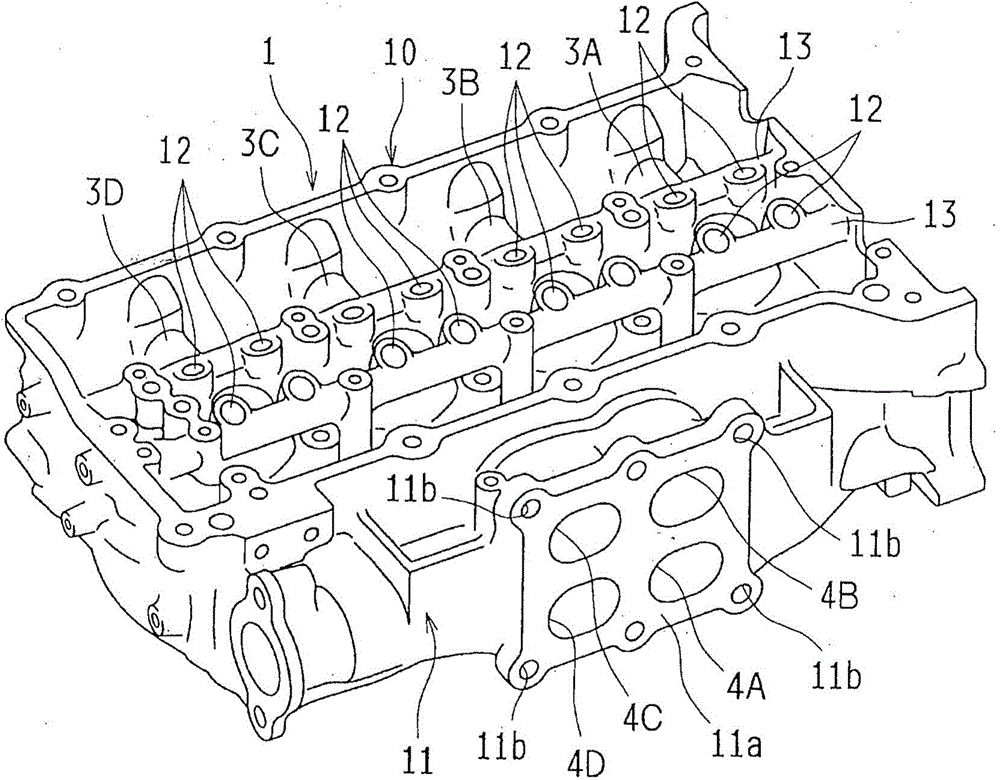

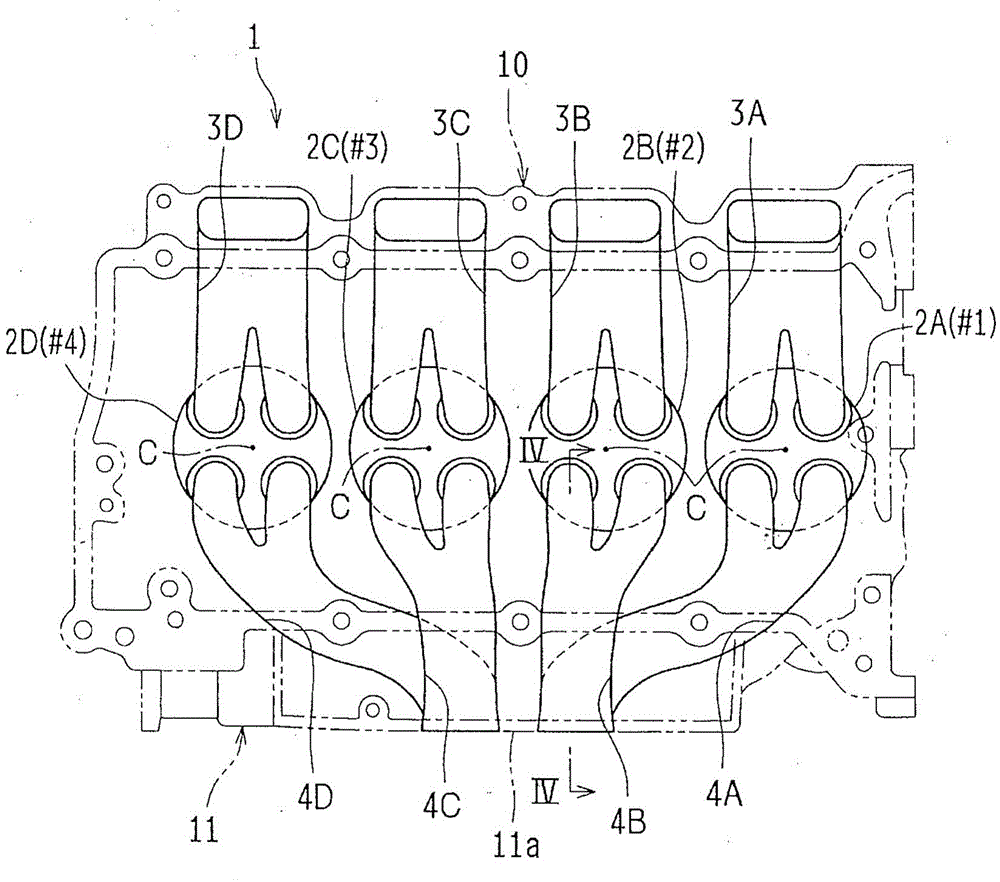

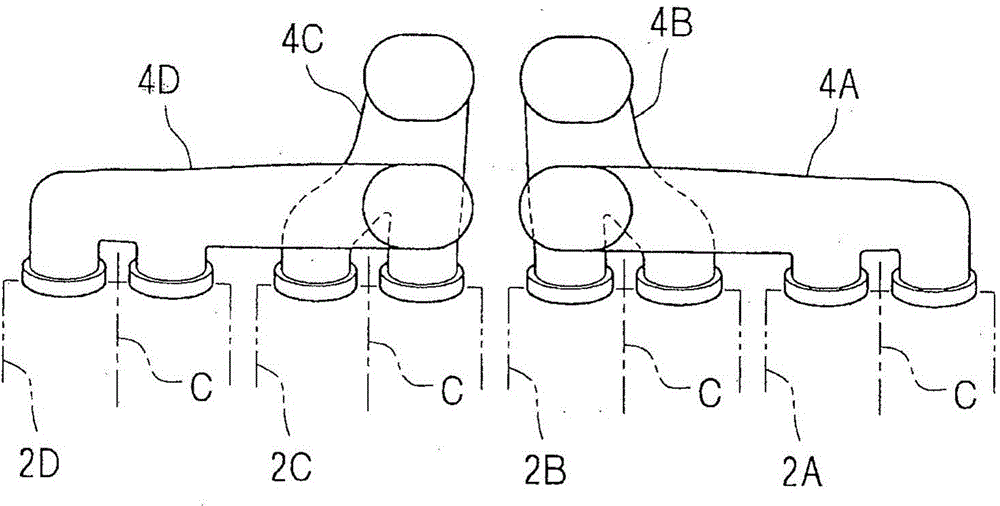

Exhaust passage structure for internal combustion engine

A technology for exhaust passages and internal combustion engines, which is applied in the direction of exhaust devices, engine cooling, mechanical equipment, etc., and can solve the problems of increasing the size and weight of the exhaust manifold cylinder head, increasing the volume or flow of coolant, and increasing the total weight, etc. , to achieve the effects of reducing the overall size, improving the preheating characteristics, and improving the heat dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -

[0061] The structure of the present invention is not limited to the embodiments described above, and may include other various forms. That is, in the embodiments described above, for example, the water jacket w is provided so as to correspond to the three bent portions 41 to 43 in the inside exhaust port 4B or 4C; however, the present invention is not limited to the aforementioned structure, and the water jacket w The sleeve w may be provided to correspond to any one of the bent portions 41 to 43 .

[0062] In this case, the water jacket w is preferably provided in at least the third bent portion 43 on the most downstream side. This is because the exhaust gas flow exists in a steady state as described above in the third bent portion 43 , so that the enhancement effect of the heat dissipation characteristic is further enhanced.

[0063] The number of bent portions provided in the inside exhaust port 4B or 4C is not limited to three, and may be four, five or more. The bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com