Great saphenous vein drawing and peeling tunnel hemostat

A hemostat and tunnel technology, applied in the field of surgical supplies, can solve the problems of reduced operation efficiency, high manpower and energy, and high mental pressure, and achieve the effects of improving efficiency, relieving mental pressure, and reducing manpower and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

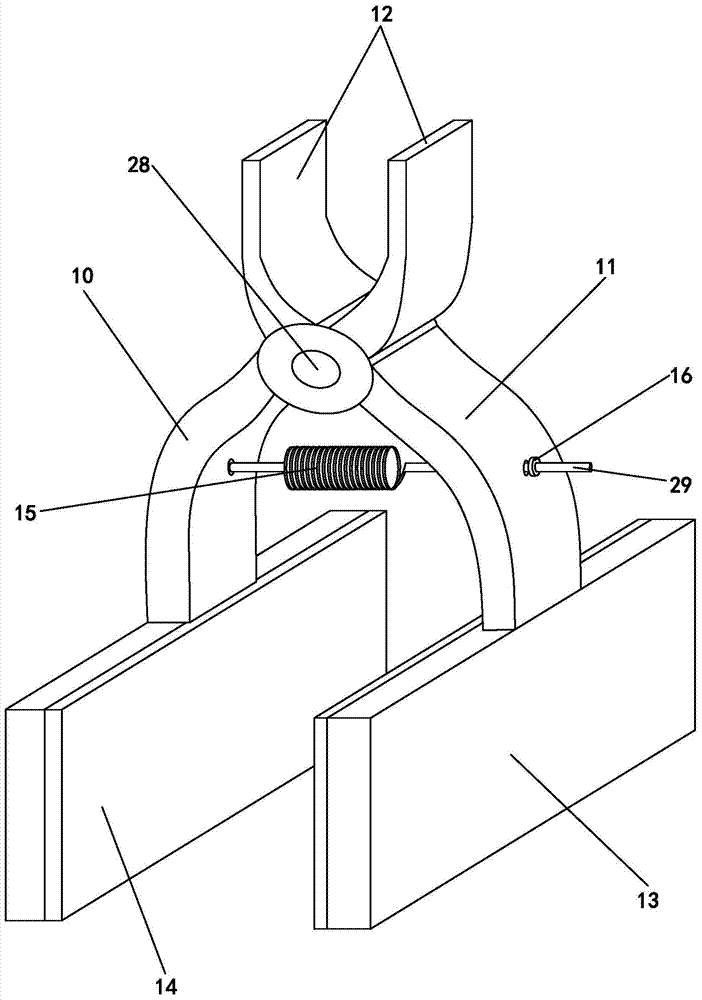

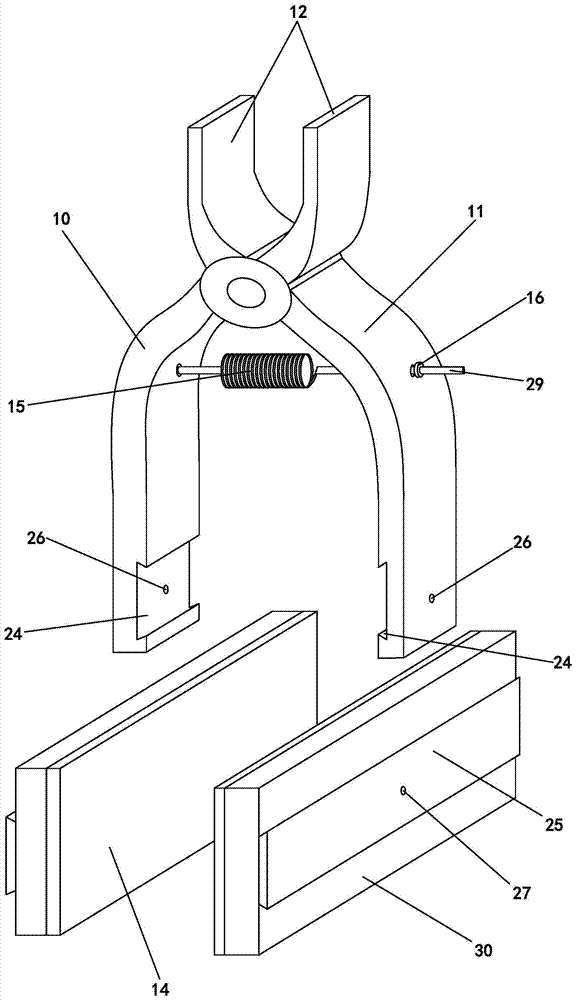

[0018] Embodiment one, such as figure 1 , figure 2 As shown, the tightness of the spring 15 can be adjusted as follows: the screw rod 29 at one end of the spring 15 and the other end of the screw rod 29 pass through the right clamp arm 11 or the left clamp arm 10 between the hinge shaft 28 and the clamping part 13 The through hole on the top is connected with the adjusting nut 16, that is, the spring 15 and the screw rod 29 are integrated, and the position of the adjusting nut 16 on the screw rod 29 can adjust the tightness of the spring 15. In this embodiment, if one end of the spring 15 is arranged on the left clip arm 10 between the hinge shaft 28 and the clamping part 13, then the other end of the spring 15 is arranged on one end of the screw rod 29, and the other end of the screw rod 29 passes through The through hole on the right clamp arm 11 between the hinge shaft 28 and the clamping part 13 is connected with the adjusting nut 16; and vice versa.

Embodiment 2

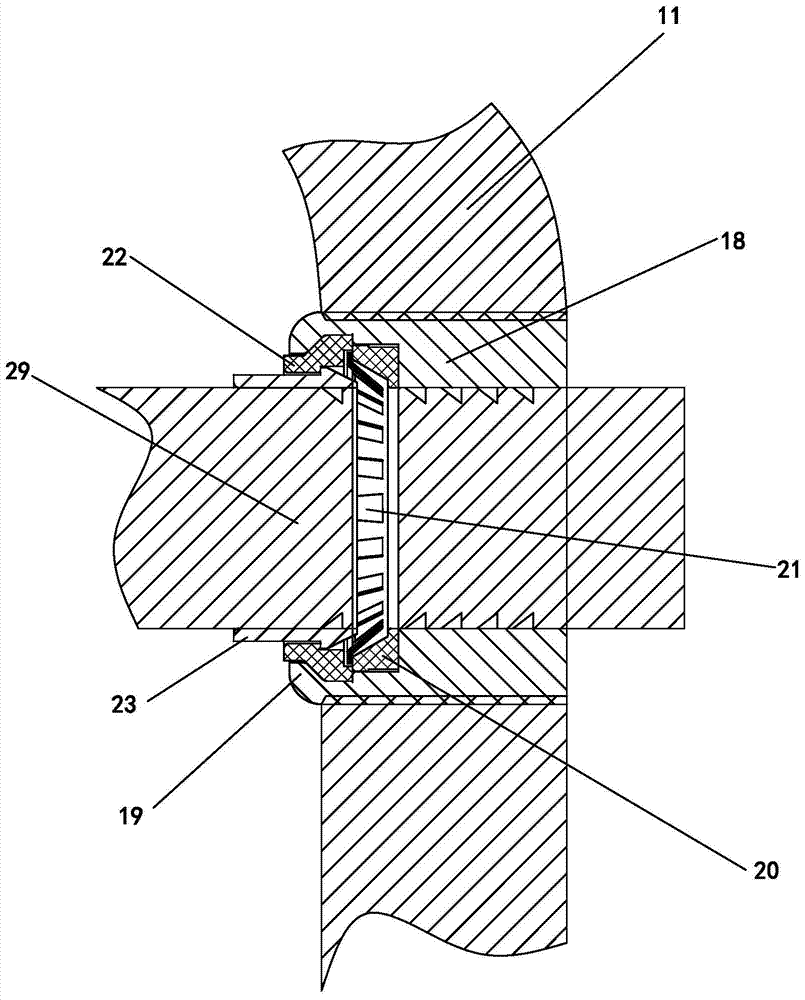

[0019] Embodiment 2, the tightness of the spring 15 can be adjusted as follows: one end of the spring 15 is arranged on the screw rod 29, and the screw rod 29 passes through and extends out of the right clamping arm 11 or the left clamping arm 11 between the hinge shaft 28 and the clamping part 13. One end of the through hole of the clamp arm 10 is provided with a plurality of ring-shaped inclined grooves 17, and the through hole of the right clamp arm 11 or the left clamp arm 10 is screwed with a clamping sleeve 18; the port of the clamping sleeve 18 is provided with Shrink mouth 19, clamping sleeve 19 is provided with elastic compression ring 20, clamping claw 21 is provided along its circumference on the clamping ring 20, and one side of claw 21 is provided with annular plastic shell 22, and the plastic shell The body 22 is clamped in the cavity between the constriction 19 and the compression ring 20 , and the unlocking sleeve 23 is clamped in the plastic shell 22 . In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com