A new type of steel ball unfolding and sorting device for visual inspection

A technology of visual inspection and sorting device, applied in sorting and other directions, can solve the problems of long public channels, long switching time, complex overall structure, etc., to reduce control difficulty and manufacturing, overcome long switching time, and overcome overall complex structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

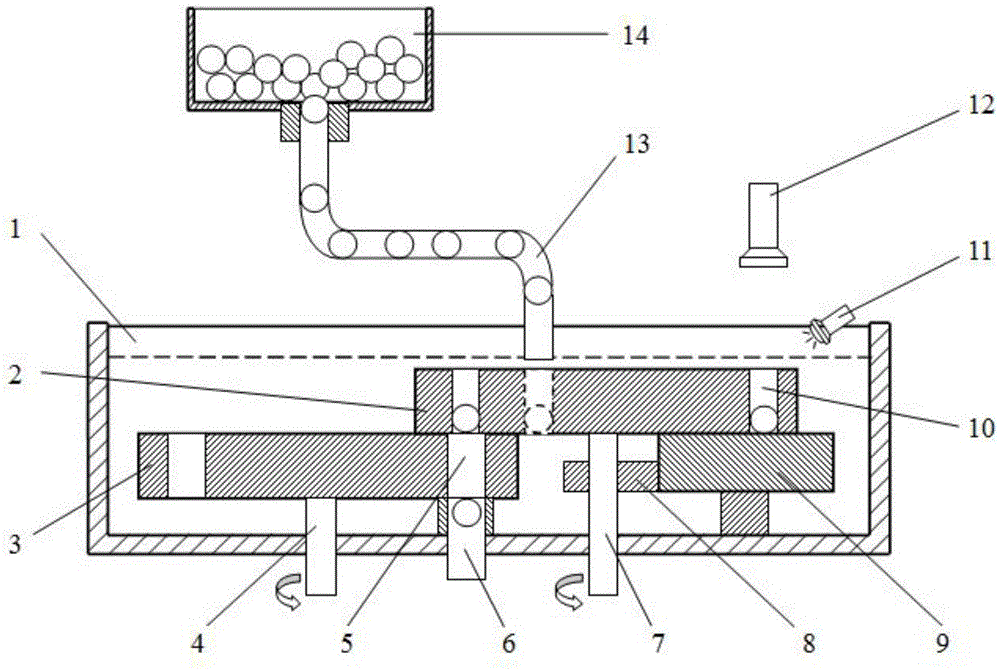

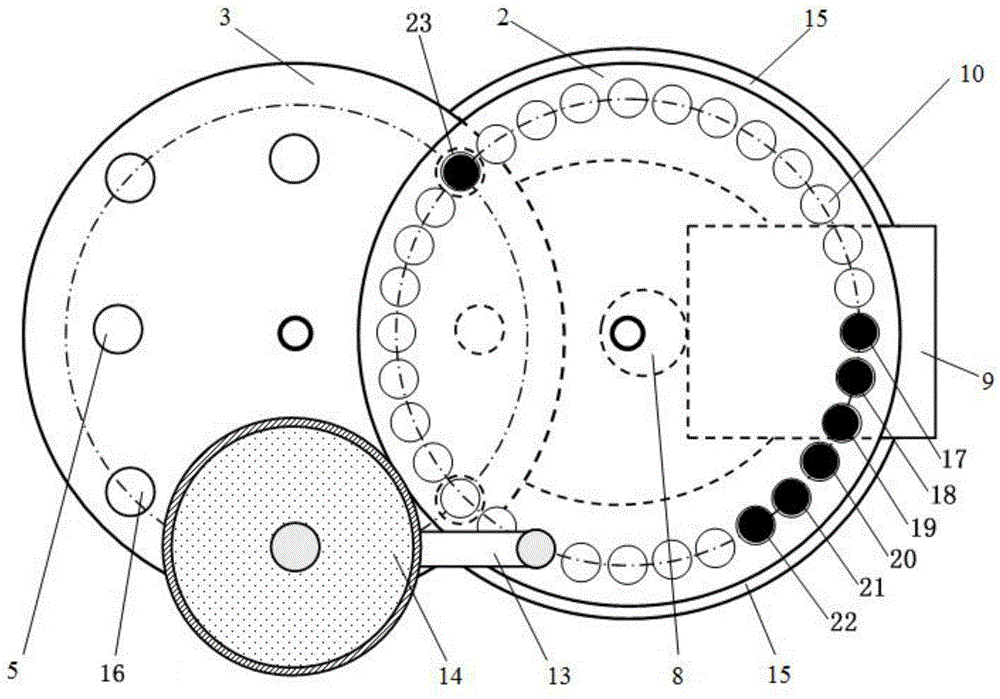

[0015] In order to describe the present invention more specifically, a new type of steel ball unfolding and sorting device for visual inspection of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as figure 1 and figure 2 As shown, a new type of steel ball expansion and sorting device for visual inspection includes a feeding mechanism 14, a feeding channel 13, a detection tank 1, a feed plate 2, a feed shaft 7, a detection chamber 10, and a detection light source 11 , Camera 12, fan-shaped support block 15, eccentric wheel 8, slide block 9, sorting disc 3, sorting shaft 4 and discharge channel 6.

[0017] The feeding mechanism 14 is connected with the feeding plate 2 installed in the detection tank 1 through the feeding channel 13, and transports the steel balls to be inspected to the feeding plate 2 according to the set ball feeding frequency. The feed plate 2 is made of milky whit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com