Variable-diameter coordinated synchronous winding variable-configuration valve capsule structure and its design method

A variable diameter, winding technology, applied in the field of aerospace aerostats, can solve problems such as disorder and inconvenience to return to the boathouse, achieve accurate return, improve the efficiency of shape control, and avoid spin motion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

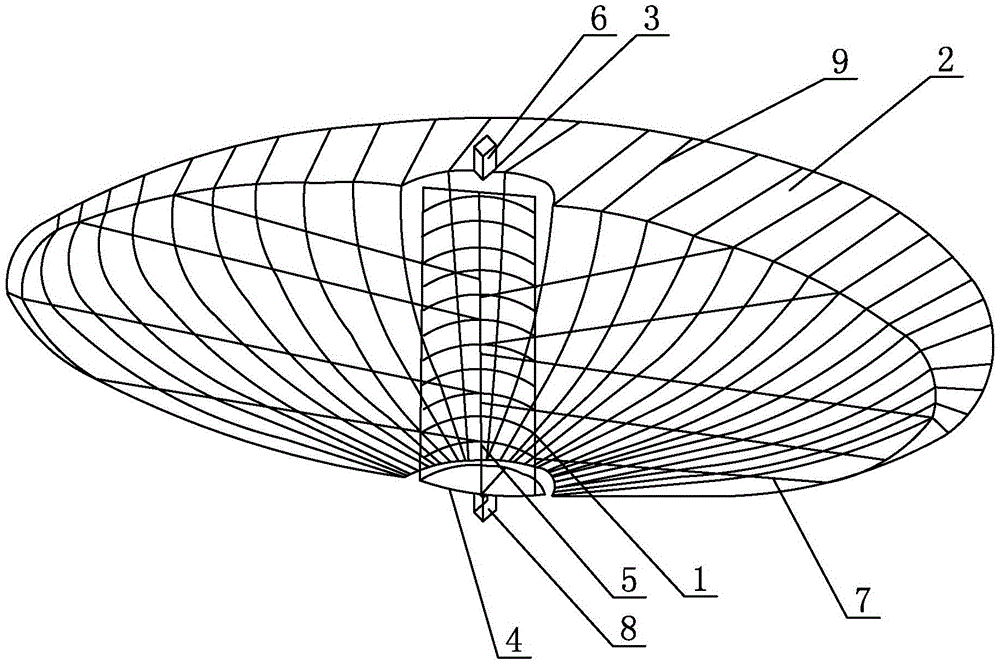

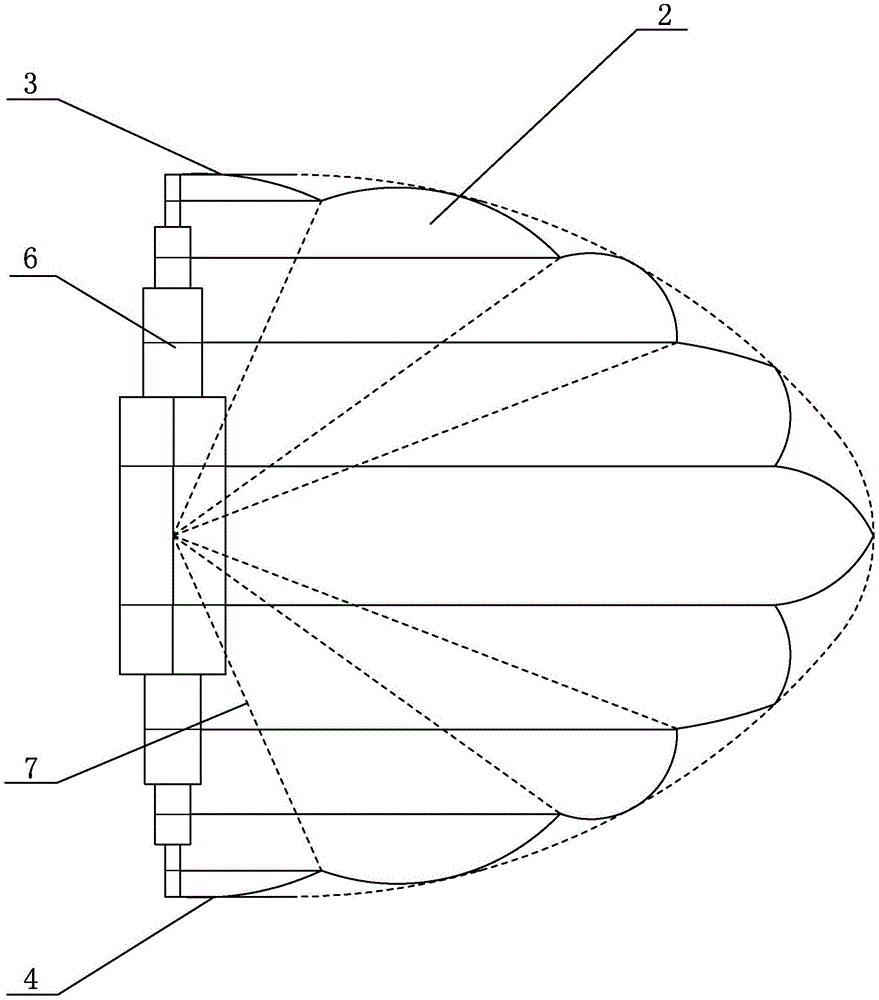

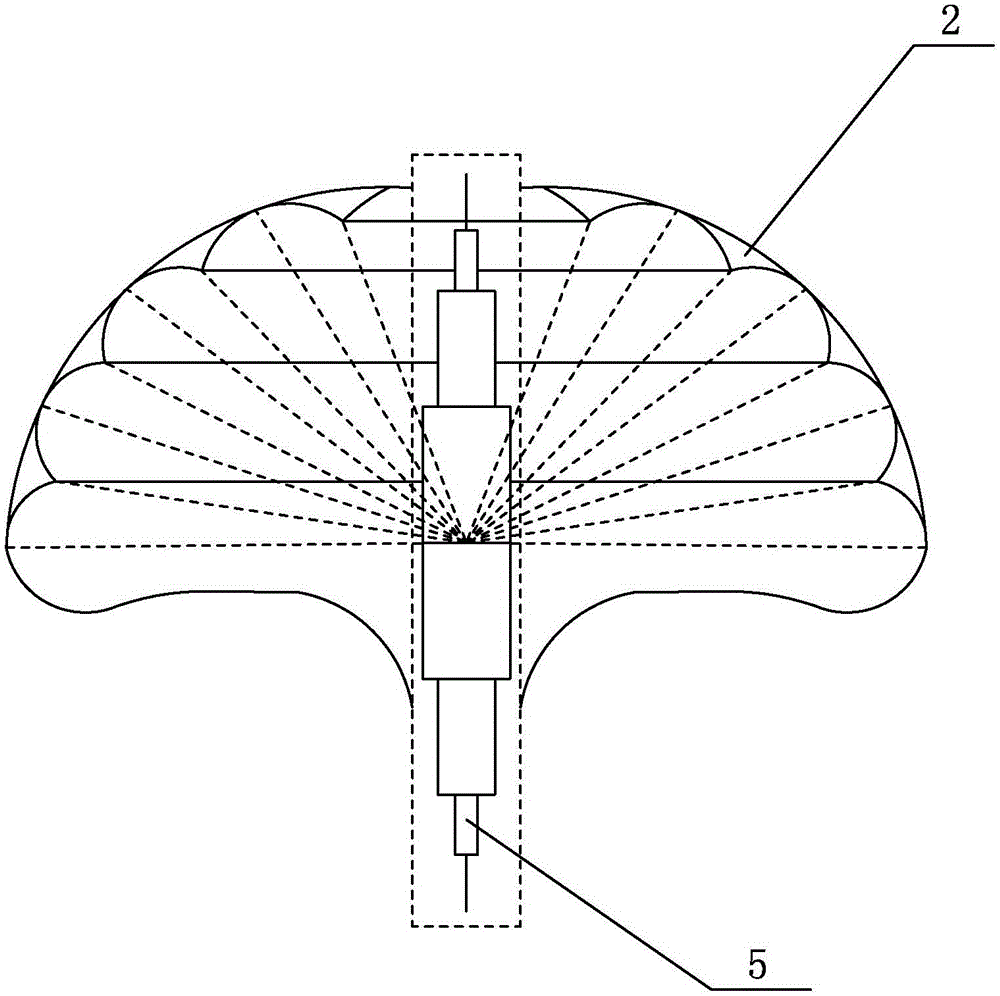

[0015] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment. The variable-diameter coordinated synchronous winding variable-configurable valve capsule structure in this embodiment includes a central cylinder 1, a pressure-resistant capsule body 2, a top connection structure 3 with airtightness, and a bottom connection structure with airtightness. 4. Symmetric variable-diameter winding center shaft 5, top drive motor 6, bottom drive motor 8 and multiple tethers 7, the top connection structure 3 with airtightness is arranged in the middle of the upper surface of the pressure-resistant capsule 2, and has airtightness The bottom connection structure 4 is arranged in the middle of the lower surface of the pressure-resistant capsule body 2, the central cylinder 1 is vertically arranged in the pressure-resistant capsule body 2, the upper end of the central cylinder 1 is connected with the top connection structure 3 with airtightness, and the central...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 5 To illustrate this embodiment, a plurality of reinforcing ribs 9 are evenly distributed on the outer wall of the pressure-resistant capsule body 2 of the variable-diameter coordinated synchronous winding type variable configuration valve sac structure described in this embodiment, and one end of each reinforcing rib 9 is connected to the The top structure 3 with airtightness is connected, and the other end of each reinforcing rib 9 is connected with the bottom structure 4 with airtightness.

[0020] The technical effect of the present embodiment is: such arrangement enhances the overall strength of the pressure-resistant capsule 2 and prevents the pressure-resistant capsule 2 from being damaged or deformed. The cord fabric makes the force between the reinforcing rib 9 and the outer surface of the pressure-resistant capsule body 2 uniformly diverge, avoiding the stress concentration when the reinforcing rib 9 and th...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, the flexible pressure-resistant capsule 2 of the variable-diameter coordinated synchronous winding variable-configuration valve capsule structure in this embodiment is composed of even-numbered hyperboloid curvature valves.

[0022] The technical effect of this embodiment is: such setting, by reducing the radius of curvature of the film, the bearing capacity of the film can be greatly improved, and the film material of the same thickness and material can withstand greater pressure, effectively enhancing the compression resistance of the valve sac structure ability. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com