A twisting machine alarm

An alarm, twisting machine technology, applied in textiles and papermaking, etc., can solve problems such as unqualified products, and achieve the effect of convenient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

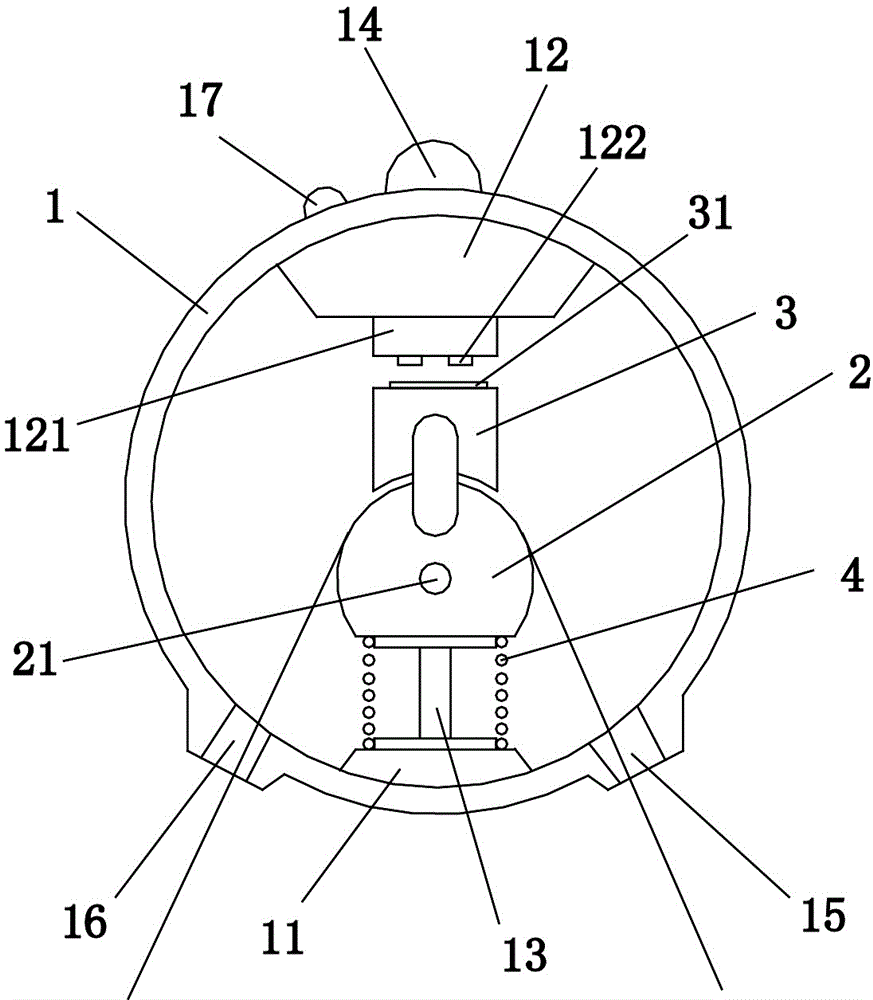

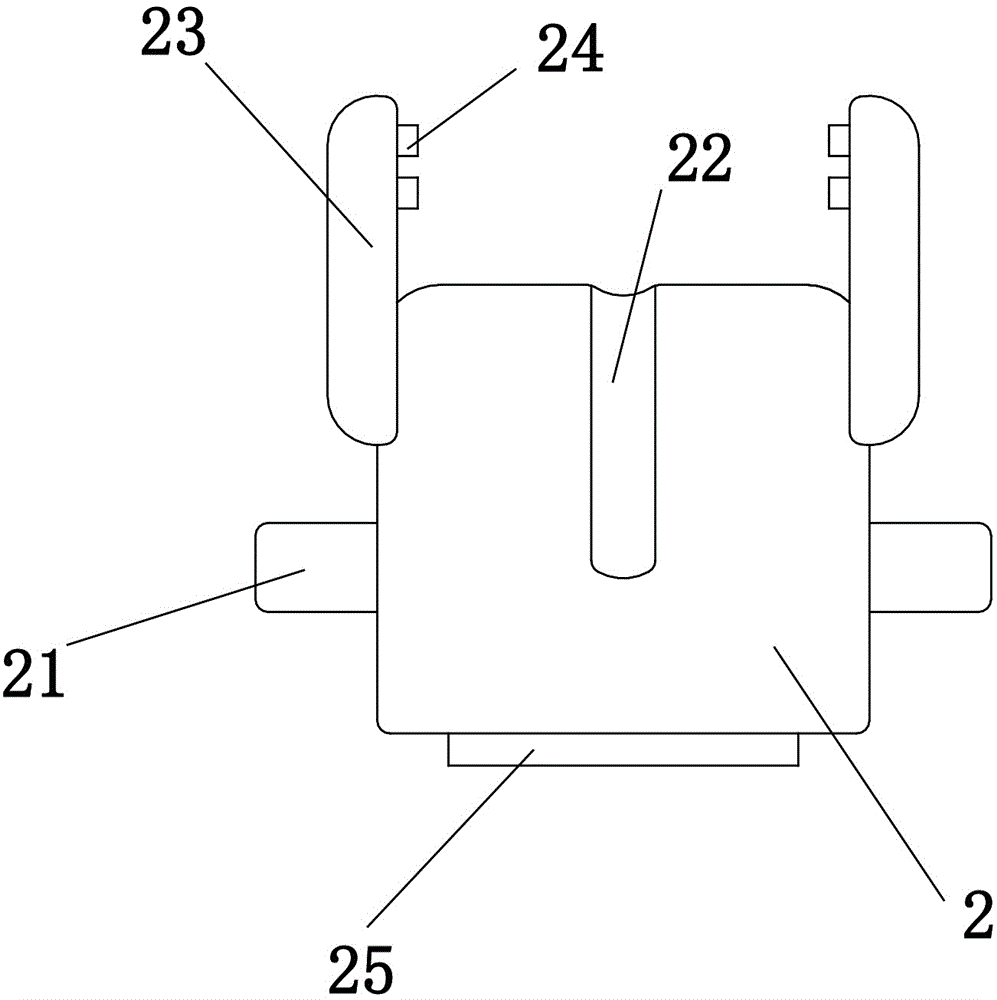

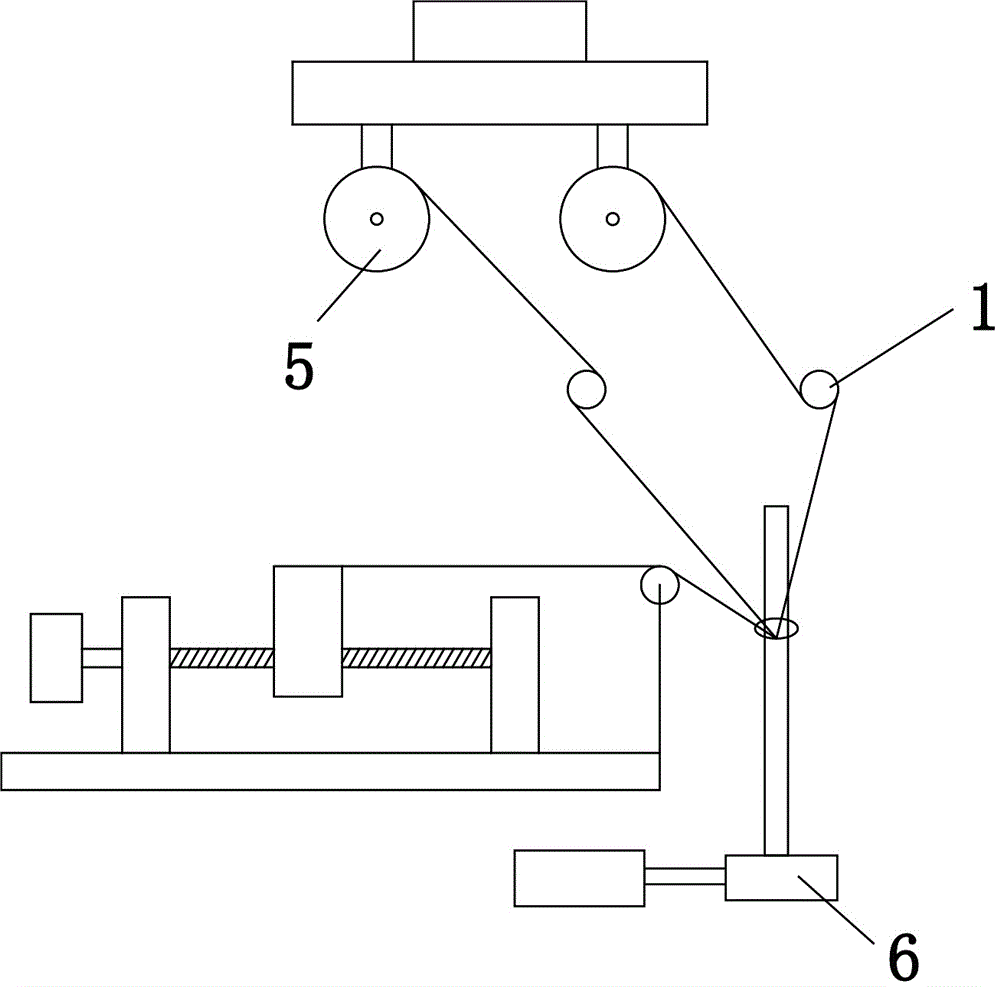

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 3 As shown, a twister alarm includes a frame 1 and a lead part 2, the frame 1 is provided with a chute 13 inside, the lead part 2 includes a guide rod 21 and a support rod 23, and the guide rod 21 is slidably arranged in the chute 13, the support rod 23 is provided with a protrusion 24, and the support rod 23 is connected with a pressing block 3 through the protrusion 24 bayonet, and a metal sheet 31 is arranged above the pressing block , a groove 22 is arranged above the lead part 2, a round platform 25 is arranged under the lead part, a spring base 11 is arranged under the frame 1, and a Spring 4, the upper part of the frame 1 is provided with a control part 12, the lower part of the control part 12 is provided with a switch part 121, the lower part of the switch part 121 is provided with two metal protrusions 122, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com