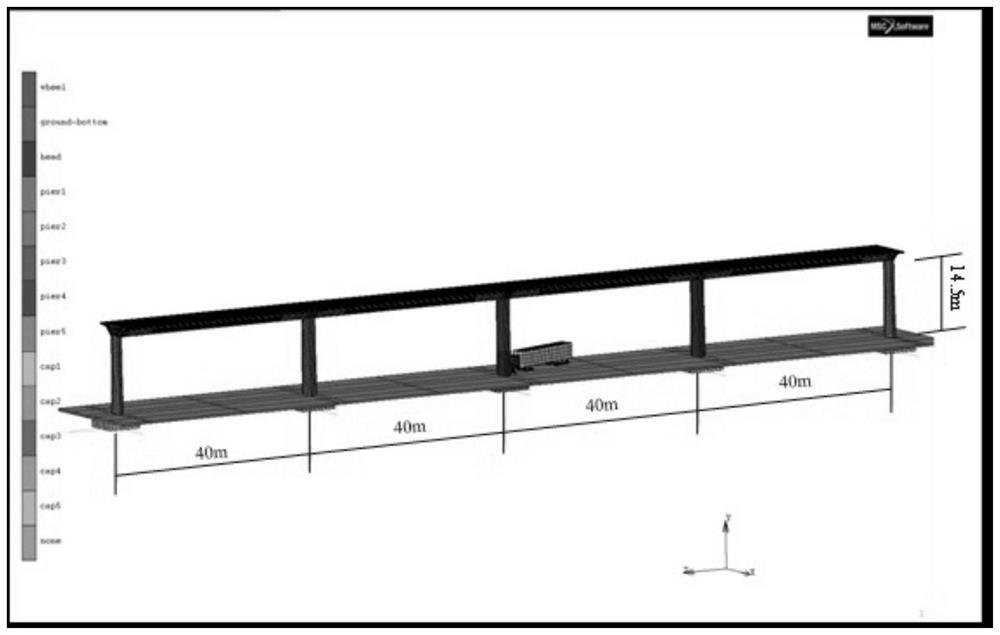

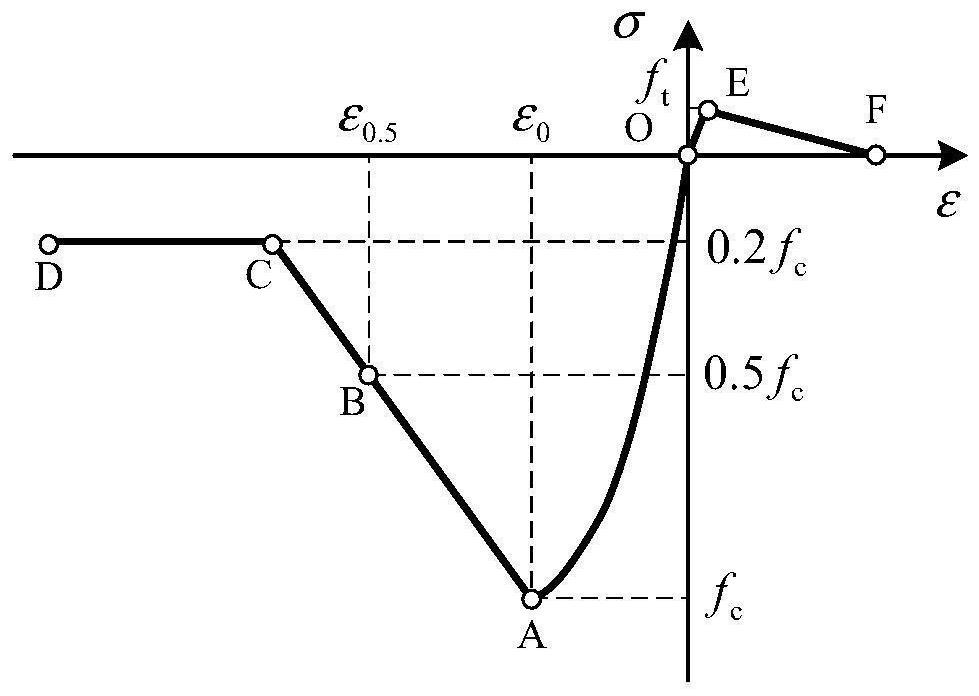

Single thin-wall continuous rigid frame bridge pier collision simulation method

PendingCN114417662ADesign optimisation/simulationSpecial data processing applicationsRigid frameBeam finite elements

The invention provides a single thin-wall continuous rigid frame bridge pier collision simulation method. The method comprises the following steps: establishing a finite element model of a whole bridge; selecting a vehicle model, and calibrating the vehicle model; performing vehicle collision simulation on the bridge; the dynamic response of the bridge in the vehicle collision process is obtained through dynamic time history analysis; and judging the damage state of the bridge pier according to the stress-strain distribution rule of the bridge pier body. According to the method, a vehicle and bridge fine finite element model considering material nonlinearity, geometric nonlinearity, geometric nonlinearity and a material rate effect is established, and numerical simulation is carried out on the process that the lower structure of the rigid frame bridge is subjected to heavy vehicle collision. The dynamic response of the bridge in the vehicle collision process is obtained through dynamic time history analysis, the damage state of the bridge pier is judged according to the distribution rule of the stress strain of the pier body, and a theoretical basis is provided for the anti-collision measure design of the single thin-wall continuous rigid frame bridge pier.

Owner:GUANGZHOU METRO DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com