Fracture surface pre-processing method for variable cross-section beam finite element model

A variable cross-section beam and finite element technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as cross-section matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will be further described below in conjunction with the examples, but it should not be understood that the scope of the subject of the present invention is limited to the following examples. Without departing from the above-mentioned technical ideas of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the protection scope of the present invention.

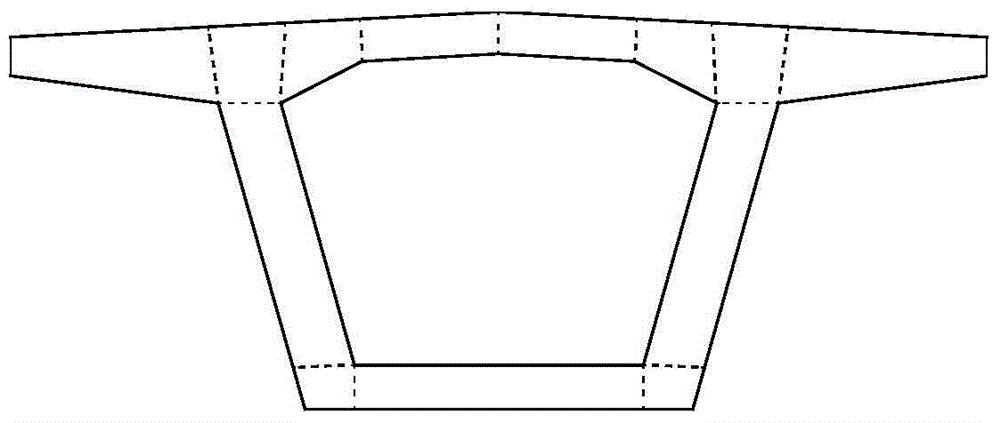

[0088] 1) Select two similar sections

[0089] Select two adjacent sections in the variable-section box girder, see attached Figure 13 , and the units in the figure are centimeters. In the axial direction, the total width of the two sections and the thickness of the plate remain constant, while the beam height changes linearly along the length.

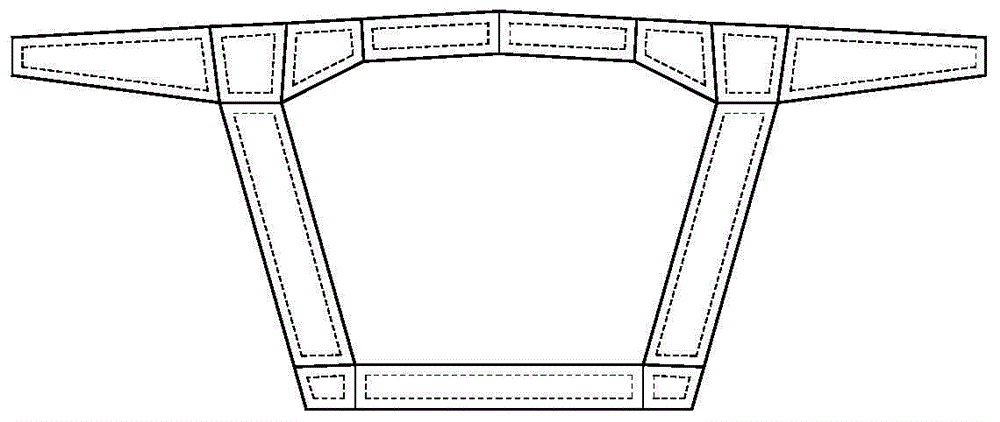

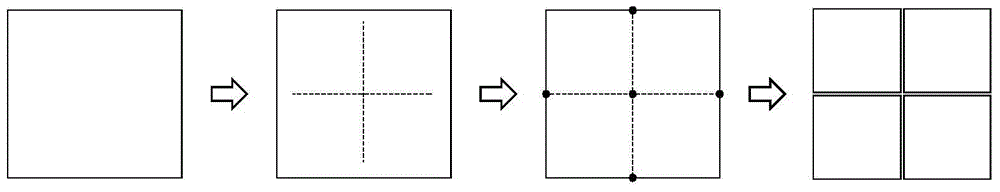

[0090] 2) Draw a dividing line in the section and automatically generate a quadrilateral unit

[0091] Draw several dividing lines in the section ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com