Pulse type automatic shoe washing machine

A pulse-type, shoe-washing machine technology, applied to brush-type washing machines, other washing machines, washing devices, etc., to achieve the effect of all-round scrubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

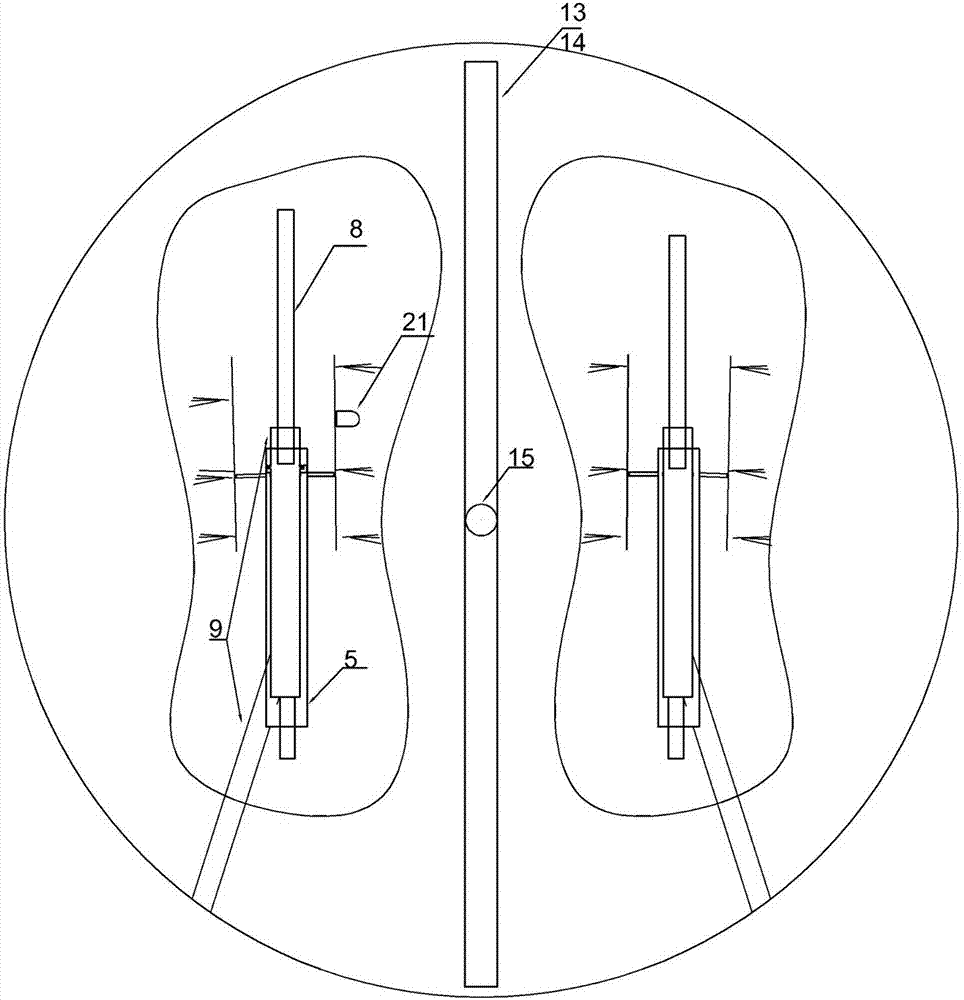

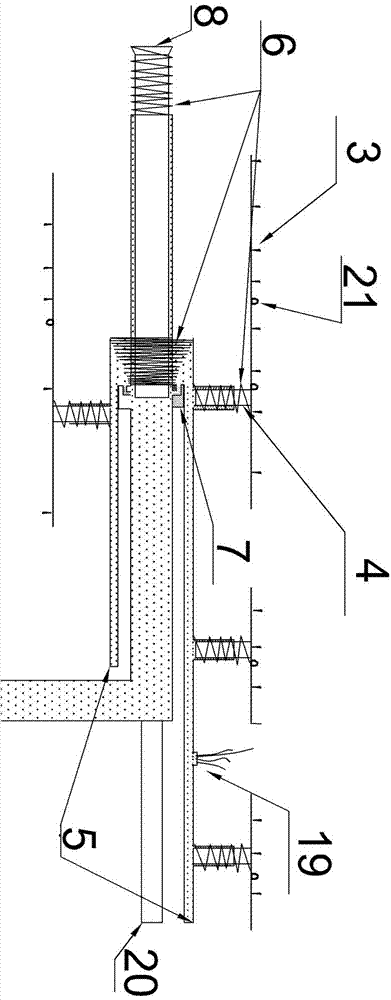

[0010] In Fig. 3, the forward fixed shaft (8) sleeve spring (6) is inserted into the main water channel (9), the fixed ring (7) is fixed on the main water channel (9), the moving device (5) and the spring (6) ) is set on the main water channel (9) and the fixed ring (7), and the small ball (21) is connected to the movement device (5) on the internal shoe brush (3) through the internal shoe brush regulator (4) and spring (6). ). It consists of the main water channel (9), the forward fixed shaft (8), the fixed ring (7), the spring (6), the movement device (5), the internal shoe brush adjuster (4), the rear fixed shaft (20) and the internal shoe The brush (3) forms a T-shaped shoe rack, as shown in Figure 2, the shoes are placed upside down on the shoe rack, and placed in parallel in the middle of the shoe washing bucket.

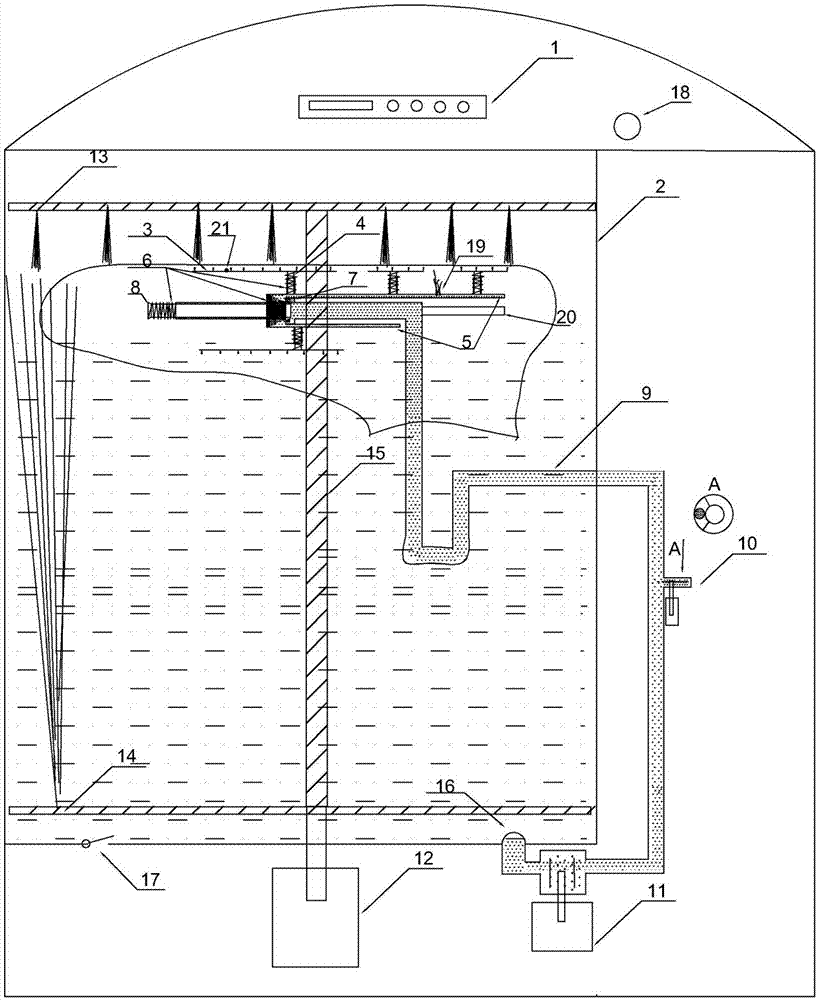

[0011] exist figure 1 The middle motor (12) drives the shoe surface cleaning brush (14) and drives the sole cleaning brush (13) through the connecting rod (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com