Improved full-automatic threading apparatus

A fully automatic and improved technology, applied in the direction of cable laying equipment, etc., can solve the problems of inability to accurately grasp whether the pull-back wire has been pulled back in place, inconvenient normal use, slow construction progress, etc., to achieve excellent limit stop function and smooth operation Cable management and take-up and release functions, extensive market application prospects, and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

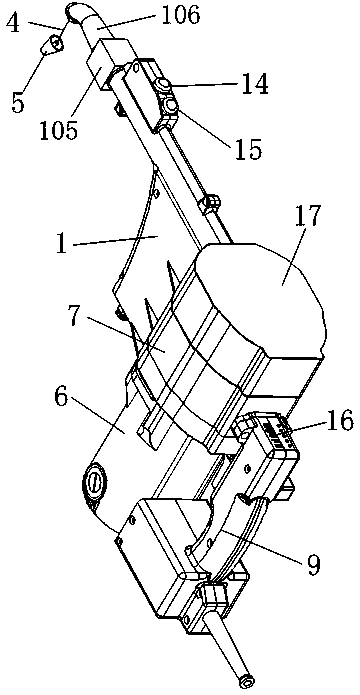

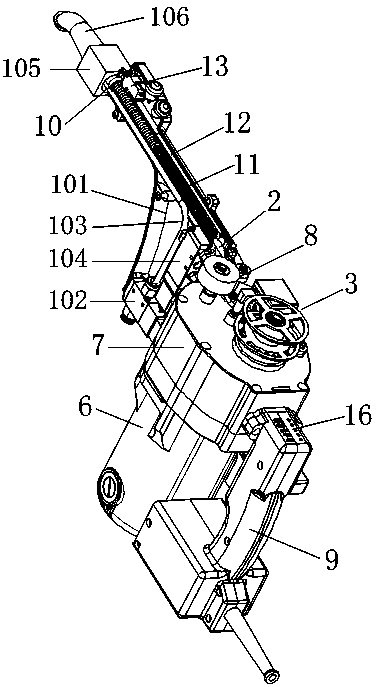

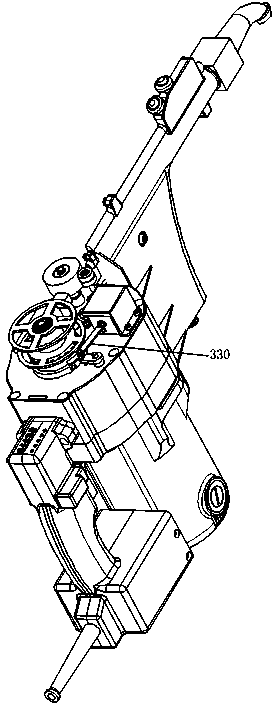

[0041] Such as Figure 1 to Figure 7 As shown, the improved fully automatic needle threader includes an air supply mechanism 1 for connecting an external air compressor and transmitting power for threading, and is arranged in the air supply mechanism with its front end pointing to the direction of the air outlet, and a lead tube 2 whose rear end passes through the air supply mechanism , the wire pay-off mechanism 3 corresponding to the position of the rear end of the lead tube, one end is fixed and wound on the pull wire pay-off mechanism and the other end passes through the guide wire tube to the guide wire 4 at the air outlet of the air delivery mechanism, and is connected to the guide wire to pass through the lead wire The bullet head 5 at one end of the barrel, the motor 6 that provides the wire-drawing and wire-drawing power for the pull-wire pay-off mechanism, the limit stop assembly that is arranged at the front of the air supply mechanism and connected with the front of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com