Method, device and system for controlling hydrostatic power transmission system

A technology of power transmission system and control device, which is applied in the direction of control device, non-electric variable control, control/regulation system, etc., can solve the problem of unsatisfactory fuel consumption saving, and achieve the effect of saving fuel consumption and ensuring matching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

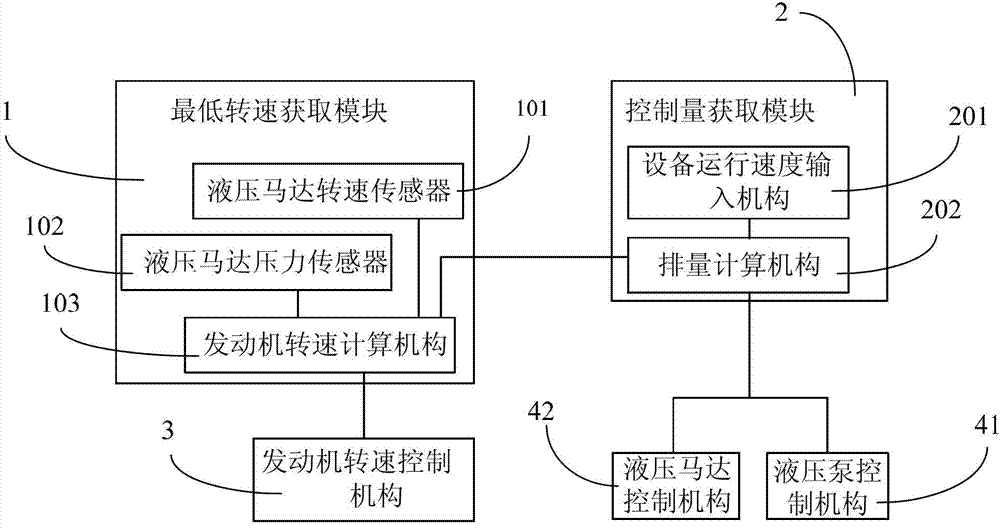

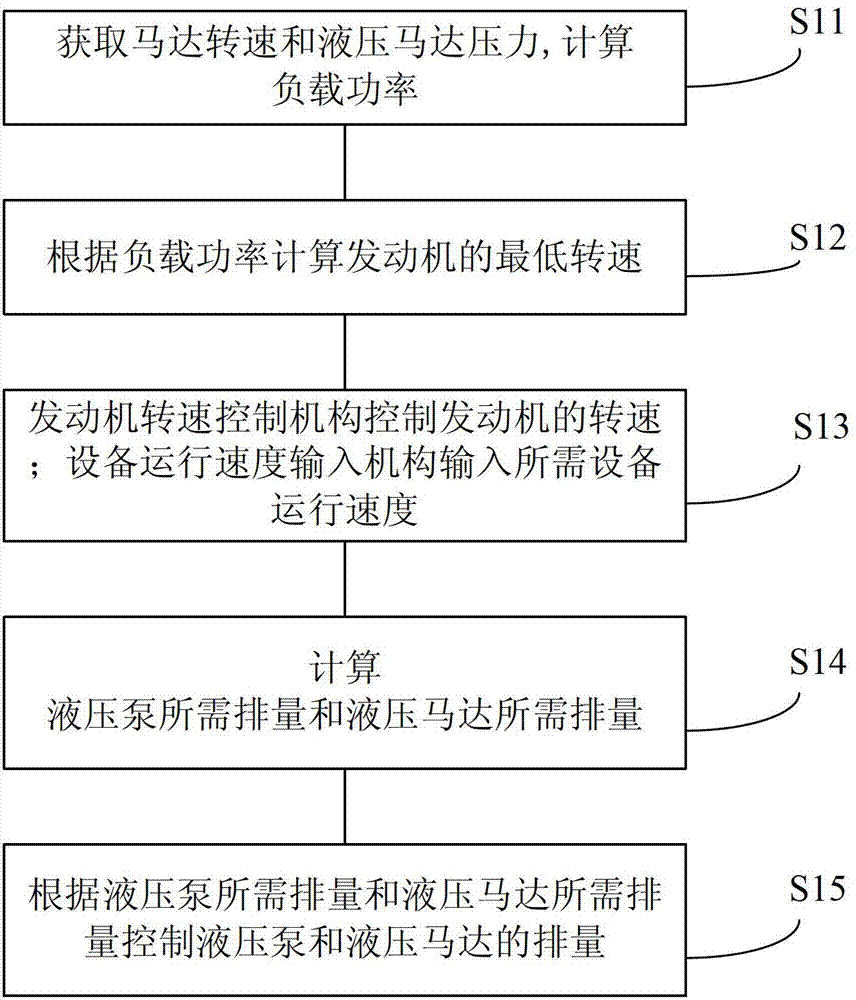

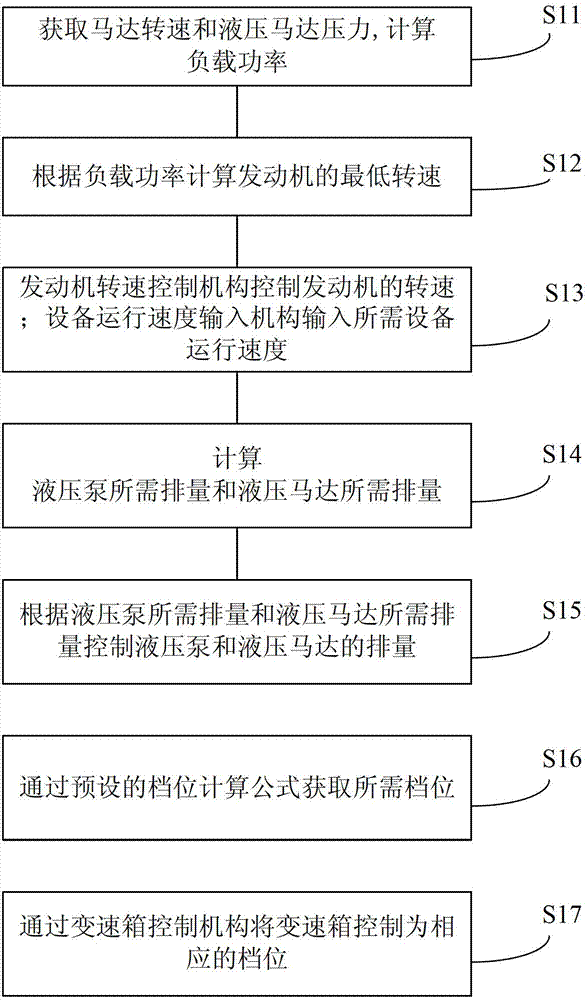

[0031] The basic idea of the present invention is: the machine operator only needs to input the required vehicle speed signal, and the setting of other parameters (such as engine speed, hydraulic pump displacement, hydraulic motor displacement, gearbox gear, etc.) The system automatically completes and executes according to the principle of the lowest fuel consumption. Specifically: after obtaining the speed of the hydraulic motor and the pressure of the hydraulic motor through the sensor, the load power and the minimum speed of the engine are obtained; and then the required displacement of the hydraulic pump and the required displacement of the hydraulic motor are calculated. Then the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com