Stapler

A stapler and staple technology, applied in the direction of nailing U-shaped nail tools, nailing tools, manufacturing tools, etc., can solve the problem of cutting sound and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

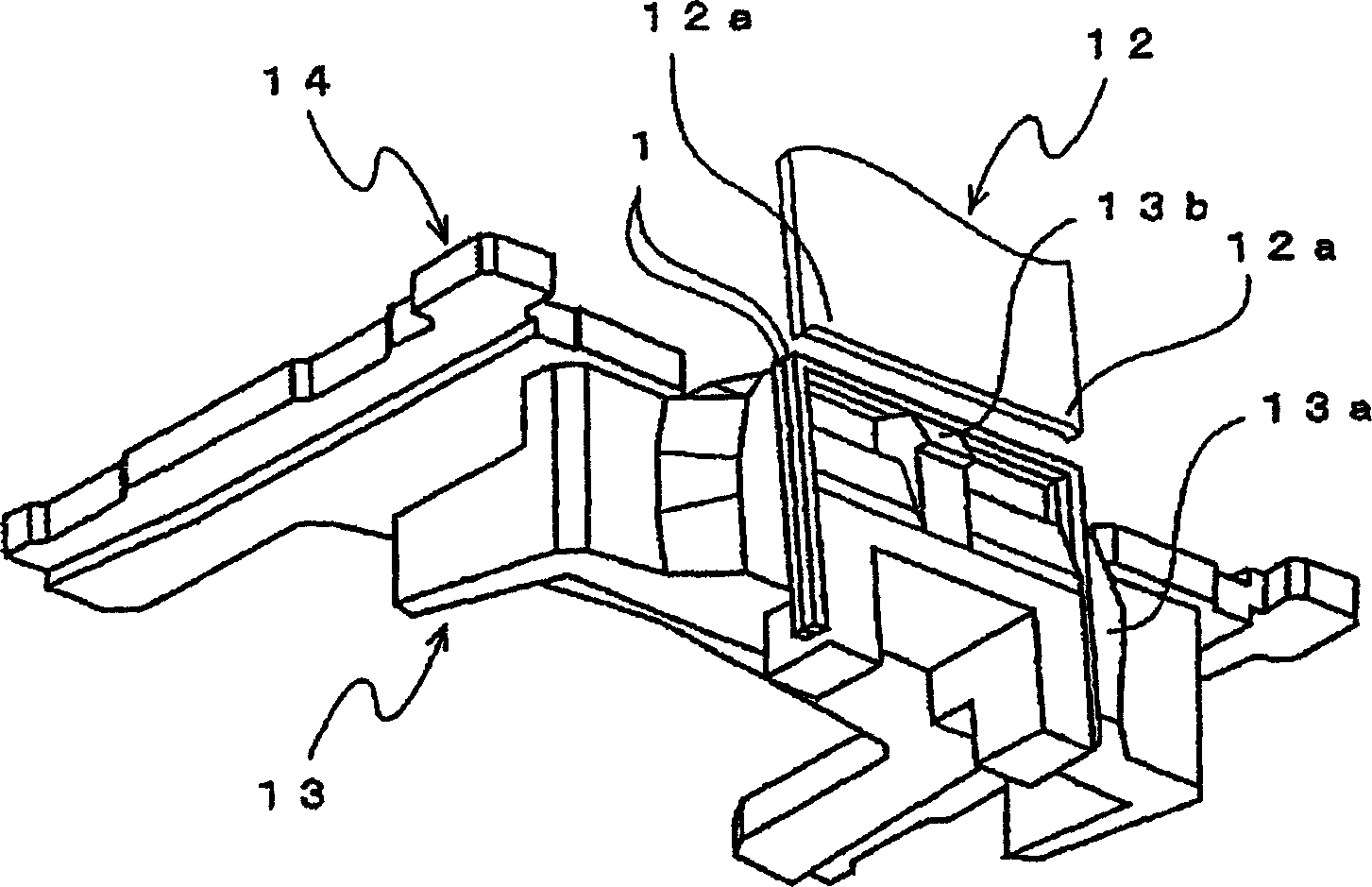

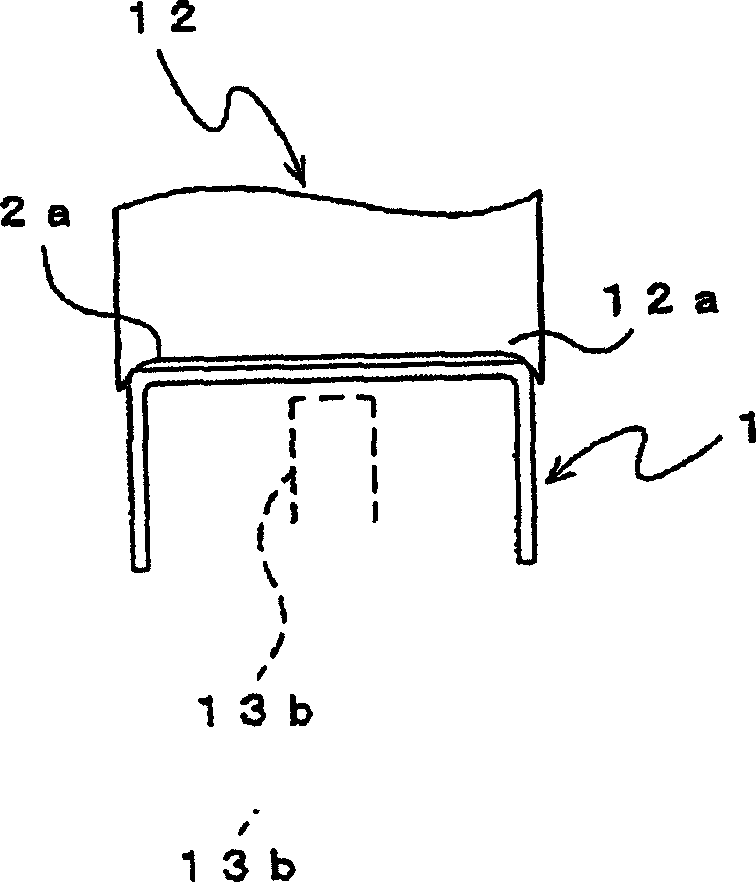

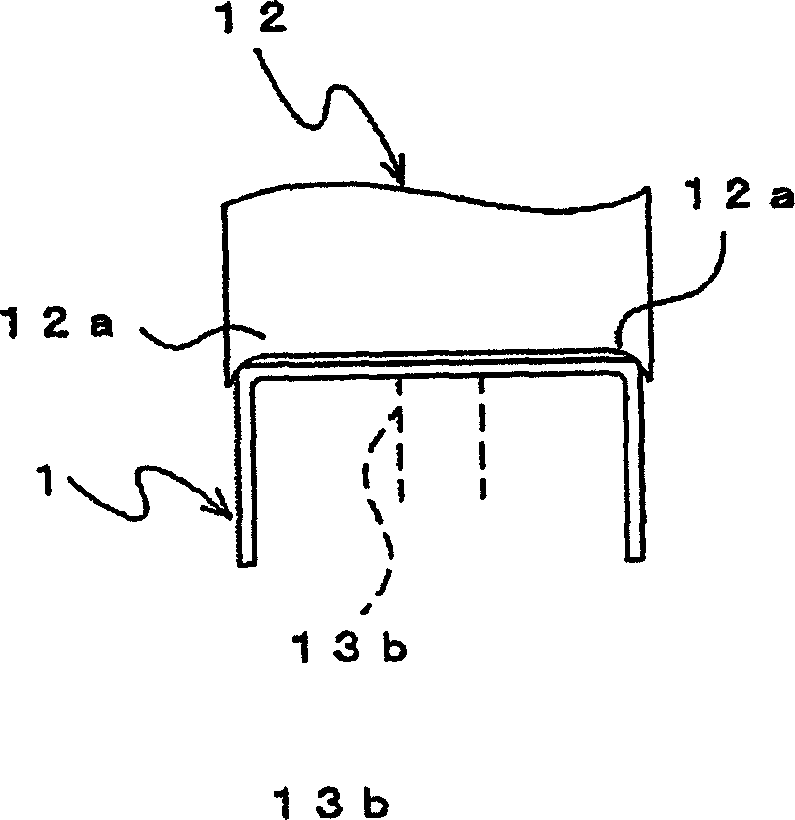

[0019] The invention is then illustrated by means of an electric stapler. Figure 1A It is a perspective view of the main part of the electric stapler, Figure 1B It is a front view of the main part of the initial state when the leading staple is separated from the next staple, Figure 1C It is a front view of the main part of the intermediate state when the most advanced staple is separated from the next staple, and FIG. 2A is the initial state when the most advanced staple is separated from the next staple. 2B is a cross-sectional view of a main part in a state in which the leading staple is separated from the next staple.

[0020] exist Figure 1A , Figure 1B and Figure 1C Among them, 1 is to form at least the most frontal staple into a roughly C-shaped staple; 12 is to separate the staple 1 from the next staple 1 and press it out so that both ends are inserted into the staple 13 is a pusher; 14 is a staple guide plate; 15 is a guide surface that guides the slide of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com