Straight sealing strip with bottom rib and top saw teeth

A sealing strip, straight technology, applied in the direction of sealing device, can solve the problems of weak sealing, poor elasticity, small compression deformation of the sealing strip, etc., and achieve the effect of good sealing, good elasticity and large compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

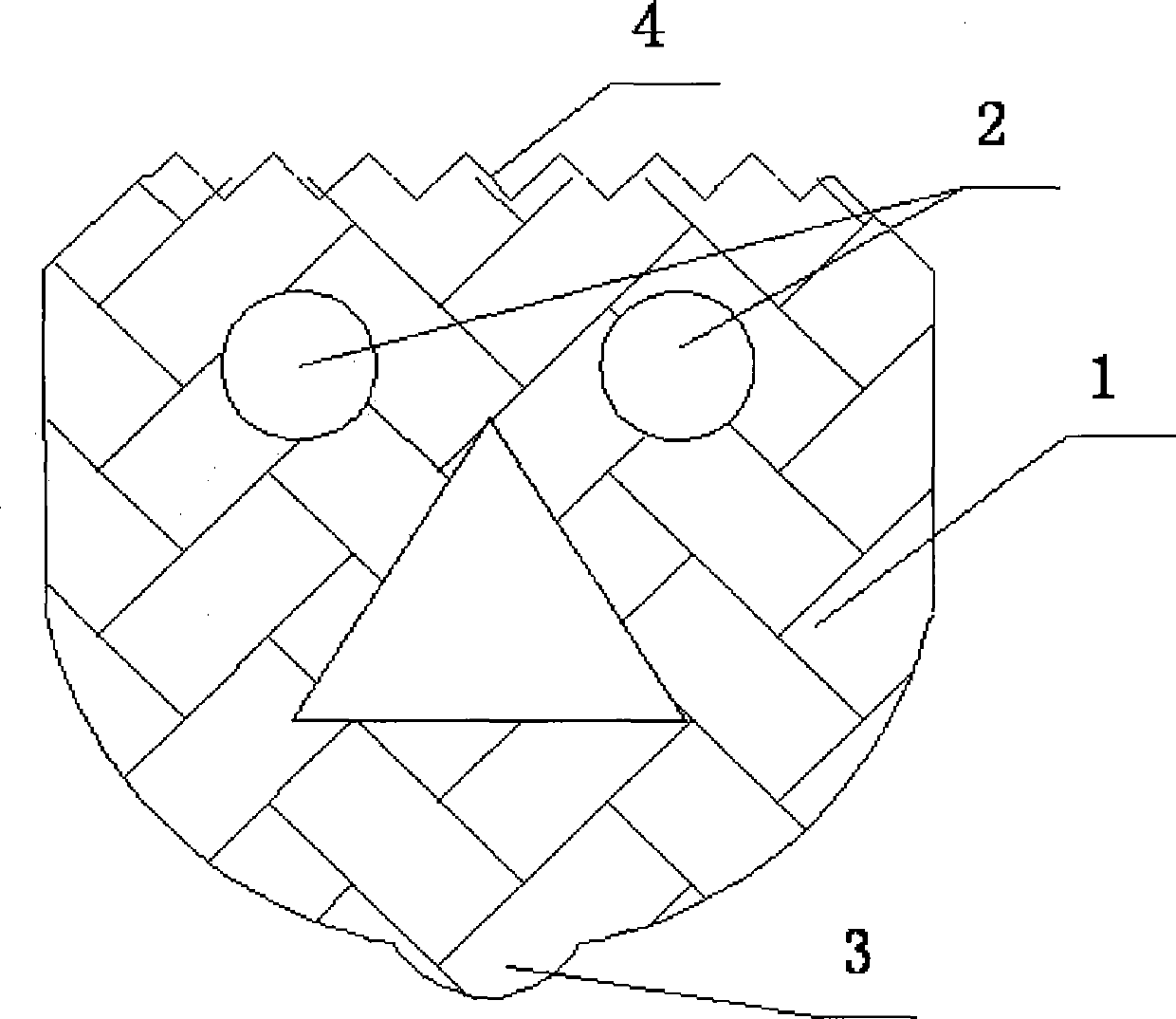

[0014] see figure 1 , figure 1 It is a schematic diagram of the cross-sectional structure of the flat sealing strip with ribs on the bottom and serrations on the bottom of the present invention. Depend on figure 1 It can be seen that the straight sealing strip with protruding bottom and sawtooth on the bottom of the present invention includes a sealing strip body 1, the sealing strip body 1 is in the shape of a straight strip, the upper part of the sealing strip body 1 is square, and the lower part is circular, and the sealing strip body 1. The material is EPDM rubber. In the sealing strip body 1, three cavities 2 are arranged in parallel along the length direction of the sealing strip body 1. Two of the cavities 2 are arranged in parallel on the upper part of the sealing strip body 1, one left and one right. Its cross-section is circular, and another hole 2 is arranged at the lower part of the sealing strip body 1. Set to sawtooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com