Bushing assembly, bushing assembly kit, apparatus including bushing assembly, and associated method

A technology for components and bushings, applied in the field of bushings, can solve problems such as manufacturing costs that cannot be ignored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

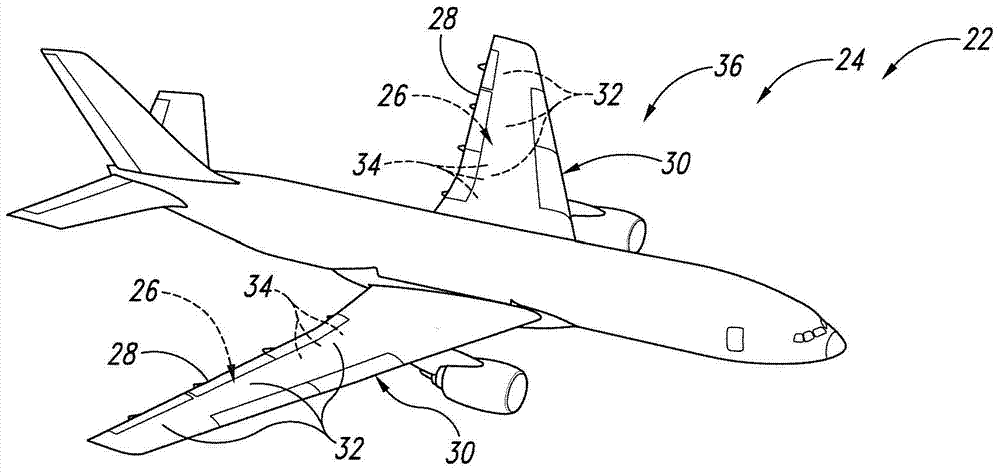

[0022] Disclosed herein are bushing assemblies, bushing assembly equipment, devices including bushing assemblies, and related methods. Bushing assemblies according to the present disclosure are configured for mounting a component to an object, such as operatively mounting the component to the object using fasteners. Examples of components, objects, and related devices discussed herein generally relate to aircraft; however, liner assemblies, liner assembly materiel, and related methods according to the present disclosure may relate to any suitable device, and the present disclosure is not limited to aerospace applications.

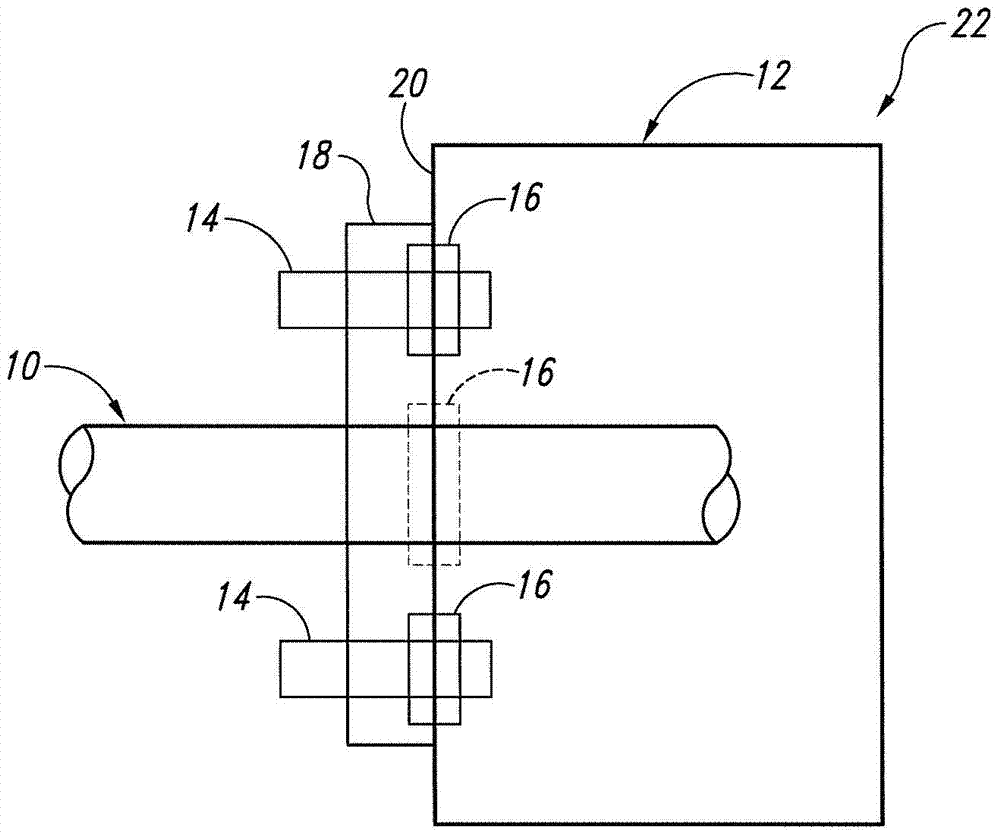

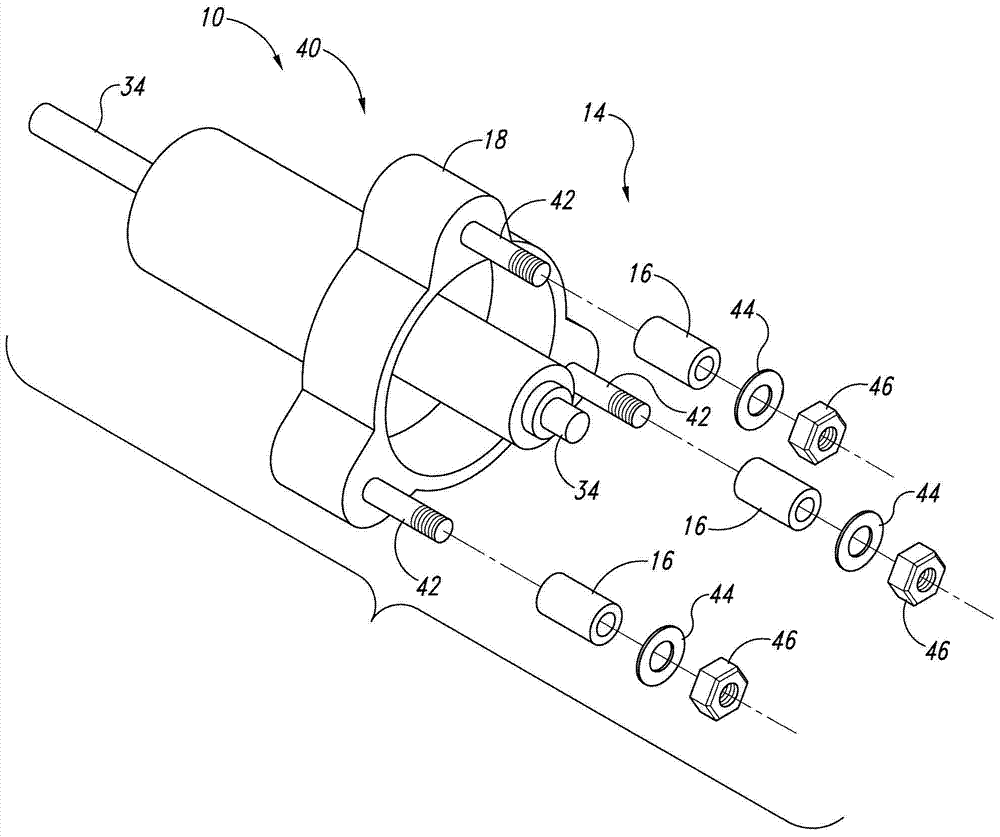

[0023] figure 1 A general component 10 mounted to a general object 12 using a fastener 14 and bushing assembly 16 is schematically illustrated. exist figure 1 In the schematic illustration of , the component 10 includes a mounting structure 18 that engages the wall 20 of the object 12 and that provides structure for the fastener 14 to operably mount the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com