Use method of graphene film in sodium ion battery and preparation method of graphene film

A technology of graphene film and sodium ion battery, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems such as small and difficult to realize sodium ion deintercalation, and achieve the effect of reducing raw material cost, small surface area, and simple process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

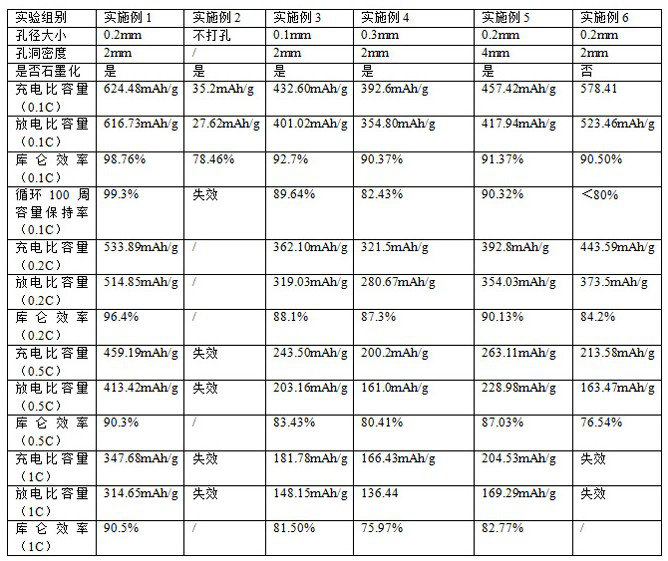

Embodiment 1

[0037] The preparation method of a self-supporting layered graphene sodium ion film negative electrode proposed by the present invention, the specific steps are as follows:

[0038] 1) The flake graphene is oxidized to graphene oxide with higher monolayer rate using the modified Hummers oxidation method.

[0039] S1. Select 3g of flake graphite (500 mesh) as the raw material, add 24ml of concentrated sulfuric acid, and slowly add K after fully stirring 2 S 2 O 8 , P 2 O 5 5g each, stir evenly, heat to 80°C, keep the temperature for 4.5h, and carry out pre-oxidation;

[0040] S2, then add 120ml of concentrated sulfuric acid, stir again and slowly add 15g KMnO dropwise 4 , put it in a low temperature environment (35°C) and slowly stir for 2h, add 250ml of deionized water, and continue to stir at 35°C for 2h, the solution is dark green at this time;

[0041] S3. Finally, slowly add 720ml of H with a mass fraction of 0.83% under stirring conditions. 2 O 2 , a bright yellow...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the graphene film is not perforated, and other steps are the same as those of Embodiment 1.

[0051] 1) The flake graphene is oxidized to graphene oxide with higher monolayer rate using the modified Hummers oxidation method.

[0052] S1. Select 3g of flake graphite (500 mesh) as the raw material, add 24ml of concentrated sulfuric acid, and slowly add K after fully stirring 2 S 2 O 8 , P 2 O 5 5g each, stir evenly, heat to 80°C, keep the temperature for 4.5h, and carry out pre-oxidation;

[0053] S2, then add 120ml concentrated sulfuric acid, stir again and slowly add 15g KMnO dropwise 4 , put it in a low temperature environment (35°C) and slowly stir for 2h, add 250ml of deionized water, and continue to stir at 35°C for 2h, the solution is dark green at this time;

[0054] S3. Finally, slowly add 720ml of H with a mass fraction of 0.83% under stirring conditions. 2 O 2 , a bright yellow graphene oxi...

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that in step 5), the hole radius of the laser penetration drilling is designed to be 0.1 mm, and other steps are the same as those of Embodiment 1.

[0064] 1) The flake graphene is oxidized to graphene oxide with higher monolayer rate using the modified Hummers oxidation method.

[0065] S1. Select 3g of flake graphite (500 mesh) as the raw material, add 24ml of concentrated sulfuric acid, and slowly add K after fully stirring 2 S 2 O 8 , P 2 O 5 5g each, stir evenly, heat to 80°C, keep the temperature for 4.5h, and carry out pre-oxidation;

[0066] S2, then add 120ml concentrated sulfuric acid, stir again and slowly add 15g KMnO dropwise 4 , put it in a low temperature environment (35°C) and slowly stir for 2h, add 250ml of deionized water, and continue to stir at 35°C for 2h, the solution is dark green at this time;

[0067] S3. Finally, slowly add 720ml of H with a mass fraction of 0.83% under stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com