Swing rod garbage compression equipment

A technology of garbage compression and equipment, which is applied in the directions of garbage conveying, garbage collection, loading/unloading, etc., which can solve the problems of rusting and jamming of hinged parts, decrease in airtightness of the body, inconvenient maintenance and disassembly, etc., so as to achieve safe garbage transfer and reduce residual waste. The effect of garbage and reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

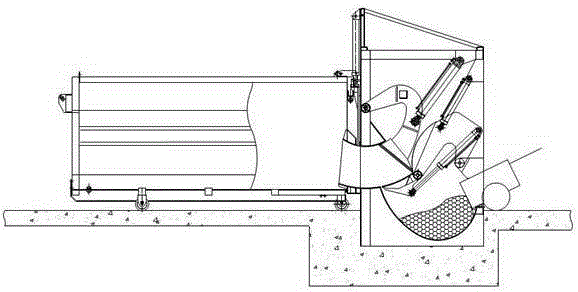

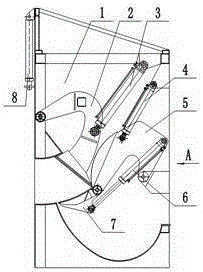

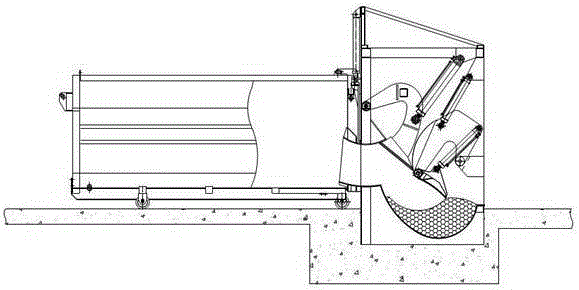

[0026] see as figure 1 and figure 2 As shown, the swing rod type garbage compression equipment of the present invention includes a body 1, a push plate 2, a push plate cylinder 3, a swing cylinder 4, a swing plate 5, a scraper cylinder 6, a scraper 7, a gate cylinder 8, a positioning box 9 and a lock Tightening mechanism 10; the front end of the body 1 is a vertical plane and is provided with a push port for materials to pass through; the push plate 2 is a "U"-shaped structure, and one end of the "U"-shaped opening is above the front end of the body 1. Hinged, the other end of the "U"-shaped opening is a pushing plane; one end of the push plate cylinder 3 is hinged with the push plate 2 at the inflection point of the "U", and the other end of the push plate cylinder 3 is hinged to the rear side of the top of the body 1, and the push plate 2 The movement trajectory of the end pushing plane extends out of the vertical plane of the front end of the body 1 as a whole at the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com