Heavy double-column vertical lathe cross beam gravity deformation prediction method based on finite difference method

A technology of finite difference method and gravity deformation, applied in the direction of large fixed members, program control, instruments, etc., can solve the problems of large difference in actual deformation value, accurate calculation of beam gravity deformation curve, etc., to reduce the number of repairs, reduce installation costs and The effect of installation man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

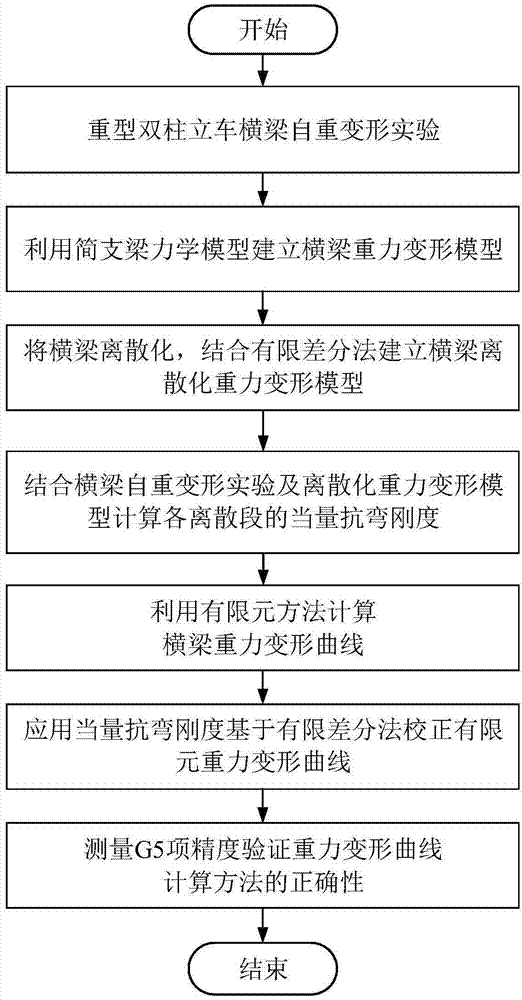

[0027] In the method for predicting the gravity deformation of the beam of a heavy-duty double-column vertical car based on the finite difference method in this embodiment, the calculation method for the gravity deformation curve of the beam is realized through the following steps:

[0028] Step 1: Simulate the actual assembly conditions to design the self-weight deformation experiment of the heavy-duty machine tool beam, and obtain the self-weight deformation curve of the beam under the condition of uneven material;

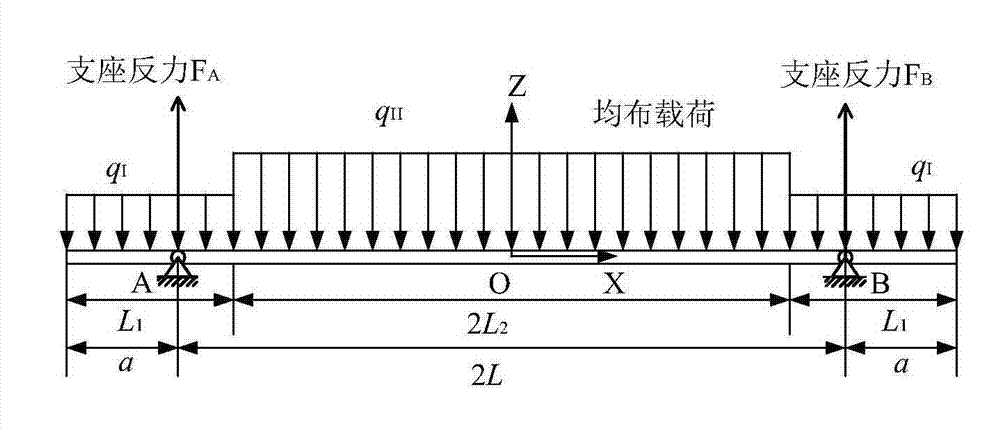

[0029] Step 2: Using the theory of material mechanics, simplify the beam into a simply supported beam mechanical model according to the force of the beam under its own weight;

[0030] Step 3: discretize the beam into a group of discrete micro-segments, discretize the mechanical model of the simply supported beam obtained in step 2, and then combine the finite difference method to establish a discretization model of the gravity deformation of the beam;

[0031] ...

specific Embodiment approach 2

[0034] The difference from the specific embodiment 1 is that in the method for predicting the gravity deformation of the beam of the heavy-duty double-column vertical car based on the finite difference method in this embodiment, the self-weight deformation experiment of the beam of the heavy-duty machine tool described in step 1 is specifically as follows:

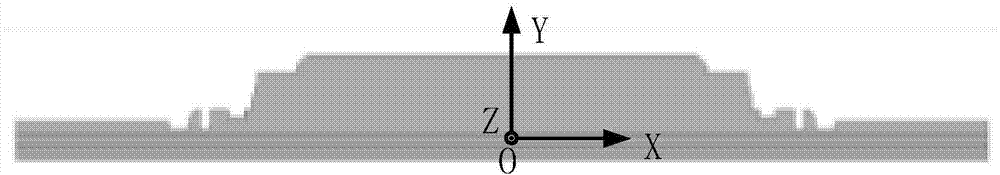

[0035] Step 11. According to the shape of the beam, take the midpoint of the beam in the horizontal plane where the beam is located as the origin O of the coordinate system, and establish a Cartesian coordinate system. The direction of the X-axis is along the direction of the guide rail of the beam, and positive to the right, and the Y-axis is perpendicular to the X-axis. And upward is positive, and the positive direction of the Z axis conforms to the right-hand rule; figure 2 shown;

[0036] Step 12: Lay the beam horizontally, and use an autocollimator to measure the Z-direction straightness data on the surface of the gu...

specific Embodiment approach 3

[0038] The difference from the specific embodiment 1 or 2 is that the method for predicting the gravitational deformation of the beam of the heavy-duty double-column vertical car based on the finite difference method in this embodiment, the method for obtaining the self-weight deformation curve of the beam described in step 1 is specifically:

[0039] The difference between the Z-direction straightness measured after placing the beam on the side described in step 13 until the deformation is stable and the Z-direction straightness data measured after placing the beam horizontally as described in step 12, and using the difference to draw the The self-weight deformation curve of the beam described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com