Automatic Press-fitting Mechanism for Sealing Steel Ball in Oil Channel Hole of Engine Cylinder Head

A technology of engine cylinder head and oil passage hole, which is applied in the field of mechanical processing, can solve the problems of missing assembly, breaking of the head of stamping rod, leakage of steel ball, etc., to reduce component configuration and manufacturing costs, press and install accurately, The effect of force balance in all directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

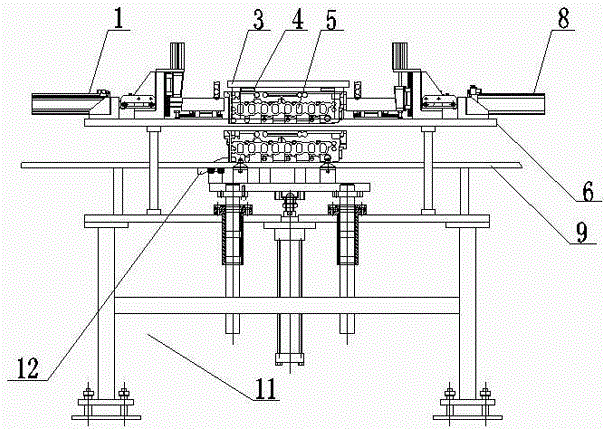

[0044] Embodiment An automatic press-fitting mechanism for the sealing steel ball in the oil passage hole of the engine cylinder head

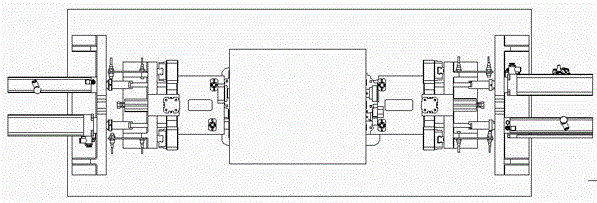

[0045] like figure 1 , figure 2 As shown, the present embodiment includes a fixedly arranged workbench 6 with a horizontal working top surface, a press-fitting unit for horizontally pressing steel balls for positioning, and a positioning unit for positioning the workpiece 5, that is, the engine cylinder head. The positioning unit, the locking device for locking the press-fitting unit of this embodiment, also includes a feeding unit for loading and unloading the workpiece 5 for the positioning unit.

[0046] The pressing unit, the positioning unit and the feeding unit are respectively located under the control of the main program of the PLC control system. in:

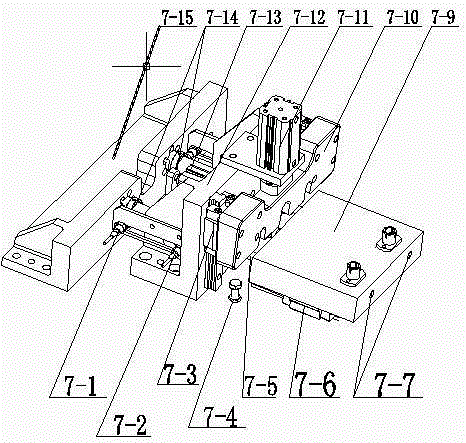

[0047] ①Pressing unit and locking device

[0048] The press-fitting unit is used to press-fit the steel balls. When the steel balls are detached from the press-fitting unit, the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com