A design method for the opening of a buried cabin

A design method and embedded technology, applied in the field of aircraft, can solve the problems of multiple parts, changes in aerodynamic shape, complex design of the embedded cabin door system, etc., to achieve improved accuracy, fewer parts, and better flight quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The design scheme of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] The invention proposes and realizes a design method for opening an internally embedded cabin, which can be used for various types of aircraft using internally embedded cabins.

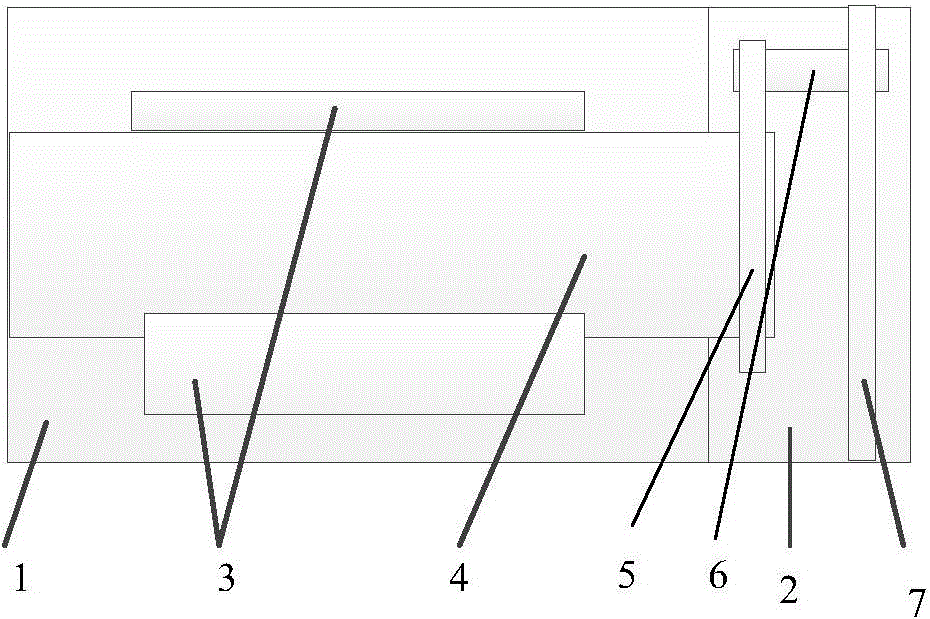

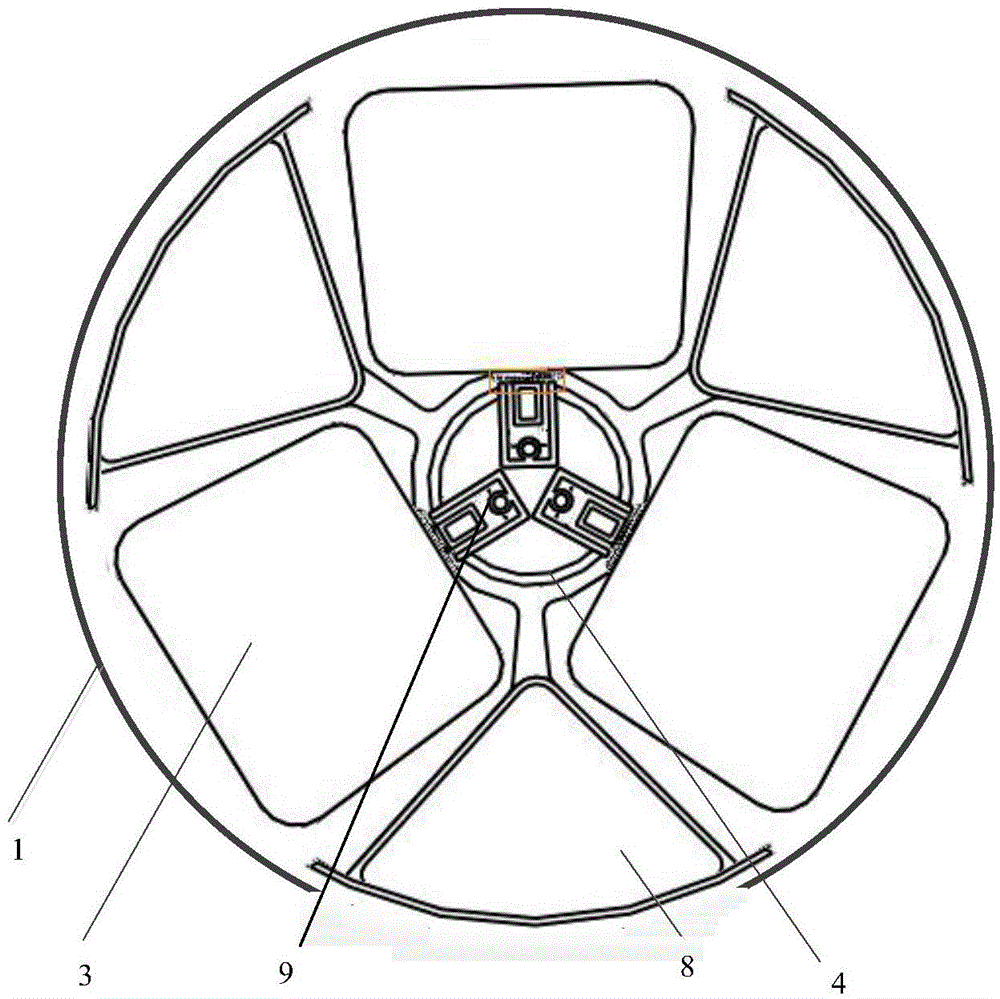

[0020] Taking the section as a circle, and dividing the entire compartment into two parts, the bomb compartment 1 and the drive compartment 2, and carrying three projectiles 3, the embedded compartment is taken as an example. Among them, the bomb bay 1 is the cabin section for installing the rotating rack, and the driving cabin 2 is the cabin section for installing the driving mechanism. The overall schematic diagram is as follows figure 1 Shown (buried type cabin also can not distinguish each cabin section, and rotary mount frame, throwing thing 3, mechanism box 9, driving device 6 etc. are installed in the cabin together). The rotary mount can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com