Spindle bearing arrangement, textile machine, method of operating a spindle bearing arrangement and use of o-ring elements

A bearing device, textile machine technology, applied in textiles and papermaking, etc., can solve the problems of complex spindle bearing device, changing suspension and damping properties, etc., to save installation space, improve axial damping capacity, and improve axial damping capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

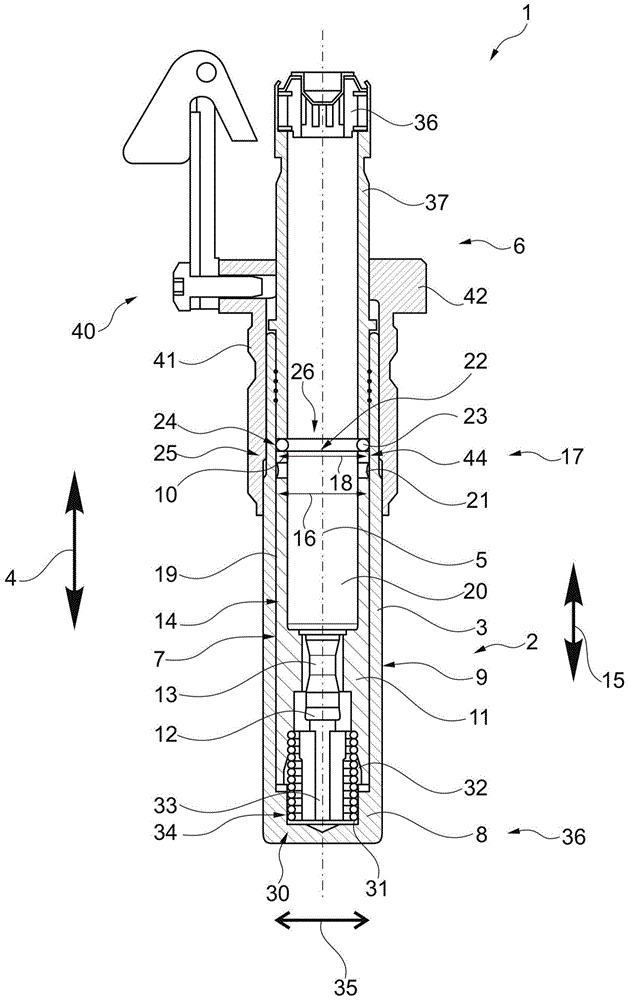

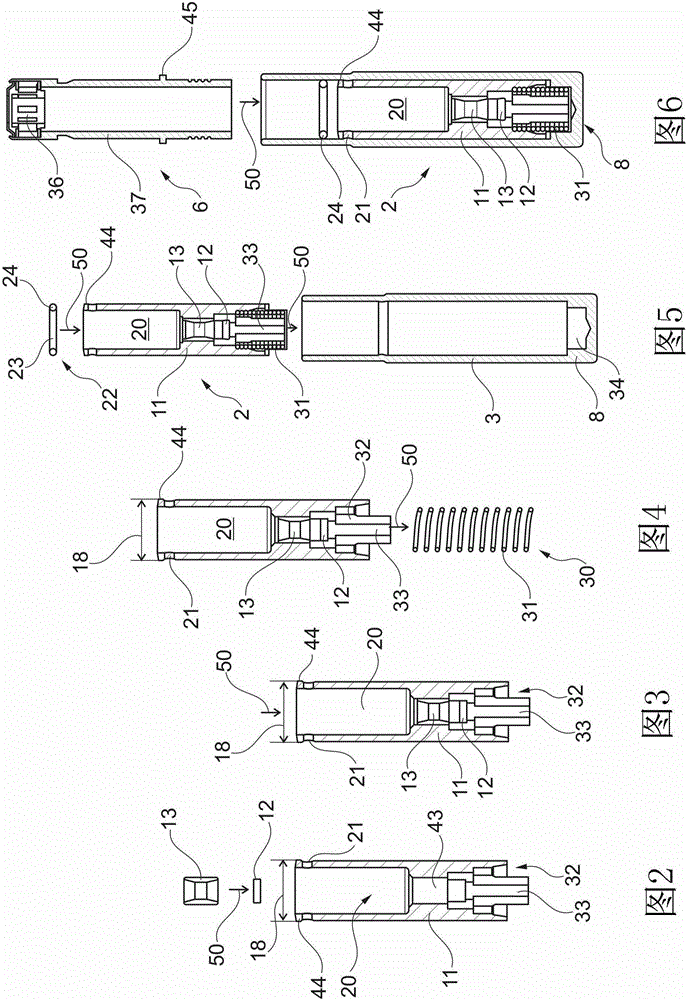

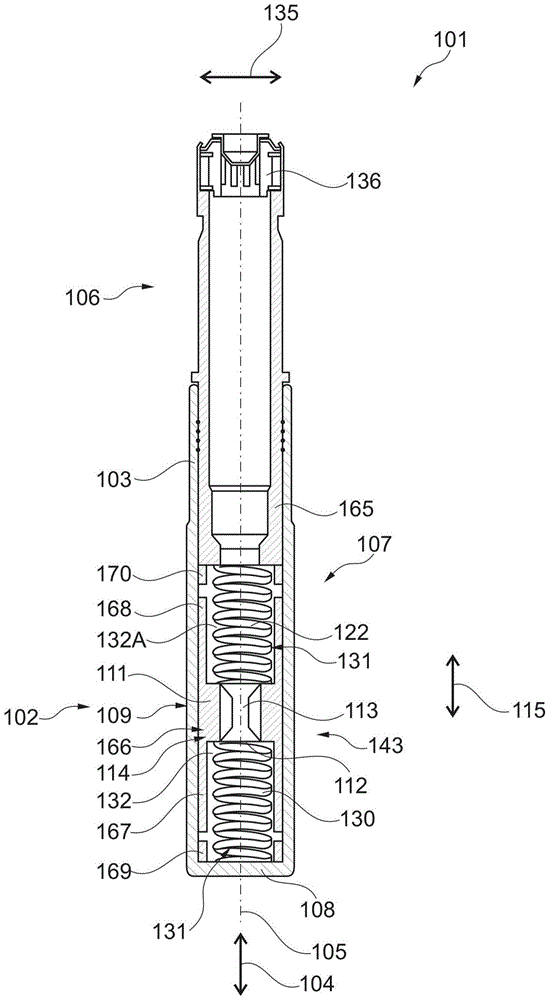

[0107] Figure 1 to Figure 6 The illustrated first spindle bearing arrangement 1 according to the invention for mounting a spinning spindle (not shown here) is equipped with a spindle step unit 2 which is mounted according to the invention in an axially prestressed manner on In the housing sleeve 3 of the spindle bearing device 1 .

[0108] Although the axially prestressed spindle step unit 2 can be displaced within the housing sleeve 3 due to this axial prestressing in the axial direction 4 with respect to the central axis 5, the spindle tube unit 6 in the other Aspects are arranged to be at least partially pressed into the housing sleeve 3 .

[0109] The bearing space 7 for the spindle step unit 2 is thus limited by the base area 8 of the housing sleeve 3 , the side wall area 9 of the housing sleeve 3 and the underside 10 of the spindle tube unit 6 pressed into the housing sleeve 3 . Thus, the spindle step unit 2 is fixed in such a way that it cannot be lost in the housin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com