Vertical profile electrostatic spray coating equipment

A technology of electrostatic spraying and painting equipment, applied in liquid spraying equipment, electrostatic spraying device, spraying device and other directions, can solve the problems of affecting the quality of spraying, powder uniformity cannot be guaranteed, etc., to reduce material cost and achieve good operation stability , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

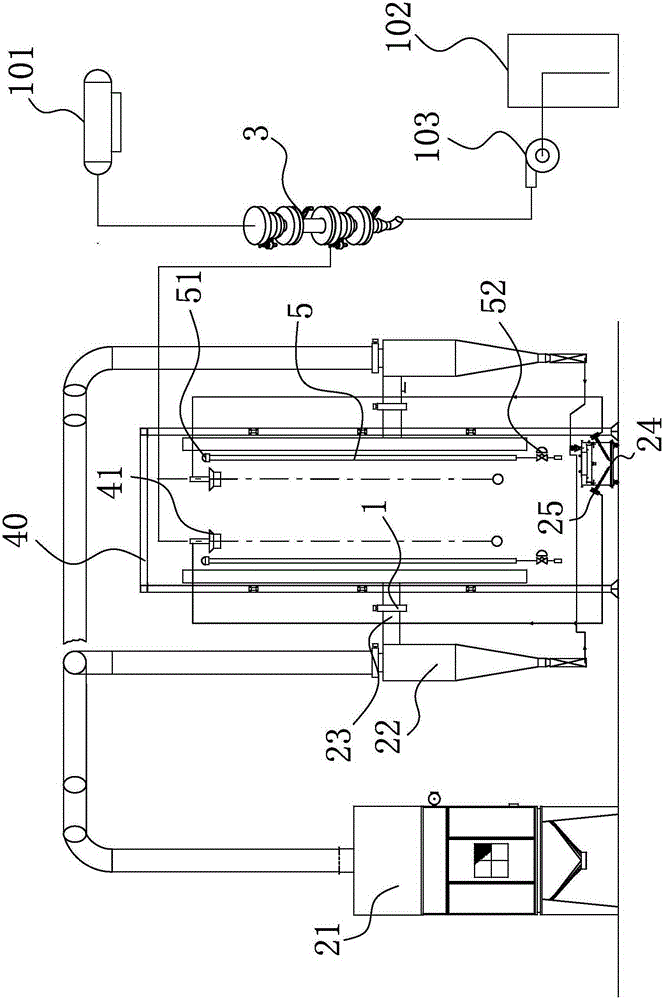

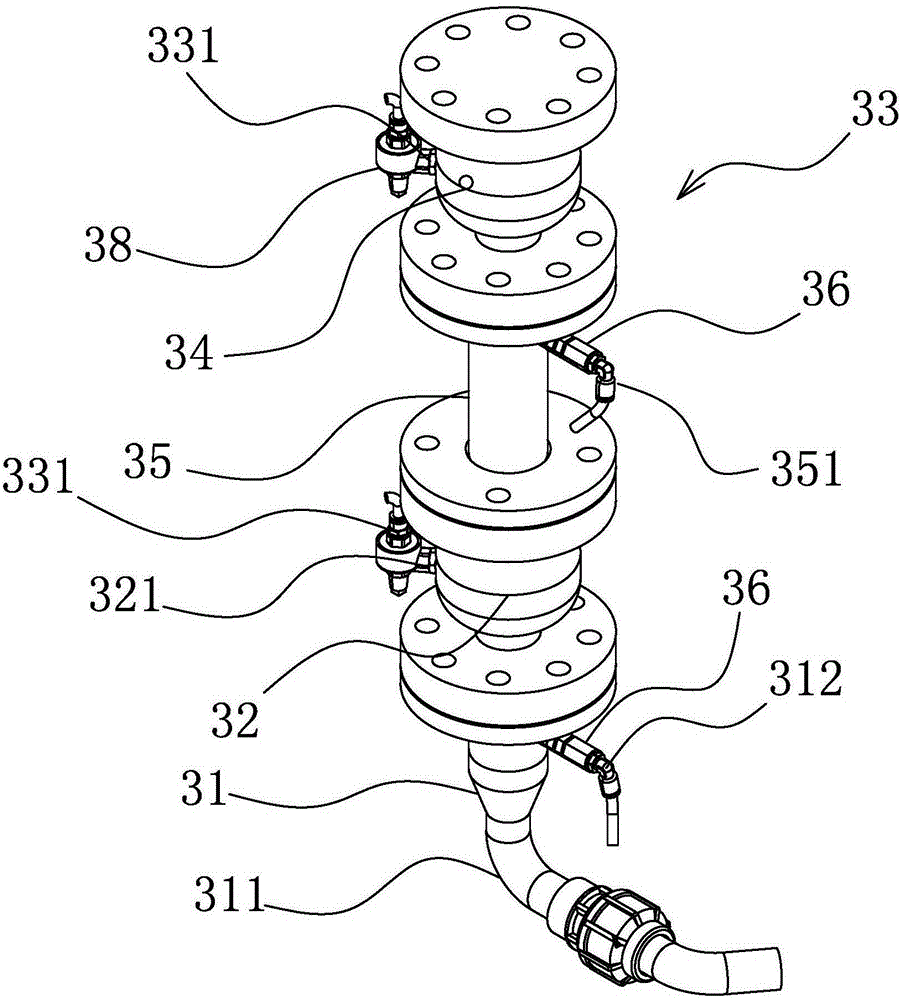

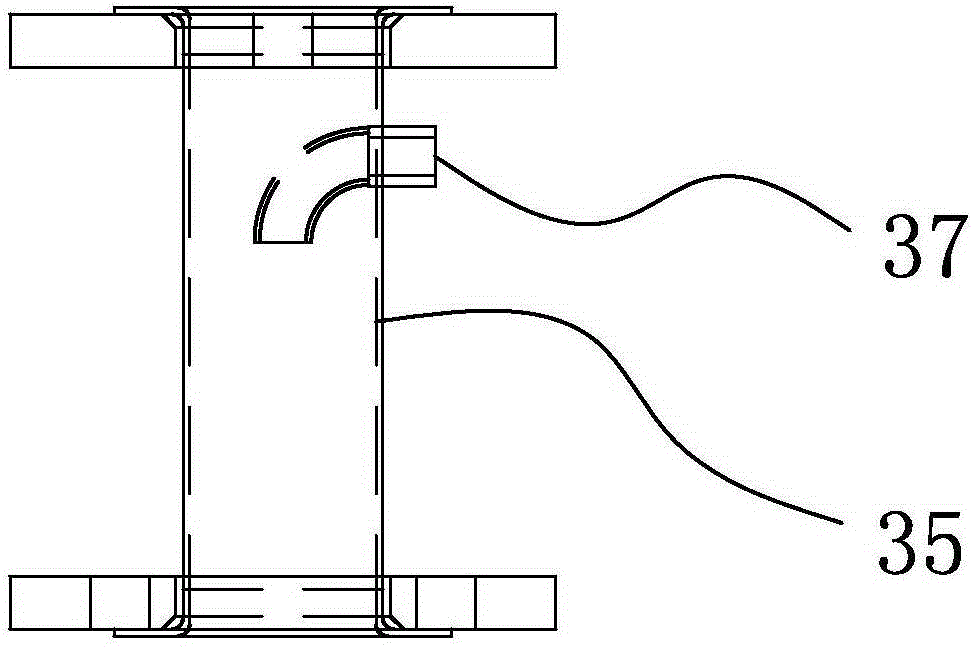

[0028] Such as Figure 1-7 As shown, a vertical profile electrostatic spraying coating equipment includes a coating machine 40, a compressed air system 101 and a spray material storage tank 102. The coating machine 40 is provided with a nozzle mechanism 41, and the compressed air system 101 is connected to the nozzle mechanism 41. , the spraying material storage tank 102 is connected to the nozzle mechanism 41 with a material delivery mechanism 103, and also includes a gas-solid mixer 3, and the gas-solid mixer 3 includes a powder feeding chamber 31 with a cavity inside, and the powder One end of the feeding chamber 31 is provided with a feeding port 311, and the other end is detachably connected to the mixing chamber 32. In this embodiment, the detachable connection adopts a flange connection, and the side wall of the powder feeding chamber 31 is provided with a first Air inlet 312; the inside of the mixing chamber 32 has a cavity and is provided with a discharge port 321 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com