Outfitting bottom concave arc surface hollow hole sponge strip for boat

A concave curved surface and sponge technology, applied in the direction of sealing devices, etc., can solve the problems of small compression deformation, weak sealing, and poor elasticity of sponge strips, and achieve large compression deformation, good sealing, and good elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

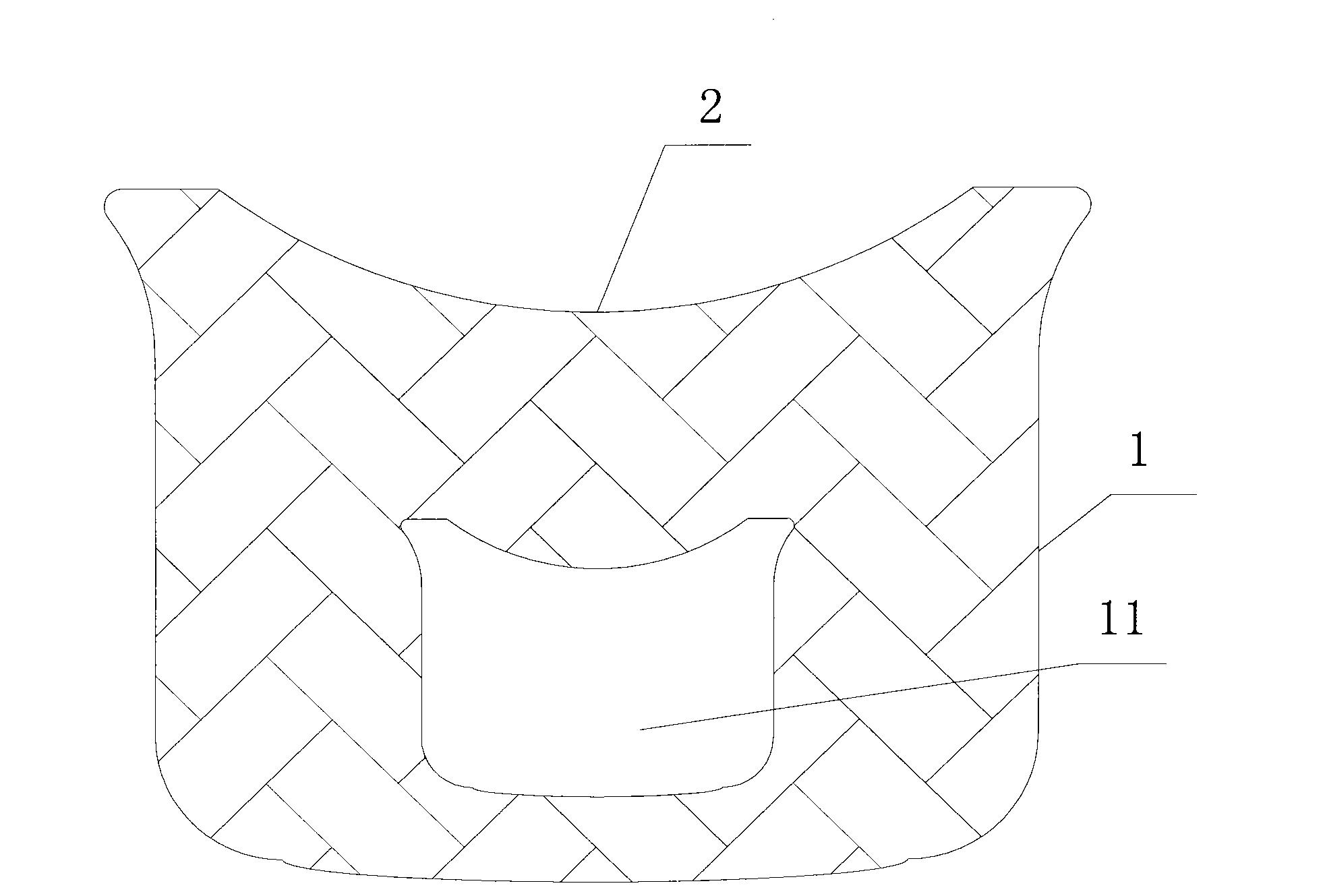

[0011] see figure 1 , figure 1 It is a schematic diagram of the cross-sectional structure of the concave curved surface cavity sponge strip at the bottom of the marine outfitting of the present invention. Depend on figure 1 It can be seen that the concave arc hollow sponge strip at the bottom of the marine outfitting of the present invention includes a sponge strip body 1, the top of the sponge strip body 1 is set as a concave arc surface 2, the bottom is set as a convex arc surface 3, and the middle is set with a A hole 11, the shape of the hole 11 is the same as that of the sponge strip body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com