Bridge static force finite element model correcting method based on super-element combination virtual deformation method

A model correction and finite element technology, which is applied in the field of finite element model correction, can solve the problems such as the inability to meet the correction of large and complex bridges with finite element models and the low efficiency of finite element model correction, so as to improve efficiency, ensure calculation accuracy, and improve calculation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

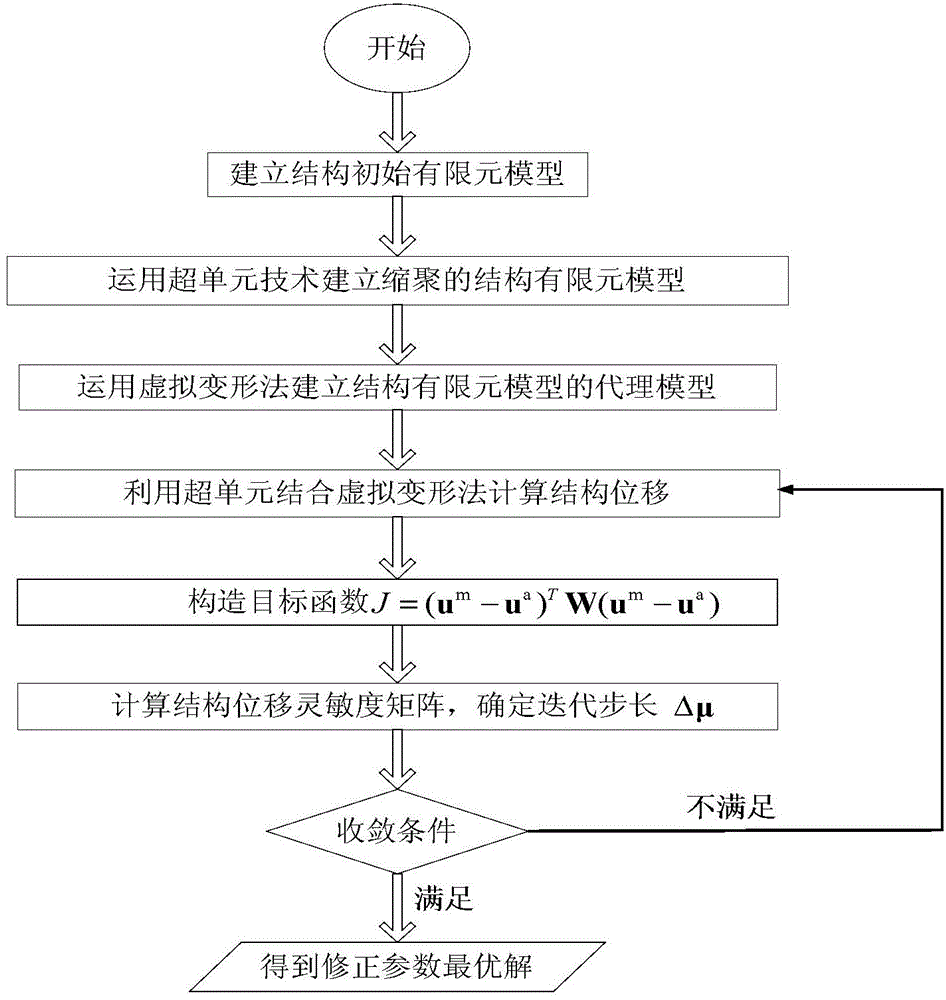

[0022] Specific implementation mode 1: the following combination figure 1 To explain this embodiment, the method for correcting the bridge static finite element model based on the superelement combined with the virtual deformation method described in this embodiment is as follows:

[0023] Step 1: Use super-element technology to shrink the initial finite element model of the bridge structure to obtain the finite element model of the bridge structure after condensation;

[0024] Step 2: Build a proxy model of the bridge structure finite element model according to the finite element condensation model of the bridge structure obtained in step 1, combined with the virtual deformation method;

[0025] Step 3: According to the proxy model of the bridge structure finite element model obtained in Step 2, the bridge structure finite element model revision based on static information is carried out.

[0026] In this embodiment, the virtual deformation method is a fast structural reanalysis metho...

specific Embodiment approach 2

[0027] Specific implementation manner 2: the following combination figure 1 This embodiment will be described. This embodiment will further explain the first embodiment. The specific process of obtaining the finite element model of the bridge structure after condensation in step one is:

[0028] Step 1: Suppose the bridge structure contains n degrees of freedom, and its characteristic equation is expressed as:

[0029]

[0030] Where λ i with Respectively represent the eigenvalue and eigenvector of the bridge structure, where i=1, 2, 3...n; K and M respectively represent the stiffness matrix and the mass matrix;

[0031] Step one and two, let x represent the displacement and eigenvector at the same time, and divide the displacement vector into the direction of the main degrees of freedom x m And from the degree of freedom direction x s , Where m and s represent the master degree of freedom and the slave degree of freedom respectively, and the stiffness matrix is divided into four s...

specific Embodiment approach 3

[0043] Specific implementation manner three: the following combination figure 1 To explain this embodiment, this embodiment further explains the first embodiment. The specific process of establishing the proxy model of the bridge structure finite element model in step 2 is:

[0044] Step 2: Analyze the eigenvalues of the stiffness matrix of the spatial beam element to obtain the six deformation forms of the spatial beam element. In the local coordinate system, the relationship between the strain transformation matrix of the element, the displacement of the element node and the generalized strain of the element is :

[0045] ϵ = Gu = - 1 L 0 0 0 0 0 1 L 0 0 0 0 0 0 0 6 L 2 0 - 3 L 0 0 0 - 6 L 2 0 - 3 L 0 0 - 6 L 2 0 0 0 - 3 L 0 6 L 2 0 0 0 - 3 L 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com