Drive device for circular bar correcting and detecting

A driving device and bar technology, applied in the direction of measuring device, mechanical measuring device, mechanical device, etc., can solve the problems of multiple rework, affecting the efficiency of round bar correction, and high labor intensity, so as to ensure the adjustment accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the present invention, the components without specific structures and connection methods are usually conventional components or connection methods.

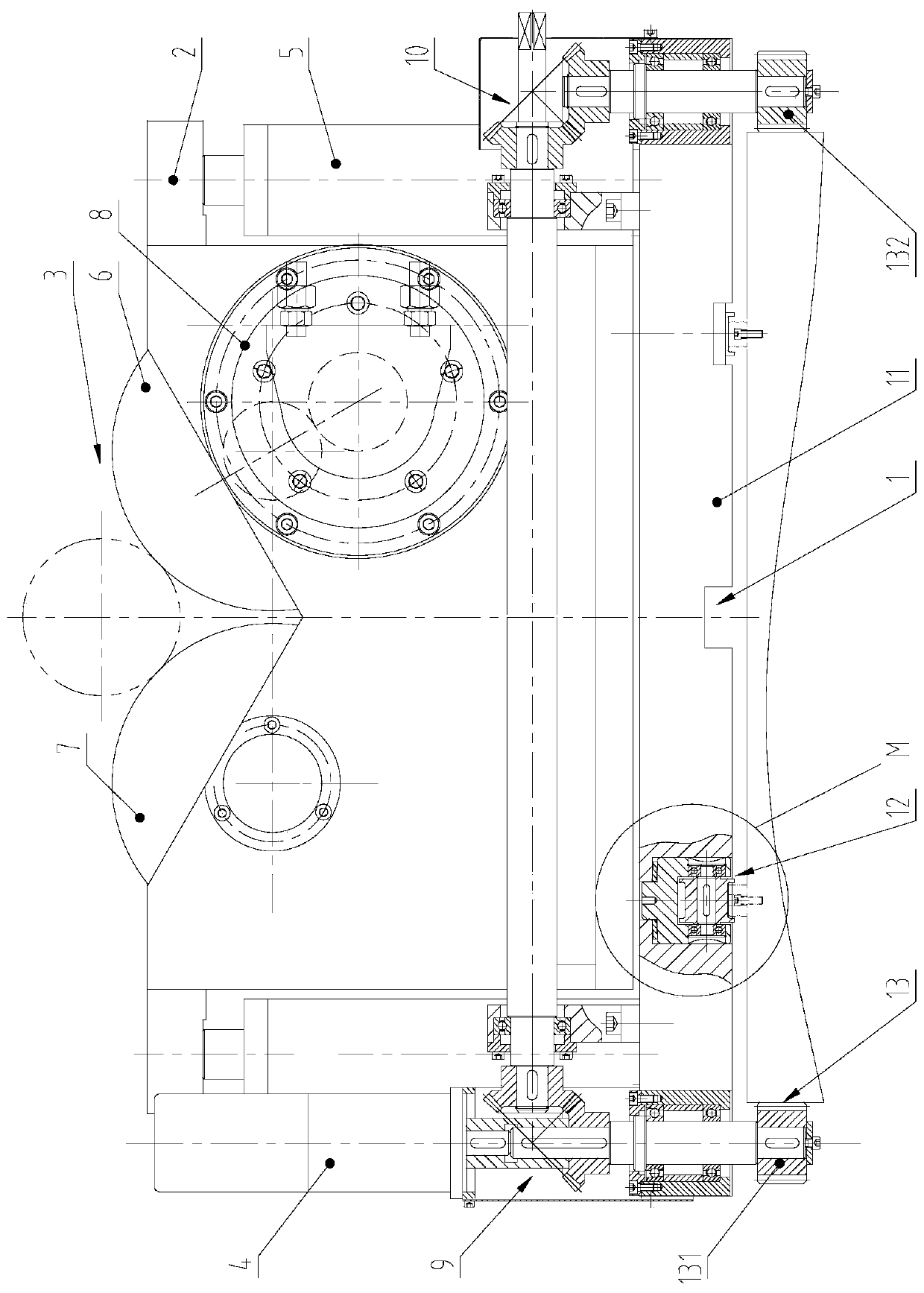

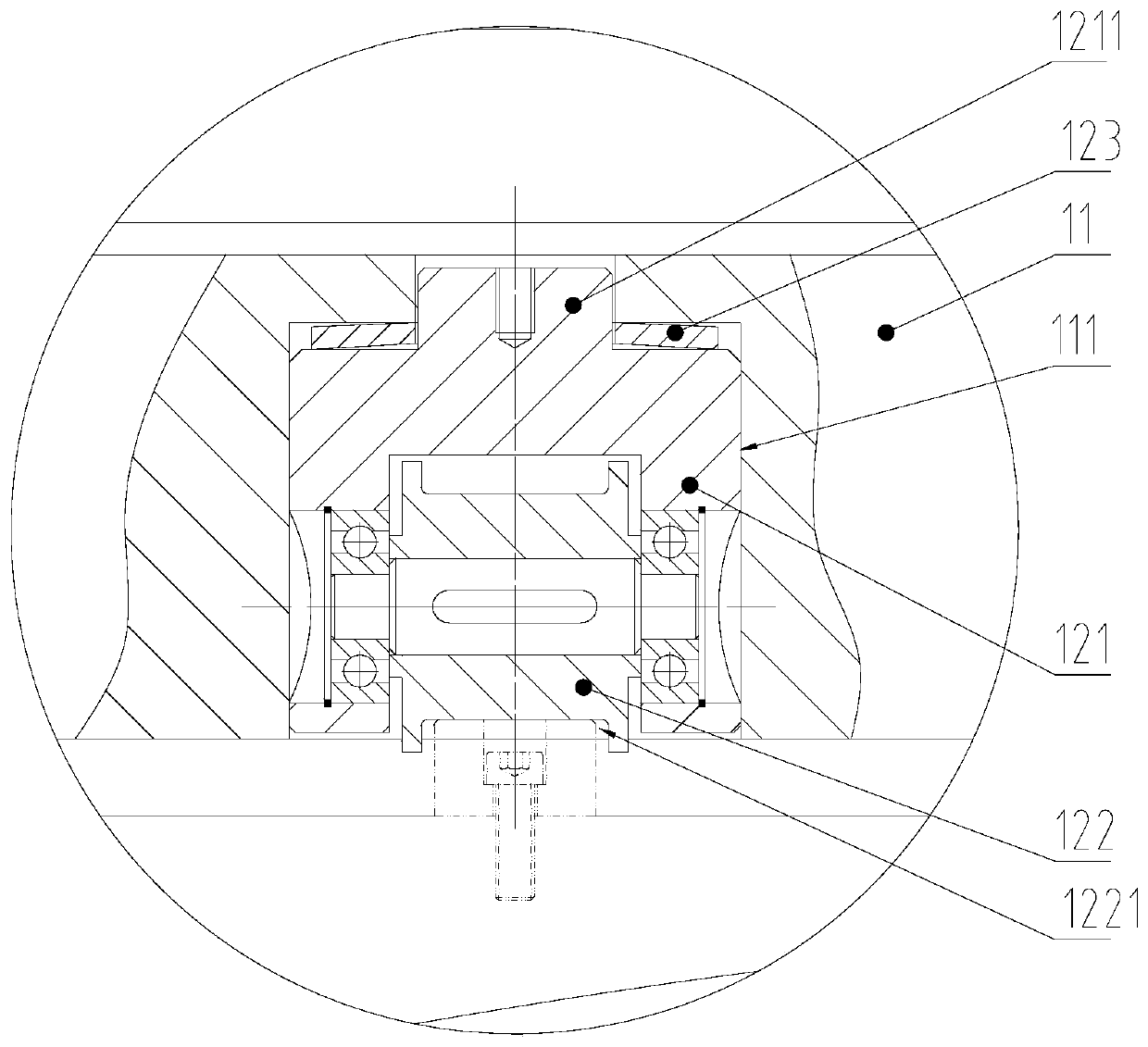

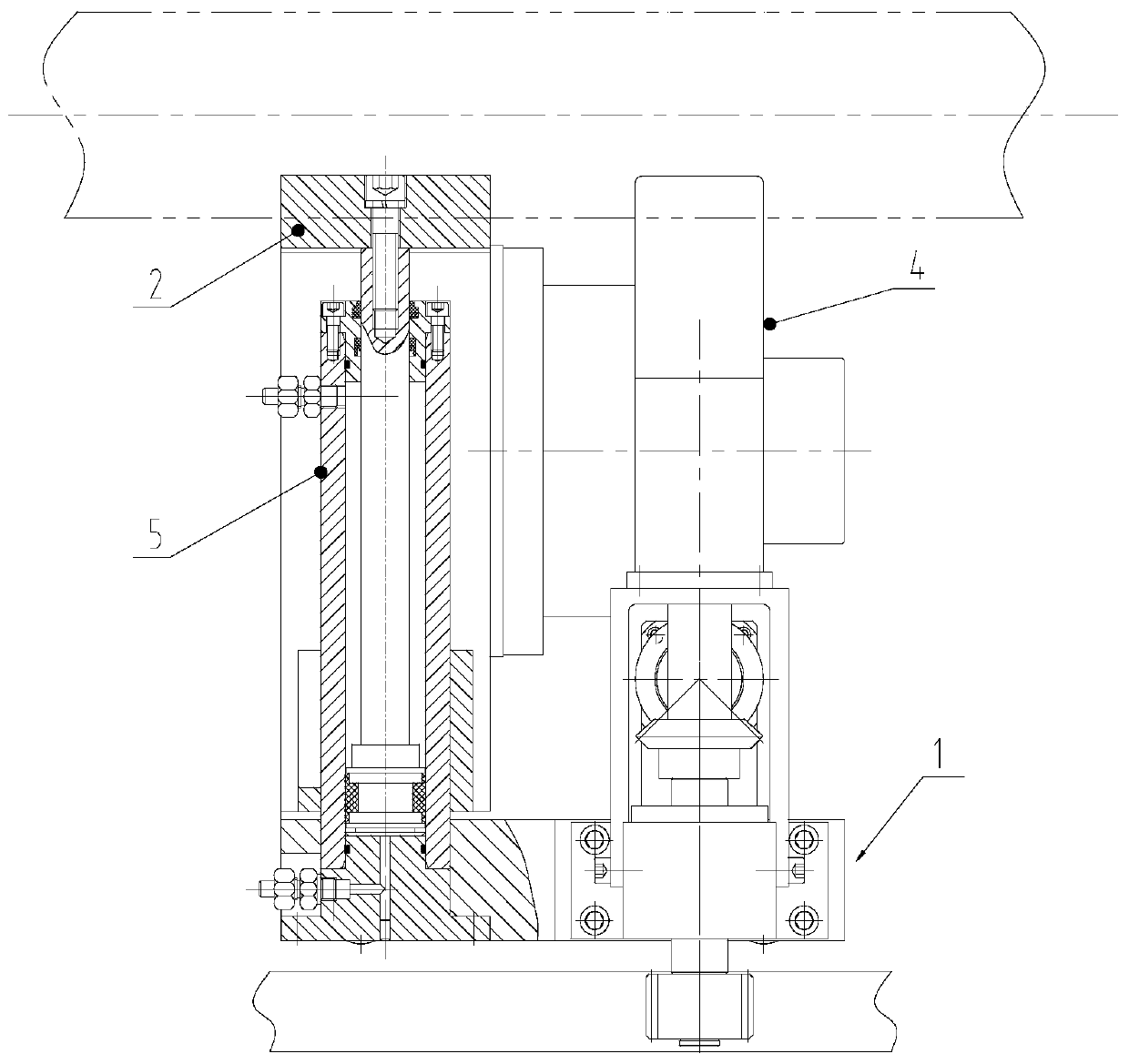

[0022] see Figure 1 to Figure 3 , is a specific embodiment of a driving device for rectifying and detecting circular rods. The driving device for round bar correction detection includes a mobile platform 1 , a lifting platform 2 , and a driving mechanism 3 . The mobile platform 1 is rolled and fit on the frame track of the straightening machine, and is driven by the stepping motor 4 to move along the length direction of the frame track of the straightening machine. In this embodiment, the mobile platform 1 includes a mobile platform body 11, a floating Roller 12, rack and pinion mechanism 13, the number of the floating rollers 12 is four, distributed on the bottom surface of the mobile platform body 11 in a 2*2 matrix, and the floating rollers on the same row correspond to the rack rails of the straightening machine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com