High-speed train

A technology for high-speed trains and shells, which is applied to railway car bodies, railway car body parts, transportation and packaging, etc., which can solve the problems of weight increase and high-speed rail weight, and achieve weight reduction, stable and safe train running, and reduced energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

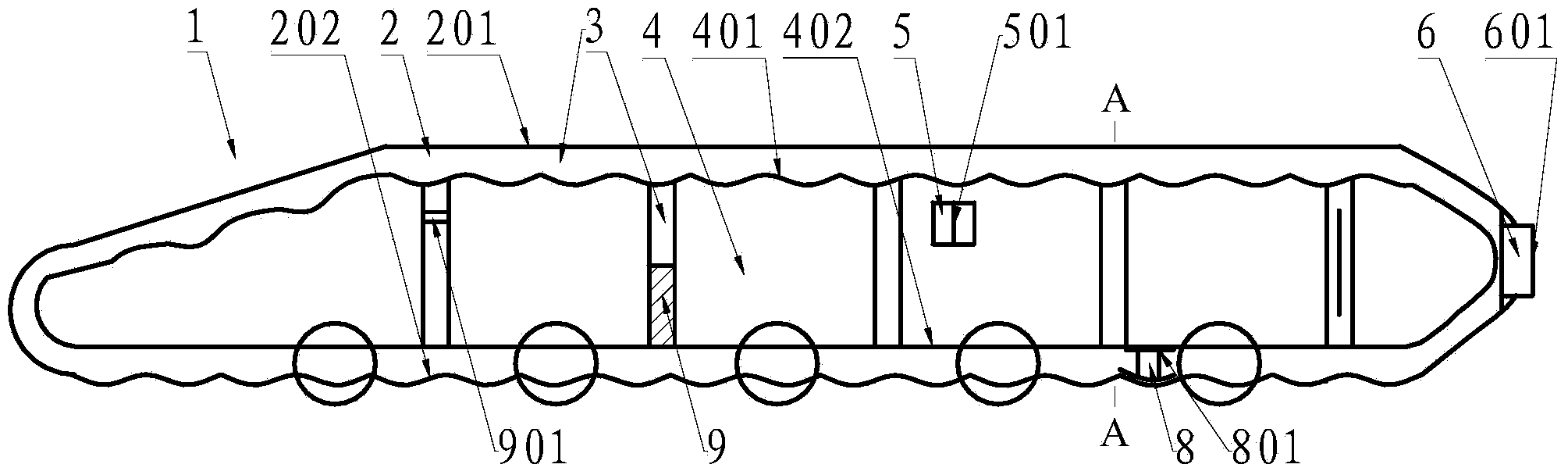

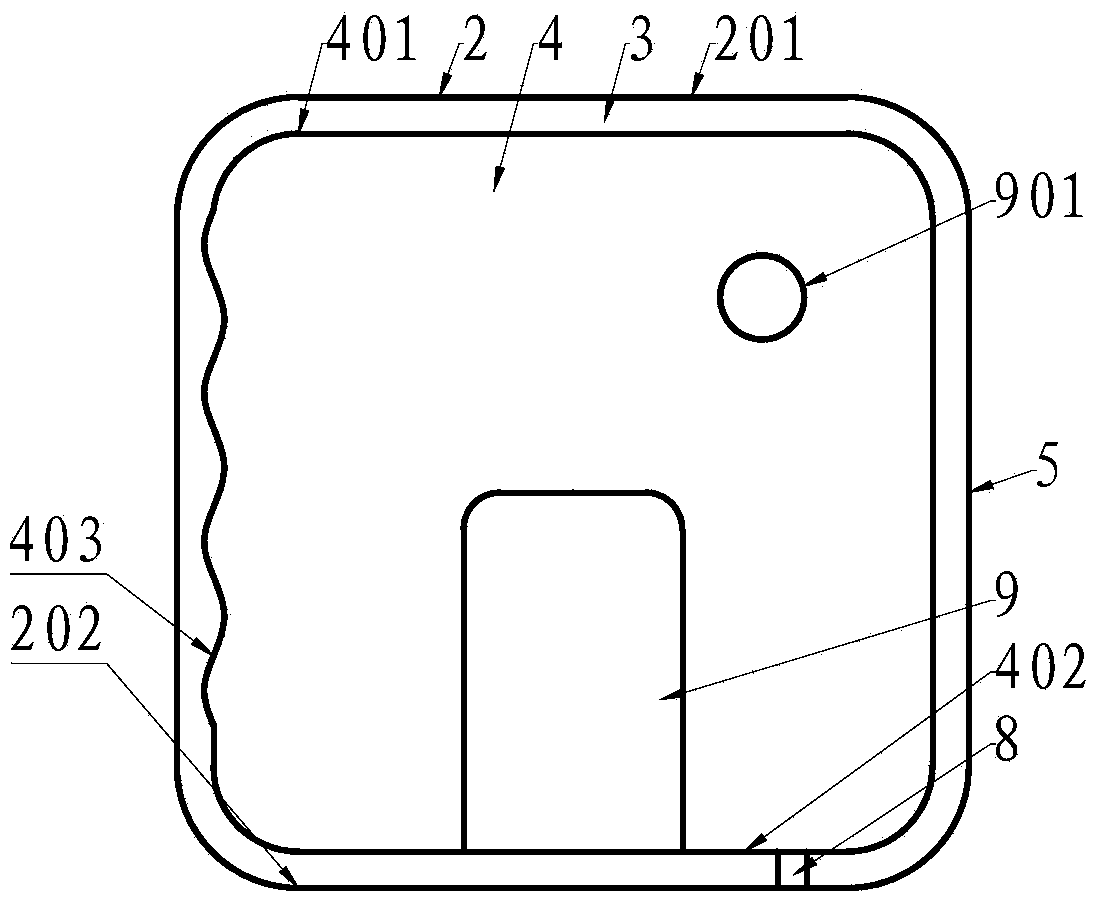

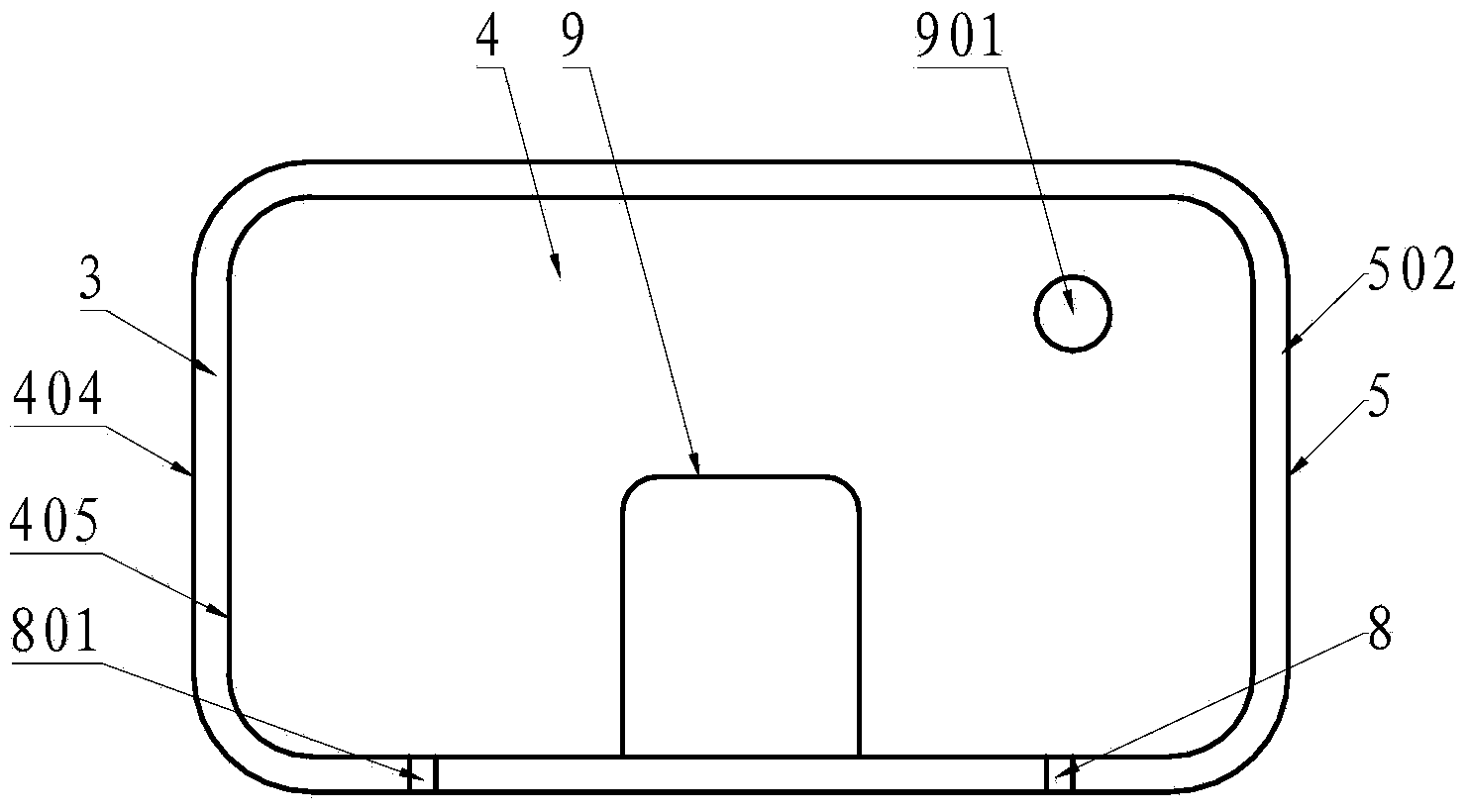

[0028] See figure 1 with figure 2 , figure 1 with figure 2 These are a front view and a cross-sectional view of the first embodiment of the present invention.

[0029] The first embodiment is a high-speed train 1, including a housing 2, the bottom 202 of the housing is connected to wheels, a plurality of inlets 5 are provided on the surface of the housing 2, and the inlets 5 are provided with open and close controllable and inlet A control device 501 with controllable air volume. The housing 2 is provided with a fluid channel 3 communicating with the inlet 5. The fluid channel 3 divides the internal space of the housing 2 into a plurality of carrier compartments 4 and passes around each carrier compartment 4, and is connected to the rear o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com