Porous graphene composite material supported by micropore and preparation method of material

A technology of porous graphene and composite materials, which is applied in the field of nuclear technology applications, and can solve the problems of not being able to play a supporting role, and the diameter of small holes cannot be too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

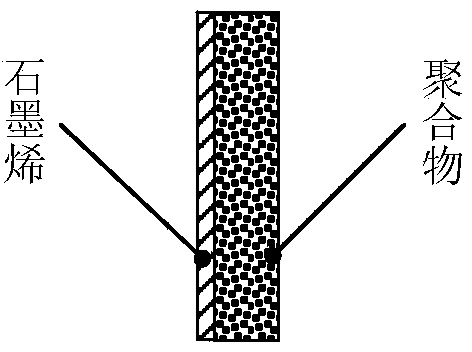

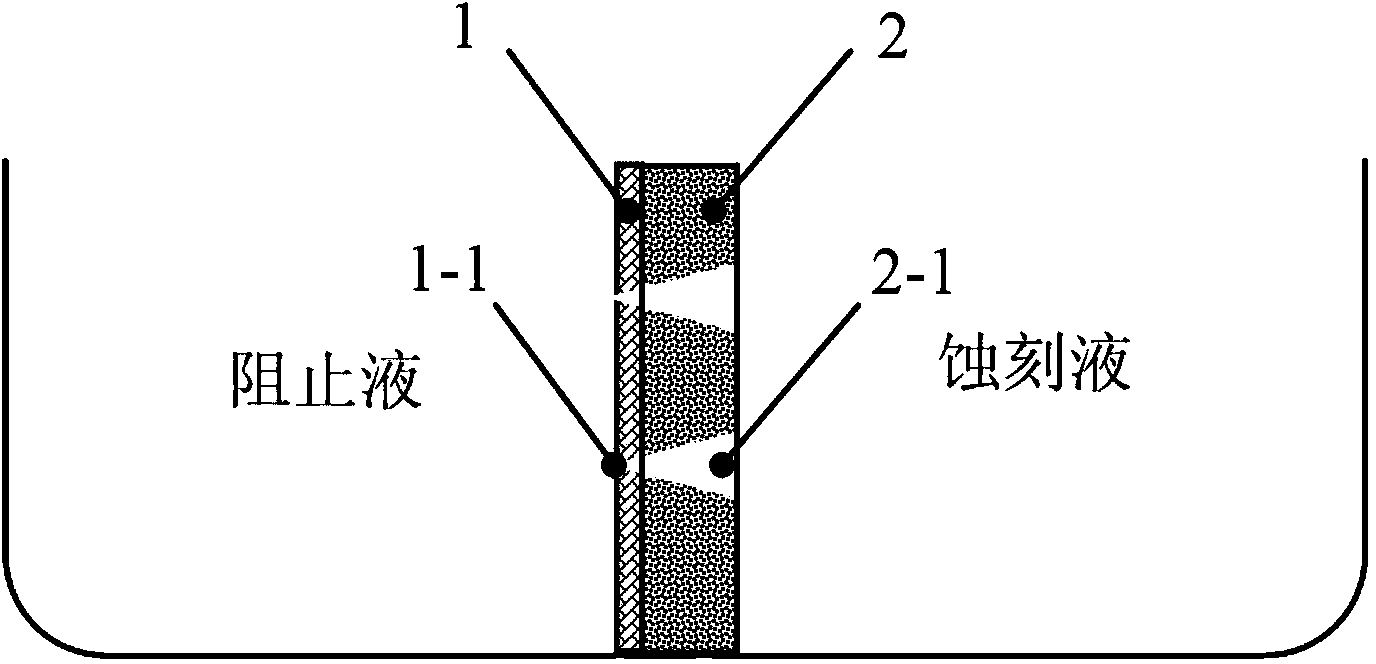

[0028] Example 1: see figure 1 , figure 2 , a porous graphene composite material with a microporous support, comprising a single-layer graphene 1 on a polymeric film 2, a nanoscale hole 1-1 and a conic shape on the polymeric film 2 on the graphene 1 Holes 2-1 overlap and communicate with each other.

[0029] The area of the single-layer graphene 1 on the polymeric film 2 is 5mm×5mm.

[0030] The polymeric film 2 is polycarbonate with a thickness of 10 μm.

Embodiment 2

[0031] Example 2: see figure 1 , a porous graphene composite material with microporous support, the area of the single-layer graphene 1 on the polymeric film 2 is 10mm×10mm. The polymeric film 2 is a polyethylene film with a thickness of 20 μm.

[0032] All the other structures are the same as in Example 1.

Embodiment 3

[0033] Embodiment 3: see figure 1 , a porous graphene composite material with microporous support, the area of the single-layer graphene 1 on the polymeric film 2 is 20mm×20mm. The polymeric film 2 is a polycarbonate film with a thickness of 30 μm.

[0034] All the other structures are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Opening diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com