Novel numerical control machine tool protective cover cleaning device

A technology of a numerical control machine tool and a cleaning device, applied in the field of numerical control machine tools, can solve the problems of incomplete wiping, affecting the observation effect of the numerical control machine tool, scratches on the observation window, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

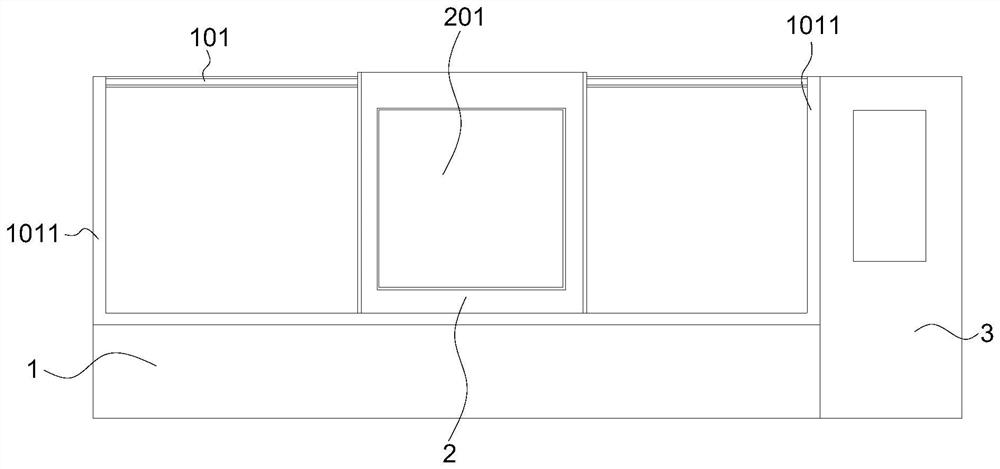

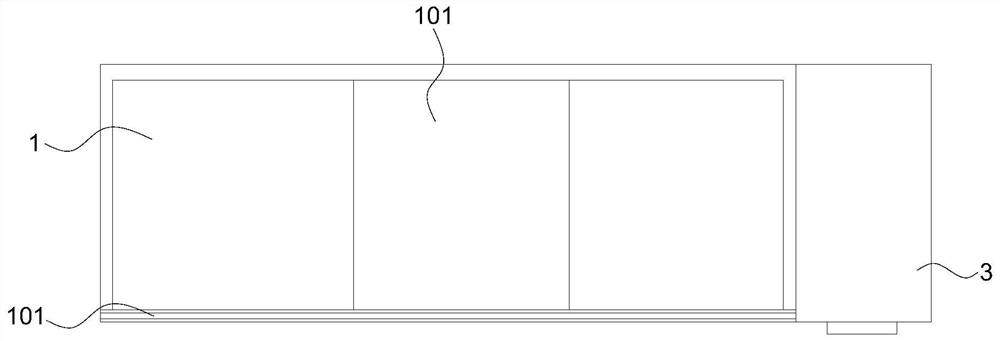

[0038] Please refer to Figure 1-Figure 4 , figure 1 It is a schematic diagram of the overall structure of the protective cover described in the embodiment of the present invention;

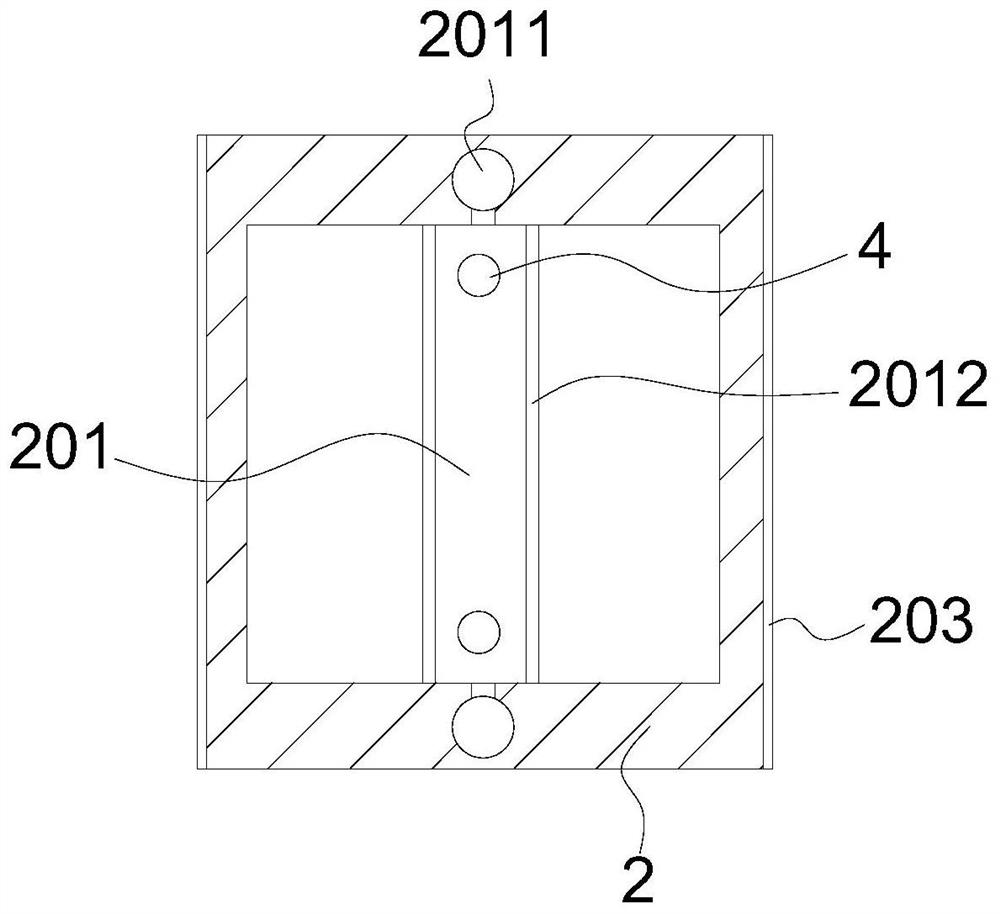

[0039] figure 2 It is a schematic top view structure diagram of the cover body 1 according to the embodiment of the present invention; image 3 It is a schematic diagram of the connection cross-sectional structure of the observation window 2 and the plate 201 according to the embodiment of the present invention; Figure 4 It is a schematic diagram of the side view structure of the observation window 2 in the embodiment of the present invention.

[0040] The embodiment of the present application provides a new type of cleaning device for the protective cover of CNC machine tools, which includes a cover body 1 that is placed above the CNC machine tool. Window 2, a see-through plate 201 is rotatably installed in the observation window 2 . The cover body 1 is located outside the CNC machine tool,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com