Method for preventing fraying of stitches and sewing machine

A technology of stitches and needle thread loops, which is applied in the field of sewing machines, can solve problems such as difficult operation of sewn products, quality reduction of sewn products, and needle thread 6 is easy to fall out, etc., and achieves the effect of avoiding needle thread loops from becoming larger and preventing thread skipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

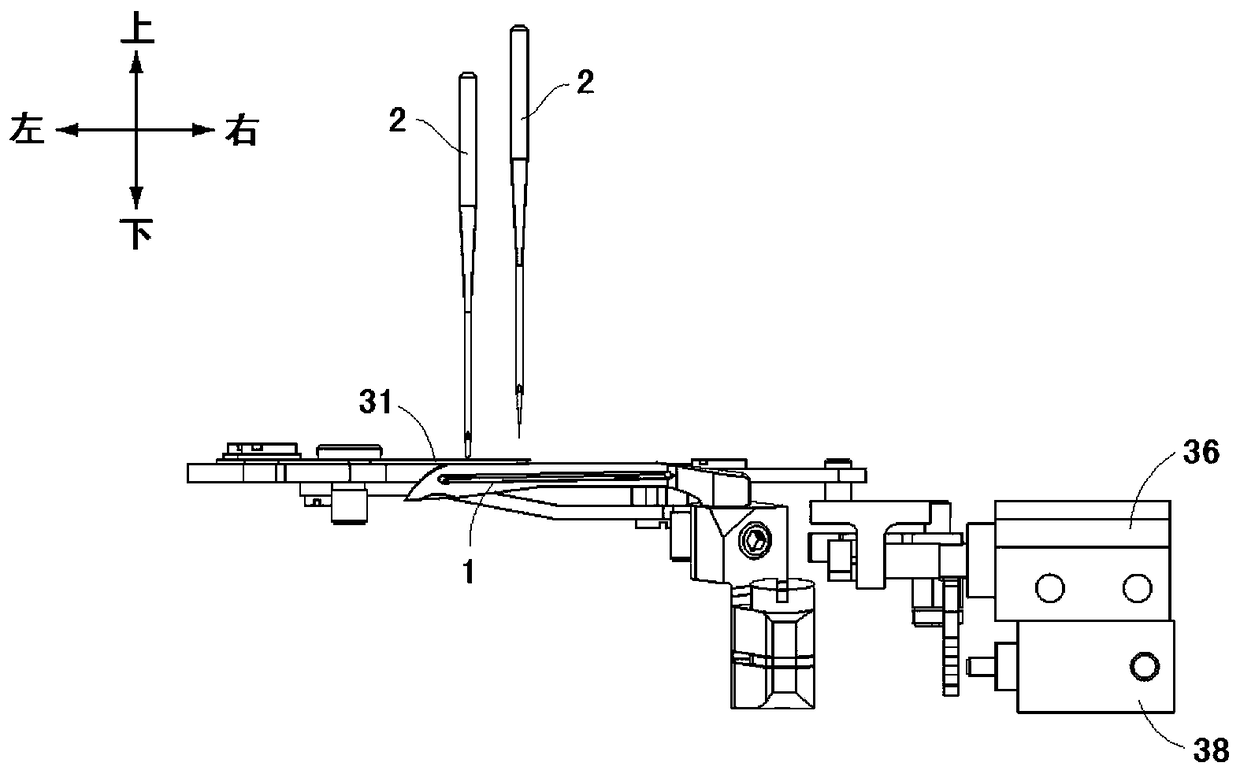

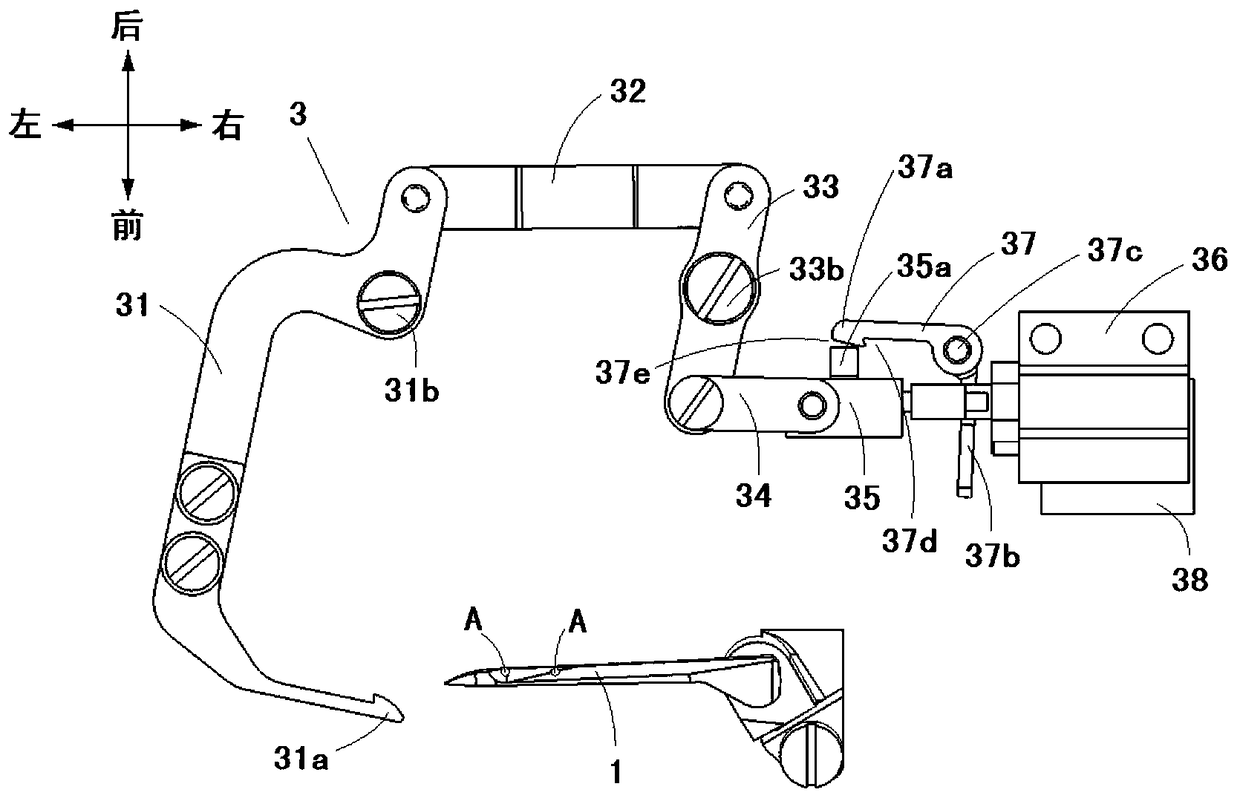

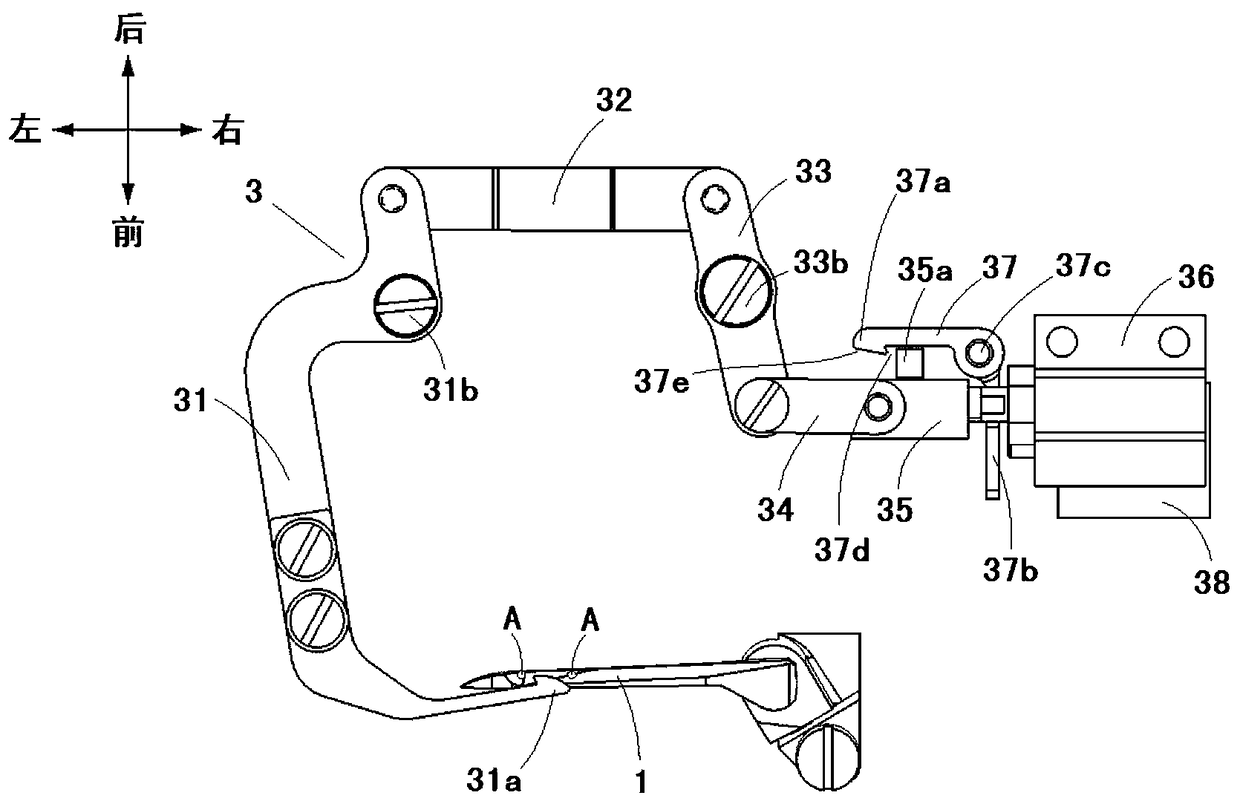

[0044] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0045] In order to facilitate the understanding of the essential part of the present invention, the following explanations are: catching and holding a needle thread loop located at the entry side of the looper among the plurality of needle thread loops caught by the looper, and the descending needle passes through the held needle thread loop. The content of the implementation form in the wire loop.

[0046] In the present invention, the direction in which the needle moves up and down is referred to as the up-down direction, and the direction in which the needle moves away from the needle plate is referred to as the up side. In the direction perpendicular to the up-down direction, the direction in which the sewing material moves under the action of the feeding mechanism is defined as the front-rear direction, the direction in which the sewing material is fed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com