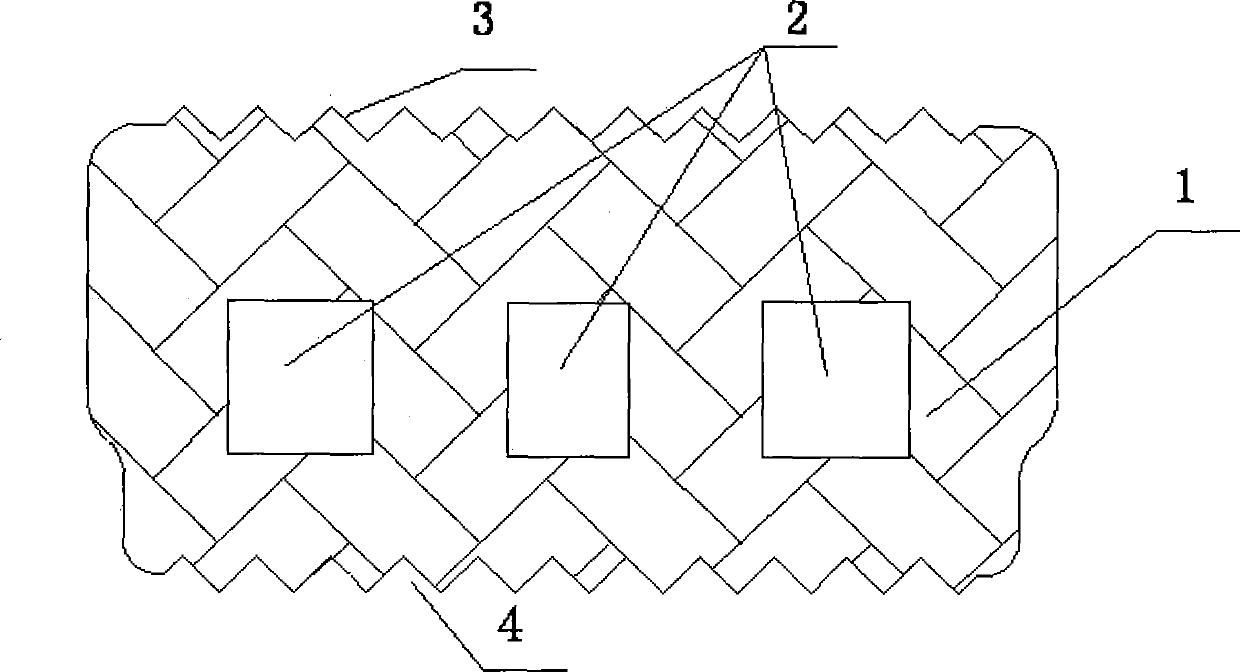

Solid sealing strip with three square cavities and serrated faces

A sealing strip and sawtooth surface technology, which is applied in the field of rubber sealing strips, can solve the problems of small compression deformation, poor elasticity, and weak sealing performance of sealing strips, and achieve the effect of good sealing, good elasticity, and large compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] see figure 1 , figure 1 It is a schematic diagram of the cross-sectional structure of the solid three-square cavity serrated surface sealing strip of the present invention. Depend on figure 1 It can be seen that the solid three-square hole sawtooth surface sealing strip of the present invention includes a sealing strip body 1, the sealing strip body 1 is in the shape of a straight strip, and the material of the sealing strip body 1 is EPDM rubber. 1, along the length direction of the sealing strip body 1, there are three cavities 2 arranged in parallel from left to right. The cross sections of the three cavities 2 are all square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com