Device, carrying body and lifting vehicle

A carrier and vehicle technology, applied in the direction of lifting devices, measuring devices, lifting equipment safety devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

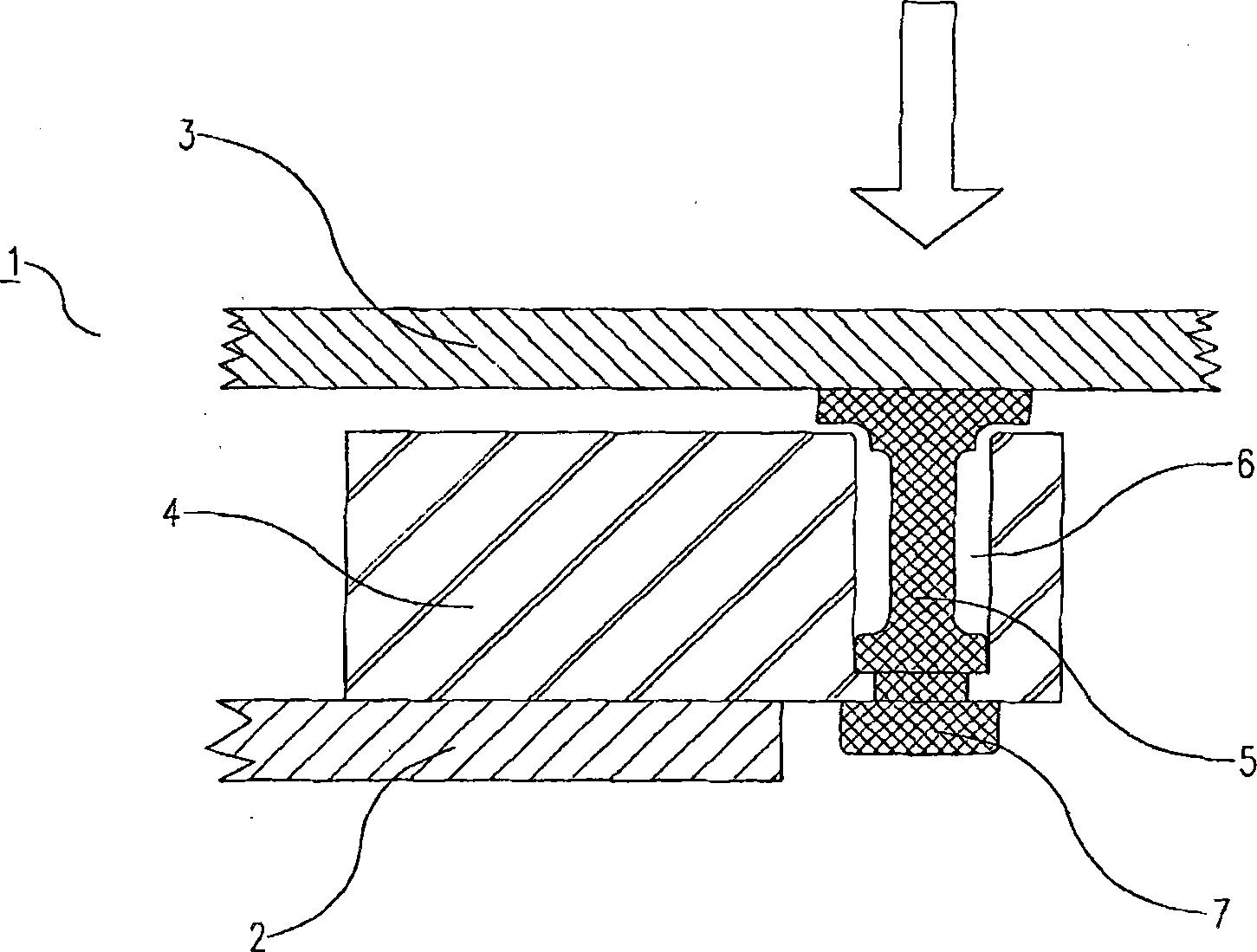

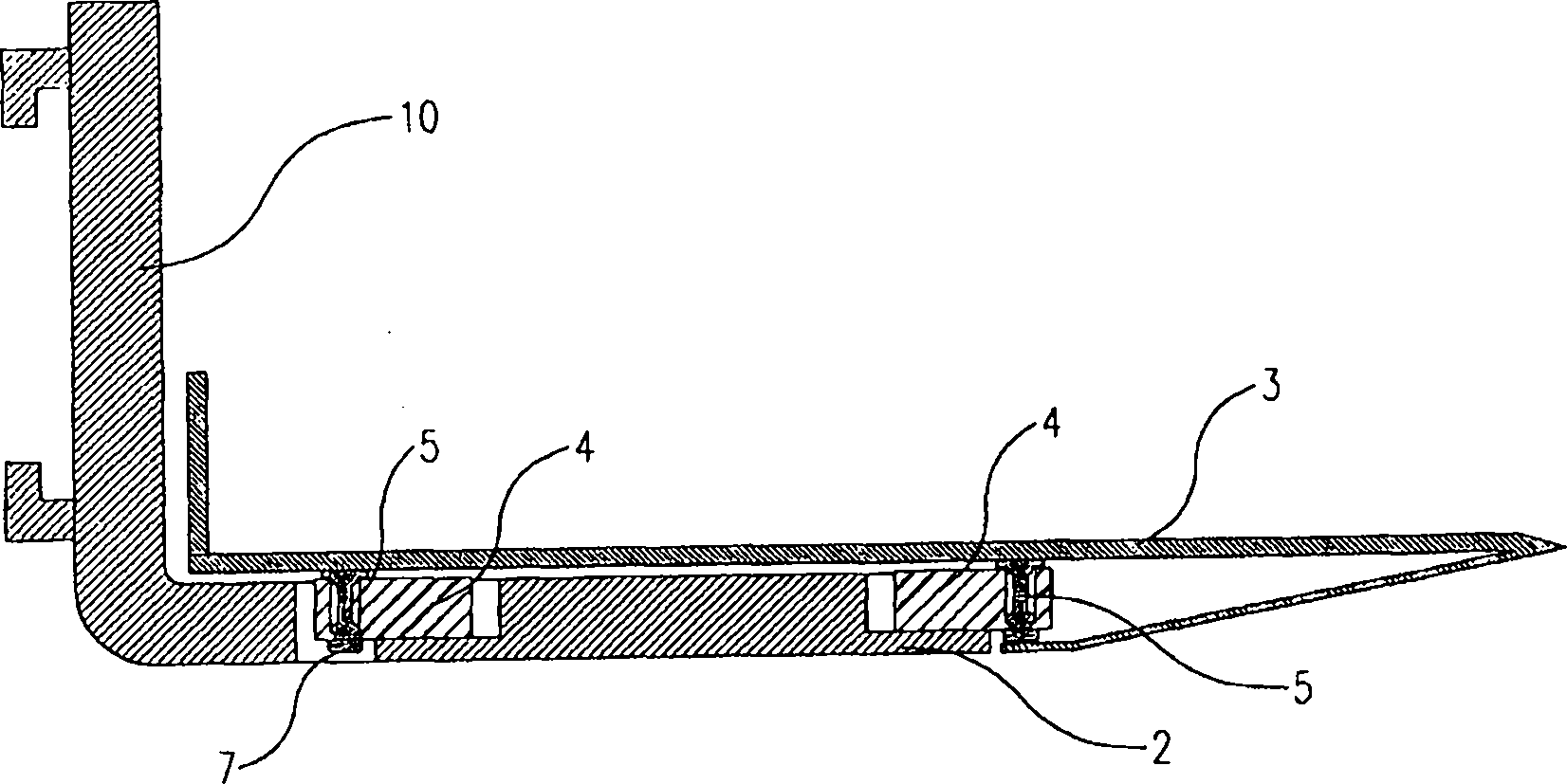

[0021] Such as figure 1 detail view in and figure 2 As shown in the side view in longitudinal section, the device 1 comprises a carrier having a first wall 3 and a second wall 2 for receiving goods. The first wall and the second wall leave a spatial gap in which the force sensor 4 is arranged. In this exemplary embodiment, the force sensor 4 is a load cell provided with a strain gauge capable of determining the deformation of the load cell and generating it as a signal. A part of the load cell 4 is attached to the second wall 2 . However, another part of the load cell 4 extends beyond the edge of the second wall 2 and is thus free to bend in the event of a vertical pressure coming from above, for example by goods placed on the first wall 3 . Through the intervention of the force transmission body 5 , there is a gap between the force measuring unit 4 and the first wall 3 . For this purpose, the force transmission body 5 comprises a laterally projecting edge on the outer en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com