An insulating aluminum profile

A technology of aluminum profiles and thermal insulation materials, applied in thermal insulation, wing leaf frames, building components, etc., can solve the problems of poor thermal insulation performance of materials, undiscovered technical solutions, low support strength, etc., and achieve improved thermal insulation performance, simple structure, and sealing good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

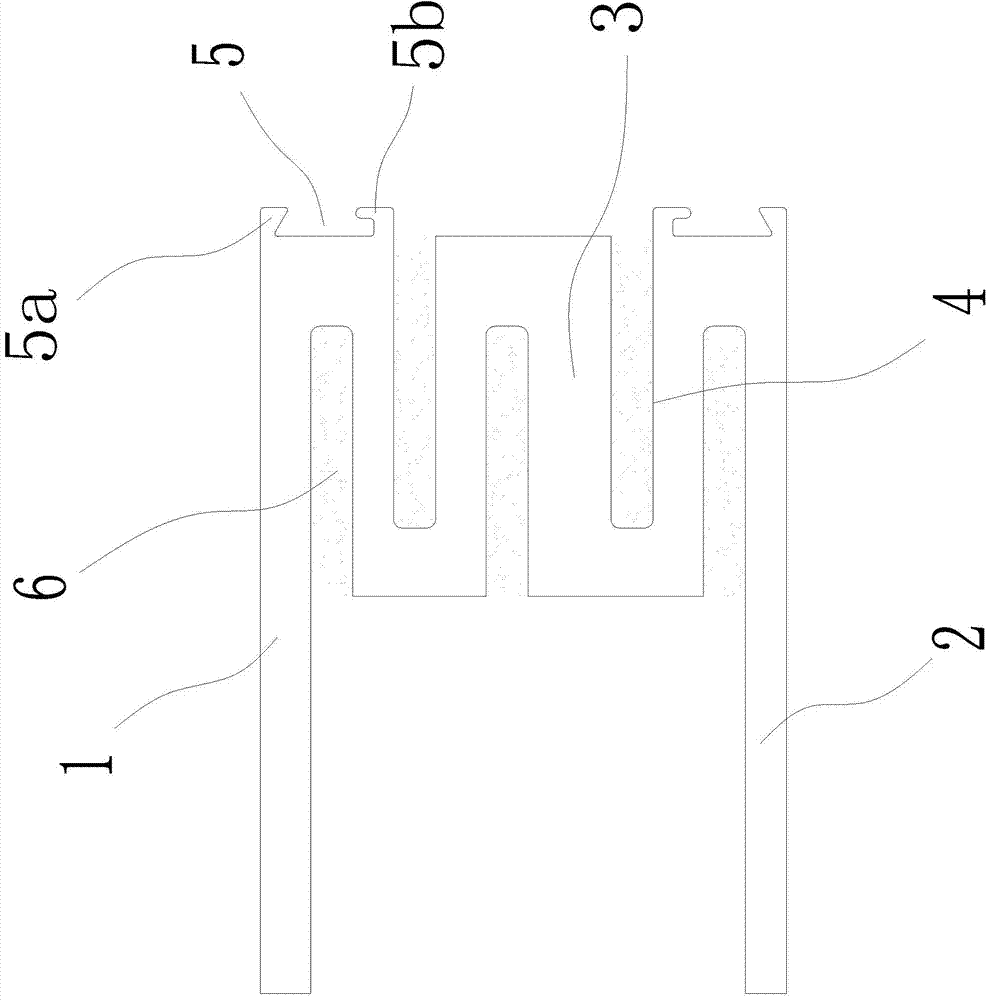

[0012] Such as figure 1 As shown, a thermal insulation aluminum profile provided by the present invention is characterized in that it includes an outer wall 1 and an inner wall 2, and is connected together by a side wall 3 on the side of the outer wall 1 and the inner wall 2, and a set of two-way An open U-shaped groove 4, the U-shaped groove 4 is opened vertically inwardly from both sides of the side wall 3, and a buckle 5 is respectively provided on the outer two ends of the side wall 3, and the inside of the U-shaped groove 4 is filled Insulation material6.

[0013] One side of the buckle 5 is an oblique hook 5a, and the other side is an L-shaped hook 5b, and the L-shaped hook 5b is arranged on the inner side.

[0014] The U-shaped slots 4 all run through the side walls 3 , and their openings are respectively set on the inner side or the outer side of the side walls 3 .

[0015] The thermal insulation material 6 adopts extruded polystyrene foam plastics, molded polystyren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com