Steel ball sorting device and method based on machine vision

A technology of machine vision and sorting devices, which is applied in the direction of sorting, measuring devices, optical devices, etc., can solve the problems of complex overall structure, reduce the accuracy of detection results, increase the unbalanced vibration of equipment, etc., achieve stable operation, overcome The effect of the overall complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

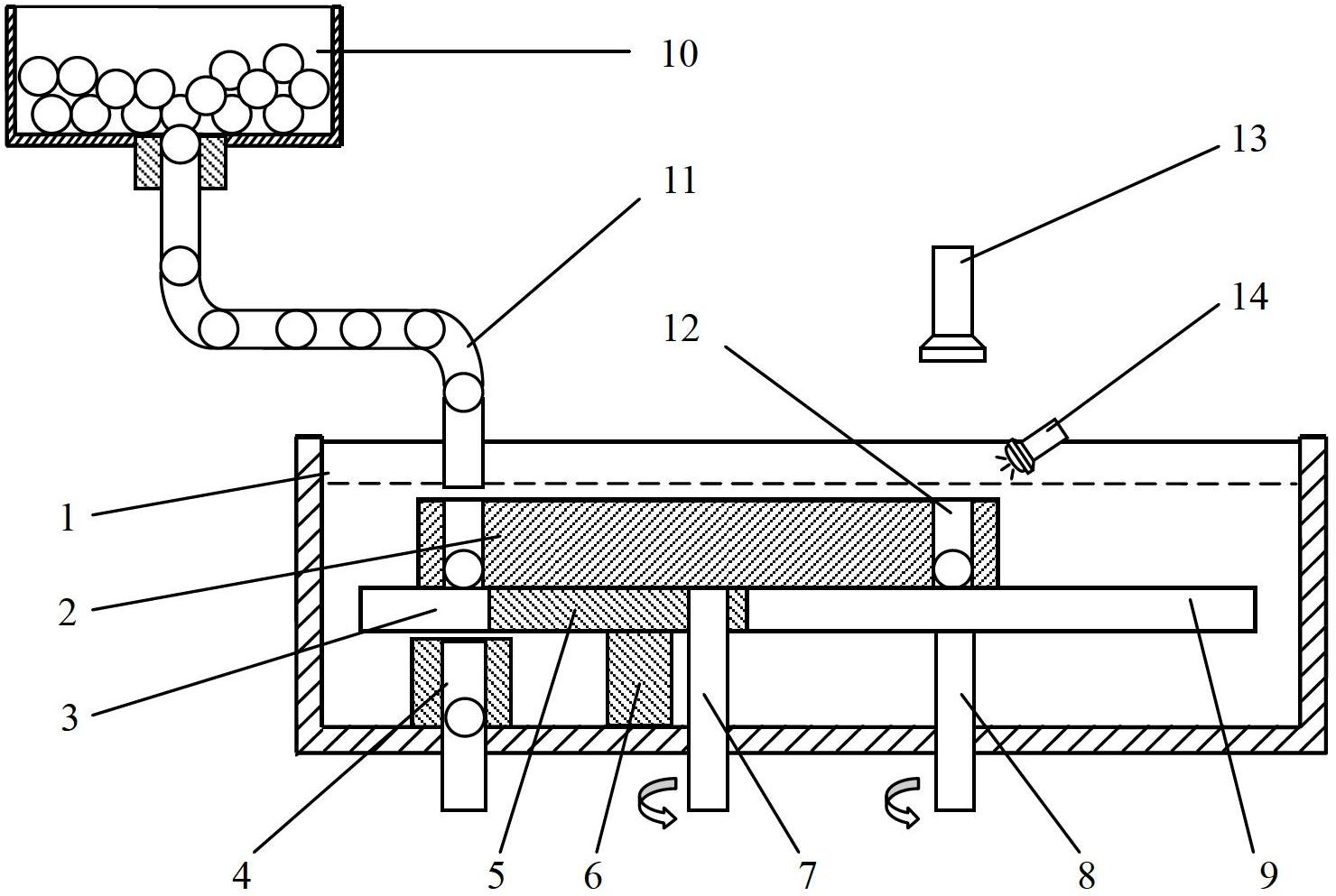

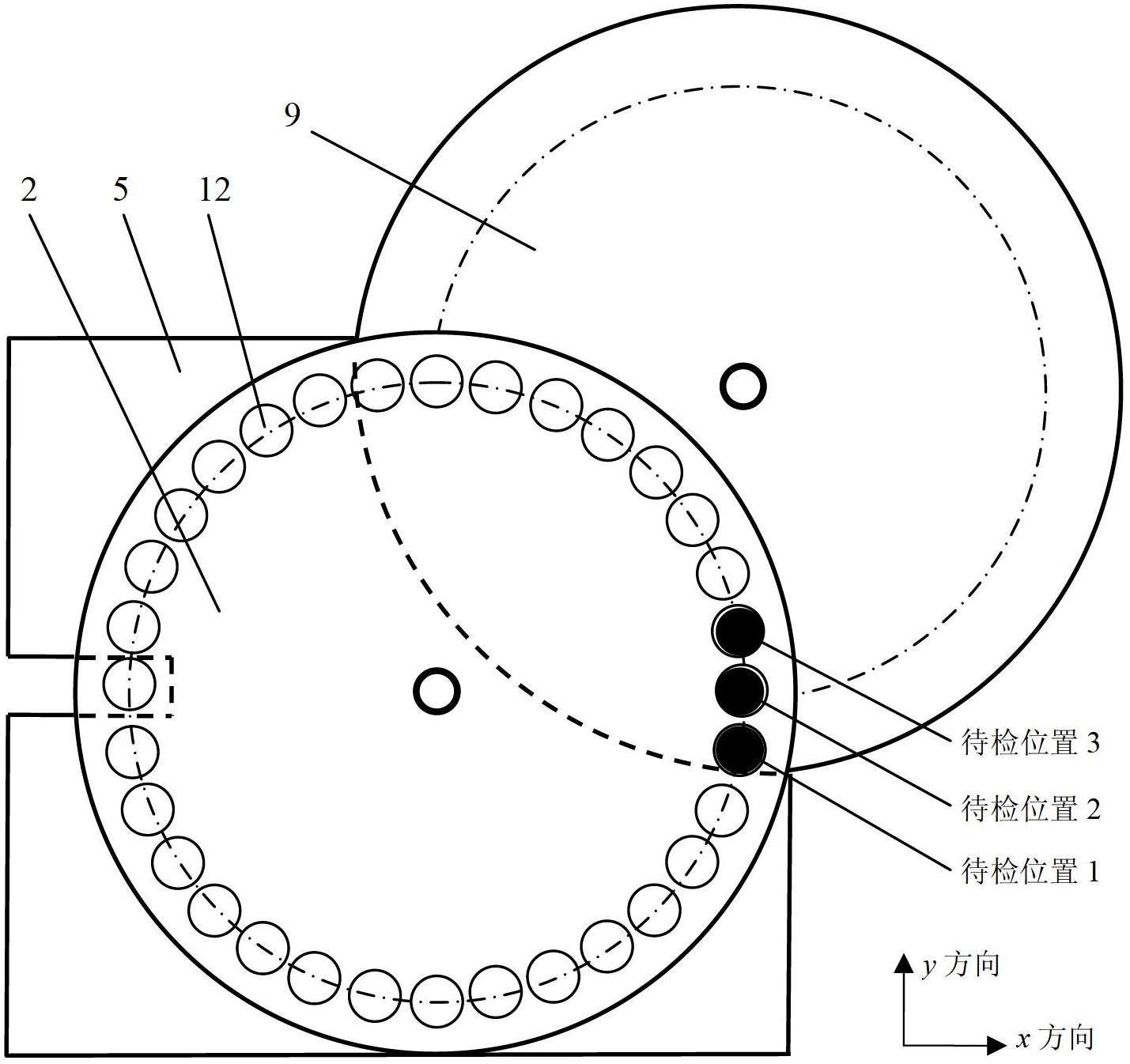

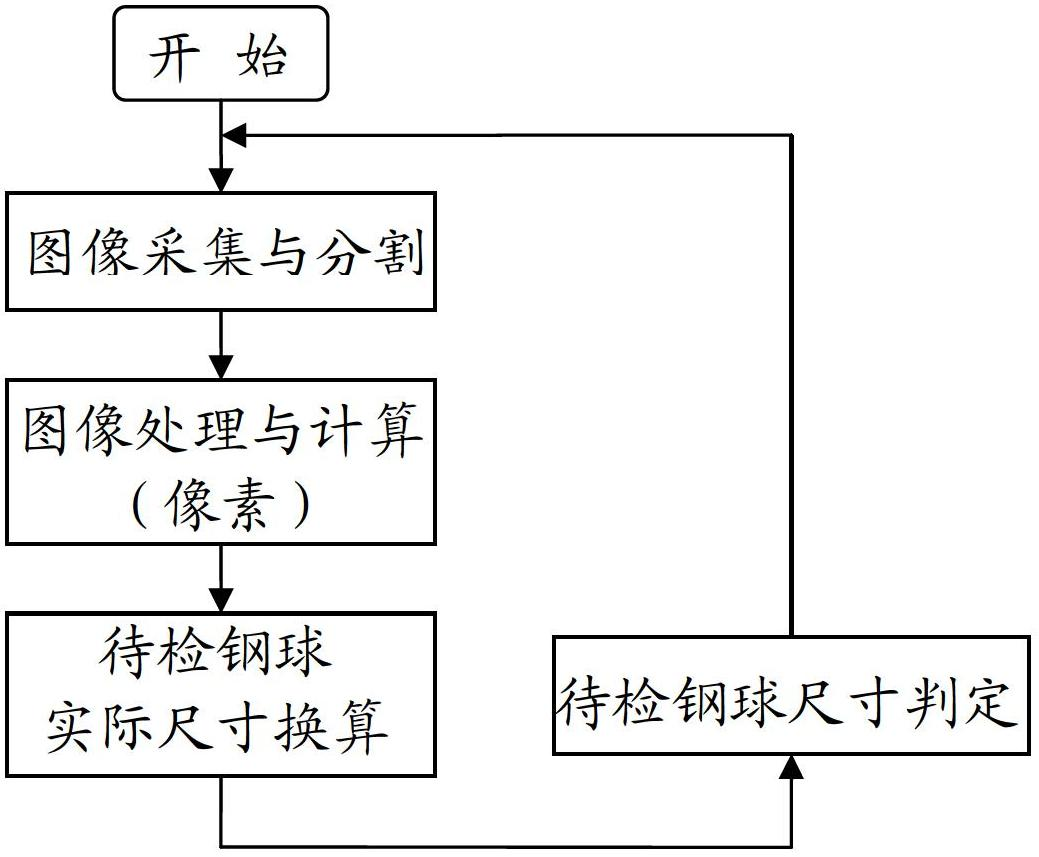

[0019] Such as figure 1 , 2 A steel ball sorting device based on machine vision includes a feeding mechanism 10, a feeding channel 11, a feeding tray 2, a detection chamber 12, a detection light source 14, a camera 13, a tray 5, a tray support 6, an unfolding tray 9, Ball outlet mechanism 4 and ball outlet 3.

[0020] The feeding mechanism 10 is connected with the feeding plate 2 installed in the detection tank 1 through the feeding channel 11, and transports the steel balls to be inspected to the feeding plate 2 according to the set ball feeding frequency. The feed plate 2 is made of milky white light-transmitting material, and a number of detection cavities 12 are evenly distributed on its circumference. The detection cavity 12 is a circular through hole penetrating the upper and lower surfaces of the feed plate 2, and its machining accuracy should meet the requirements for measuring the outer diameter of the steel ball. The distance between the centers of the several det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com