Door closer

A door closer and door leaf technology, used in door/window fittings, switches with brakes, wing leaf parts, etc., can solve the problems of high production costs, troublesome plunger installation, increased costs, etc., and achieve production costs. Reduced, simple-to-build effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

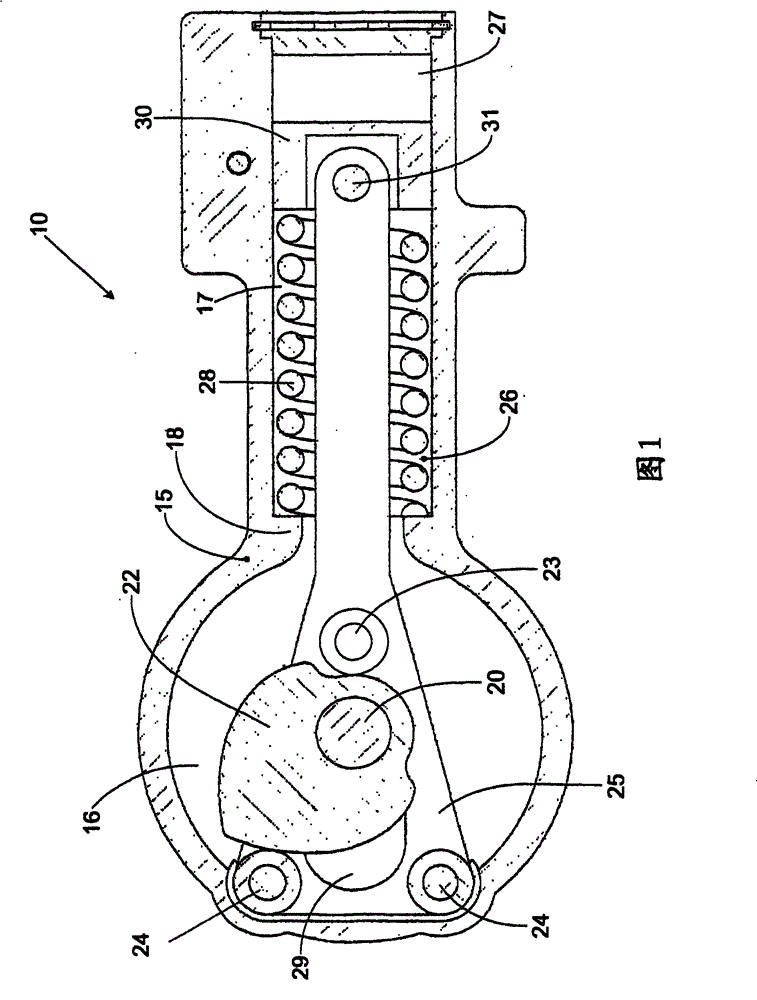

[0023] figure 1 A door closer 10 known from the prior art is shown in . The door closer 10 has a housing 15 in which a sliding plate carriage 25 is integrated. The plate carriage has a recess 29 through which a drive shaft 20 passes. The drive shaft 20 is connected to a (not shown) door leaf. Connected to the drive shaft 20 is a cam disc 22 designed in the shape of an eccentric. The connection can be a positive and / or non-positive connection. Movement of the door leaf causes rotation of the cam disc 22 . To convert the rotational movement into a translational movement, the cam disk 22 is arranged between three support or pressure means 23 , 24 . If the drive shaft 20 is rotated in the counterclockwise direction, the cam disc 22 is pressed against one of the pressure means 24 , which causes the slide carriage 25 to move into the front region 16 of the housing 15 .

[0024] The rear region 17 of the housing 15 is designed cylindrically. A spring 28 is mounted in the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com